weight SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 4 of 828

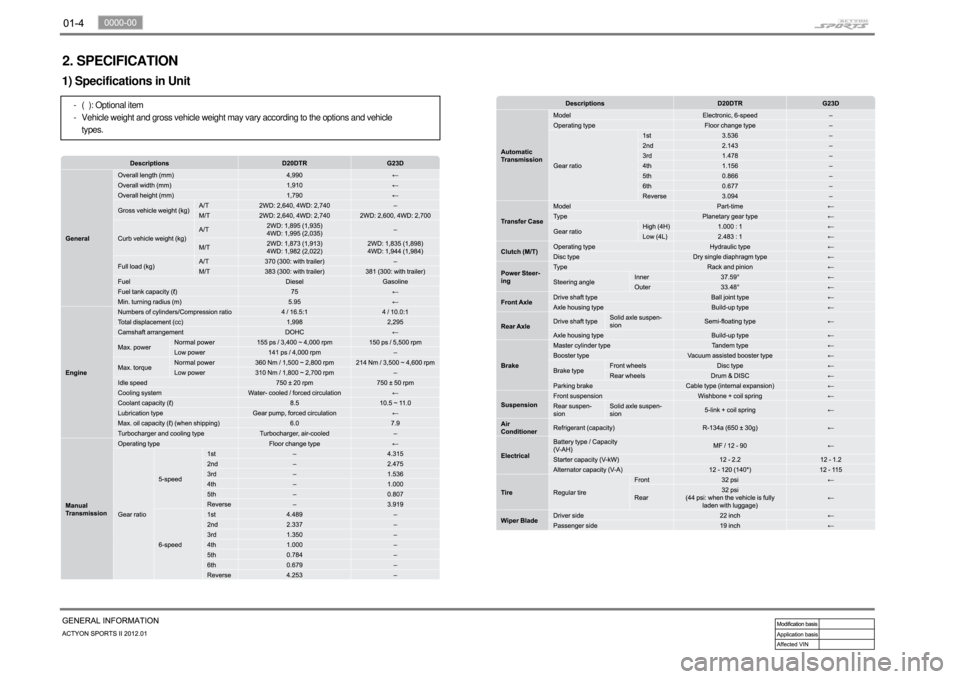

2. SPECIFICATION1) Specifications in Unit

( ): Optional item

Vehicle weight and gross vehicle weight may vary according to the options and vehicle

types. -

-

Page 98 of 828

01-70000-00

2. SPECIFICATION

1) Specifications in Unit

( ): Optional item

Vehicle weight and gross vehicle weight may vary according to the options and vehicle

types. -

-

Page 118 of 828

02-90000-00

1336-01 Timing gear case cover

Added the belt tension mounting boss

1130-01 Crankshaft assembly

- Reduced weight

- Deleted ring gear

1130-18 Drive plate assembly (A/T)

Changed the location of torque converter

mounting hole1130-13 Dual mass flywheel

Deleted centering sleeve

1115-02 Engine mounting bracket

D20DTR (Actyon Sports)

OldNew

OldNew

OldNew

Old

New

OldNew

with center bearingwithout center

bearing

Page 159 of 828

02-22

Rear view

5. CYLINDER HEAD COVER AND OIL SEPARATOR

The cylinder head cover is made by high strength plastic to reduce the weight. The multi twist type

oil separator improves the oil consumption.

Components ▶

1) Cylinder Head Cover

Front view

Cylinder head cover

Page 166 of 828

02-290000-00

(2) Layout

Chain upper bush

Type: single bush

Chains:112 EA

Tensioner rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

Hydraulic tensioner

Contains tensioner housing

plug, spring and check valve,

and operated by hydraulic

pressure

Crankshaft sprocket

Teeth: 21 EA

Oil pump sprocket

Teeth: 33 EA

Chain lower bush

Chain type: single bush

Chains: 60 EA

Mechanical type tensioner

Operated by internal spring

Clamping rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

Exhaust camshaft

sprocket

Teeth: 42 EA

1) Chain Drive

(1) Overview

The drive chain is single chain drive system with simple design and variable performance, and it

utilizes the hydraulic tensioner to reduce the wave impact generated by the chain. This chain is light

weight and has high durability through single bush chain. Shoulder bolts are used for better NHV.

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTR engine uses single stage chain drive system. Timing chain drives the exhaust side and

gear drive the intake side. Timing chain is single bush type. Upper chain drives HP pump

connected to intake Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil

pump to lubricate the engine.

Page 210 of 828

04-31719-00

1. SPECIFICATION

Shorten the service interval under severe conditions such as driving on a dusty road or offroad. *

Unit Description Specification

Air cleaner elementFilter type Dry, filter element

Initial resistance Max. 300 mmAq

Service interval EU; Clean or change every 20,000 km

GEN: Clean or change every 15,000 km

Air cleaner assemblyWeight 103.9 kg

Operating temperature-30 ~ 100˚C

IntercoolerCore material Aluminum

Size 614W x 192H x 30T

Core size 614W x 192H x 30T

Tank material Plastic (Molding)

Efficiency 80%

Page 223 of 828

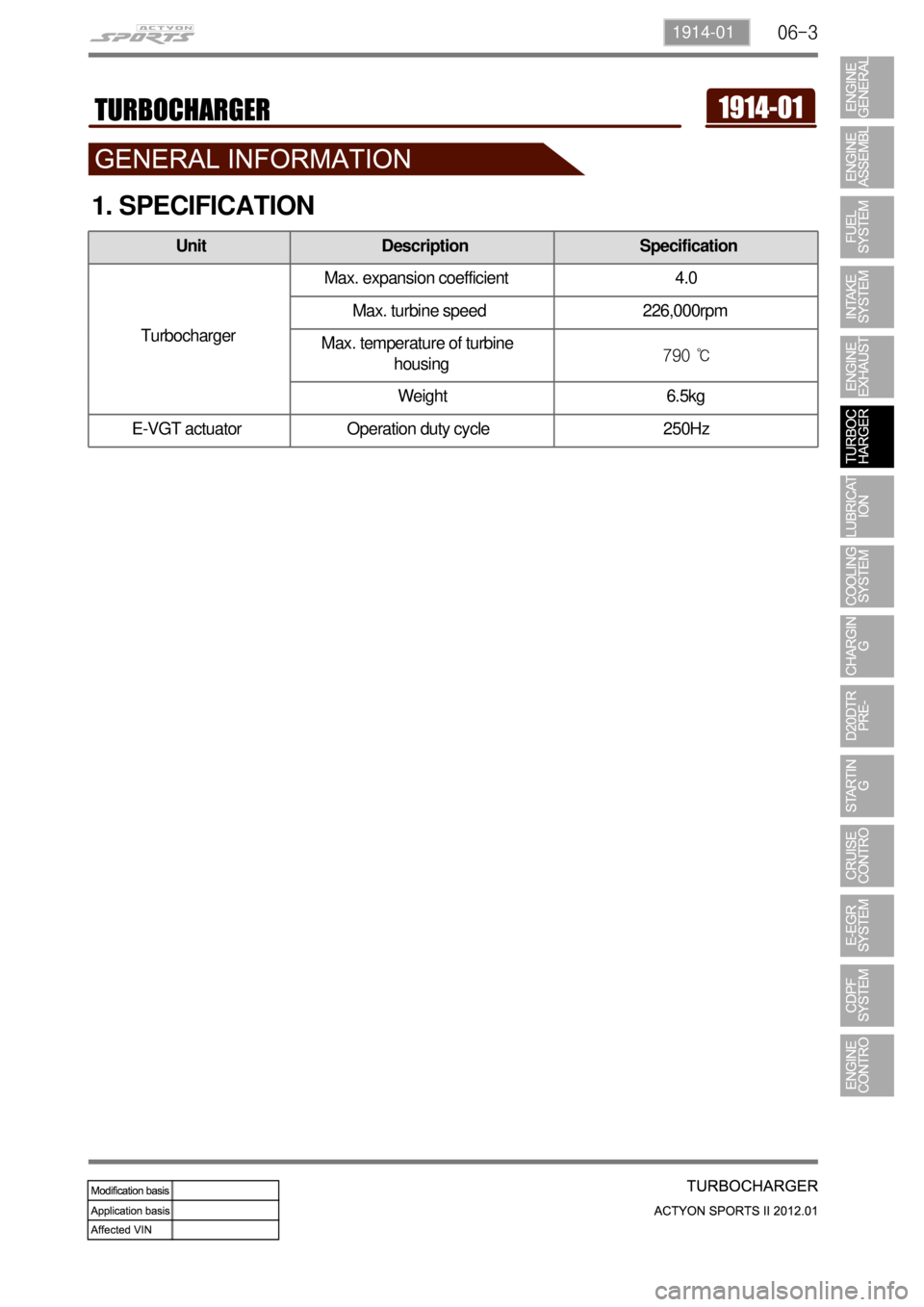

06-31914-01

1. SPECIFICATION

Unit Description Specification

TurbochargerMax. expansion coefficient 4.0

Max. turbine speed 226,000rpm

Max. temperature of turbine

housing790 ℃

Weight 6.5kg

E-VGT actuator Operation duty cycle 250Hz

Page 270 of 828

11-31461-01

1. SPECIFICATION

Description Specification

Capacity 12 V, 2.3 kW

Engagement Meshed type

Rotating direction Clockwise

Pinion gear manufacturing Cooled forging

Solenoid operating voltage Max. 8 V

Weight 2.5 kg

Bracket manufacturing Aluminum die casting

Page 382 of 828

04-6

2. DESCRIPTION AND OPERATION

1) General Description

The cooling system maintains the engine temperature at an efficient level during all engine

operating conditions.

When the engine is cold, the cooling system cools the engine slowly or not at all. This slow

cooling of the engine allows the engine to warm up quickly.

The cooling system includes a radiator and recovery subsystem, cooling fans, a thermostat and

housing, a water pump, and a water pump drive belt. The timing belt drives the water pump.

All components must function properly for the cooling system to operation. The water pump

draws the coolant from the radiator. The coolant then circulates through water jackets in the

engine block, the intake manifold, and the cylinder head. When the coolant reaches the operating

temperature of the thermostat, the thermostat opens. The coolant then goes back to the radiator

where it cools.

This system directs some coolant through the hoses to the heat core. This provides for heating

and defrosting.

The coolant reservoir is connected to the radiator to recover the coolant displaced by expansion

from the high temperatures. The coolant reservoir maintains the correct coolant level.

The cooling system for this vehicle has no radiator cap or filler neck. The coolant is added to the

cooling system through the coolant reservoir.

2) Radiator

This vehicle has a lightweight tube-and-fin aluminum radiator. Plastic tanks are mounted on the

upper and the lower sides of the radiator core.

On vehicles equipped with automatic transaxles, the transaxle fluid cooler lines run through the

radiator tank.

A radiator drain plug is on this radiator.

To drain the cooling system, open the drain plug.

3) Coolant Reservoir

The coolant reservoir is a transparent plastic reservoir, similar to the windshield washer reservoir.

The coolant reservoir is connected to the radiator by a hose and to the engine cooling system by

another hose.

As the vehicle is driven, the engine coolant heats and expands. The portion of the engine coolant

displaced by this expansion flows from the radiator and the engine into the coolant reservoir. The

air trapped in the radiator and the engine is degassed into the coolant reservoir.

When the engine stops, the engine coolant cools and contracts. The displaced engine coolant is

then drawn back into the radiator and the engine. This keeps the radiator filled with the coolant to

the desired level at all times and increases the cooling efficiency.

Maintain the coolant level between the MIN and MAX marks on the coolant reservoir when the

system is cold.

Page 537 of 828

09-38790-01

1. COMPONENT SPECIFICATIONS

The PAS (parking aid system) emits the ultrasonic wave signals from the sensors on the rear

bumper at a specific interval

and detects the reflected signals from obstacles when reversing. The alarm interval increases as

the obstacle approaches.

This supplementary system is useful to measure the distance when parking.

Parking Aid Unit ▶

Parking Aid Sensor ▶

Detecting type: Ultrasonic wave (Piezo

ceramic element)

Calculates the distance between the

sensor and the object by calculating the

return time of the emitted the ultrasonic

wave

Frequency used: 50 KHz ± 1 KHz

Detection distance: 30 cm ~ 120 cm

(based on lineal distance between sensor

and obstacle)

Tolerance: ± 10 cm

Sensor detection range (at -6 dB) -

-

-

-

-

LH/RH sensor

Center sensor

Item Value Item Value

Rated voltage DC 12 V Operating temperature-30˚C ~ +80˚C

Operating voltage DC 9 V ~ 16 V Storage temperature-40˚C ~ +85˚C

Current

consumptionUnit 100 mA or less Relative humidity 95% RH max

Sensor 20 mA or less (each)

WeightUnit72 ± 10 g

Sensor40 ± 5 g