sensor SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 616 of 751

11-14

2) EBD (Electronic Brake-force Distribution) Warning Lamp (Brake

Warning Lamp)

EBD warning lamp when the system perform the self diagnosis and when it detects the malfunction of

EBD system. However, the brake warning lamp comes on regardless of EBD when the parking brake is

applied.

EBD warning lamp ON:

When turning the ignition switch to ON position, ABS warning lamp and the brake warning lamp

comes on for 3 seconds for self diagnosis and goes off if the system is OK (initialization mode).

When applying the parking brake, the brake warning lamp comes on.

When the brake fluid is not sufficient, the brake warning lamp comes on.

When disengaging the connector, the warning lamp comes on.

When the system is defective, ABS warning lamp and the brake warning lamp come on

simultaneously. 1.

2.

3.

4.

5.

When the solenoid valve is defective

When one or more wheel sensors are defective

When ABS HECU is defective

When the voltage is abnormal

When valve relay is defective a.

b.

c.

d.

e.

When the communication between warning lamp CAN module in meter cluster, the warning

lamp comes on. 6.

3) ESP OFF Indicator

ESP OFF indicator ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for self

diagnosis and goes off if the system is OK (initialization mode).

When the ESP OFF switch is pressed to turn off ESP function, ESP OFF indicator comes on. 1.

2.

4) ESP Warning Lamp

ESP warning lamp ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for

self diagnosis and goes off if the system is OK (initialization mode).

When the system is defective, the warning lamp comes on.

When the ESP function is activated, ESP warning lamp blinks with the interval of 2 Hz.

When the communication between warning lamp CAN module in meter cluster, the warning lamp

comes on. 1.

2.

3.

4.

5.

5) ESP OFF Switch

If ESP OFF switch is pressed, ESP function is deactivated and the ESP OFF indicator in the instrument

cluster comes on.

To resume the ESP function, press the switch again. At this time, ESP OFF indicator goes out.

Page 618 of 751

11-16

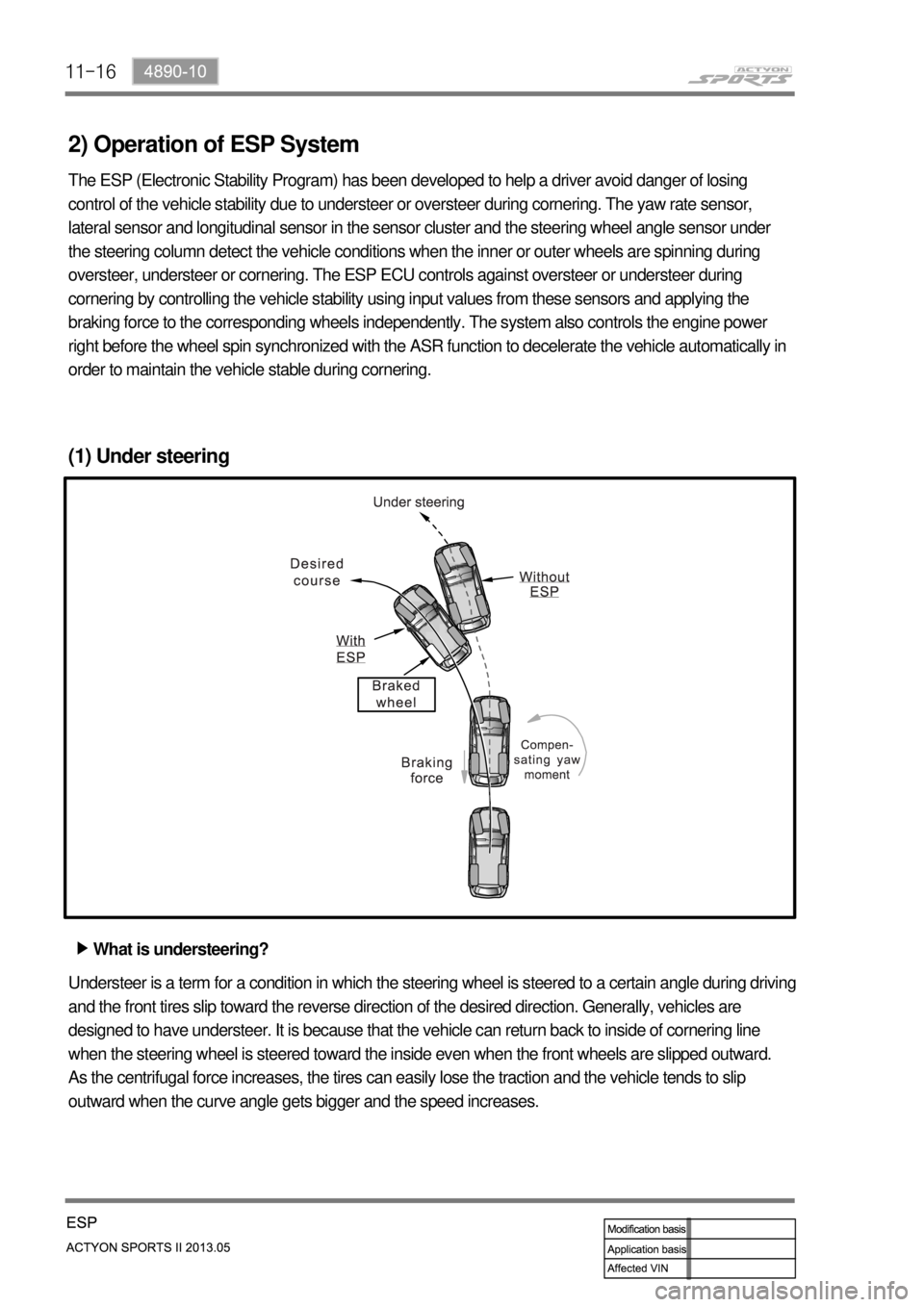

2) Operation of ESP System

The ESP (Electronic Stability Program) has been developed to help a driver avoid danger of losing

control of the vehicle stability due to understeer or oversteer during cornering. The yaw rate sensor,

lateral sensor and longitudinal sensor in the sensor cluster and the steering wheel angle sensor under

the steering column detect the vehicle conditions when the inner or outer wheels are spinning during

oversteer, understeer or cornering. The ESP ECU controls against oversteer or understeer during

cornering by controlling the vehicle stability using input values from these sensors and applying the

braking force to the corresponding wheels independently. The system also controls the engine power

right before the wheel spin synchronized with the ASR function to decelerate the vehicle automatically in

order to maintain the vehicle stable during cornering.

(1) Under steering

What is understeering? ▶

Understeer is a term for a condition in which the steering wheel is steered to a certain angle during driving

and the front tires slip toward the reverse direction of the desired direction. Generally, vehicles are

designed to have understeer. It is because that the vehicle can return back to inside of cornering line

when the steering wheel is steered toward the inside even when the front wheels are slipped outward.

As the centrifugal force increases, the tires can easily lose the traction and the vehicle tends to slip

outward when the curve angle gets bigger and the speed increases.

Page 619 of 751

11-174890-10

ESP controls during understeer ▶

The ESP system recognizes the directional angle with the steering wheel angle sensor and senses the

slipping route that occurs reversely against the vehicle cornering direction during understeer with the ya

w

rate sensor and lateral sensor. Then, the ESP system applies the braking force to the rear inner wheel to

compensate the yaw moment value. In this way, the vehicle does not lose its driving direction and the

driver can steer the vehicle as intended.

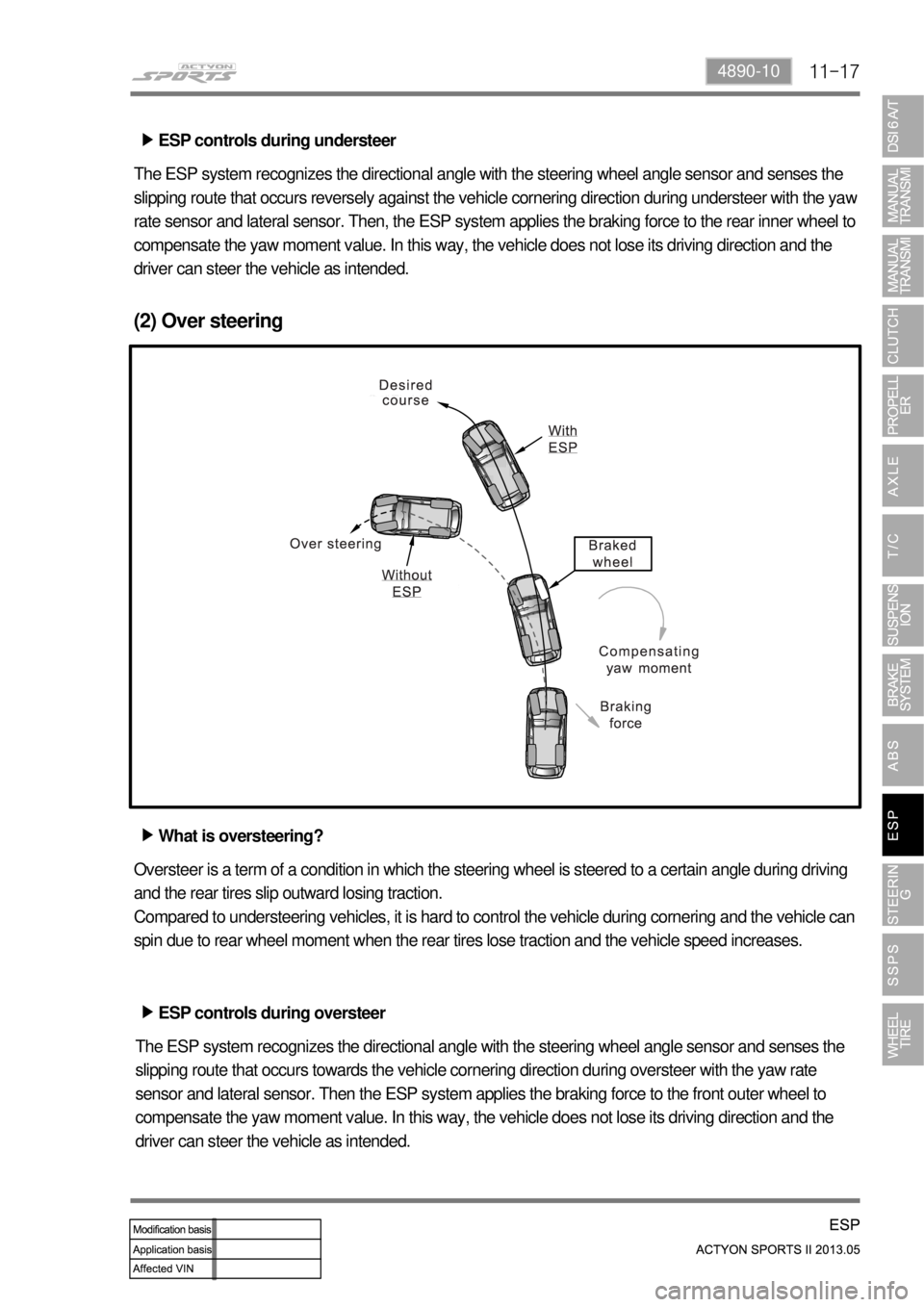

(2) Over steering

What is oversteering? ▶

Oversteer is a term of a condition in which the steering wheel is steered to a certain angle during driving

and the rear tires slip outward losing traction.

Compared to understeering vehicles, it is hard to control the vehicle during cornering and the vehicle can

spin due to rear wheel moment when the rear tires lose traction and the vehicle speed increases.

ESP controls during oversteer ▶

The ESP system recognizes the directional angle with the steering wheel angle sensor and senses the

slipping route that occurs towards the vehicle cornering direction during oversteer with the yaw rate

sensor and lateral sensor. Then the ESP system applies the braking force to the front outer wheel to

compensate the yaw moment value. In this way, the vehicle does not lose its driving direction and the

driver can steer the vehicle as intended.

Page 621 of 751

11-194890-10

4) HBA (Hydraulic Brake Assist System)

(1) Purpose

HBA (Hydraulic Brake Assist) system helps in an emergency braking situation when the driver applies

the brake fast, but not with sufficient pressure, which leads to dangerously long braking distance. ECU

recognizes the attempt at full braking and transmits the signal calling for full brake pressure from the

hydraulic booster. An inexperienced, elderly or physically weak driver may suffer from the accident by not

fully pressing the brake pedal when hard braking is required under emergency. The HBA System

increases the braking force under urgent situations to enhance the inputted braking force from the driver.

Based on the fact that some drivers depress the brake pedal too soft even under when hard braking is

necessary, the HECU system is a safety supplementary system that builds high braking force during

initial braking according to pressure value of the brake pressure sensor and the pressure changes of the

pressure sensor intervals. When the system is designed to apply high braking force when brake pedal is

depressed softly by an elderly or physically weak driver, the vehicle will make abrupt stopping under

normal braking situation due to high braking pressure at each wheels.

(2) Operation

The brake pressure value and the changed value of the pressure sensor are the conditions in which the

HBA System operates. There are 2 pressure sensors under the master cylinder. When the ESP ECU

system determines that emergency braking is present, the pump operates, the brake fluid in the master

cylinder is sent to the pump and the braking pressure is delivered to the wheels via the inlet valves . If the

drive depress the brake pedal slowly, the pressure change is not high. In this case, only the conventional

brake system with booster is activated.

(3) Operating conditions

Sensor pressure: over 40 bar

Pressure changes: over 850 bar/sec

Vehicle speed: over 30 km/h -

-

-

Page 622 of 751

11-20

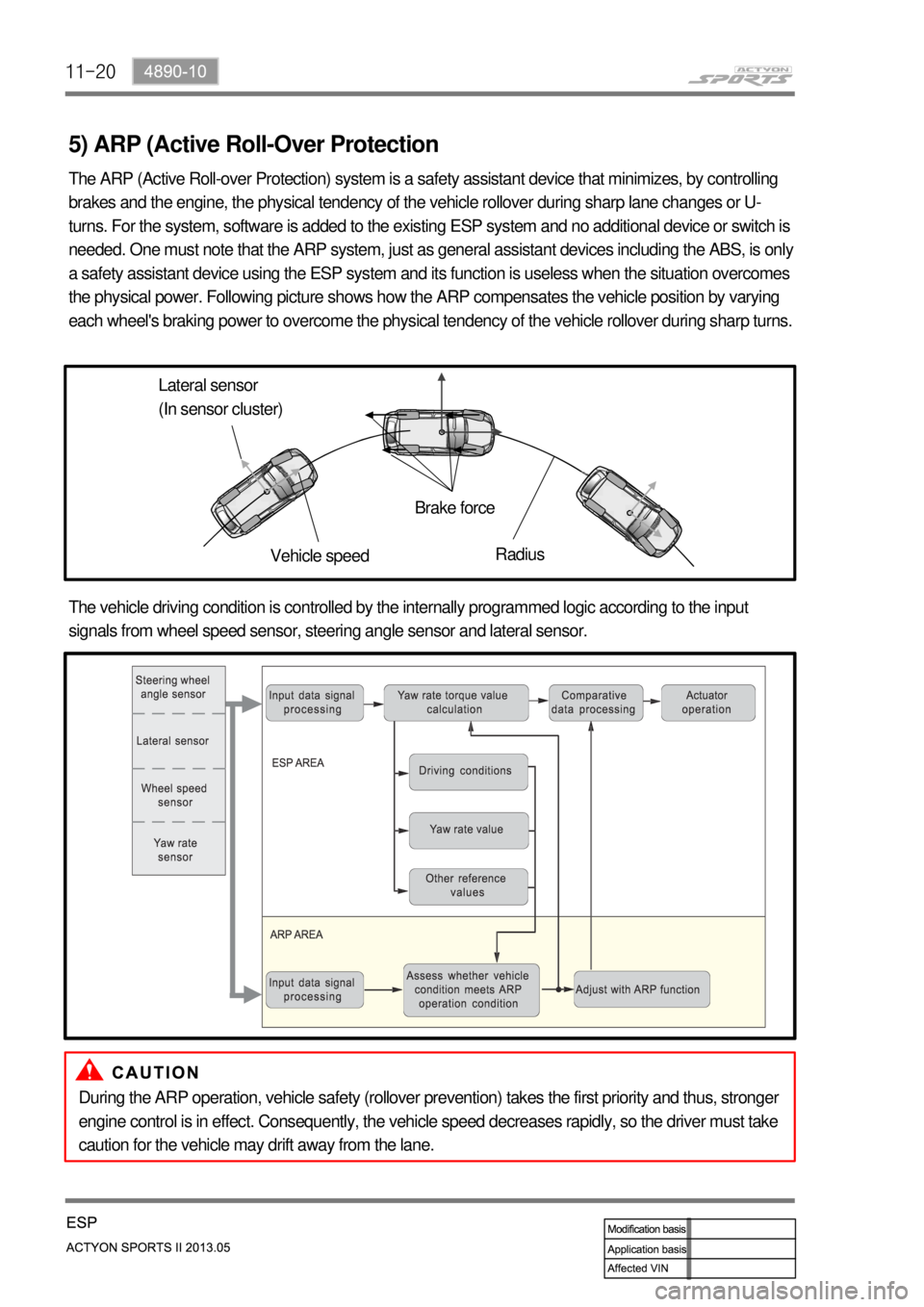

5) ARP (Active Roll-Over Protection

The ARP (Active Roll-over Protection) system is a safety assistant device that minimizes, by controlling

brakes and the engine, the physical tendency of the vehicle rollover during sharp lane changes or U-

turns. For the system, software is added to the existing ESP system and no additional device or switch is

needed. One must note that the ARP system, just as general assistant devices including the ABS, is only

a safety assistant device using the ESP system and its function is useless when the situation overcomes

the physical power. Following picture shows how the ARP compensates the vehicle position by varying

each wheel's braking power to overcome the physical tendency of the vehicle rollover during sharp turns.

Lateral sensor

(In sensor cluster)

Vehicle speedBrake force

Radius

The vehicle driving condition is controlled by the internally programmed logic according to the input

signals from wheel speed sensor, steering angle sensor and lateral sensor.

During the ARP operation, vehicle safety (rollover prevention) takes the first priority and thus, stronger

engine control is in effect. Consequently, the vehicle speed decreases rapidly, so the driver must take

caution for the vehicle may drift away from the lane.

Page 629 of 751

11-274890-10

5) Hydraulic Circuit of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as in the

ESP operation. When HECU recognizes that it is an emergency and it is required for hard braking,

depending on the pressure value of the brake pressure sensor and pressure changes caused by the

pressure sensor timing, it operates the pump immediately to apply the brake pressure at the wheels.

Then, the pressure in the pump increases until just before the corresponding wheel gets locked. The

motor still keeps rotating and the outlet valve and the separation valve will stay closed. When the wheel

starts to lock, the HBA function cancels and switches to ABS operation.

Page 684 of 751

01-56810-01

3. COMPONENTS

Blower and evaporator assembly

Actuator assembly - Intake

Air filter assembly

Cover - Air filter

Blower motor assembly

Resistor

Expansion valve assembly

Wiring assembly - Heater & evaporator

Heater assembly 1.

2.

3.

4.

5.

6.

7.

9.

10.Actuator assembly - Temperature

Actuator assembly - Mode

Heater assembly - PTC

Control assembly - Heater and A/C control

Bulb

Insert assembly - Ventilation

Sensor assembly - Humid and Incar

Sensor assembly - Intake 11.

12.

15.

20.

21.

22.

23.

24.

Page 687 of 751

01-8

The FATC has a self-diagnosis function that can diagnose the system by itself. Before checking a

component, be sure to check the fault code by using the self-diagnosis function. The self-diagnosis

consists of 6 steps. The temperature control dial (step 2 to 5) and fan speed dial (step 6) are used to

enter each step of the self-diagnosis. The 6 steps of the self-diagnosis are:

▶ Step 1

▶ Step 2

▶ Step 3

▶ Step 4- The VFD and all LED segments are checked for proper illumination.

- The sensors and air mix door are checked for proper operation.

- The position and condition of the air source door and mode door are checked.

The actuator door position, fan speed and compressor operation are checked. Pressing the

defroster switch after entering step 4 changes the diagnosis mode as follows: 41 -> 42 -> 43 ->

44 -> 45 -> 46 -> 41. -

4. TROUBLESHOOTING

1) Overview

Page 688 of 751

01-96810-01

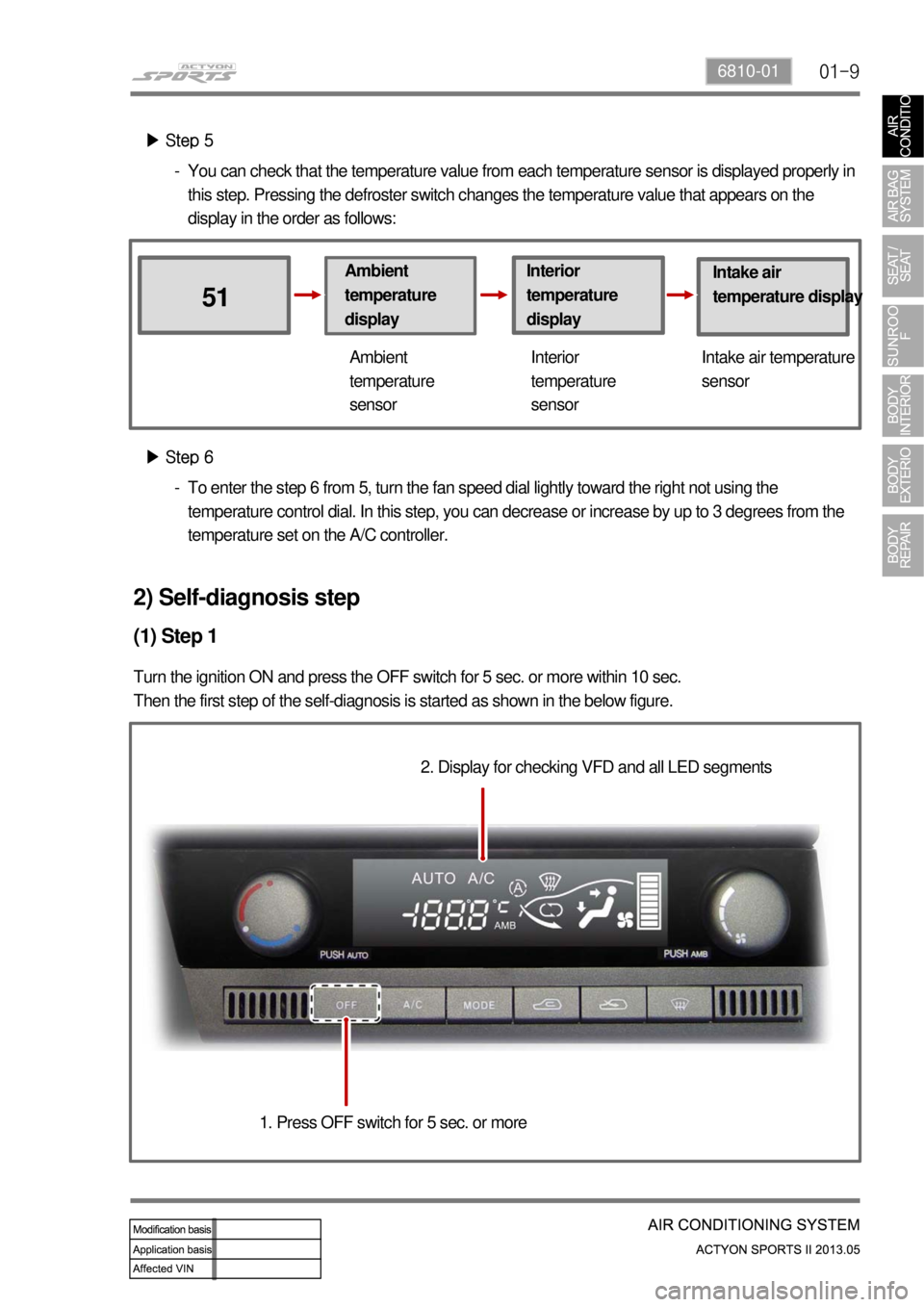

▶ Step 5

Ambient

temperature

display

51

Interior

temperature

displayIntake air

temperature display

Ambient

temperature

sensorInterior

temperature

sensorIntake air temperature

sensor

▶ Step 6

To enter the step 6 from 5, turn the fan speed dial lightly toward the right not using the

temperature control dial. In this step, you can decrease or increase by up to 3 degrees from the

temperature set on the A/C controller. -You can check that the temperature value from each temperature sensor is displayed properly in

this step. Pressing the defroster switch changes the temperature value that appears on the

display in the order as follows: -

2) Self-diagnosis step

(1) Step 1

Turn the ignition ON and press the OFF switch for 5 sec. or more within 10 sec.

Then the first step of the self-diagnosis is started as shown in the below figure.

2. Display for checking VFD and all LED segments

1. Press OFF switch for 5 sec. or more

Page 689 of 751

01-10

(2) Step 2

The sensors and air mix door are checked for proper operation in this step. When the step 2 is started,

the number "2", which indicates that the system is in the step 2, apprears on the display and the check

for sensors is performed. Once the check is done (for 10 to 20 sec.), the one digit number between 0

and 8 is added behind "2". "20" means there is no fault code. For the meaning of the rest of the

numbers, refer to the description below.

1. Turn temperature dial lightly toward right to enter step 2

10 to 20

sec.

System starts sensor

check after "2" is displayed 2.

Fault code for sensor

appears and blinks 3.

Fault code no. 1

(ambient temperature

sensor) blinks twiceFault code no. 5 (sun

sensor) blinks twice

(fault codes appears

sequentially)

If "-" is displayed before "2", it means that

the sensor for that flashing fault code has

a short circuit.

Ambient temperature

sensor short circuited

Refer to the following table for the meaning of the fault code.