check oil SSANGYONG NEW ACTYON SPORTS 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 125 of 751

06-111914-01

3. TROUBLESHOOTING

The followings are cautions to take in handling defects of turbocharger, which must be fully aware of.

1) Cautions

After stopping the engine, check whether the bolts on pipe connecting section are loose as well as the

connecting condition of vacuum port and modulator, which is connected to the actuator.

During idling of the engine, check for leakage in the connecting section of pipe (hoses and

pipes, duct connections, after the turbocharger) by applying soap water. The leakage condition

in the engine block and turbine housing opening can be determined by the occurrence of

abnormal noise of exhaust.

By running the engine at idle speed, abnormal vibration and noise can be checked. Immediately

stop the engine when abnormal vibration and noise is detected and make thorough inspection

whether the turbocharger shaft wheel has any damages as well as checking the condition of

connections between pipes.

In case where the noise of engine is louder than usual, there is possibility of dampness in the

areas related with air cleaner and engine or engine block and turbocharger. And it could affect

the smooth supply of engine oil and discharge.

Check for damp condition in exhaust gas when there is sign of thermal discoloration or

discharge of carbon in connecting area of the duct.

When the engine rotates or in case where there is change in noise level, check for clogging of

air cleaner or air cleaner duct or if there is any significant amount of dust in the compressor

housing.

During the inspection of center housing, inspect inside of the housing by removing the oil drain

pipe to check for sludge generation and its attachment condition at shaft area or turbine side.

Inspect or replace the air cleaner when the compressor wheel is damaged by inflow of foreign

materials.

Inspect both side of the turbocharger wheel after removing inlet and outlet pipe of the turbocharger. 1.

2.

3.

4.

5.

6.

7.

8.

9.

Page 137 of 751

07-31543-00

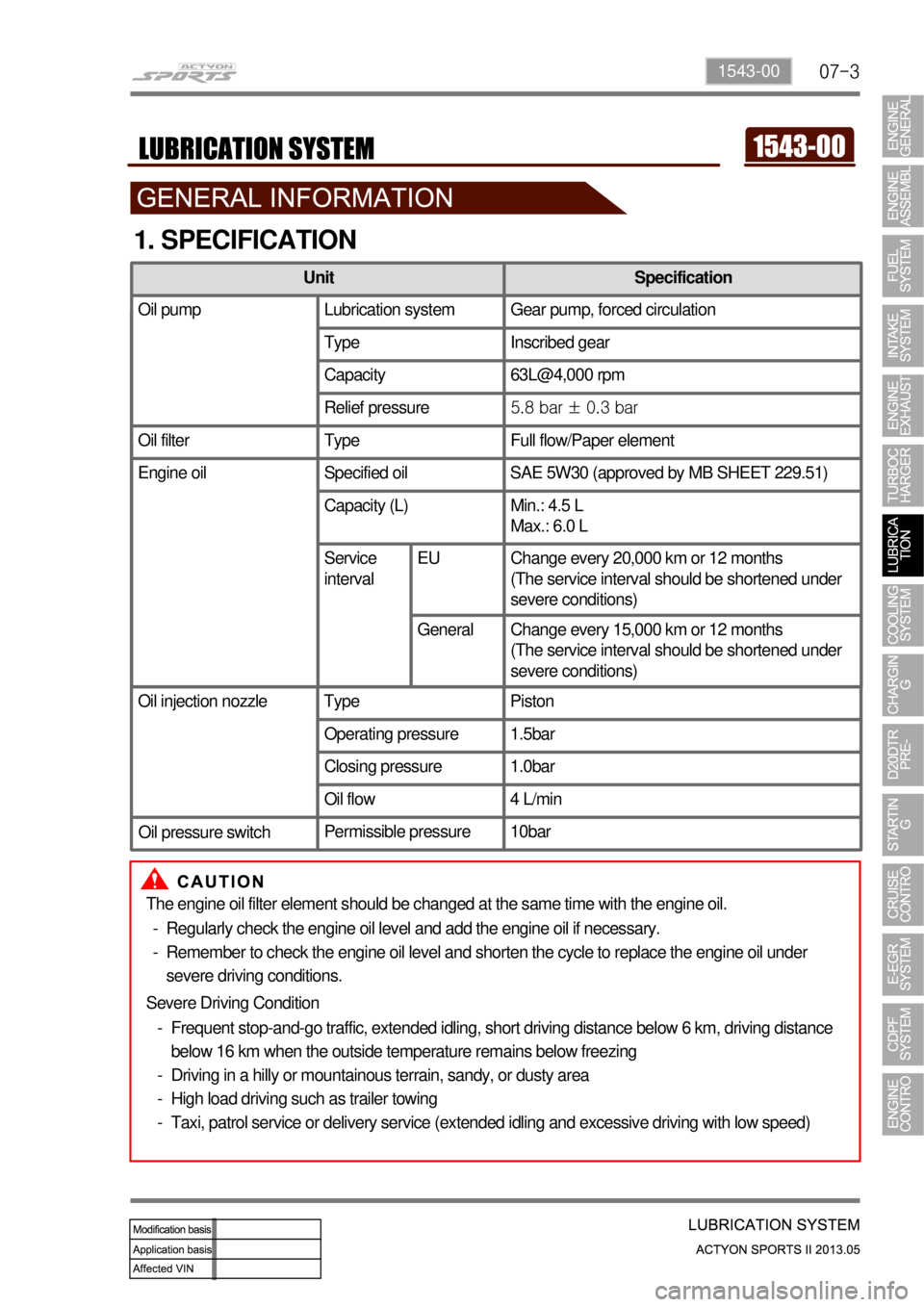

1. SPECIFICATION

The engine oil filter element should be changed at the same time with th\

e engine oil.Regularly check the engine oil level and add the engine oil if necessary\

.

Remember to check the engine oil level and shorten the cycle to replace \

the engine oil under

severe driving conditions.

-

-

Severe Driving Condition Frequent stop-and-go traffic, extended idling, short driving distance be\

low 6 km, driving distance

below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive\

driving with low speed)

-

-

-

-

Unit

Specification

Oil pump Lubrication system Gear pump, forced circulation

Type Inscribed gear

Capacity 63 L at 4,000 rpm

Relief pressure 5.8 bar ± 0.3 bar

Oil filter Type Full flow/Paper element

Engine oil Specified oil SAE 5W30 (approved by MB SHEET 229.51)

Capacity (L) Min.: 4.5 L

Max.: 6.0 L

Service interval Change every 15,000 km or 12 months (But, shorten the service interval under severe condition)

Oil injection nozzle Type Piston

Operating pressure 1.5bar

Closing pressure 1.0bar

Oil flow 4 L/min

Permissible pressure 10bar

Unit Specification

Oil pump Lubrication system Gear pump, forced circulation

Type Inscribed gear

Capacity 63L@4,000 rpm

Relief pressure 5.8 bar ± 0.3 bar

Oil filter Type Full flow/Paper element

Engine oil Specified oilSAE 5W30 (approved by MB SHEET 229.51)

Capacity (L) Min.: 4.5 L

Max.: 6.0 L

Service

interval EU Change every 20,000 km or 12 months

(The service interval should be shortened under

severe conditions)

General Change every 15,000 km or 12 months (The service interval should be shortened under

severe conditions)

Oil pressure switch

Page 138 of 751

07-4

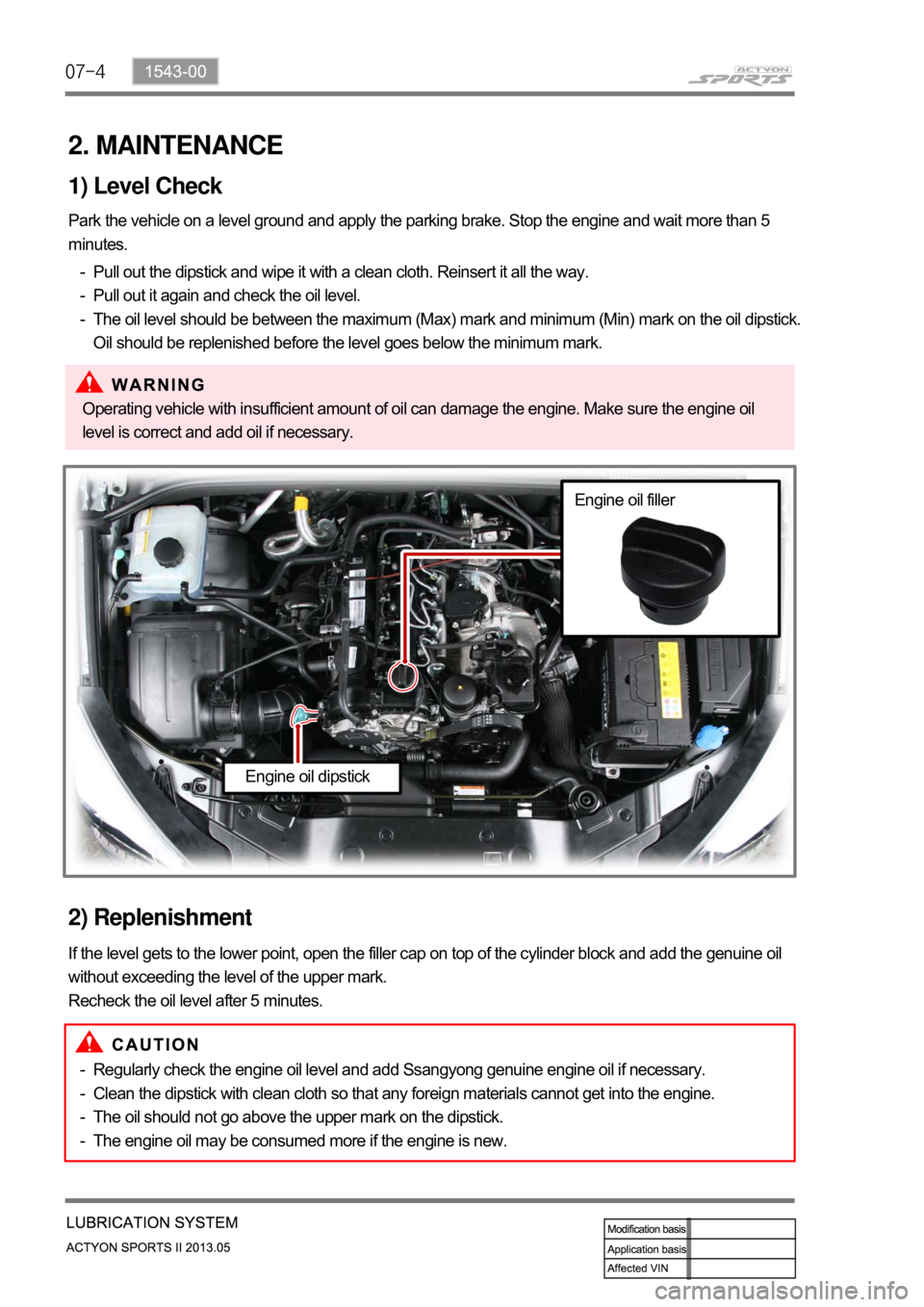

2. MAINTENANCE

1) Level Check

Park the vehicle on a level ground and apply the parking brake. Stop the engine and wait more than 5

minutes.Pull out the dipstick and wipe it with a clean cloth. Reinsert it all the way.

Pull out it again and check the oil level.

The oil level should be between the maximum (Max) ma rk and minimum (Min) mark on the oil dipstick.

Oil should be replenished before the level goes below the minimum mark.

-

-

-

Operating vehicle with insufficient amount of oil can damage the engine. Make sure the engine oil

level is correct and add oil if necessary.

2) Replenishment

If the level gets to the lower point, open the filler cap on top of the cylinder block and add the genuine oil

without exceeding the level of the upper mark.

Recheck the oil level after 5 minutes.

Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary.

Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine.

The oil should not go above the upper mark on the dipstick.

The engine oil may be consumed more if the engine is new.

-

-

-

-

Engine oil dipstick

Engine oil filler

Page 149 of 751

09-4

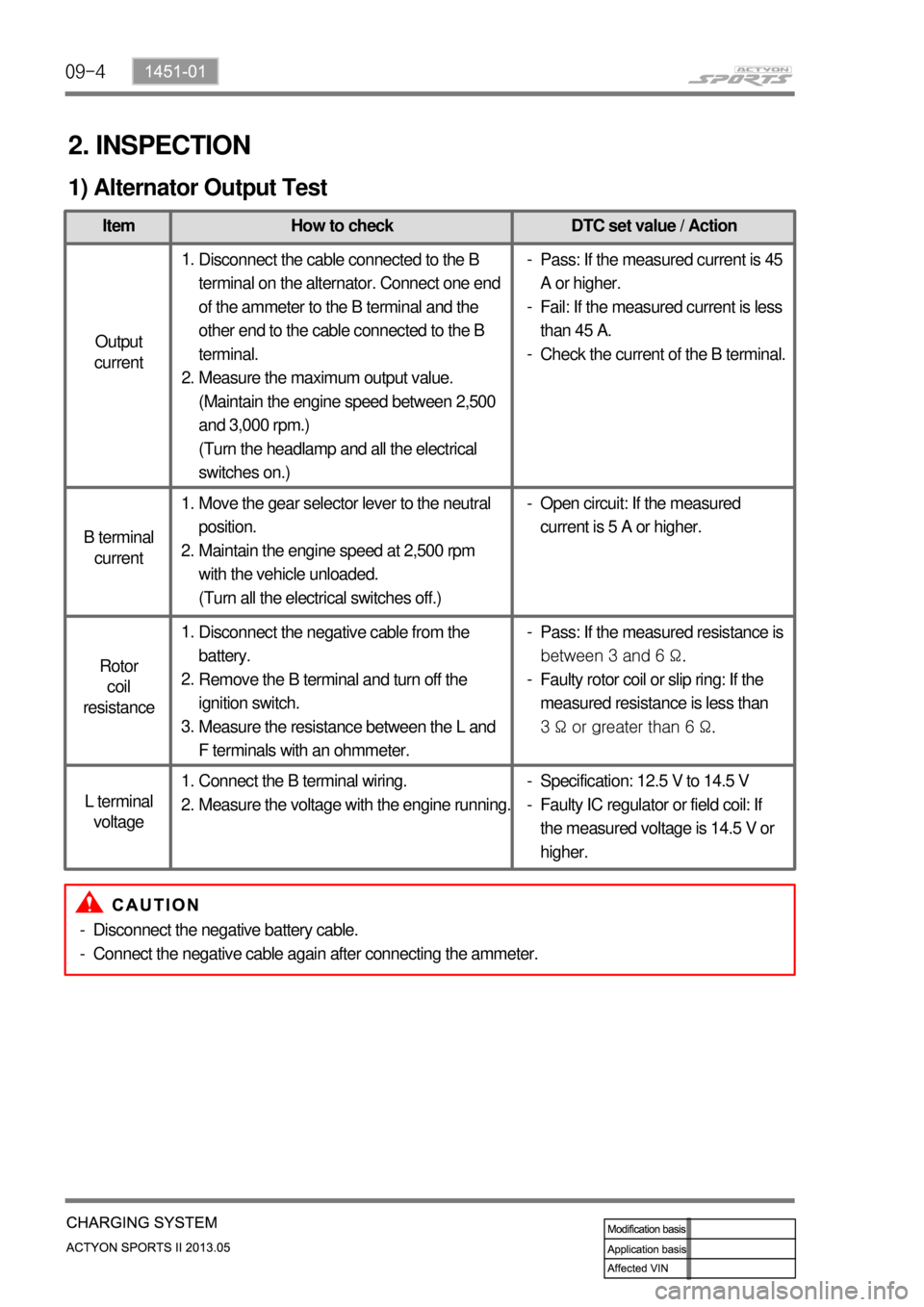

2. INSPECTION

1) Alternator Output Test

Item How to check DTC set value / Action

Output

current

B terminal

current

Rotor

coil

resistance

L terminal

voltage

Disconnect the cable connected to the B

terminal on the alternator. Connect one end

of the ammeter to the B terminal and the

other end to the cable connected to the B

terminal.

Measure the maximum output value.

(Maintain the engine speed between 2,500

and 3,000 rpm.)

(Turn the headlamp and all the electrical

switches on.) 1.

2.Pass: If the measured current is 45

A or higher.

Fail: If the measured current is less

than 45 A.

Check the current of the B terminal. -

-

-

Move the gear selector lever to the neutral

position.

Maintain the engine speed at 2,500 rpm

with the vehicle unloaded.

(Turn all the electrical switches off.) 1.

2.Open circuit: If the measured

current is 5 A or higher. -

Disconnect the negative cable from the

battery.

Remove the B terminal and turn off the

ignition switch.

Measure the resistance between the L and

F terminals with an ohmmeter. 1.

2.

3.Pass: If the measured resistance is

between 3 and 6 Ω.

Faulty rotor coil or slip ring: If the

measured resistance is less than

3 Ω or greater than 6 Ω. -

-

Connect the B terminal wiring.

Measure the voltage with the engine running. 1.

2.Specification: 12.5 V to 14.5 V

Faulty IC regulator or field coil: If

the measured voltage is 14.5 V or

higher. -

-

Disconnect the negative battery cable.

Connect the negative cable again after connecting the ammeter. -

-

Page 188 of 751

14-4

2. CAUTIONS

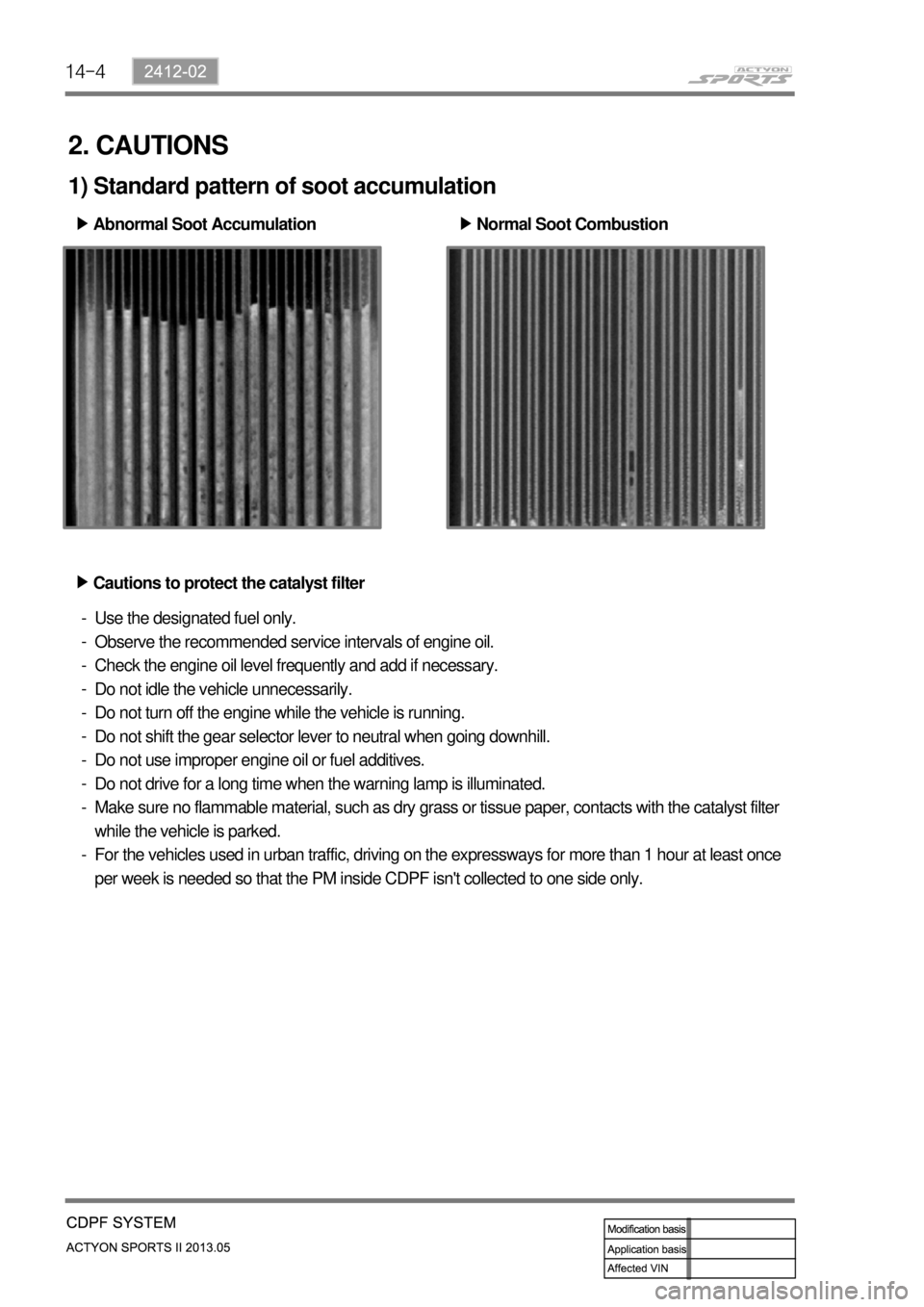

1) Standard pattern of soot accumulation

Abnormal Soot Accumulation ▶

Normal Soot Combustion ▶

Cautions to protect the catalyst filter ▶

Use the designated fuel only.

Observe the recommended service intervals of engine oil.

Check the engine oil level frequently and add if necessary.

Do not idle the vehicle unnecessarily.

Do not turn off the engine while the vehicle is running.

Do not shift the gear selector lever to neutral when going downhill.

Do not use improper engine oil or fuel additives.

Do not drive for a long time when the warning lamp is illuminated.

Make sure no flammable material, such as dry grass or tissue paper, contacts with the catalyst filter

while the vehicle is parked.

For the vehicles used in urban traffic, driving on the expressways for more than 1 hour at least once

per week is needed so that the PM inside CDPF isn't collected to one side only. -

-

-

-

-

-

-

-

-

-

Page 258 of 751

01-91113-01

4. DIAGNOSTIC INFORMATION AND PROCEDURE

1) Oil Leak Diagnosis

Most fluid oil leaks are easily located and repaired by visually finding the leak and replacing or repairing

the necessary parts. On some occasions a fluid leak may be difficult to locate or repair. The following

procedures may help you in locating and repairing most leaks.

Finding the Leak ▶

Identify the fluid. Determine whether it is engine oil, automatic transmission fluid, power steering

fluid, etc.

Identify where the fluid is leaking from. -

-

After running the vehicle at normal operating temperature, park the vehicle over a large sheet

of paper.

Wait a few minutes.

You should be able to find the approximate location of the leak by the drippings on the paper. ·

·

·

Visually check around the suspected component.

Check around all the gasket mating surfaces for leaks. A mirror is useful for finding leaks in

areas that are hard to reach.

If the leak still cannot be found, it may be necessary to clean the suspected area with a

degreaser, steam or spray solvent. -

-

Clean the area well.

Dry the area.

Operate the vehicle for several miles at normal operating temperature and varying speeds.

After operating the vehicle, visually check the suspected component.

If you still cannot locate the leak, try using the powder or black light and dye method. ·

·

·

·

·

Clean the suspected area.

Apply an aerosol-type powder (such as foot powder) to the suspected area.

Operate the vehicle under normal operating conditoins.

Visually inspect the suspected component. You should be able to trace the leak path over the

white powder surface to the source. -

-

-

- Powder Method ▶

Page 259 of 751

01-10

Black Light and Dye Method ▶

A dye and light kit is available for finding leaks, Refer to the manufacturer's directions when using the kit.

Pour the specified amount of dye into the engine oil fill tube.

Operate the vehicle normal operating conditions as directed in the kit.

Direct the light toward the suspected area. The dyed fluid will appear as a yellow path leading to

the source. -

-

-

Once the origin of the leak has been pinpointed and traced back to its source, the cause of the leak must

be determined in order for it to be repaired properly.

If a gasket is replaced, but the sealing flange is bent, the new gasket will not repair the leak. The bent

flange must be repaired also. Before attempting to repair a leak, check for the following conditions and

correct them as they may cause a leak.Repairing the Leak ▶

Gaskets ▶

The fluid level/pressure is too high.

The crankcase ventilation system is malfunctioning.

The seal bore is damaged (scratched, burred or nicked).

The seal is damaged or worn.

Improper installation is evident.

There are cracks in the components.

The shaft surface is scratched, nicked or damaged.

A loose or worn bearing is causing excess seal wear. -

-

-

-

-

-

-

-

Page 262 of 751

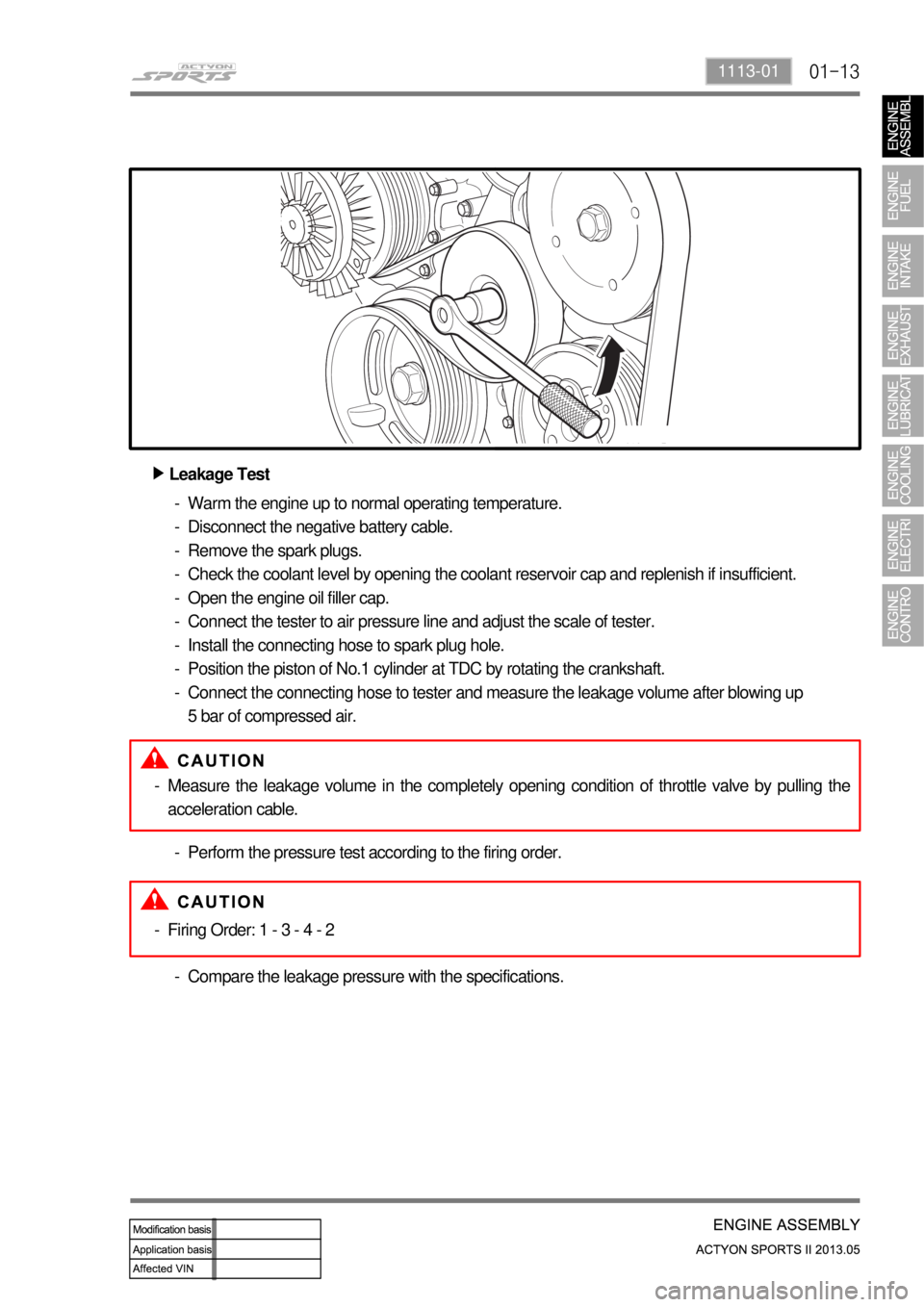

01-131113-01

Leakage Test ▶

Warm the engine up to normal operating temperature.

Disconnect the negative battery cable.

Remove the spark plugs.

Check the coolant level by opening the coolant reservoir cap and replenish if insufficient.

Open the engine oil filler cap.

Connect the tester to air pressure line and adjust the scale of tester.

Install the connecting hose to spark plug hole.

Position the piston of No.1 cylinder at TDC by rotating the crankshaft.

Connect the connecting hose to tester and measure the leakage volume after blowing up

5 bar of compressed air. -

-

-

-

-

-

-

-

-

Measure the leakage volume in the completely opening condition of throttle valve by pulling the

acceleration cable. -

Perform the pressure test according to the firing order. -

Firing Order: 1 - 3 - 4 - 2 -

Compare the leakage pressure with the specifications. -

Page 388 of 751

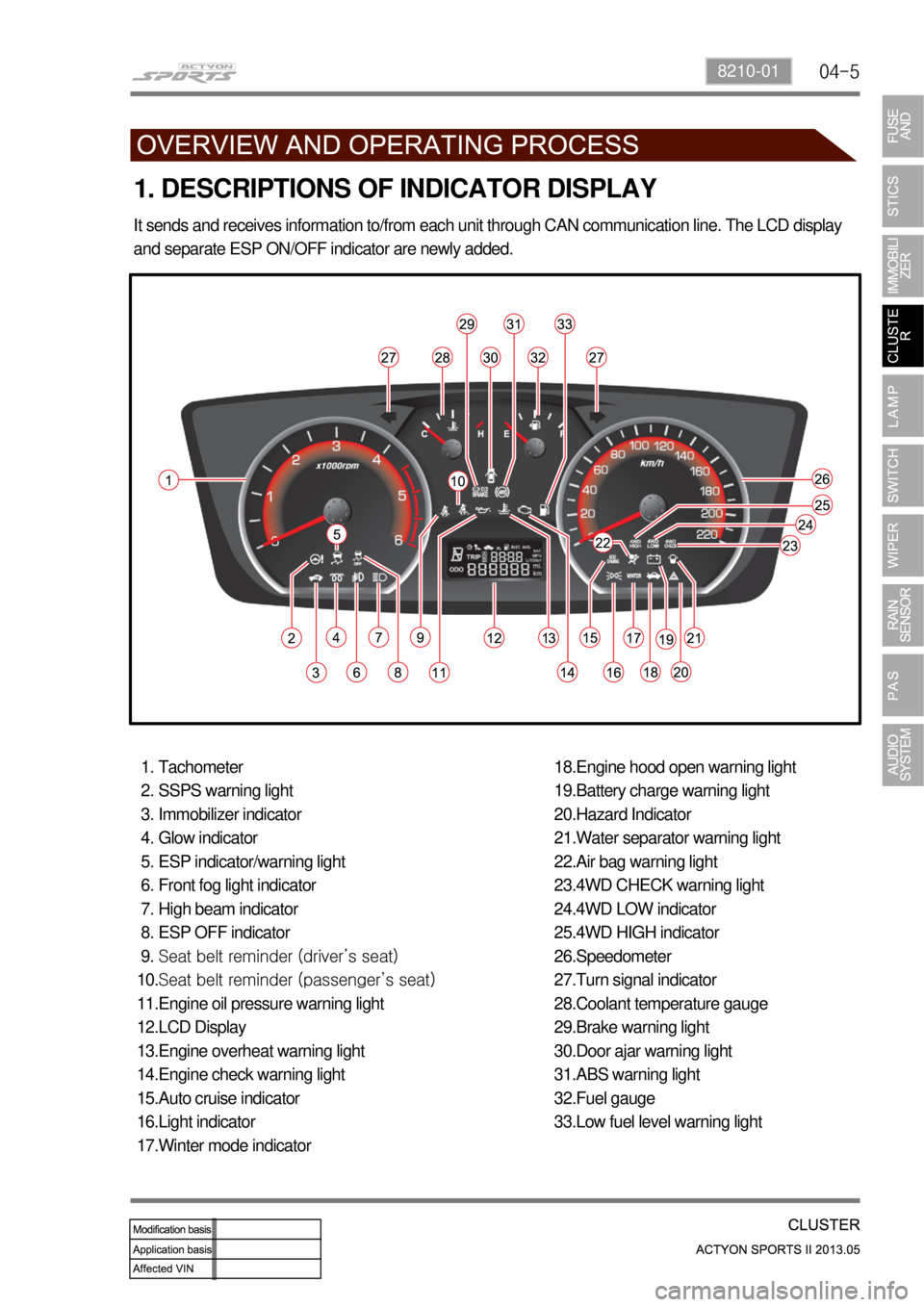

04-58210-01

1. DESCRIPTIONS OF INDICATOR DISPLAY

Tachometer

SSPS warning light

Immobilizer indicator

Glow indicator

ESP indicator/warning light

Front fog light indicator

High beam indicator

ESP OFF indicator

Seat belt reminder (driver’s seat)

Seat belt reminder (passenger’s seat)

Engine oil pressure warning light

LCD Display

Engine overheat warning light

Engine check warning light

Auto cruise indicator

Light indicator

Winter mode indicator 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.Engine hood open warning light

Battery charge warning light

Hazard Indicator

Water separator warning light

Air bag warning light

4WD CHECK warning light

4WD LOW indicator

4WD HIGH indicator

Speedometer

Turn signal indicator

Coolant temperature gauge

Brake warning light

Door ajar warning light

ABS warning light

Fuel gauge

Low fuel level warning light 18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33. It sends and receives information to/from each unit through CAN communication line. The LCD display

and separate ESP ON/OFF indicator are newly added.

Page 390 of 751

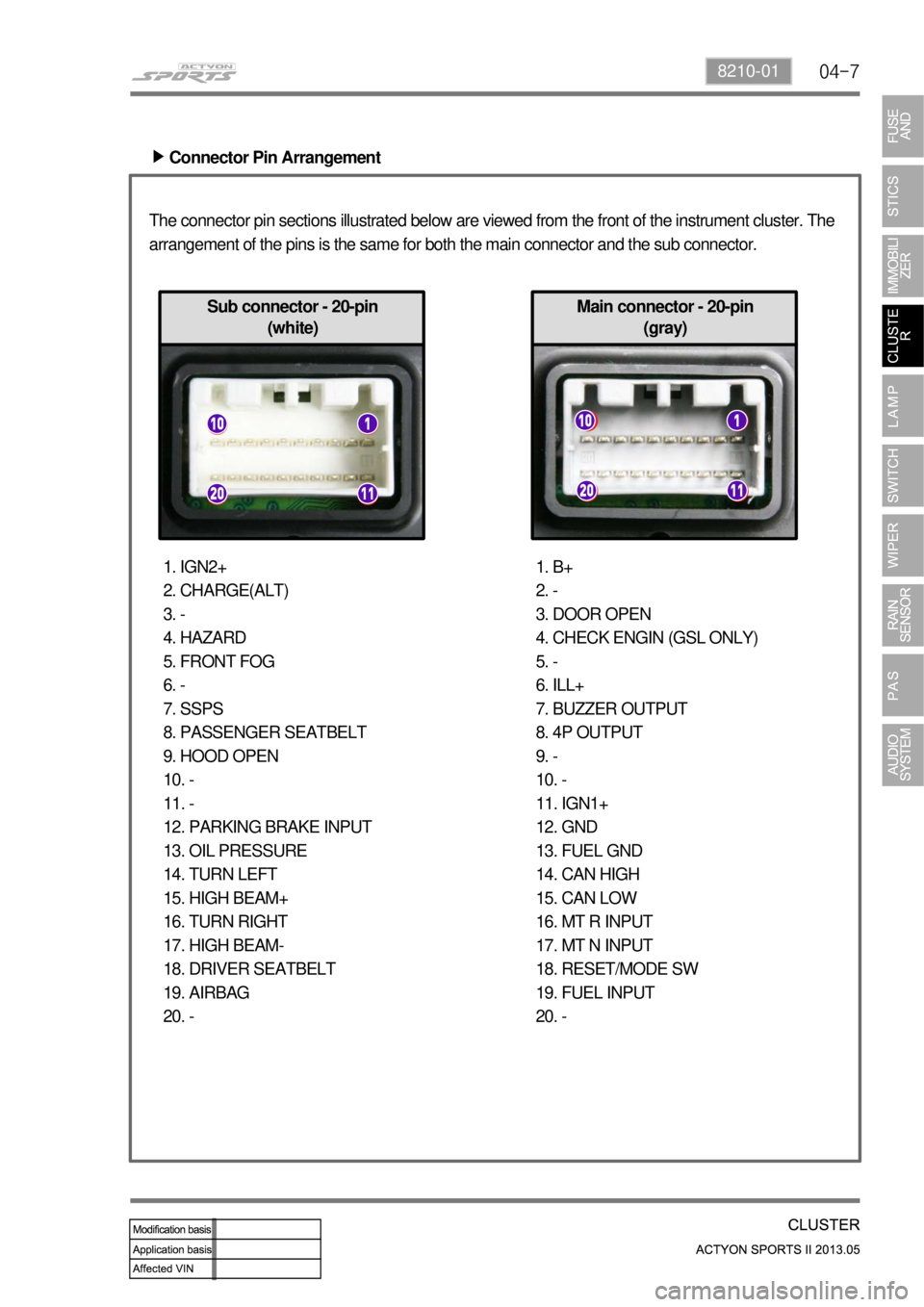

04-78210-01

Sub connector - 20-pin

(white)

Connector Pin Arrangement ▶

The connector pin sections illustrated below are viewed from the front of the instrument cluster. The

arrangement of the pins is the same for both the main connector and the sub connector.

1. IGN2+

2. CHARGE(ALT)

3. -

4. HAZARD

5. FRONT FOG

6. -

7. SSPS

8. PASSENGER SEATBELT

9. HOOD OPEN

10. -

11. -

12. PARKING BRAKE INPUT

13. OIL PRESSURE

14. TURN LEFT

15. HIGH BEAM+

16. TURN RIGHT

17. HIGH BEAM-

18. DRIVER SEATBELT

19. AIRBAG

20. -1. B+

2. -

3. DOOR OPEN

4. CHECK ENGIN (GSL ONLY)

5. -

6. ILL+

7. BUZZER OUTPUT

8. 4P OUTPUT

9. -

10. -

11. IGN1+

12. GND

13. FUEL GND

14. CAN HIGH

15. CAN LOW

16. MT R INPUT

17. MT N INPUT

18. RESET/MODE SW

19. FUEL INPUT

20. -

Main connector - 20-pin

(gray)