weight SSANGYONG NEW ACTYON SPORTS 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 547 of 751

08-10

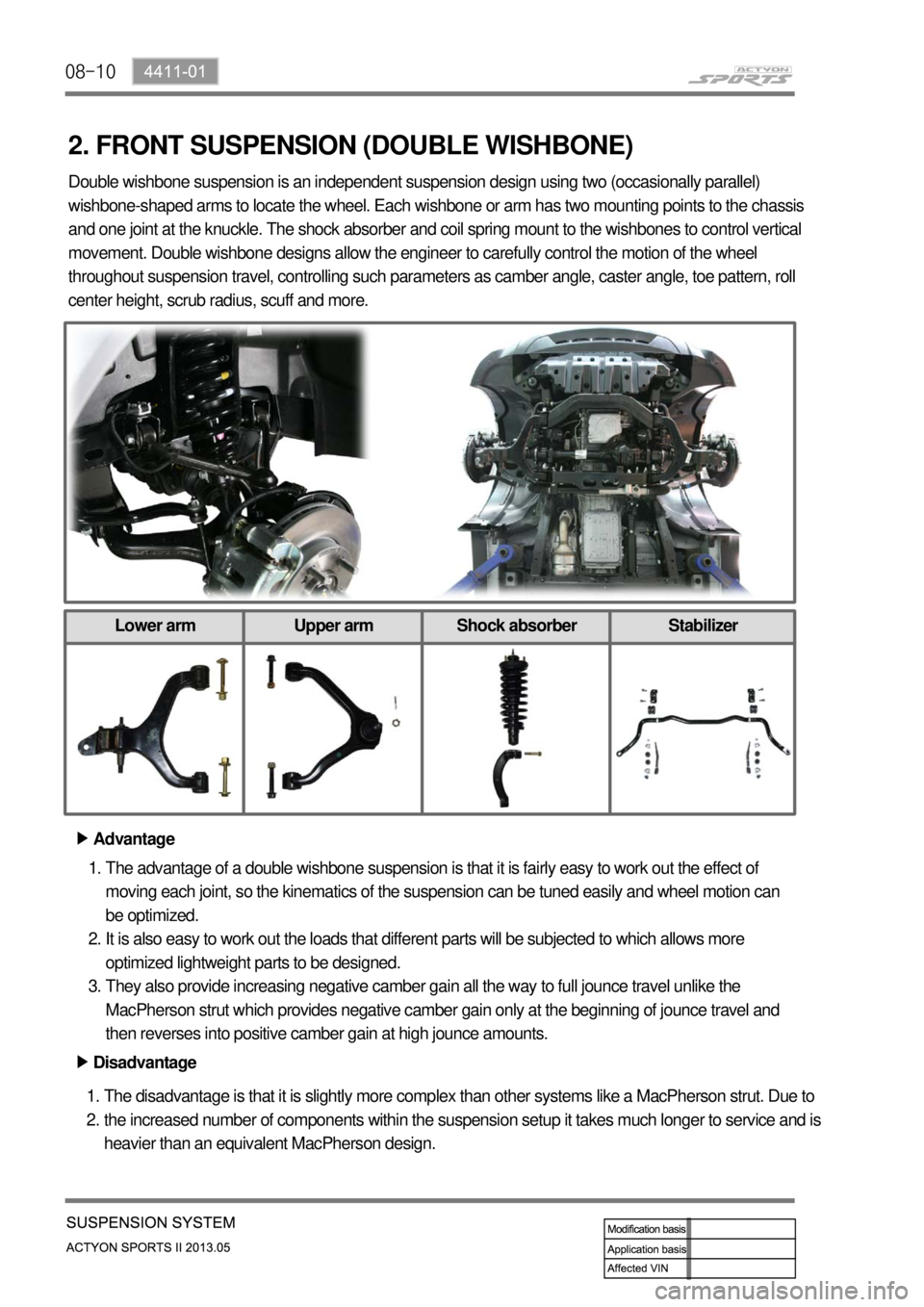

2. FRONT SUSPENSION (DOUBLE WISHBONE)

Advantage ▶

The advantage of a double wishbone suspension is that it is fairly easy to work out the effect of

moving each joint, so the kinematics of the suspension can be tuned easily and wheel motion can

be optimized.

It is also easy to work out the loads that different parts will be subjected to which allows more

optimized lightweight parts to be designed.

They also provide increasing negative camber gain all the way to full jounce travel unlike the

MacPherson strut which provides negative camber gain only at the beginning of jounce travel and

then reverses into positive camber gain at high jounce amounts. 1.

2.

3.

Disadvantage ▶

The disadvantage is that it is slightly more complex than other systems like a MacPherson strut. Due to

the increased number of components within the suspension setup it takes much longer to service and is

heavier than an equivalent MacPherson design. 1.

2. Double wishbone suspension is an independent suspension design using two (occasionally parallel)

wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis

and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical

movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel

throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll

center height, scrub radius, scuff and more.

Lower arm Upper arm Shock absorber Stabilizer

Page 548 of 751

08-114411-01

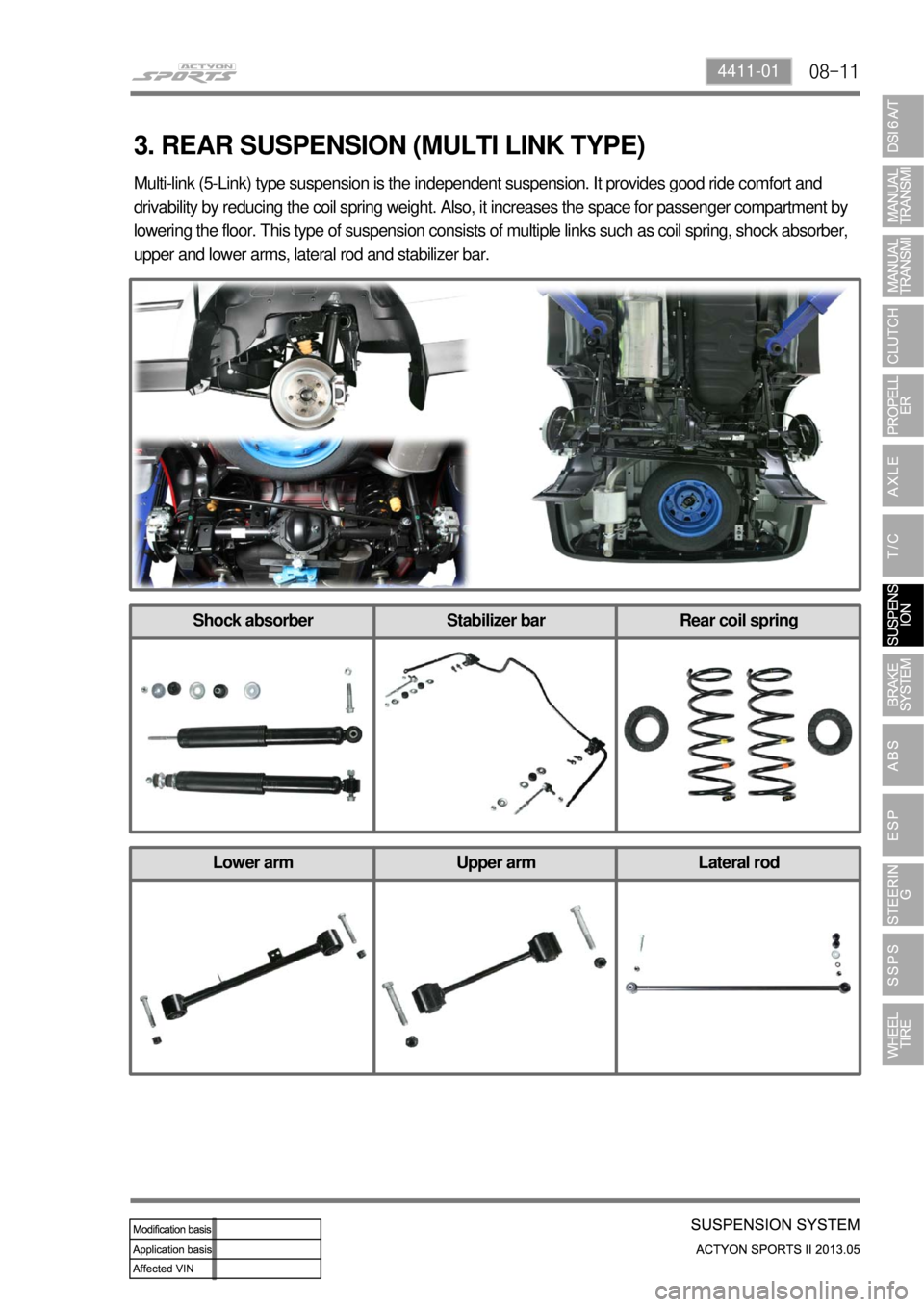

3. REAR SUSPENSION (MULTI LINK TYPE)

Multi-link (5-Link) type suspension is the independent suspension. It provides good ride comfort and

drivability by reducing the coil spring weight. Also, it increases the space for passenger compartment by

lowering the floor. This type of suspension consists of multiple links such as coil spring, shock absorber,

upper and lower arms, lateral rod and stabilizer bar.

Shock absorber Stabilizer bar Rear coil spring

Lower arm Upper arm Lateral rod

Page 594 of 751

10-14

2) Basic Theory of ABS Function

To give you a better understanding of the tasks and functions of ABS, we will first look at the physics

principles.

(1) Stopping distance

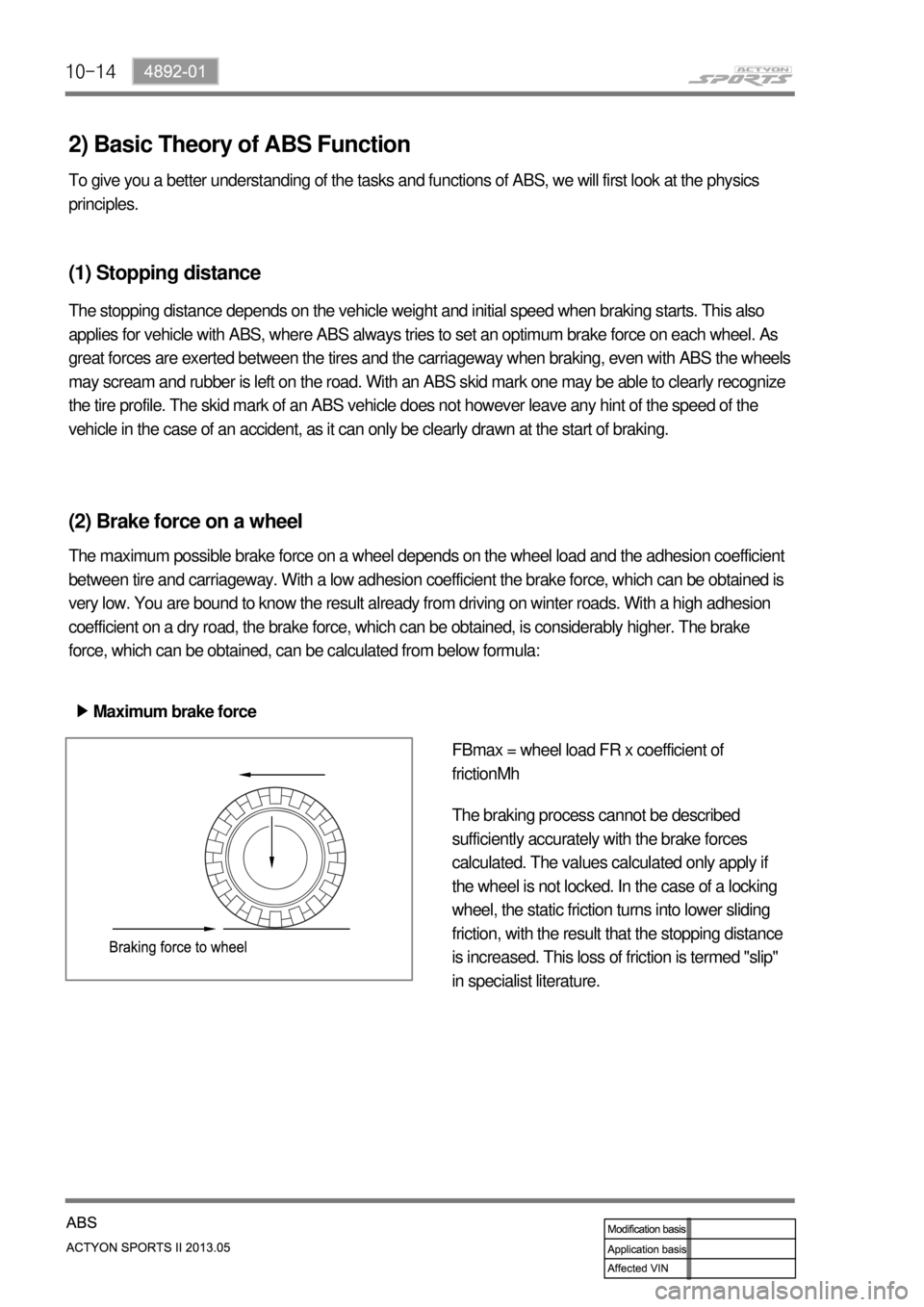

(2) Brake force on a wheel

The maximum possible brake force on a wheel depends on the wheel load and the adhesion coefficient

between tire and carriageway. With a low adhesion coefficient the brake force, which can be obtained is

very low. You are bound to know the result already from driving on winter roads. With a high adhesion

coefficient on a dry road, the brake force, which can be obtained, is considerably higher. The brake

force, which can be obtained, can be calculated from below formula:

Maximum brake force ▶

FBmax = wheel load FR x coefficient of

frictionMh

The braking process cannot be described

sufficiently accurately with the brake forces

calculated. The values calculated only apply if

the wheel is not locked. In the case of a locking

wheel, the static friction turns into lower sliding

friction, with the result that the stopping distance

is increased. This loss of friction is termed "slip"

in specialist literature.

The stopping distance depends on the vehicle weight and initial speed when braking starts. This also

applies for vehicle with ABS, where ABS always tries to set an optimum brake force on each wheel. As

great forces are exerted between the tires and the carriageway when braking, even with ABS the wheels

may scream and rubber is left on the road. With an ABS skid mark one may be able to clearly recognize

the tire profile. The skid mark of an ABS vehicle does not however leave any hint of the speed of the

vehicle in the case of an accident, as it can only be clearly drawn at the start of braking.

Page 653 of 751

13-34620-01

1. SPECIFICATIONS

Item Item Specification

SSPS solenoid valveRated voltage DC 12 V

Rated voltage 1.0 A

Resistance6.7 ±1 Ω

Power steering oil pump

(with SSPS)Operating temperature-40℃~150℃

Release pressure 90 bar

Displacement 9.3 cc/rev

Flow velocity 9.75~6 l/mn

Pulley sizeØ115

Pulley type 6 groove

Housing material Aluminium

Power steering fluid reservoir

(with SSPS)Fracture pressuremin 8kgf/㎠

Air leakage2 kgf/㎠×min

Cap open torque 9.8 to 14.2 Nm

Oil capacity FULL 550cc

Power steering gear box

(with SSPS)Gear type Rack & pinion type

Gear ratio 40.245

Fixed rack 3.78

Gear weight 12.800 kg

Steering angleInner36.2°

Outer32.4°

Page 664 of 751

14-34170-09

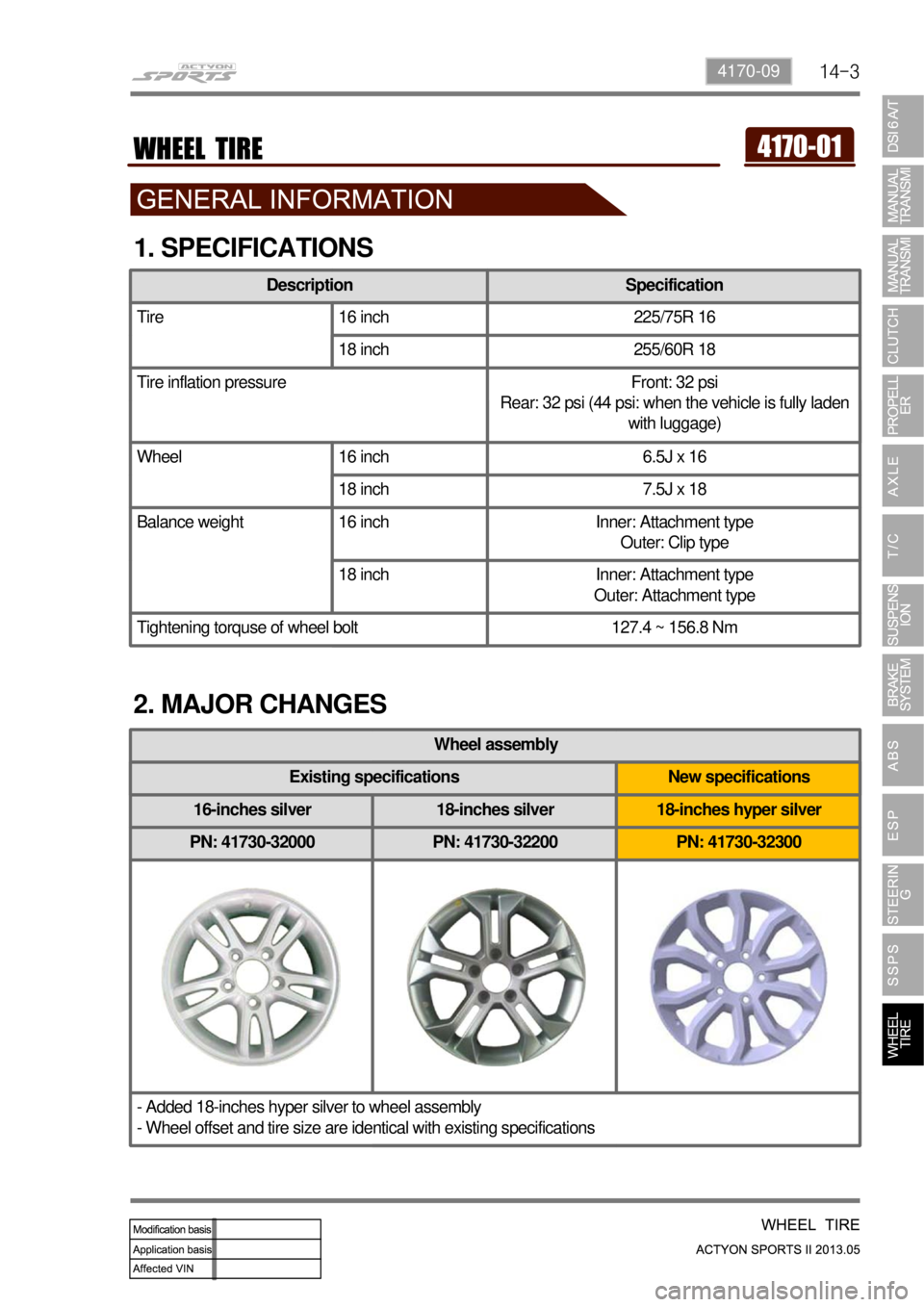

1. SPECIFICATIONS

2. MAJOR CHANGES

Wheel assembly

16-inches silver 18-inches silver 18-inches hyper silver

PN: 41730-32000 PN: 41730-32200 PN: 41730-32300

- Added 18-inches hyper silver to wheel assembly

- Wheel offset and tire size are identical with existing specifications

Existing specifications New specifications

Description Specification

Tire 16 inch 225/75R 16

18 inch 255/60R 18

Tire inflation pressure Front: 32 psi

Rear: 32 psi (44 psi: when the vehicle is fully laden

with luggage)

Wheel 16 inch 6.5J x 16

18 inch 7.5J x 18

Balance weight 16 inch Inner: Attachment type

Outer: Clip type

18 inch Inner: Attachment type

Outer: Attachment type

Tightening torquse of wheel bolt 127.4 ~ 156.8 Nm

Page 670 of 751

14-94170-09

Wheel balance 5.

Check the wheel balance when the wheel

is unbalanced or the tire is repaired.

The total weight of the wheel weight

should not exceed 150 g.

Ensure that the balance weight installed is

not projected over 3mm from the wheel

surface.

Use the specified aluminum wheel balance

weights for aluminum wheels.

Weight balance can be added by 5 g.

There are two types of weight balance,

tape type and adhesion type. -

-

-

-

-

-

Make sure to read the manual of the

manufacturer thoroughly before using

wheel balance tester. -

Change tire location

To avoid uneven wear of tires and to prolong

tire life, inspect and rotate your tires every

5,000 km. 6.

Mixing tires could cause to lose control while driving. Be sure to use the same size and type tires of

the same manufacturer on all wheels. -

Page 672 of 751

14-114170-09

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct line from

one bead to the other across the tread. In addition, a radial tire has a belt overwrap under the tread

surface to provide greater structural stability. The belt overwrap of a radial tire distortion while the radial

structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time, transmits

<009b008f008c004700970096009e008c00990047009b009600470097009900960097008c0093005300470089009900880092008c004700880095008b0047009a009b008c008c00990047009600950047009b008f008c0047009900960088008b0055004700

70009b004700880093009a00960047008d009c0095008a009b>ions to maintain a vehicle’s

movement. In order to complete such tasks, a tire must be structured to be a resilient vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6 mm from

the groove bottom. This wear limit mark is not seen from the outside so there is additional "▲"

mark on the shoulder to let the driver find the wear mark easily. To measure the tire groove depth,

measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire inflation

pressure, changed tire location, etc.

Page 678 of 751

14-174170-09

If weight is not equally distributed around the wheel, unbalance centrifugal force by the wheel rotation

produces vibration. As the centrifugal force is produced proportional to the square of the rotating speed,

the wheel weight should be balanced even at high speed. There are two types of the tire and wheel

balancing: static and dynamic. Abnormal vibration may also occur due to unbalanced rigidity or size of

tires.

Static Balance ▶

When the free rotation of the wheel is allowed,

the heavier part is stopped on the bottom if the

wheel weight is unbalanced and this is called

"Static Unbalance". Also, the state at which tire's

stop position is not same is called "Static

Balance" when the wheel is rotated again. If the

part A is heavier as shown in the figure 1, add

the balance weight of a weight corresponding to

unbalanced weight from B to A to maintain the

static balance. If the static balance is not

maintained, tramping, up and down vibration of

the wheels, occurs.

Dynamic Balance ▶

The static unbalance of the wheel creates the

vibration in the vertical direction, but the dynamic

unbalance creates the vibration in the lateral

direction. As shown in the figure 2 (a), if two

parts, (2) and (3), are heavier when the wheels

are under the static balance condition, dynamic

unbalance is created, resulting in shimmy, left

and right vibration of the wheels, and the torque

Fxa is applied in the axial direction. To correct

the dynamic unbalance, add the balance weight

of a same weight for two points of the

circumference of the rim, A and B, as shown in

the figure 2 (b), and apply the torque in the

opposite direction to the torque Fxa to offset in

order to ensure smooth rotation of the wheel.

Center

A

B

(a) (b)

[Figure 1]

[Figure 2]

3. WHEEL BALANCE

Page 679 of 751

14-18

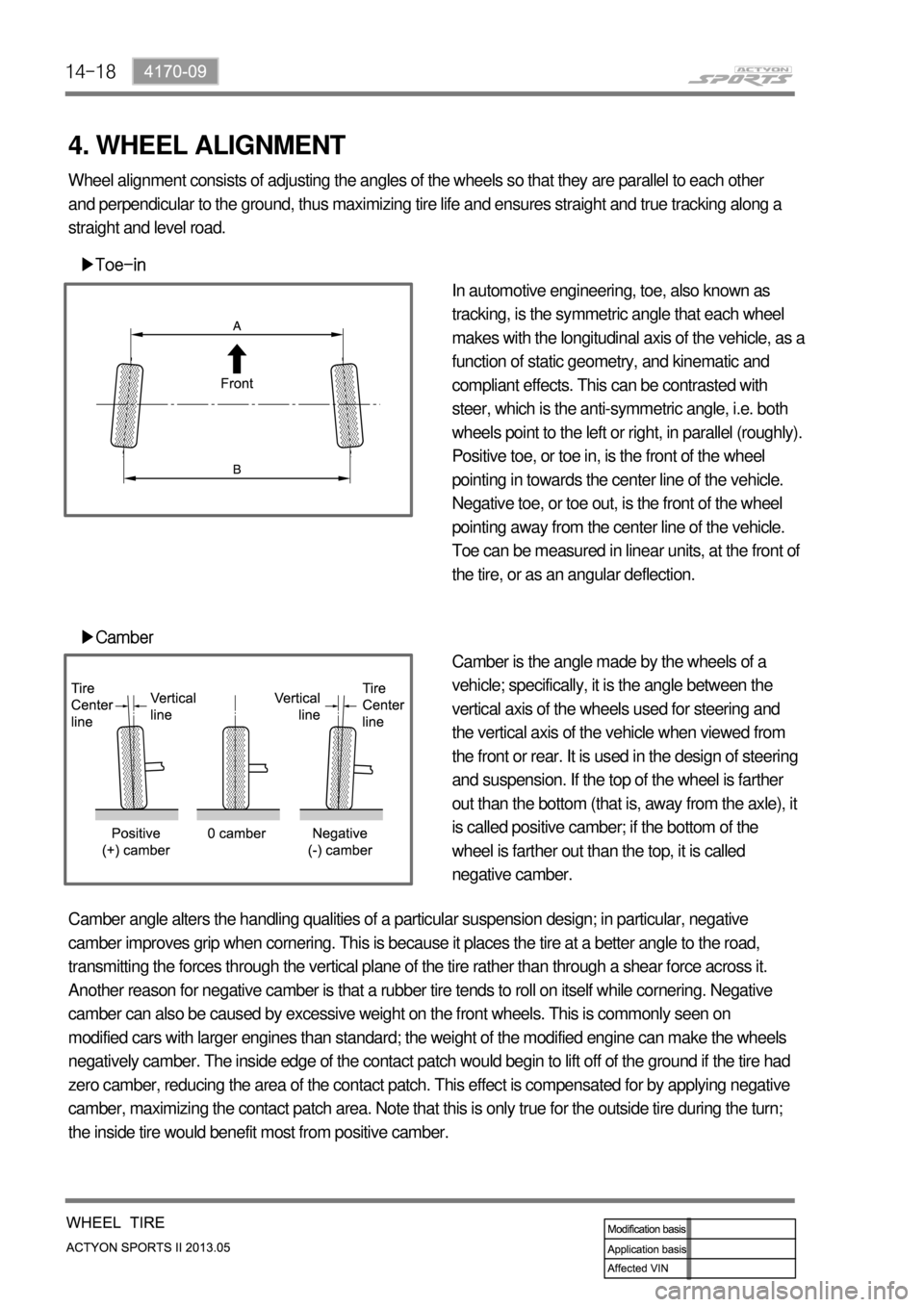

4. WHEEL ALIGNMENT

▶Toe-in

▶Camber

In automotive engineering, toe, also known as

tracking, is the symmetric angle that each wheel

makes with the longitudinal axis of the vehicle, as a

function of static geometry, and kinematic and

compliant effects. This can be contrasted with

steer, which is the anti-symmetric angle, i.e. both

wheels point to the left or right, in parallel (roughly).

Positive toe, or toe in, is the front of the wheel

pointing in towards the center line of the vehicle.

Negative toe, or toe out, is the front of the wheel

pointing away from the center line of the vehicle.

Toe can be measured in linear units, at the front of

the tire, or as an angular deflection.

Camber is the angle made by the wheels of a

vehicle; specifically, it is the angle between the

vertical axis of the wheels used for steering and

the vertical axis of the vehicle when viewed from

the front or rear. It is used in the design of steering

and suspension. If the top of the wheel is farther

out than the bottom (that is, away from the axle), it

is called positive camber; if the bottom of the

wheel is farther out than the top, it is called

negative camber. Wheel alignment consists of adjusting the angles of the wheels so that they are parallel to each other

and perpendicular to the ground, thus maximizing tire life and ensures straight and true tracking along a

straight and level road.

Camber angle alters the handling qualities of a particular suspension design; in particular, negative

camber improves grip when cornering. This is because it places the tire at a better angle to the road,

transmitting the forces through the vertical plane of the tire rather than through a shear force across it.

Another reason for negative camber is that a rubber tire tends to roll on itself while cornering. Negative

camber can also be caused by excessive weight on the front wheels. This is commonly seen on

modified cars with larger engines than standard; the weight of the modified engine can make the wheels

negatively camber. The inside edge of the contact patch would begin to lift off of the ground if the tire had

zero camber, reducing the area of the contact patch. This effect is compensated for by applying negative

camber, maximizing the contact patch area. Note that this is only true for the outside tire during the turn;

the inside tire would benefit most from positive camber.

Page 681 of 751

14-20

Even friction coefficient road Uneven friction coefficient road

Driving Force

Braking Force

Supporting the Vehicle Weight ▶Transferring the Driving Force & Braking Force to Road ▶

5. FUNCTIONS OF TIRE

Supporting the Vehicle Weight ▶