coolant SSANGYONG NEW ACTYON SPORTS 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 160 of 751

10-4

Glow plug control unit

(GCU)

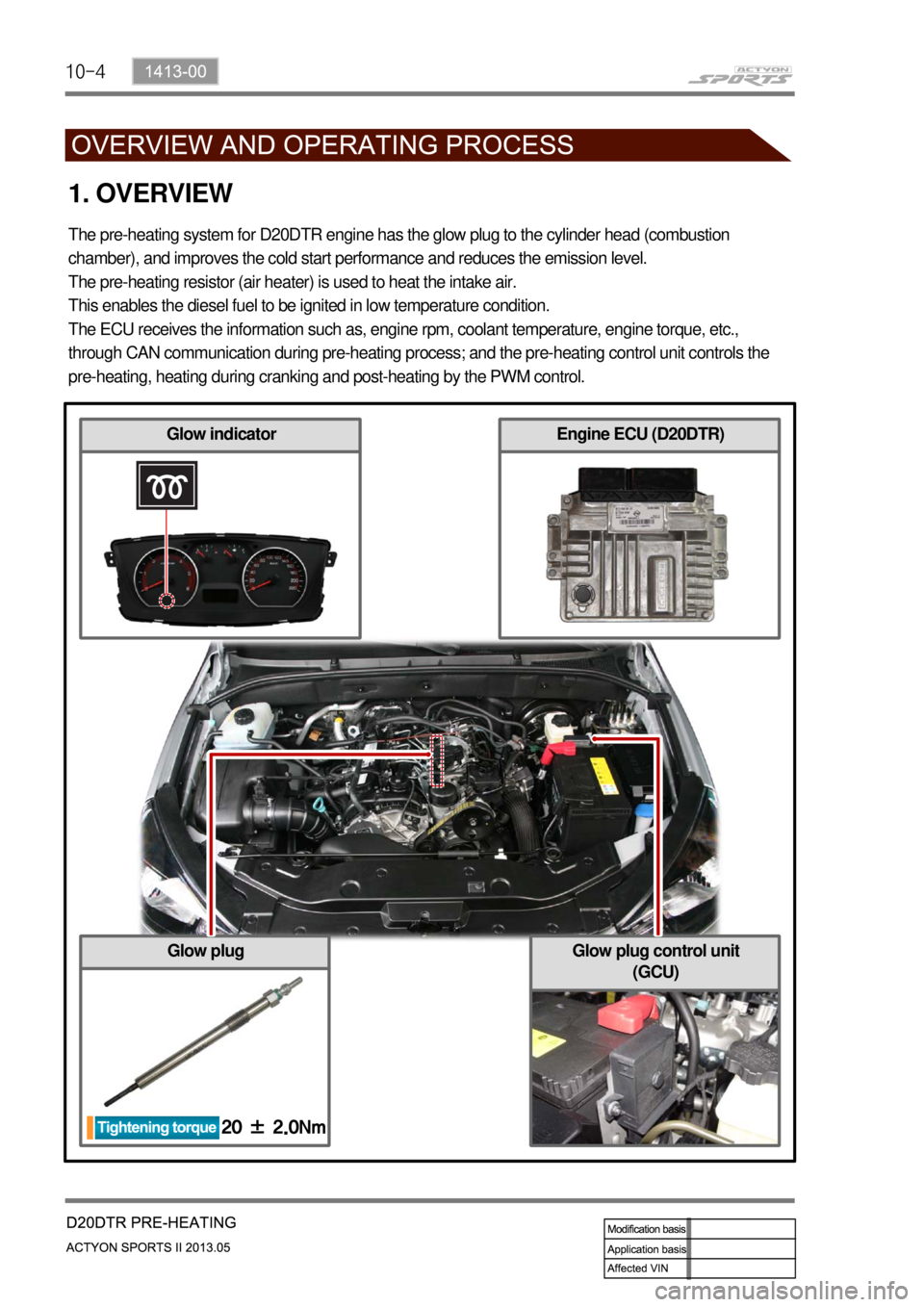

1. OVERVIEW

The pre-heating system for D20DTR engine has the glow plug to the cylinder head (combustion

chamber), and improves the cold start performance and reduces the emission level.

The pre-heating resistor (air heater) is used to heat the intake air.

This enables the diesel fuel to be ignited in low temperature condition.

The ECU receives the information such as, engine rpm, coolant temperature, engine torque, etc.,

through CAN communication during pre-heating process; and the pre-heating control unit controls the

pre-heating, heating during cranking and post-heating by the PWM control.

Glow plug

Glow indicatorEngine ECU (D20DTR)

Page 163 of 751

10-71413-00

4) Operation

Glow plug is installed in the cylinder head. It enhances the cold starting performance and reduces the

exhaust gas during cold starting.

ECU receives the data (engine rpm, coolant temperature, vehicle speed) through CAN lines. Based on

the data, GCU controls the pre-glow, cranking and post-glow. It also checks the glow plugs, and sends

the result to ECU.

(1) Temperature/Current Properties of GCU

GCU increases the temperature of glow plug very rapidly (approx. 2 seconds up to 100

FETs (similar to transistor) for each cylinder are integrated in GCU. During the pre-glow

period, battery voltage is supplied to the glow plugs directly to heat them rapidly.

After getting the desired temperature by pre-glowing, the temperature is controlled by duty

ratio. Step 1:

Step 2 & 3:

Step 4:

This shows the supplying voltage and time by GCU in each step. The step 4 is the period to keep the

temperature. -Step 1: I1

Step 2: I2

Step 3: I3

Step 4: I4

Page 183 of 751

13-51793-00

E-EGR valve

Receives the electric signal from the ECU to

control the valve.

E-EGR cooler and bypass valve

The cooler lowers the high temperature of the

exhaust gas and the bypass valve directly

supplies the exhaust gas to the intake duct

without passing through the EGR cooler to

reduce the emission of exhaust gas before

warming up the engine.

2) Location and Components

HFM sensor

Used as a main map value to control the EGR.

The coolant temperature, engine rpm, engine

load, intake air temperature (HFM: decreased at

60˚C or more), atmospheric pressure

(atmospheric pressure sensor: altitude

compensation) are used as auxiliary map values.

EGR pipe

Transports the exhaust gas from the EGR cooler

and EGR bypass valve to the intake duct.

See the section "Engine control" for E-EGR

valve control logic.

EGR cooler

EGR bypass

For details, see the section "Engine control". *

Page 186 of 751

13-8

3) Control Logic

The EGR system controls the EGR amount based on the map values shown below:

Main map value: Intake air volume

Auxiliary map value: ※

※

Compensation by the coolant temperature

Compensation by the atmospheric pressure: Altitude compensation

Compensation by the boost pressure deviation (the difference between the requested value and the

measured value of boost pressure)

Compensation by the engine load: During sudden acceleration

Compensation by the intake air temperature -

-

-

-

-

The engine ECU calculates the EGR amount by adding main map value (intake air volume) and auxiliary

map value and directly drives the solenoid valve in the E-EGR to regulate the opening extent of the EGR

valve and sends the feedback to the potentiometer.

(1) Operating conditions

Intake air temperature: between -10 and 50℃

Atmospheric pressure: 0.92 bar or more

Engine coolant temperature: between 0 and 100°C

When there is no fault code related to EGR -

-

-

-

(2) Shut off conditions

Abrupt acceleration: with engine speed of 2600 rpm or more

When the engine is idling for more than 1 minute

Vehicle speed: 100 km/h or more

Engine torque: 380 Nm or more -

-

-

-

Page 203 of 751

15-30000-00

1. ENGINE DATA LIST

Data Unit Value

Coolant temperature℃ 0.436 V (130℃) to 4.896 V (-40℃)

Intake air temperature℃ -40 to 130℃ (varies by ambient air

temperature or engine mode)

Idle speed rpm750 ± 20

Engine load % 18~25%

Mass air flow kg/h 16 to 25 kg/h

Throttle position angle°TA 0° (Full Open) to 78° (Close)

Engine torque Nm varies by engine conditions

Injection time ms 3 to 5ms

Battery voltage V 13.5 V to 14.1 V

Accelerator pedal position 1 V 0.4. to 4.8V

Accelerator pedal position 2 V 0.2 to 2.4 V

Throttle position 1 V 0.3 to 4.6 V

Throttle position 2 V 0.3 to 4.6 V

Oxygen sensor mV 0 to 5 V

A/C compressor switch 1=ON / 0=OFF -

Full load 1=ON / 0=OFF -

Gear selection (A/T) 1=ON / 0=OFF -

Knocking control 1=ON / 0=OFF -

Brake switch 1=ON / 0=OFF -

Cruise control 1=ON / 0=OFF -

Page 207 of 751

15-70000-00

Fuel rail pressure

sensorEGR valveFuel temperature

sensor

Electric throttle bodyKnock sensor

(2 ea)

Coolant temperature

sensor

T-MAP sensorD20DTR ECU

E-VGT actuator

Water sensorGCU (Preglow control

unit)

E-EGR bypass valve

Page 209 of 751

15-90000-00

Fuel rail pressure

sensor

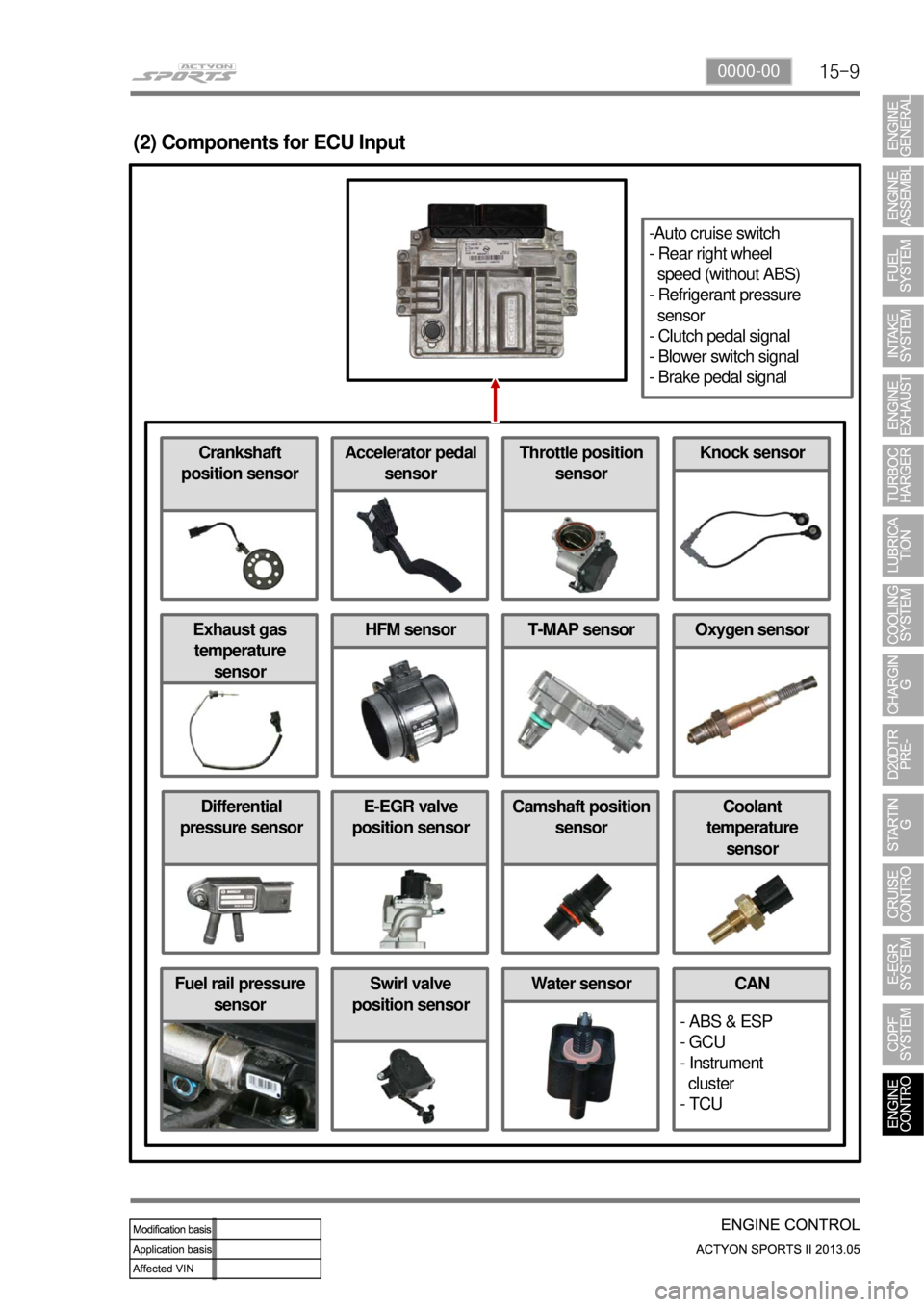

(2) Components for ECU Input

CAN

- ABS & ESP

- GCU

- Instrument

cluster

- TCUSwirl valve

position sensor

Differential

pressure sensorE-EGR valve

position sensorCamshaft position

sensorCoolant

temperature

sensor

Exhaust gas

temperature

sensorHFM sensorOxygen sensorT-MAP sensor

Crankshaft

position sensorAccelerator pedal

sensorThrottle position

sensorKnock sensor

-Auto cruise switch

- Rear right wheel

speed (without ABS)

- Refrigerant pressure

sensor

- Clutch pedal signal

- Blower switch signal

- Brake pedal signal

Water sensor

Page 213 of 751

15-130000-00

b. Pilot Injection

Injection before main injection. Consists of 1st and 2nd pilot injection, and Pre-injection

Inject a small amount of fuel before main injection to make the combustion smooth. Also, called as

preliminary injection or ignition injection. This helps to reduce Nox, engine noise and vibration, and to

stabilize the idling.

The injected fuel volume is changed and stopped according to the coolant temperature and intake air

volume.

Pilot injection is much earlier than main injection due to higher engine rpm

Too small injection volume (insufficient injection pressure, insufficient fuel injection volume in main

injection, engine braking)

System failure (fuel system, engine control system) -

-

-

Pilot injection

Main injection

Combustion pressure with pilot injection

Combustion pressure without pilot injection 1.

2.

1a.

2b. Stop conditions

Combustion pressure characteristic curve for pilot injection ▶

Page 214 of 751

15-14

c. Main Injection

The power of the vehicle is determined by the main fuel injection volume.

Main injection calculates the fuel volume based on pilot injection. The calculation uses the value for

accelerator pedal position, engine rpm, coolant temperature, intake air temperature, boost pressure,

boost temperature and atmospheric pressure etc.

d. Post Injection

Injection after main injection. Consists of After injection, Post 1, Post 2 injection.

Post injection reduces PM and smoke from exhaust gas. No actual output is generated during these

injections, instead, fuel is injected to the unburned gas after main injection to enable fuel activation. The

PM amount in the emission and smoke can be reduced through these processes.

Only up to 5 types of injections can be performed within 1 cycle. If these 7 injections are all performed,

fuel economy and emission performance becomes poor.

Page 215 of 751

15-150000-00

(3) Fuel Pressure Control

Fuel pressure is controlled by IMV opening according to the calculated value by ECU.

Pressure in the fuel rail is determined according to engine speed and load on the engine. ▶

When engine speed and load are high

The degree of turbulence is very great and the fuel can be injected at very high pressure in order to

optimize combustion.

When engine speed and load are low

The degree of turbulence is low. If injection pressure is too high, the nozzle's penetration will be

excessive and part of the fuel will be sprayed directly onto the sides of the cylinder, causing

incomplete combustion. So there occurs smoke and damages engine durability. -

-

Fuel pressure is corrected according to air temperature, coolant temperature and atmospheric pressure

and to take account of the added ignition time caused by cold running or by high altitude driving. A

special pressure demand is necessary in order to obtain the additional flow required during starts. This

demand is determined according to injected fuel and coolant temperature.

Open loop determines the current which needs to be sent to the actuator in order to obtain the

flow demanded by the ECU. ▶

Closed loop will correct the current value depending on the difference between the pressure

demand and the pressure measured. ▶

If the pressure is lower than the demand, current is reduced so that the fuel sent to the high pressure

pump is increased.

If the pressure is higher than the demand, current is increased so that the fuel sent to the high

pressure pump is reduced. -

-Fuel Pressure ▶