engine SSANGYONG NEW ACTYON SPORTS 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 57 of 751

02-26

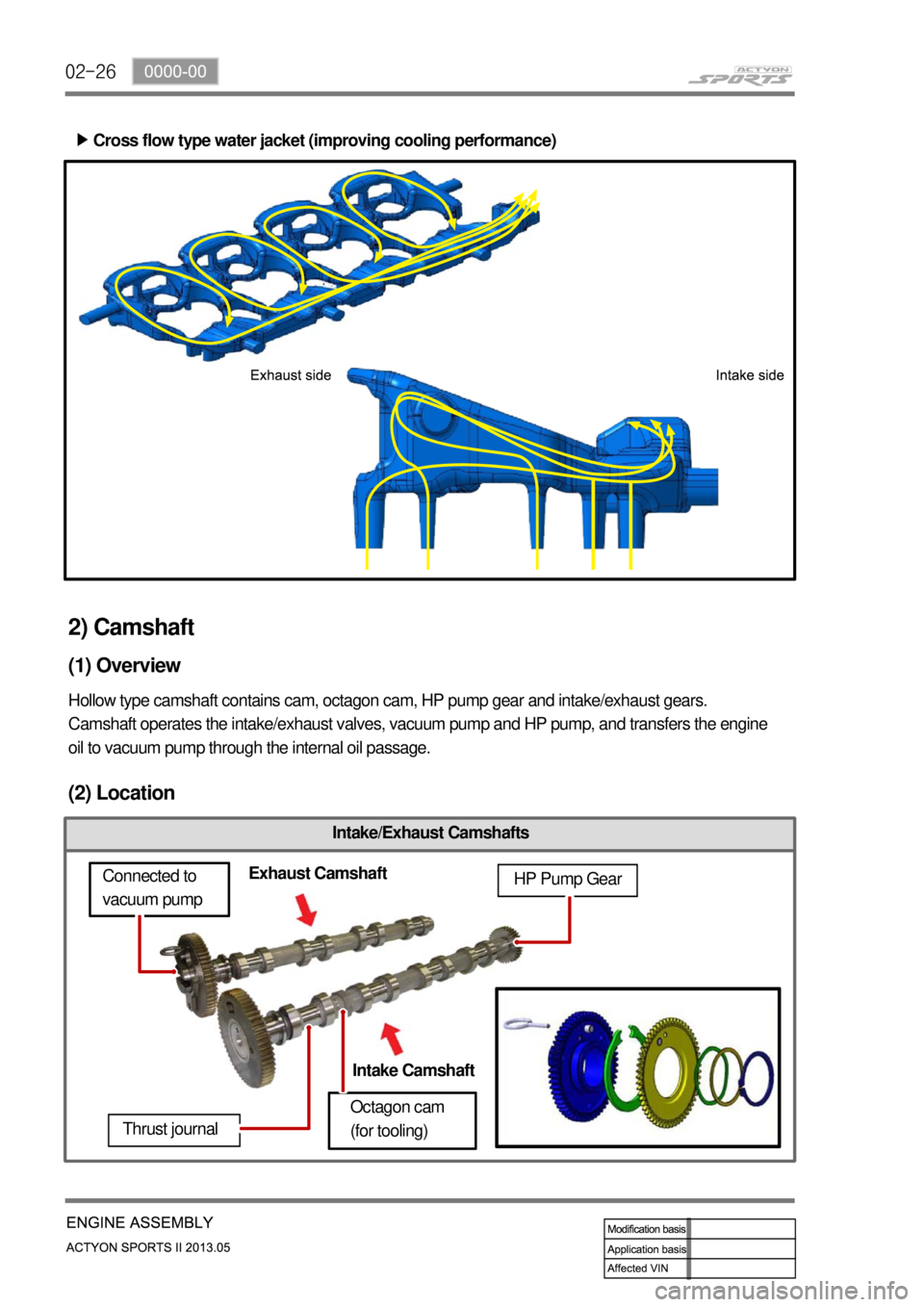

Intake/Exhaust Camshafts

2) Camshaft

(1) Overview

Hollow type camshaft contains cam, octagon cam, HP pump gear and intake/\

exhaust gears.

Camshaft operates the intake/exhaust valves, vacuum pump and HP pump, an\

d transfers the engine

oil to vacuum pump through the internal oil passage.

(2) Location

Exhaust CamshaftHP Pump Gear

Octagon cam

(for tooling)

Thrust journal

Connected to

vacuum pumpIntake Camshaft

Cross flow type water jacket (improving cooling performance)

▶

Page 59 of 751

02-28

Thickness markingEx: 1.3t

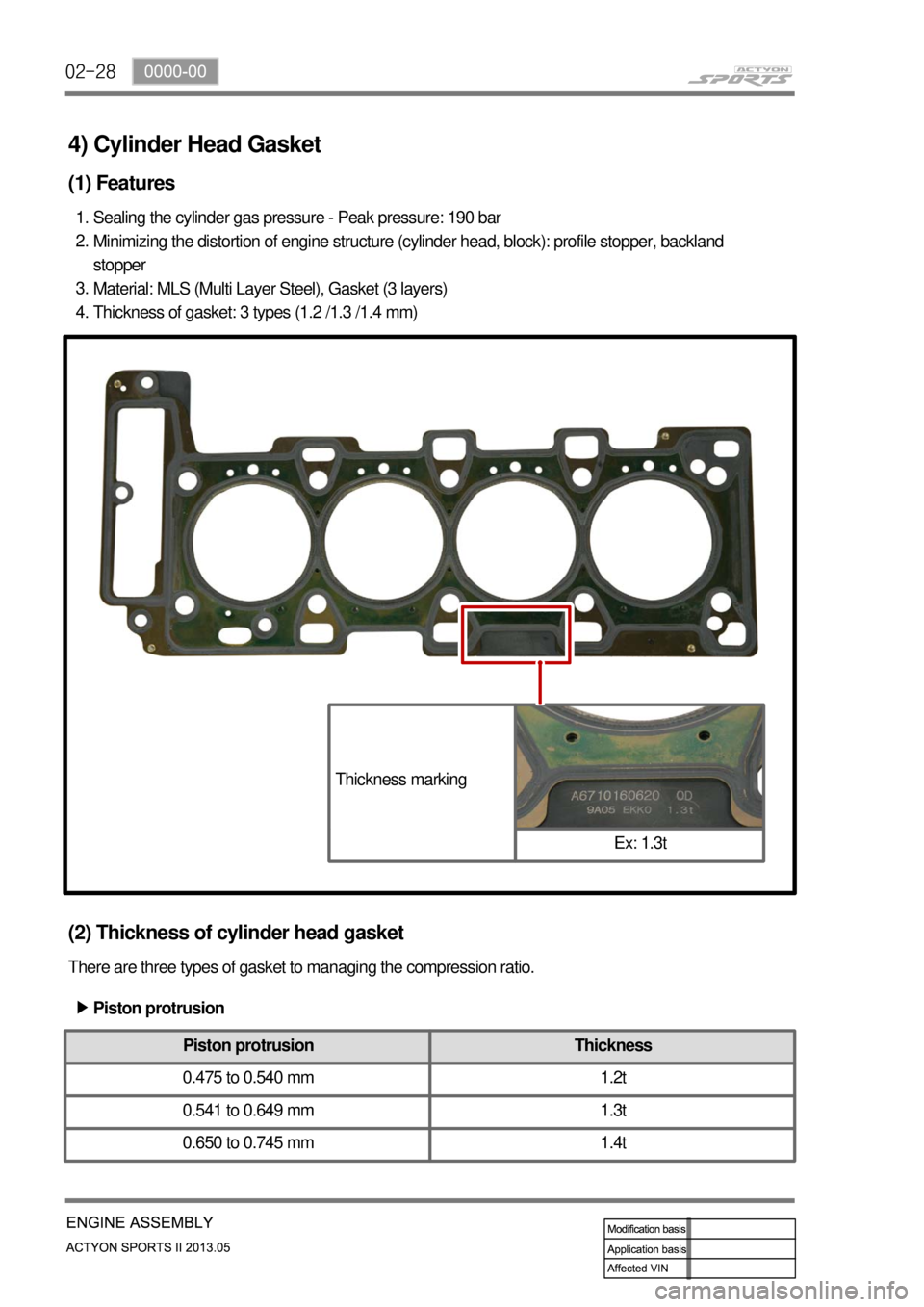

4) Cylinder Head Gasket

(1) Features

Sealing the cylinder gas pressure - Peak pressure: 190 bar

Minimizing the distortion of engine structure (cylinder head, block): \

profile stopper, backland

stopper

Material: MLS (Multi Layer Steel), Gasket (3 layers)

Thickness of gasket: 3 types (1.2 /1.3 /1.4 mm)

1.

2.

3.

4.

(2) Thickness of cylinder head gasket

There are three types of gasket to managing the compression ratio.

Piston protrusion

▶

Piston protrusion

Thickness

0.475 to 0.540 mm 1.2t

0.541 to 0.649 mm 1.3t

0.650 to 0.745 mm 1.4t

Page 60 of 751

02-290000-00

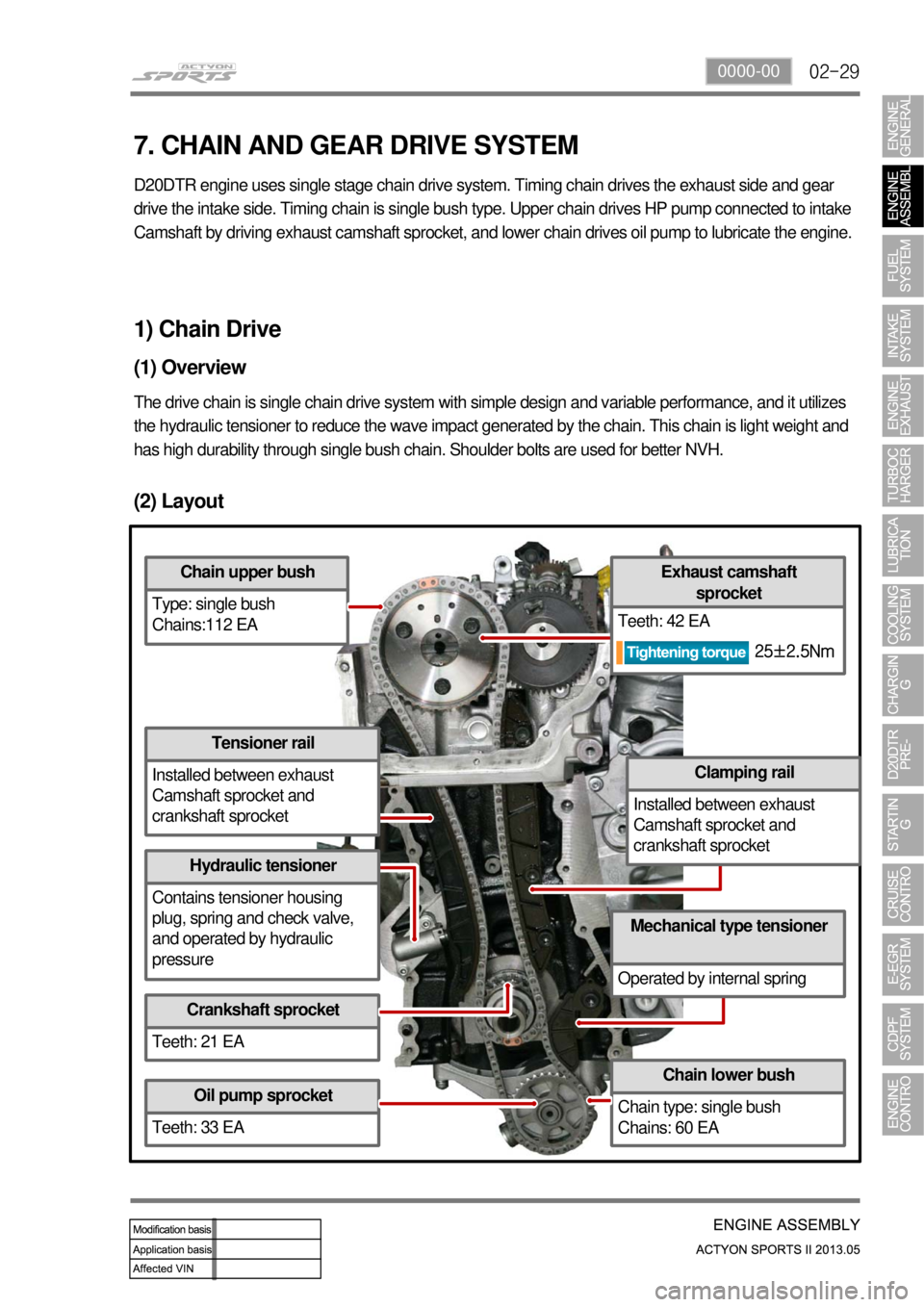

(2) Layout

Chain upper bush

Type: single bush

Chains:112 EA

Tensioner rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

Hydraulic tensioner

Contains tensioner housing

plug, spring and check valve,

and operated by hydraulic

pressure

Crankshaft sprocket

Teeth: 21 EA

Oil pump sprocket

Teeth: 33 EA

Chain lower bush

Chain type: single bush

Chains: 60 EA

Mechanical type tensioner

Operated by internal spring

Clamping rail

Installed between exhaust

Camshaft sprocket and

crankshaft sprocket

Exhaust camshaft sprocket

Teeth: 42 EA

1) Chain Drive

(1) Overview

The drive chain is single chain drive system with simple design and variable performance, and it utilizes

the hydraulic tensioner to reduce the wave impact generated by the chain\

. This chain is light weight and

has high durability through single bush chain. Shoulder bolts are used f\

or better NVH.

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTR engine uses single stage chain drive system. Timing chain drives the exhaust side and gear

drive the intake side. Timing chain is single bush ty pe. Upper chain drives HP pump connected to intake

Camshaft by driving exhaust camshaft sprocket, and lowe r chain drives oil pump to lubricate the engine.

25±2.5Nm

Page 61 of 751

02-30

2) Timing Chain and Gear

(1) Timing chain

Simple layout: optimized timing, enhanced

NVH

Single stage layout: minimized chain load -

-

Chain upper bush

- Single bush type (112 EA)

Chain lower bush

- Single bush type (60 EA)

(2) Tensioner

Tensioner adjusts the chain tension to keep it tight during engine running. This reduces the wear in

guide rail and spoke.

Operating principle

- Use the spring tension in tensioner and hydraulic pressure

Tensioner type

- Compensation and impact absorbing

Static and dynamic force

- Spring + Hydraulic pressure 1.

2.

3.

Plunger

HousingSpring

Check valve

Hydraulic tensioner assembly ▶

Page 65 of 751

02-34

Oil pan sassembly

8. OIL PAN

The oil pan in D20DTR engine improves the NVH. Especially, the oil draining is much easier than before.

Components ▶

Page 66 of 751

02-350000-00

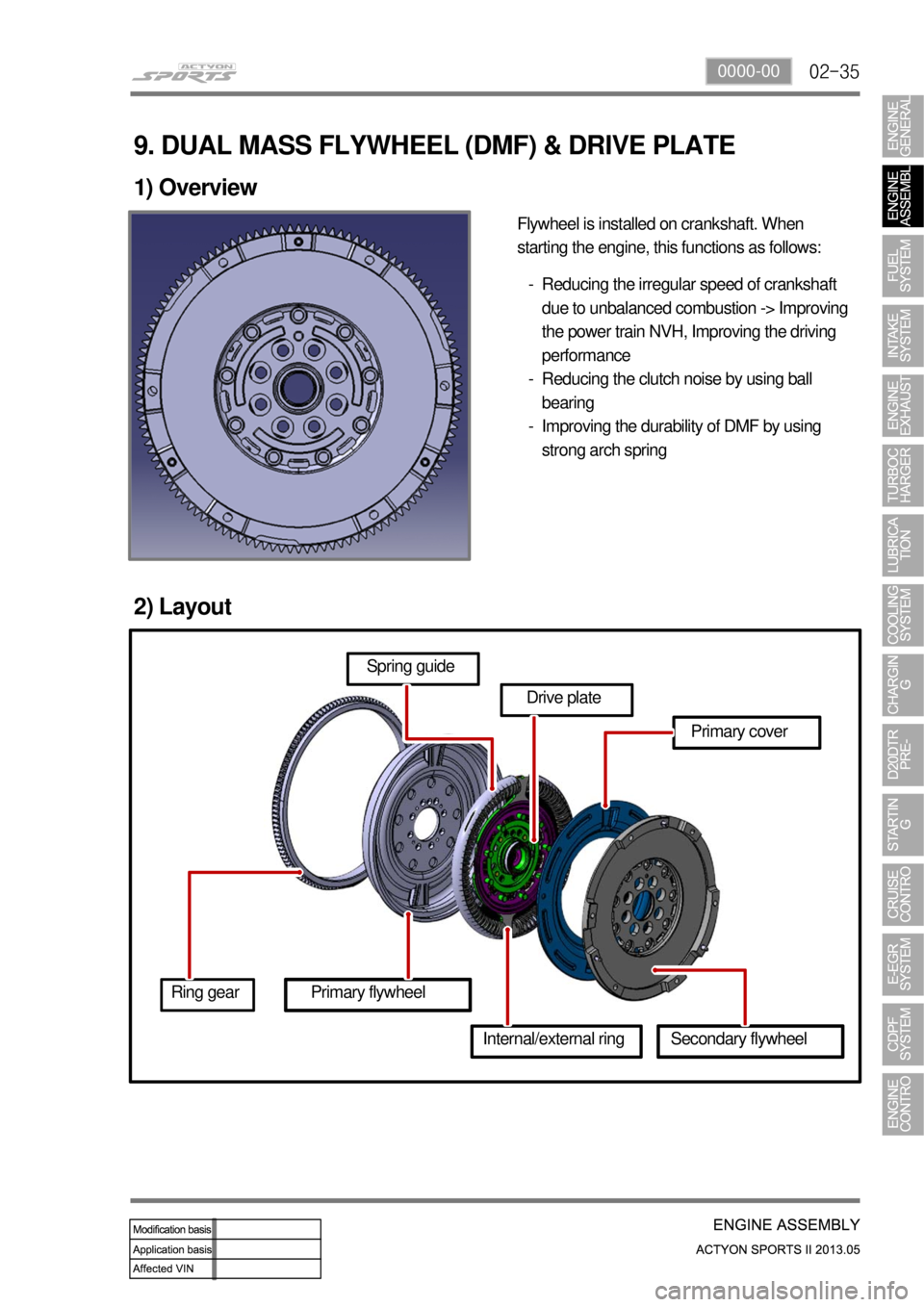

9. DUAL MASS FLYWHEEL (DMF) & DRIVE PLATE

1) Overview

Flywheel is installed on crankshaft. When

starting the engine, this functions as follows:

Reducing the irregular speed of crankshaft

due to unbalanced combustion -> Improving

the power train NVH, Improving the driving

performance

Reducing the clutch noise by using ball

bearing

Improving the durability of DMF by using

strong arch spring -

-

-

2) Layout

Spring guide

Drive plate

Primary cover

Primary flywheel

Internal/external ringSecondary flywheel

Ring gear

Page 67 of 751

02-36

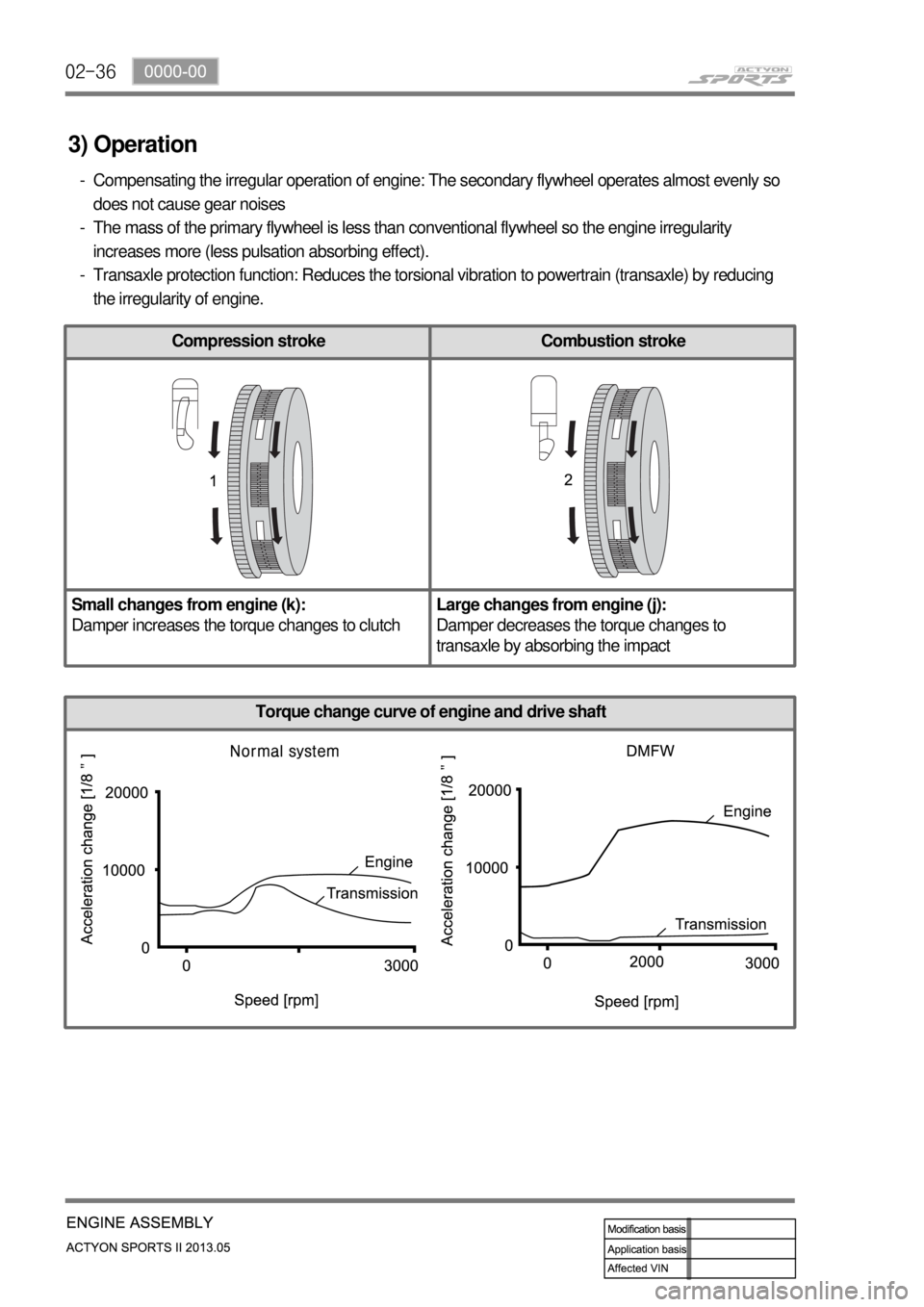

Torque change curve of engine and drive shaft

Compression stroke Combustion stroke

Small changes from engine (k):

Damper increases the torque changes to clutchLarge changes from engine (j):

Damper decreases the torque changes to

transaxle by absorbing the impact

3) Operation

Compensating the irregular operation of engine: The secondary flywheel operates almost evenly so

does not cause gear noises

The mass of the primary flywheel is less than conventional flywheel so the engine irregularity

increases more (less pulsation absorbing effect).

Transaxle protection function: Reduces the torsional vibration to powertrain (transaxle) by reducing

the irregularity of engine. -

-

-

Page 68 of 751

02-370000-00

4) Features

Reduced vibration noise from the powertrain by blocking the torsional vibrations

Enhanced vehicle silence and riding comforts: reduced engine torque fluctuation

Reduced shifting shocks

Smooth acceleration and deceleration -

-

-

-

5) Advantages

Improved torque response by using 3-stage type spring: Strengthens the torque response in all

ranges (low, medium, and high speed) by applying respective spring constant at each range.

Stable revolution of the primary and secondary wheel by using planetary gear: Works as auxiliary

damper against spring changes

Less heat generation due to no direct friction against spring surface: Plastic material is covered on

the spring outer surface

Increased durability by using plastic bushing (extends the lifetime of grease) -

-

-

-

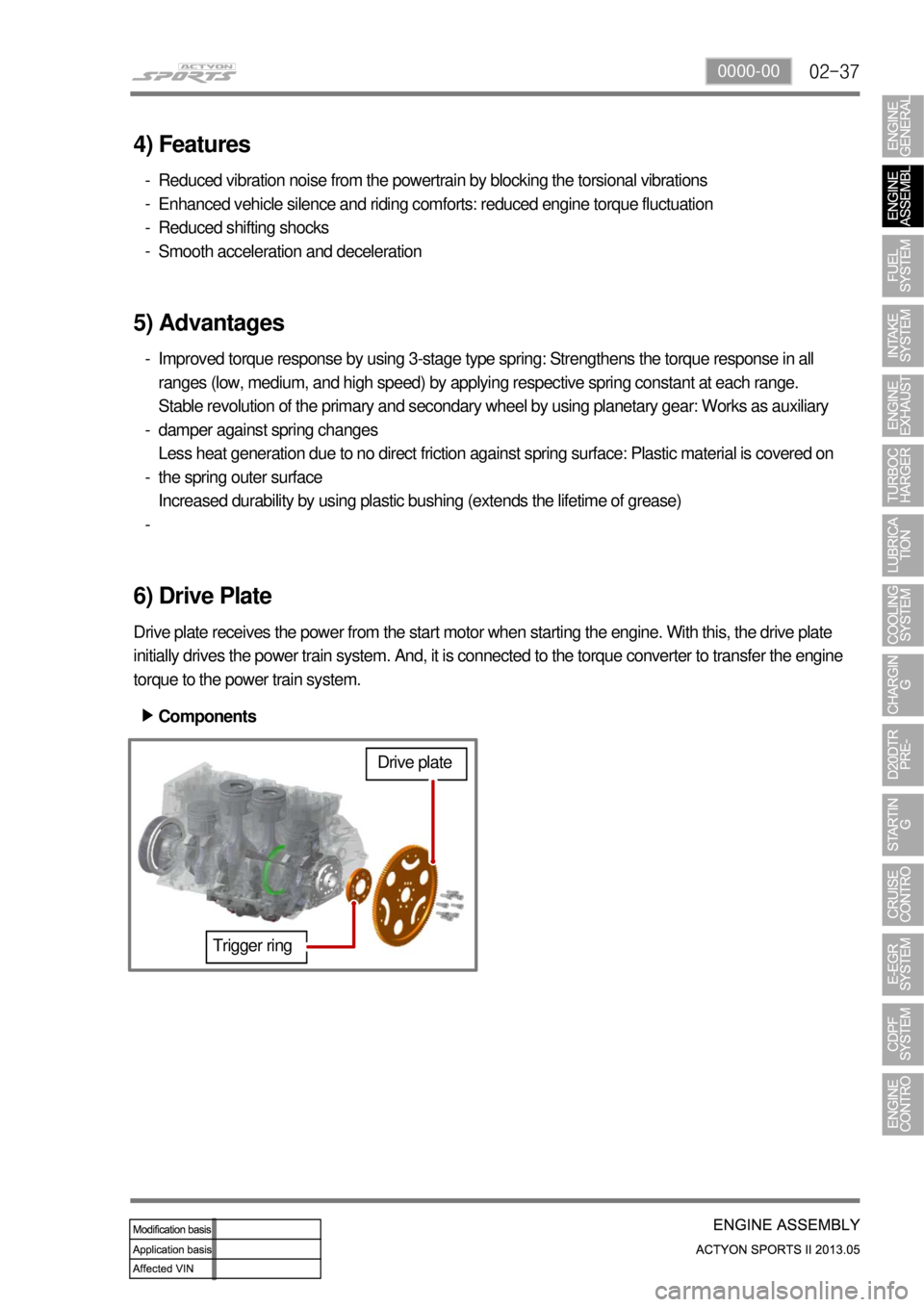

6) Drive Plate

Drive plate receives the power from the start motor when starting the engine. With this, the drive plate

initially drives the power train system. And, it is connected to the torque converter to transfer the engine

torque to the power train system.

Trigger ring

Drive plate

Components ▶

Page 70 of 751

02-390000-00

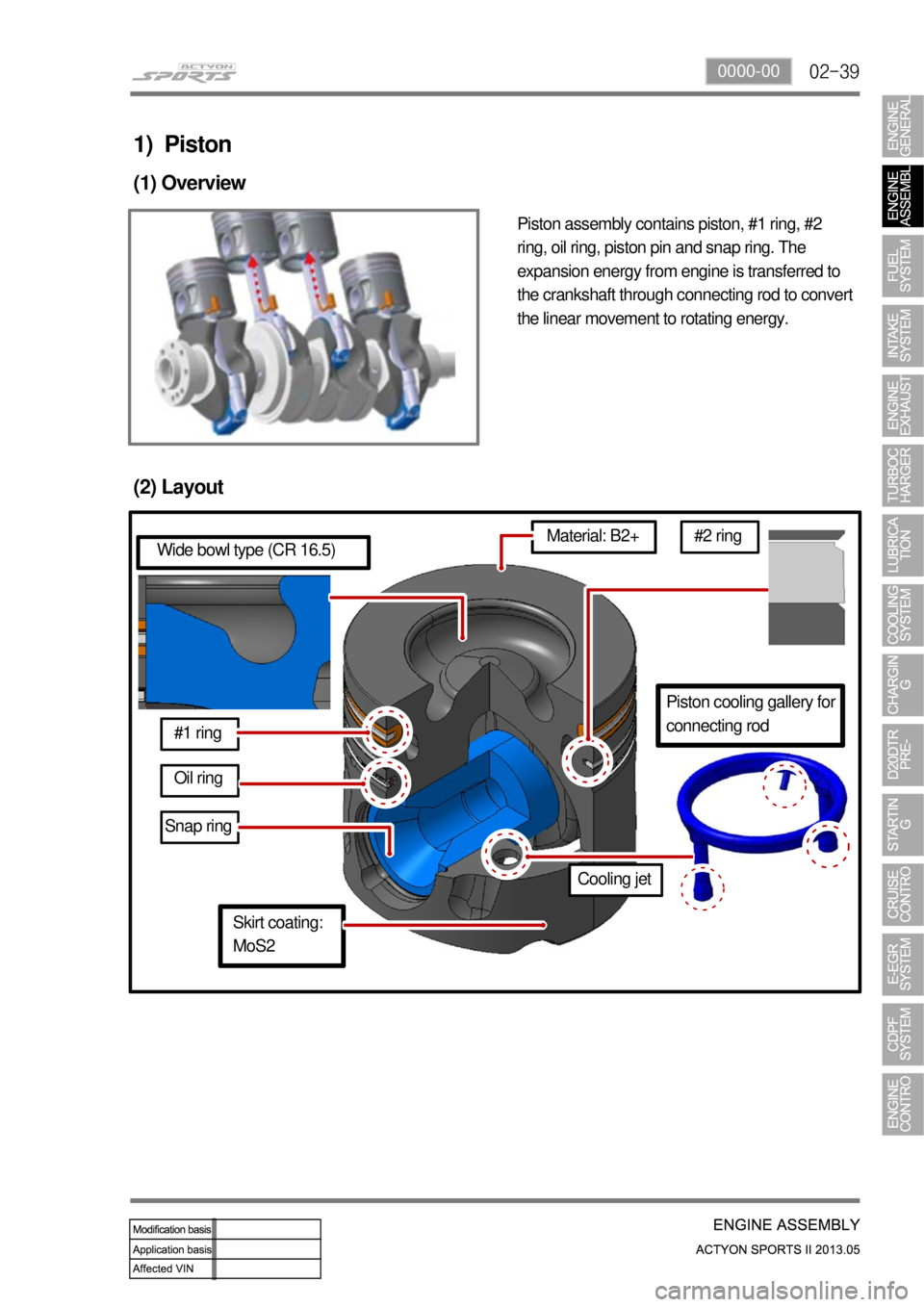

1) Piston

(1) Overview

Piston assembly contains piston, #1 ring, #2

ring, oil ring, piston pin and snap ring. The

expansion energy from engine is transferred to

the crankshaft through connecting rod to convert

the linear movement to rotating energy.

(2) Layout

#1 ring

Oil ring

Snap ring

#2 ringMaterial: B2+

Skirt coating:

MoS2

Piston cooling gallery for

connecting rod

Wide bowl type (CR 16.5)

Cooling jet

Page 71 of 751

02-40

(3) Functions

Piston transfers the combustion energy from engine to connecting rod. Es\

pecially in the direct injection

engine such as D20DTR, it provides the combustion space and largely effects to the engine performance

and exhaust gas.

Piston ring

#1 ring (Top ring) : Prevents the high pressurized combustion gas from leaking into crank chamber,

and prevents the engine oil getting into combustion chamber.

#2 ring: Scrapes the engine oil on the cylinder bore, and prevents the leaked combustion gas from #1

ring from leaking into the crank chamber.

Oil ring: Scrapes the engine oil on the cylinder bore.

Piston pin

Connects the piston the connecting rod, and transfers the linear movemen\

t of piston to connecting rod

to convert it to rotating energy

Snap ring

Locks the piston pin.

▶

-

-

-

▶ -

▶ -

(4) Assembling the piston

Install the piston rings with the "Y" mark on the

ring facing upwards.

Position the end gap of #1 ring at 180˚

away from the end gap of #1 ring.

Position the end gap of oil ring at 180˚

away from the end gap of coil spring, and

position the end gap of oil ring at 90˚ away

from the end gap of #2 ring.

1.

2.

3.