ignition SSANGYONG NEW ACTYON SPORTS 2013 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 276 of 751

02-72211-06

7) Battery Voltage Correction Mode

When battery voltage is low, the ECM can compensate for a weak spark delivered by the ignition

module by using the following methods:

Increasing the fuel injector pulse width.

Increasing the idle speed rpm.

Increasing the ignition dwell time. -

-

-

8) Fuel Cut-Off Mode

No fuel is delivered by the fuel injectors when the ignition is off. This prevents dieseling or engine runon.

Also, the fuel is not delivered if there are no reference pulses received from the CKP sensor. This

prevents flooding.

Page 292 of 751

07-31452-01

1. DIAGNOSTIC INFORMATION AND PROCEDURE

1) Ignition System

Page 293 of 751

07-4

2) Ignition System (Cont'd)

Page 297 of 751

07-8

5) Jump Starting Procedure

Position the vehicle with the charged battery so that the jumper cables will reach from the charged

battery to the battery that requires charging.

Turn off the ignition, all the lights, and all the electrical loads in both vehicles.

Leave the hazard flasher on if jump starting where there may be other traffic and any other lights

needed for the work area.

Apply the parking brake firmly in both vehicles. 1.

2.

3.

4.

Shift an automatic transmission to PARK. 5.

Clamp one end of the first jumper cable to the positive terminal on the booster battery. Make sure it

does not touch any other metal parts.

Clamp the other end of the same cable to the positive terminal on the discharged battery. Never

connect the other end to the negative terminal of the discharged battery. 6.

7.

Clamp one end of the second cable to the negative terminal of the booster battery.

Make the final connection to a solid engine ground, such as the engine lift bracket at least 450

millimeters (18 inches) from the discharged battery.

Start the engine of the vehicle with the good battery.

Run the engine at a moderate speed for several minutes.

Then start the engine of the vehicle with the discharged battery.

Remove the jumper cables by reversing the above sequence exactly, removing the negative cable

from the vehicle with the discharged battery first.

While removing each clamp, take care that it does not touch any other metal while the other end

remains attached. 8.

9.

10.

11.

12.In order to avoid damaging the vehicle make sure the cables are not on or near pulleys, fans, or

other parts that will move when the engine starts.

In order to avoid injury, do not use cables that have loose or missing insulation.

Page 298 of 751

07-91452-01

6) Alternator

Alternators are equipped with internal regulators.

Unlike three-wire generators, the alternator may be used with only two connections: battery positive and

an "D+" terminal to the charge indicator lamp.

As with other charging systems, the charge indicator lamp lights when the ignition switch is turned to

RUN, and goes out when the engine is running.

If the charge idicator is on with the engine running, a charging system defect is indicated. This indicato

r

light will glow at full brilliance for several kinds of defects as well as when the system voltage is too high

or too low.

The regulator voltage setting varies with temperature and limits the system voltage by controlling roto

r

field current.

Achieve correct average field current for proper system voltage control by varying the on-off time. At high

speeds, the on-time may be 10 percent and the off-time 90 percent.

At low speeds, with high electrical loads, the on-time may be 90 percent and the off-time 10 percent.

7) Charging System

Generators use a new type of regulator that incorporates a diode trio.

A Delta stator, a rectifier bridge, and a rotor with slip rings and brushes are electrically similar

to earlier generators.

A conventional pulley and fan are used.

There is no test hole.

8) Starter

Wound field starter motors have pole pieces, arranged around the armature, which are energized by

wound field coils.

Enclosed shift lever cranking motors have the shift lever mechanism and the solenoid plunger enclosed

in the drive housing, protecting them from exposure to dirt, icy conditions, and splashes.

In the basic circuit, solenoid windings are energized when the switch is closed.

The resulting plunger and shift lever movement causes the pinion to engage the engine flywheel ring

gear.

The solenoid main contacts close. Cranking then takes place.

When the engine starts, pinion overrun protects the armature from excessive speed until the switch is

opened, at which time the return spring causes the pinion to disengage.

To prevent excessive overrun, the switch should be released immediately after the engine starts.

Page 299 of 751

07-10

9) Starting System

The engine electrical system includes the battery, the ignition, the starter, the generator, and all the

related wiring.

Diagnostic tables will aid in troubleshooting system faults. When a fault is traced to a particula

r

component, refer to that component section of the service manual.

The starting system circuit consists of the battery, the starter motor, the ignition switch, and all the related

electrical wiring.

All of these components are connected electrically.

Page 313 of 751

02-38710-01

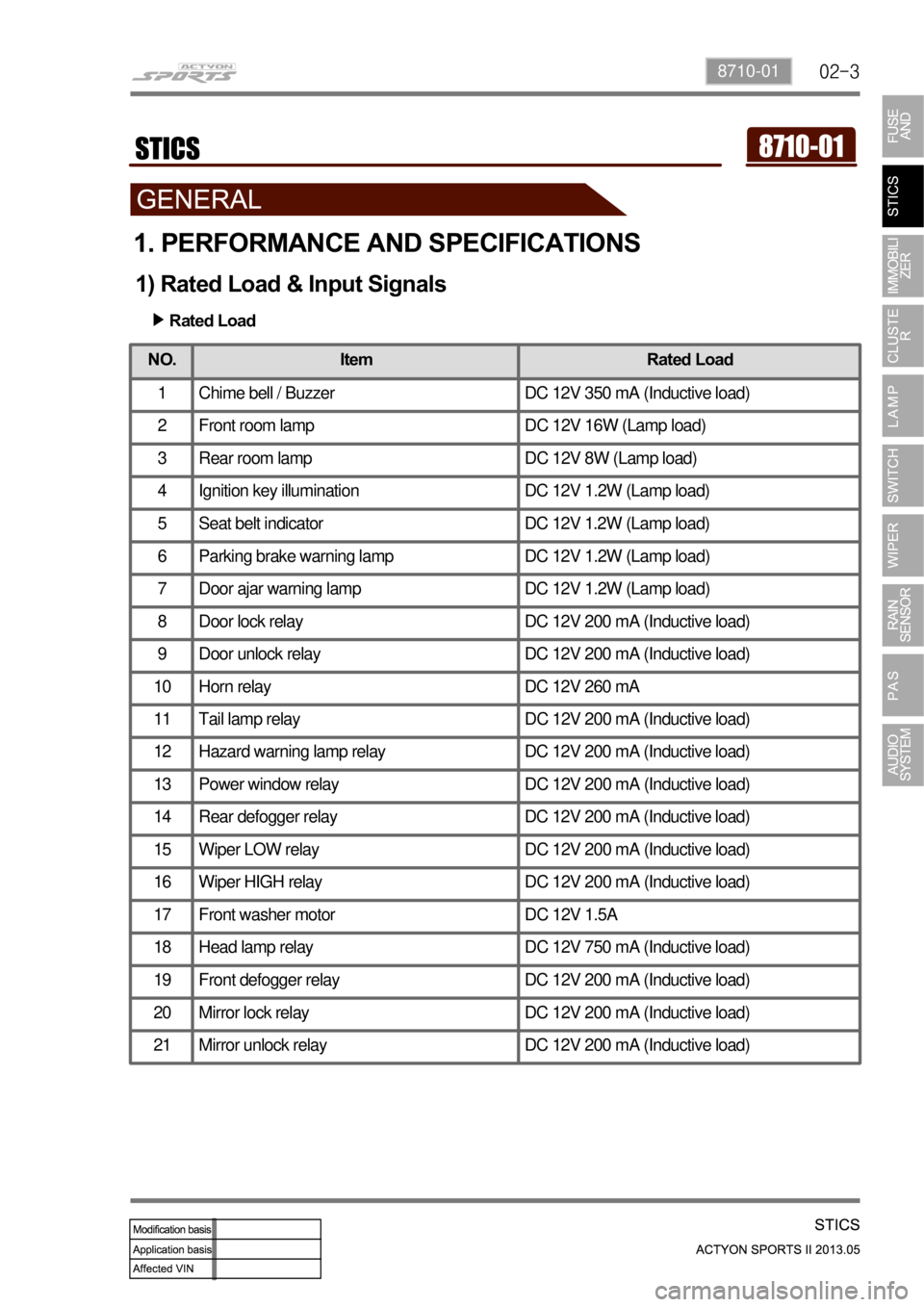

1. PERFORMANCE AND SPECIFICATIONS

1) Rated Load & Input Signals

Rated Load

▶

NO.

Item Rated Load

1 Chime bell / Buzzer DC 12V 350 mA (Inductive load)

2 Front room lamp DC 12V 16W (Lamp load)

3 Rear room lamp DC 12V 8W (Lamp load)

4 Ignition key illumination DC 12V 1.2W (Lamp load)

5 Seat belt indicator DC 12V 1.2W (Lamp load)

6 Parking brake warning lamp DC 12V 1.2W (Lamp load)

7 Door ajar warning lamp DC 12V 1.2W (Lamp load)

8 Door lock relay DC 12V 200 mA (Inductive load)

9 Door unlock relay DC 12V 200 mA (Inductive load)

10 Horn relay DC 12V 260 mA

11 Tail lamp relay DC 12V 200 mA (Inductive load)

12 Hazard warning lamp relay DC 12V 200 mA (Inductive load)

13 Power window relay DC 12V 200 mA (Inductive load)

14 Rear defogger relay DC 12V 200 mA (Inductive load)

15 Wiper LOW relay DC 12V 200 mA (Inductive load)

16 Wiper HIGH relay DC 12V 200 mA (Inductive load)

17 Front washer motor DC 12V 1.5A

18 Head lamp relay DC 12V 750 mA (Inductive load)

19 Front defogger relay DC 12V 200 mA (Inductive load)

20 Mirror lock relay DC 12V 200 mA (Inductive load)

21 Mirror unlock relay DC 12V 200 mA (Inductive load)

Page 318 of 751

02-8

2) Operation Logic

▶Wiper MIST and Front Washer Coupled Wiper

The wiper relay is turned on at 0.3 seconds after from the time when the washer switch is turned

on for 0.1 to 0.59 seconds with the ignition switch "ON".If the wiper parking terminal gets off, the

wiper relay is turned off.

-

The wiper relay is turned on at 0.3 seconds after from the time when the\

washer switch is turned

on for more than 0.6 seconds with the ignition switch "ON". The wiper re\

lay gets on 3 times

immediately after turning off the washer switch.

-

Page 320 of 751

02-10

▶Auto Washer and Wiper Switch (AFW)When the auto washer switch is turned on with the ignition switch "ON" and the INT switch

"OFF", the washer motor output gets ON for 1 second. If the system recog\

nizes the output signal,

the wiper relay output gets ON during 4 cycles and the washer motor output gets ON for 1

second. Then, the wiper relay output gets OFF after 3 cycles.

-

Page 323 of 751

02-138710-01

Rain sensing unit

(AUTO light integrated type)

▶INT Switch Auto Position Remi nder (Power-Up Reminder Wiper)

When turning off and on the auto INT switch, the system drives the wiper motor through LOW

relay regardless of communication with rain sensor.

When turning the INT-AUTO switch from the "OFF" to "ON" position with the ignition switch in the

"ON" mode, the LOW relay operates to drive the wiper motor for 1 cycle, regar\

dless of the rain

sensor communication.

After that, when turning the INT-AUTO switch fr om the "OFF" to "ON" position, the LOW relay

operates to drive the wiper motor for 1 cycle only if data from the rain\

sensor indicates rain drops.

-

-

Multifunction wiper switch:

AUTO and sensitivity control

A sensor that emits infrared rays through LED and

then detects the amount of rain drops by receiving

reflected rays against sensing section (rain senso

r

mounting section on the windshield) with

photodiode (auto light sensor integrated type) AUTO

: Wiper operates automatically by rain sensor

FAST↔SLOW : Auto delay/Auto speed control. A

position that can control sensitivity against rains on

the windshield and transmits wiping demand signal

accordingly