Torque SSANGYONG NEW ACTYON SPORTS 2013 Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 463 of 751

01-173680-01

5. ELECTRONIC CONTROL SYSTEM

1) Overview

The transmission control unit (TCU) and its input/output networks control the operations of transmission:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

In addition, the TCU receives input signals from certain transmission-related sensors and switches. The

TCU also uses these signals when determining transmission operating strategy. Using all of these input

signals, the TCU can determine when the time and conditions are right for a shift, or when to apply or

release the torque converter clutch. It will also determine the pressure needed to optimise shift feel. To

accomplish this, the TCU operates six variable bleed control solenoids and four ON/OFF solenoids to

control the operations of transmission.

2) Transmission Control Unit (TCU)

The transmission control unit (TCU) is mounted under the driver's seat and controls the operation of the

transmission.

TCU processes the analog information from the internal sensors and the digital information through CAN

communication lines. TCU monitors all the input and output signals. If there is any failure, TCU changes

the system to “Limp Home Mode” and alerts to the driver through the warning lamp on the

instrument cluster.

(1) Hard-wired (Analog) Input/Output

Input/Output Data between TGS Lever and TCU ▶

Position and conditions of gear select lever

Driving moded (Winter or Standard) -

-

Position of inhibitor switch - Input/Output Data between Inhibitor and TCU ▶

6 control signals for variable bleed solenoid

4 control signals for ON/OFF solenoid

Transmission input speed

Transmission output speed

Transmission oil temperature

EMM (Embeded Memory Module) -

-

-

-

-

- Input/Output Data between Automatic Transmission and TCU ▶

Input/Output Data between Self Diagnostic Connector and TCU ▶

Various DTC codes and TCU information -

Page 466 of 751

01-20

3) Transmission Control Monitoring System

TCU monitors all input and output signals to identify possible failures. If a fault is detected, TCU activates

<009b008f008c0047009a0088008d008c009b00a0004700940096008b008c0047009b009600470092008c008c00970047009b008f008c0047008b00990090009d008c009902c5009a0047009a0088008d008c009b00a0004700880095008b0047009b008f00

8c004700930090008d008c0047009a00970088009500470096>f transmission.

Monitoring the Supply Voltage ▶

Monitoring the Supply Voltage to Solenoid ▶

Monitoring the Gear Ratio ▶

Monitoring the Torque Converter ▶ If the battery voltage is too high or too low, the TCU sets the DTC.

TCU monitors the circuits for open or short to ground or supply. The monitoring function evaluates the

voltage characteristics while the switch is ON.

TCU monitors the gear is engaged properly in the allowed time.

TCU checks if the torque converter can be locked up properly. If it is failed, TCU releases the torque

converter clutch to activate the fail-safe operation.

4) Shift Energy Management

This function involves reducing or increasing the engine output torque during shifting. This reduces the

energy which is dissipated in the friction elements of the transmission during up-shift. This is done by

reducing the engine torque during the gear ratio change without interrupting the tractive drive.

This function is used for:

Increasing the life span of transmission by shortening the slipping time

Improving the shift comfort by reducing the step changes due to gearshift

Transferring a higher engine power -

-

-

Real-time control of engine torque is required to maintain the proper shift operations and the durability of

transmission. TCU controls the engine torque during the gearshift by synchronizing the operation of

transmission clutches.

Page 467 of 751

01-213680-01

Pressure Modulation ▶

To provide a higher level of shift comfort and durability, the hydraulic pressure in the shift related friction

elements of the transmission must be matched accurately to the input torque to transmission. This

hydraulic pressure is composed of a hydraulically pre-set basic pressure and a control pressure which is

set by one of the variable bleed solenoids.

The transmission input torque can be directly calculated from the following operating parameters:

engine torque signals

engine speed or any signal transmitted from ECU through CAN lines

converter slip -

-

-

Separate pressure characteristics for each gear change make it possible to adapt precisely to the

particular shift operation.

5) Shift Mode Selection by TCU

The driver can select Standard (S) or Winter mode (W) with the mode switch. TCU automatically

changes the shift mode according to the transmission oil temperature, uphill or downhill gradient, and

altitude to keep the good driving conditions.

Standard Mode (S) ▶

Uphii and Downhill Mode ▶

Altitude Mode ▶ Standard Mode is selected when setting the mode switch in Standard (S) position with the gear select

<0093008c009d008c0099004700900095004702c8006b02c9004700880095008b0047009b008f008c0047009b009900880095009a00940090009a009a00900096009500470096009000930047009b008c00940097008c00990088009b009c0099008c004700

9000950047009500960099009400880093004700960097008c>rating range. Proper shift timing

provides the optimized fuel economy and good driving conditions.

In this mode, the operating points of torque converter lock-up clutch and the shifting points are adjusted

according to the vehicle weight.

In this mode, the shifting points are automatically adjusted according to the altitude to compensate the

engine torque changes due to barometric pressure and temperature.

Page 468 of 751

01-22

Winter Mode (W) ▶

Low Range Driving Mode ▶

Warm Up Mode ▶ When the Winter mode is selected, the second gear is engaged to start off the vehicle easily to prevent

wheel spin on slippery surfaces and WINTER mode indicator comes ON. The first gear is not available

in this mode.

When the vehicle is in 4L driving mode, the transmission uses a different shift mode to optimize the low

range driving. Similar to Winter mode, the first gear is not available.

This mode is normally used when the transmission oil temperature is below 20°C.

<007b008f008c0047009b009600990098009c008c0047008a00960095009d008c0099009b008c00990047008a0088009500950096009b00470089008c004700930096008a0092008c008b0054009c009700470089008c00930096009e00470059005700b600

6a0047009b00960047009700990096009d0090008b008c0047>the warming up process of

transmission.

Hot Mode ▶

<0070008d0047009b008f008c0047009b009900880095009a00940090009a009a00900096009500470096009000930047009b008c00940097008c00990088009b009c0099008c00470090009a00470089008c009b009e008c008c0095004700580058005700

b6006a004700880095008b00470058005b005c00b6006a0053> the system provides the cooling

and reduces the load to the transmission. This is called Hot Mode.

Above 110°C:

Above 130°C:

Above 145°C: -

-

-

In Hot Mode, any of shift mode is not available.

Cruise Control ▶

When the cruise control is activated, the engine ECU requests the downshift to increase the engine

brake effect.PWM fan ON

the engine torque is reduced and WINTER indicator is blinking

the transmission is held in Neutral (N) gear until the oil temperature falls below

120°C (Final protection)

Page 496 of 751

03-4

2. SPECIFICATIONS AND TIGHTENING TORQUE OF

MANUAL TRANSMISSION

1) Specifications

Page 497 of 751

03-53170-01

2) Tightening Torque

Page 504 of 751

02-6

3. TIGHTENING TORQUE

Part nameTightening torque

(Nm)Numbers Adhesive

1. Seal bolt (rolling plunger and guide spring) 53.9~67.6 1EA Loctite

2. Guide bolt 14.7~21.5 1EA Loctite

3. Pocket ball bearing bolt 29.4~41.1 1EA Loctite

4. Reverse shift fork retainer bolt 53.9~67.6 2EA Loctite

5. Backup lamp switch 29.4~34.3 1EA Loctite

6. Oil drain plug 58.8~78.4 1EA Loctite

7. Interlock bolt 14.7~21.5 1EA -

8. Neutral switch 29.4~34.3 1EA Loctite

9. Oil filler plug 58.8~78.4 1EA Loctite

10. Extension housing bolt 42.1~53.9 12EA -

11. Concentric slave cylinder bolt 9.8~15.6 3EA -

12. Front bearing retainer bolt 19.6~24.5 8EA Loctite

Page 524 of 751

04-8

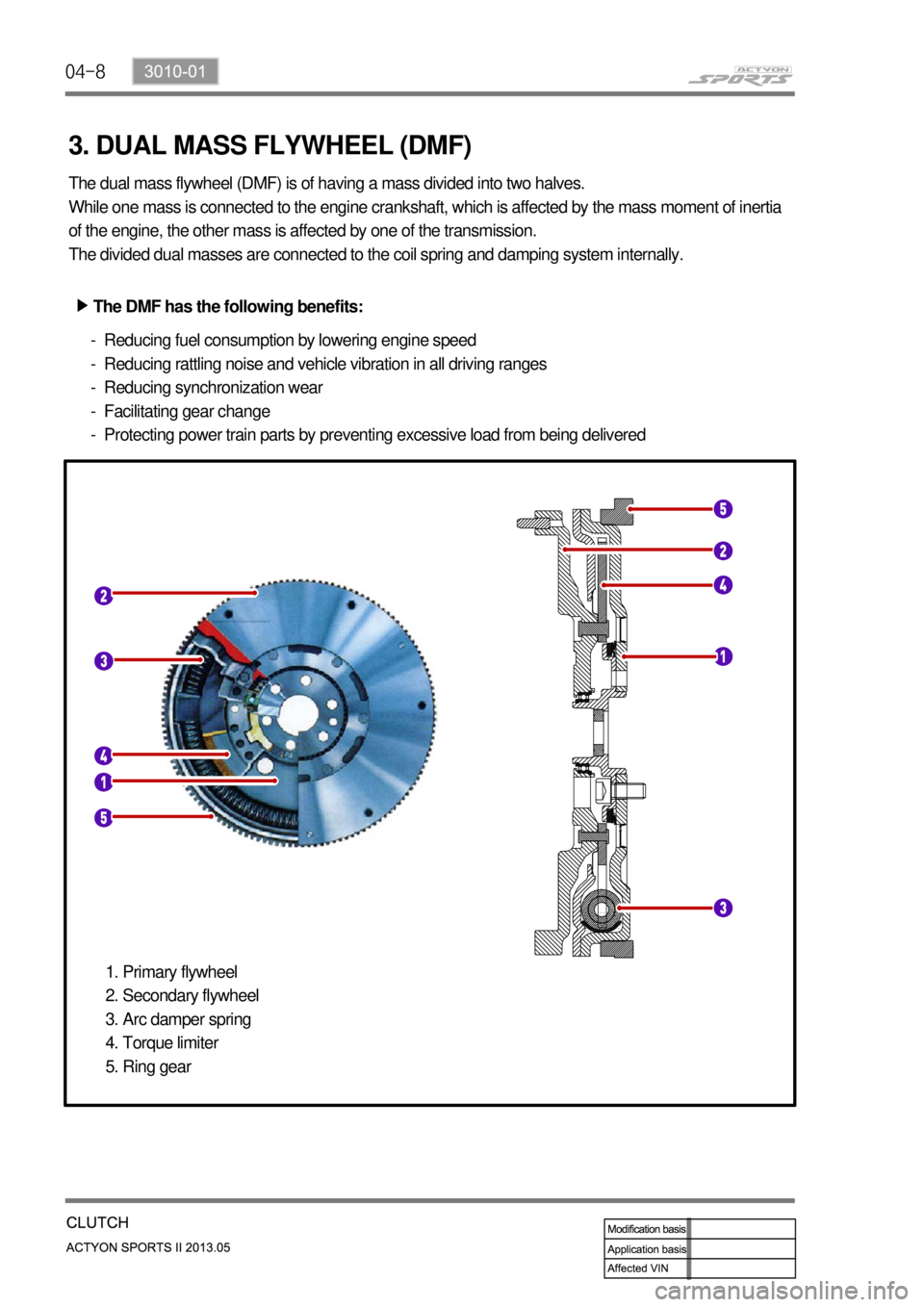

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of inertia

of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 525 of 751

05-33310-00

1. SPECIFICATION

Description Specification

Structure Universal joint with yoke arm and spider

Number of spiders Front Part time T/C Two

Rear Three

Runout Max. 0.3mm

Unbalance Max. 18 g.cm / 4,500 rpm

Dimension of front

propeller shaft (Length x

Dia.) (mm)A/T 552.3*Φ63.5 (Compressed)

M/T 603.8*Φ63.5 (Compressed)

Dimension of front

propeller shaft (Length x

Dia.) (mm)2WD Front1136.0*Φ63.5

Rear743.*Φ63.5(Compressed)

4WD(M/T) Front785.1*Φ63.5

Rear743.*Φ63.5(Compressed)

4WD(A/T) Front836.8*Φ63.5

Rear743.*Φ63.5(Compressed)

2. TIGHTENING TORQUE

Fastener Tightening torque

Mounting bolts for front/rear axle 66.7 ~ 73.5Nm

Mounting bolts for T/M and T/C 79.4 ~ 87.2Nm

Mounting bolts for center bearing 78.4 ~93.1Nm

Page 526 of 751

05-4

1. OVERVIEW

The propeller shaft transfers the power through the transmission and transfer case to the front/rear axle

differential carrier (final reduction gear).

It is manufactured by a thin rounded steel pipe to have the strong resisting force against the torsion and

bending.

Both ends of propeller shaft are connected to the spider and the center of propeller shaft is connected to

the spline to accommodate the changes of the height and length.

The rubber bushing that covers the intermediate bearing keeps the balance of rear propeller shaft and

absorbs its vibration.

Function of propeller shaft ▶

Transmits driving torque.

Compensates the angle change (universal joint / CV joint).

Compensates the axial length change (splines for the slip joint). -

-

-

Front propeller shaft

Rear propeller shaft