ECO mode SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 189 of 751

14-52412-02

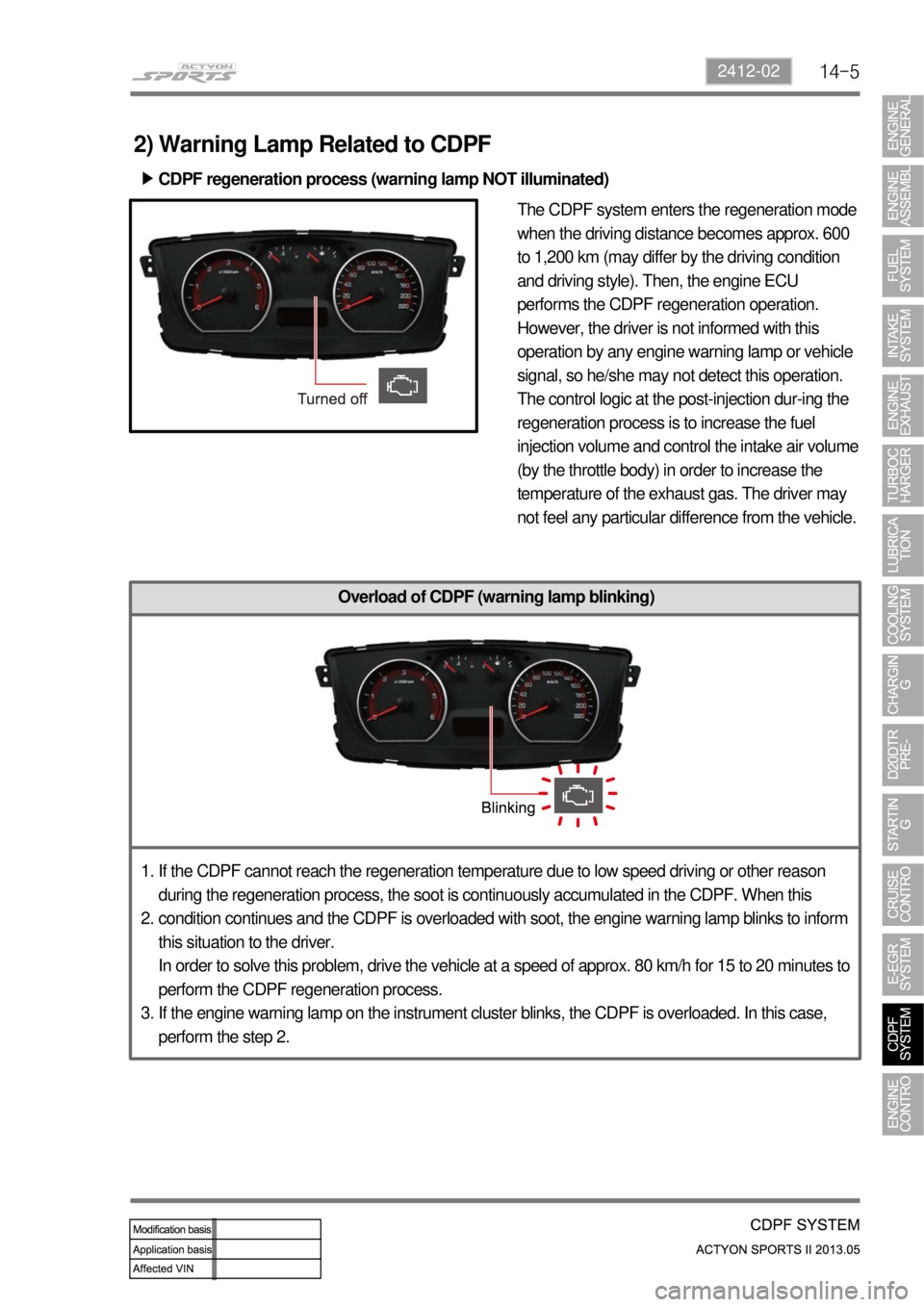

The CDPF system enters the regeneration mode

when the driving distance becomes approx. 600

to 1,200 km (may differ by the driving condition

and driving style). Then, the engine ECU

performs the CDPF regeneration operation.

However, the driver is not informed with this

operation by any engine warning lamp or vehicle

signal, so he/she may not detect this operation.

The control logic at the post-injection dur-ing the

regeneration process is to increase the fuel

injection volume and control the intake air volume

(by the throttle body) in order to increase the

temperature of the exhaust gas. The driver may

not feel any particular difference from the vehicle.

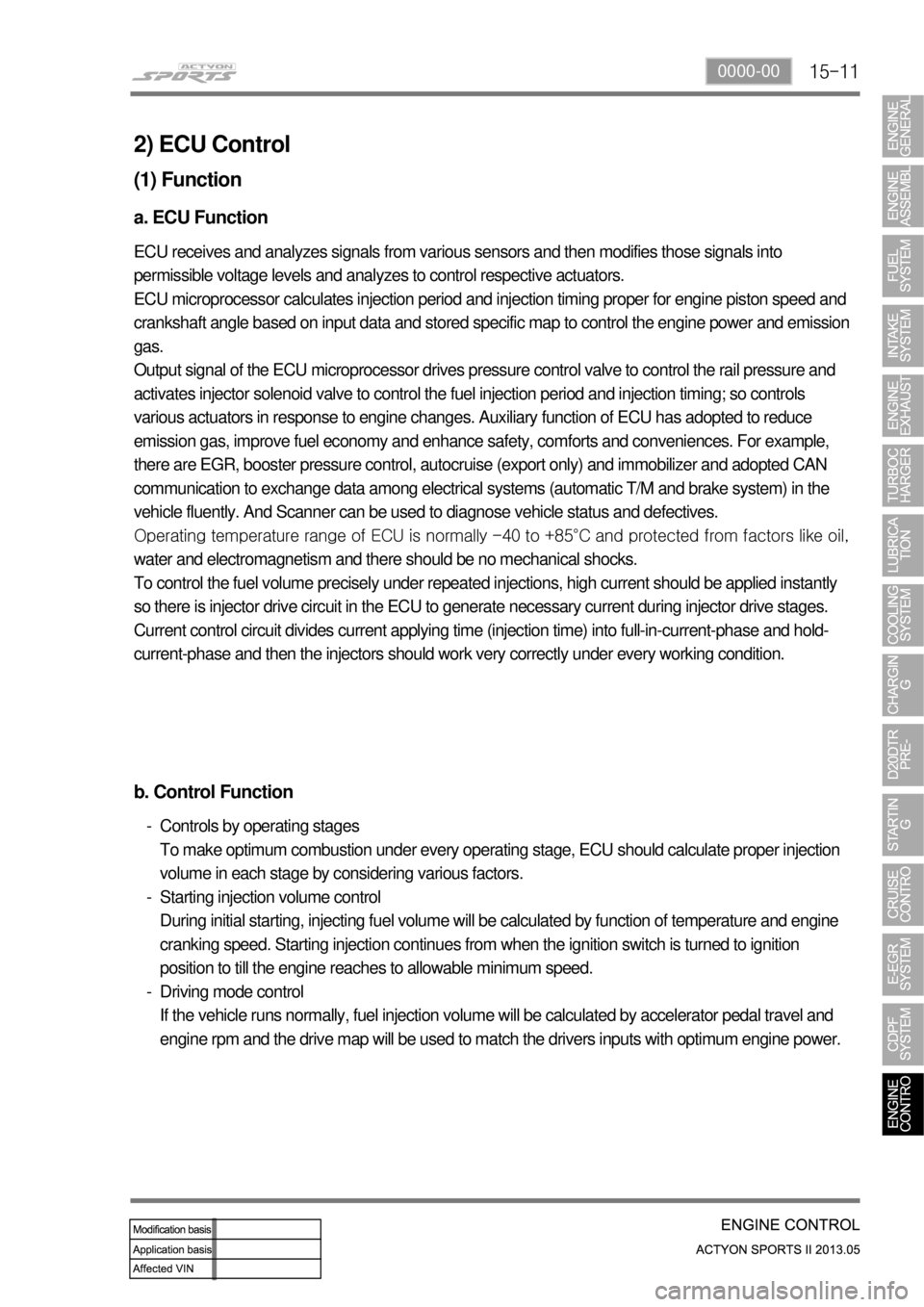

Overload of CDPF (warning lamp blinking)

2) Warning Lamp Related to CDPF

CDPF regeneration process (warning lamp NOT illuminated) ▶

If the CDPF cannot reach the regeneration temperature due to low speed driving or other reason

during the regeneration process, the soot is continuously accumulated in the CDPF. When this

condition continues and the CDPF is overloaded with soot, the engine warning lamp blinks to inform

this situation to the driver.

In order to solve this problem, drive the vehicle at a speed of approx. 80 km/h for 15 to 20 minutes to

perform the CDPF regeneration process.

If the engine warning lamp on the instrument cluster blinks, the CDPF is overloaded. In this case,

perform the step 2. 1.

2.

3.

Page 211 of 751

15-110000-00

2) ECU Control

(1) Function

a. ECU Function

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor drives pressure control valve to control the rail pressure and

activates injector solenoid valve to control the fuel injection period and injection timing; so controls

various actuators in response to engine changes. Auxiliary function of ECU has adopted to reduce

emission gas, improve fuel economy and enhance safety, comforts and conveniences. For example,

there are EGR, booster pressure control, autocruise (export only) and immobilizer and adopted CAN

communication to exchange data among electrical systems (automatic T/M and brake system) in the

vehicle fluently. And Scanner can be used to diagnose vehicle status and defectives.

<00760097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c0047009900880095008e008c00470096008d0047006c006a007c00470090009a0047009500960099009400880093009300a000470054005b005700

47009b009600470052005f005c00b6006a004700880095008b> protected from factors like oil,

water and electromagnetism and there should be no mechanical shocks.

To control the fuel volume precisely under repeated injections, high current should be applied instantly

so there is injector drive circuit in the ECU to generate necessary current during injector drive stages.

Current control circuit divides current applying time (injection time) into full-in-current-phase and hold-

current-phase and then the injectors should work very correctly under every working condition.

b. Control Function

Controls by operating stages

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 224 of 751

15-24

This is done periodically under certain operating conditions. When the resetting is finished, the new

minimum pulse value replaces the value obtained during the previous resetting. The first MDP value is

provided by the C3I. Each resetting then allows the closed loop of the MDP to be updated according to

the deviation of the injector.

B. Detection of leaks in the cylinders

The accelerometer is also used to detect any injector which may have stuck open. The detection

principle is based on monitoring the ratio. If there is a leak in the cylinder, the accumulated fuel self-

ignites as soon as the temperature and pressure conditions are favorable (high engine speed, high load

and small leak).

This combustion is set off at about 20 degrees before TDC and before main injection.

The ratio therefore increases considerably in the detection window. It is this increase which allows the

leaks to be detected. The threshold beyond which a fault is signaled is a percentage of the maximum

possible value of the ratio.

Because of the severity of the recovery process (engine shut-down), the etection must be extremely

robust.

An increase in the ratio can be the consequence of various causes:

Pilot injection too much

Main combustion offset

Fuel leak in the cylinder -

-

-

If the ratio becomes too high, the strategy initially restricts the pilot injection flow and retards the main

injection. If the ratio remains high despite these interventions, this shows that a real leak is present, a

fault is signaled and the engine is shut down.

C. Detection of an accelerometer fault

This strategy permits the detection of a fault in the sensor or in the wiring loom connecting the sensor to

the ECU.

It is based on detection of the combustion. When the engine is idling, the detection window is set too low

for the combustion caused by the main injection. If the ratio increases, this shows that the knock sensor

is working properly, but otherwise a fault is signaled to indicate a sensor failure. The recovery modes

associated with this fault consist of inhibition of the pilot injection and discharge through the injectors.

Page 275 of 751

02-6

1) Starting Mode

When the ignition is turned ON, the ECM turns the fuel pump relay on for 1 second. The fuel pump then

builds fuel pressure. The ECM also checks the Engine Coolant Temperature (ECT) sensor and the

Throttle Position (TP) sensor and determines the proper air/fuel ratio for starting the engine. This ranges

from1.5 to 1 at -36 °C (-33 °F) coolant temperature to 14.7 to 1 at 94 °C (201 °F) coolant

temperature. The ECM controls the amountof fuel delivered in the starting mode by changing how long

the fuel injector is turned on and off. This is done by ''pulsing" the fuel injectors for very short times.

2) Run Mode

The run mode has two conditions called ''open loop" and ''closed loop".

3) Open Loop

When the engine is first started and it is above 690 rpm, the system goes into "open loop" operation. In

"open loop", the ECM ignores the signal from the HO2S and calculates the air/fuel ratio based on inputs

from the ECT sensor and the MAF sensor. The ECM stays in "open loop" until the following conditions

are met:

The O2 has a varying voltage output, showing that it is hot enough to operate properly.

The ECT sensor is above a specified temperature (22.5 °C).

A specific amount of time has elapsed after starting the engine. -

-

-

4) Closed Loop

The specific values for the above conditions vary with different engines and are stored in the

Electronically Erasable Programmable Read-Only Memory (EEPROM).

When these conditions are met, the system goes into "closed loop" operation. In "closed loop", the ECM

calculates the air/fuel ratio (fuel injector on- time) based on the signals from the O2 sensors. This allows

the air/fuel ratio to stay very close to 14.7 to 1.

5) Acceleration Mode

The ECM responds to rapid changes in throttle position and airflow and provides extra fuel.

6) Deceleration Mode

The ECM responds to changes in throttle position and airflow and reduces the amount of fuel. When

deceleration is very fast, the ECM can cut off fuel completely for short periods of time.

Page 297 of 751

07-8

5) Jump Starting Procedure

Position the vehicle with the charged battery so that the jumper cables will reach from the charged

battery to the battery that requires charging.

Turn off the ignition, all the lights, and all the electrical loads in both vehicles.

Leave the hazard flasher on if jump starting where there may be other traffic and any other lights

needed for the work area.

Apply the parking brake firmly in both vehicles. 1.

2.

3.

4.

Shift an automatic transmission to PARK. 5.

Clamp one end of the first jumper cable to the positive terminal on the booster battery. Make sure it

does not touch any other metal parts.

Clamp the other end of the same cable to the positive terminal on the discharged battery. Never

connect the other end to the negative terminal of the discharged battery. 6.

7.

Clamp one end of the second cable to the negative terminal of the booster battery.

Make the final connection to a solid engine ground, such as the engine lift bracket at least 450

millimeters (18 inches) from the discharged battery.

Start the engine of the vehicle with the good battery.

Run the engine at a moderate speed for several minutes.

Then start the engine of the vehicle with the discharged battery.

Remove the jumper cables by reversing the above sequence exactly, removing the negative cable

from the vehicle with the discharged battery first.

While removing each clamp, take care that it does not touch any other metal while the other end

remains attached. 8.

9.

10.

11.

12.In order to avoid damaging the vehicle make sure the cables are not on or near pulleys, fans, or

other parts that will move when the engine starts.

In order to avoid injury, do not use cables that have loose or missing insulation.

Page 317 of 751

02-78710-01

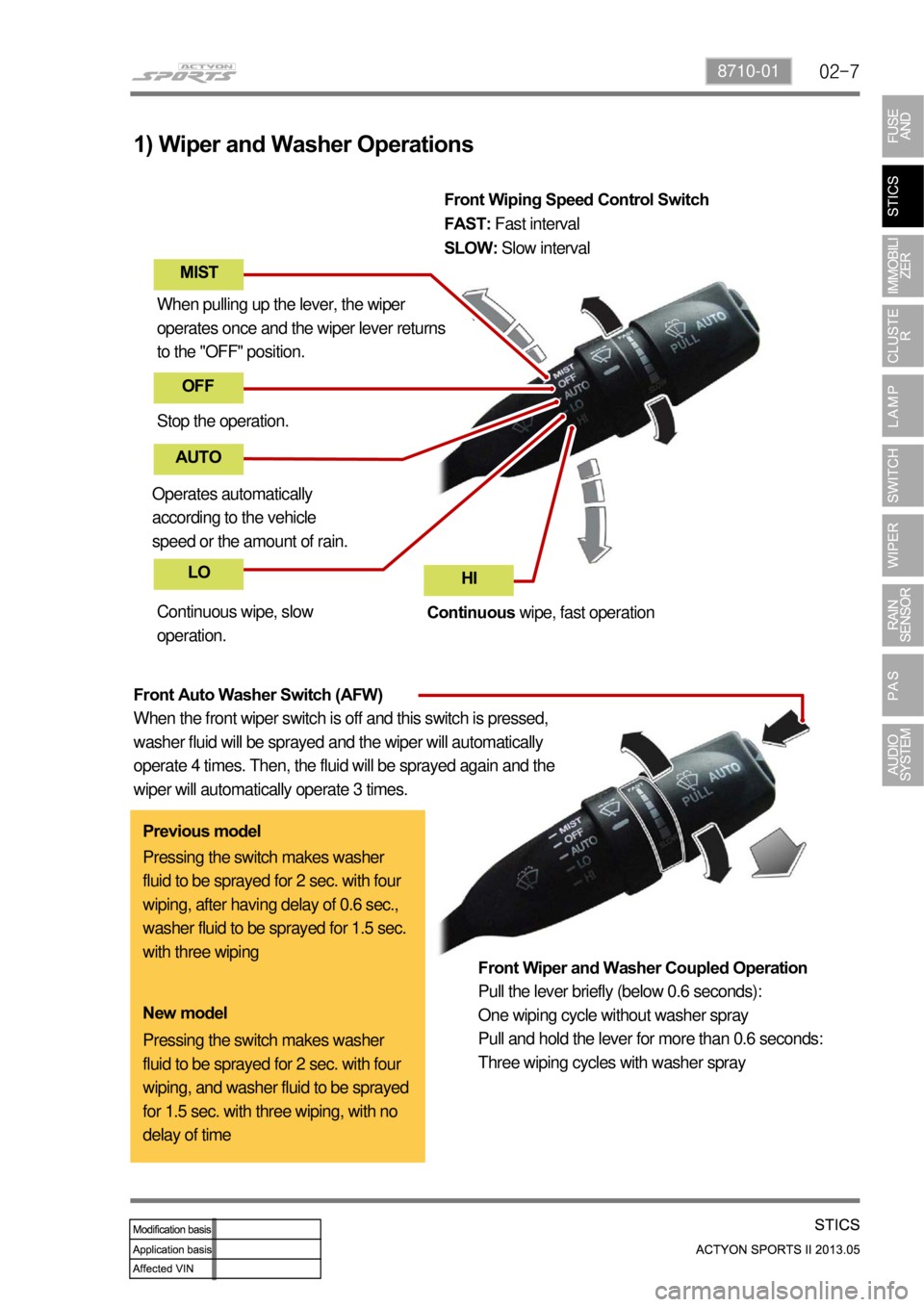

1) Wiper and Washer Operations

When pulling up the lever, the wiper

operates once and the wiper lever returns

to the "OFF" position.

Stop the operation.

Operates automatically

according to the vehicle

speed or the amount of rain. Continuous wipe, slow

operation. Front Wiping Speed Control Switch

FAST: Fast interval

SLOW: Slow interval

Continuous wipe, fast operation

Front Wiper and Washer Coupled Operation

Pull the lever briefly (below 0.6 seconds):

One wiping cycle without washer spray

Pull and hold the lever for more than 0.6 seconds:

Three wiping cycles with washer spray

Front Auto Washer Switch (AFW)

When the front wiper switch is off and this switch is pressed,

washer fluid will be sprayed and the wiper will automatically

operate 4 times. Then, the fluid will be sprayed again and the

wiper will automatically operate 3 times.

MIST OFF

AUTO

LO HI

Previous model

Pressing the switch makes washer

fluid to be sprayed for 2 sec. with four

wiping, after having delay of 0.6 sec.,

washer fluid to be sprayed for 1.5 sec.

with three wiping

Pressing the switch makes washer

fluid to be sprayed for 2 sec. with four

wiping, and washer fluid to be sprayed

for 1.5 sec. with three wiping, with no

delay of time New model

Page 331 of 751

02-218710-01

▶Volume Sensitive INT (Intermittent) Wiper

For RKSTICS without the rain sensor, perform the following operation:

Controls the wiper intermittent operation by the values from the vehicle\

speed and the volume

(resistance).

-

Calculates and converts the Intermittent interv al automatically by obtaining the INT VOLUME

when the ignition switch and the INT switch is in the "ON" position.

The wipers are operated in vehicle speed sensitiv e mode when turning the INT switch to the

"ON" position with the engine running or starting the engine with the INT switch positioned to

"ON".

Intermittent interval (at 0 km/h): 3 ± 0.5 ~ 19 ± 2 seconds

˙

˙

˙

Vehicle speed calculation

-

[Input the vehicle speed]

It is calculated by the numbers of input pulses for one second.

VOLUME calculation

-

The pause time of the vehicle speed sensitive INT wiper is calculated by\

the INT volume (inpu

t

voltage). Each level has the hysteresis.

˙

Pause time calculation

-

Pause time means the duration that wipers are stopped at parking positio\

n.

Elapsed time means the duration after the wiper motor started to operate from parking

position.

The pause time is calculated by the vehicle speed and the VOLUME.

※If the pause time is below 1.0 second, the wipers operate without pause.

※If the pause time is over 1.5 seconds, the wipers operate intermittently.

˙

˙

˙ 60 [km/h] × 60 [sec]

1 [PULSE/SEC] =

637 × 4 PULSE ≒ 1.41 [km/h]

Page 340 of 751

02-30

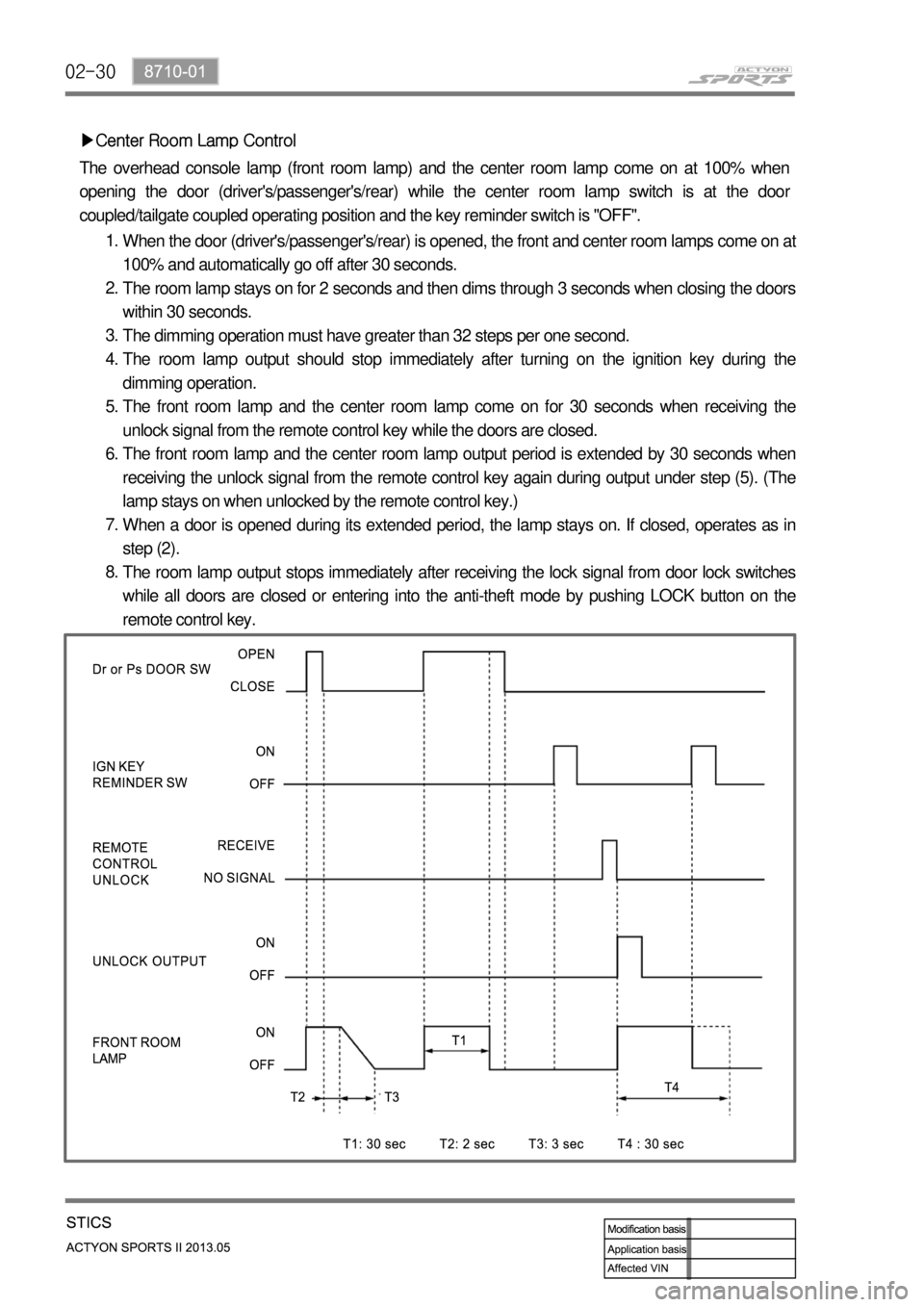

▶Center Room Lamp Control

The overhead console lamp (front room lamp) and the center room lamp come on at 100% when

opening the door (driver's/passenger's/rear) while the center room lamp switch\

is at the doo

r

coupled/tailgate coupled operating position and the key reminder switch \

is "OFF".

When the door (driver's/passenger's/rear) is opened, the front and center room lamps come on at

100% and automatically go off after 30 seconds.

The room lamp stays on for 2 seconds and then dims through 3 seconds whe\

n closing the doors

within 30 seconds.

The dimming operation must have greater than 32 steps per one second.

The room lamp output should stop immediately after turning on the ignition key during the

dimming operation.

The front room lamp and the center room lamp come on for 30 seconds when\

receiving the

unlock signal from the remote control key while the doors are closed.

The front room lamp and the center room lamp output period is extended b\

y 30 seconds when

receiving the unlock signal from the remote control key again during output under step (5). (The

lamp stays on when unlocked by the remote control key.)

When a door is opened during its extended period, the lamp stays on. If closed, operates as in

step (2).

The room lamp output stops immediately after receiving the lock signal from door lock switches

while all doors are closed or entering into the anti-theft mode by pushi\

ng LOCK button on the

remote control key.

1.

2.

3.

4.

5.

6.

7.

8.

Page 342 of 751

02-32

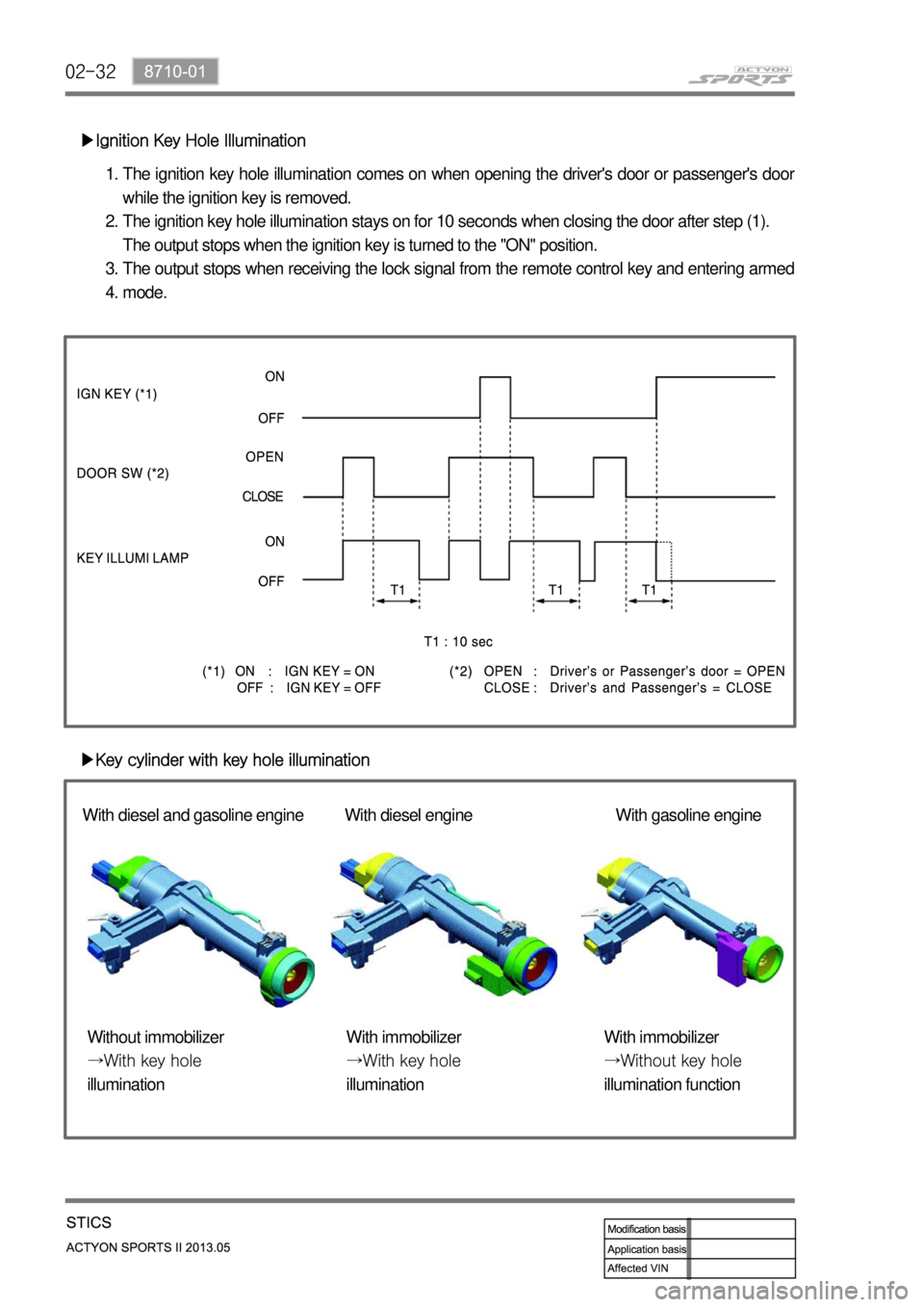

▶Ignition Key Hole IlluminationThe ignition key hole illumination comes on when opening the driver's door or passenger's doo

r

while the ignition key is removed.

The ignition key hole illumination stays on for 10 seconds when closing \

the door after step (1).

The output stops when the ignition key is turned to the "ON" position.

The output stops when receiving the lock signal from the remote control key and entering armed

mode.

1.

2.

3.

4.

▶Key cylinder with key hole illumination With diesel and gasoline engine With diesel engine With gasoline engine

Without immobilizer

→With key hole

illumination With immobilizer

→With key hole

illumination With immobilizer

→Without key hole

illumination function

Page 353 of 751

02-438710-01

▶Time Lag Power Window Control

The power window relay output is "ON" when turning on the ignition switc\

h.

The power window relay output is "ON" for 30 seconds when turning off th\

e ignition switch.

The power window relay output is "OFF" when opening the driver's door or the passenger's

door.

The power window relay is turned "OFF" when receiving the remote control\

key lock signal

(armed mode) during its extended operation period of 30 seconds.

1.

2.

3.