belt SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 28 of 751

01-110000-00

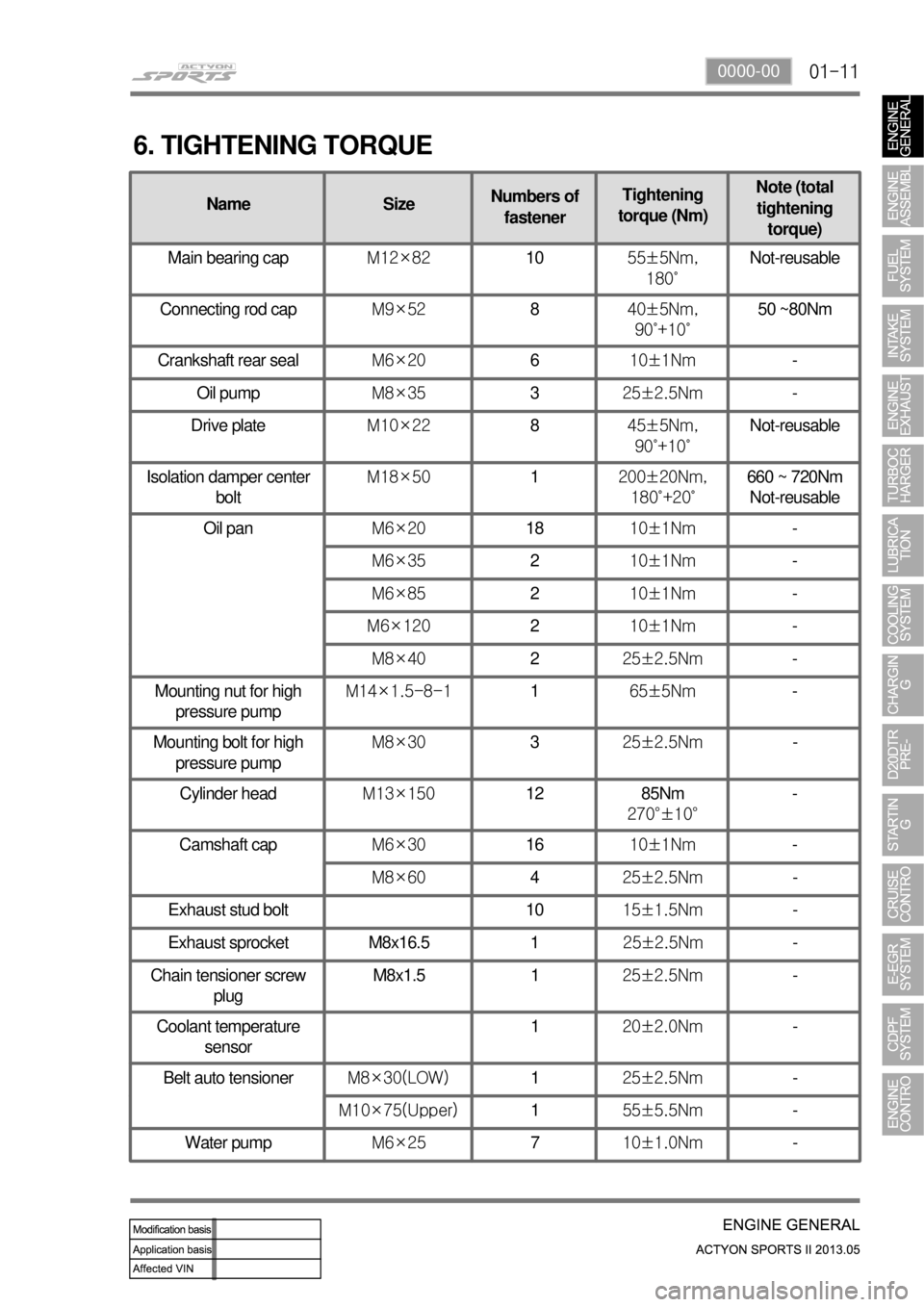

6. TIGHTENING TORQUE

NameSizeNumbers of

fastener Tightening

torque (Nm) Note (total

tightening torque)

Main bearing cap M12×82 10 55±5Nm,

180˚ Not-reusable

Connecting rod cap M9×52 8 40±5Nm,

90˚+10˚ 50 ~80Nm

Crankshaft rear seal M6×20 6 10±1Nm -

Oil pump M8×35 3 25±2.5Nm -

Drive plate M10×22 8 45±5Nm,

90˚+10˚ Not-reusable

Isolation damper center bolt M18×50

1 200±20Nm,

180˚+20˚ 660 ~ 720Nm

Not-reusable

Oil pan M6×20 18 10±1Nm -

M6×35 2 10±1Nm -

M6×85 2 10±1Nm -

M6×120 2 10±1Nm -

M8×40 2 25±2.5Nm -

Mounting nut for high pressure pump M14×1.5-8-1

1 65±5Nm -

Mounting bolt for high pressure pump M8×30

3 25±2.5Nm -

Cylinder head M13×150 12 85Nm

270°±10° -

Camshaft cap M6×30 16 10±1Nm -

M8×60 4 25±2.5Nm -

Exhaust stud bolt 10 15±1.5Nm -

Exhaust sprocket M8x16.5 1 25±2.5Nm -

Chain tensioner screw plug M8x1.5

1 25±2.5Nm -

Coolant temperature sensor 1

20±2.0Nm -

Belt auto tensioner M8×30(LOW) 1 25±2.5Nm -

M10×75(U

pper) 1 55±5.5Nm -

Water pump M6×25 7 10±1.0Nm -

Page 38 of 751

02-70000-00

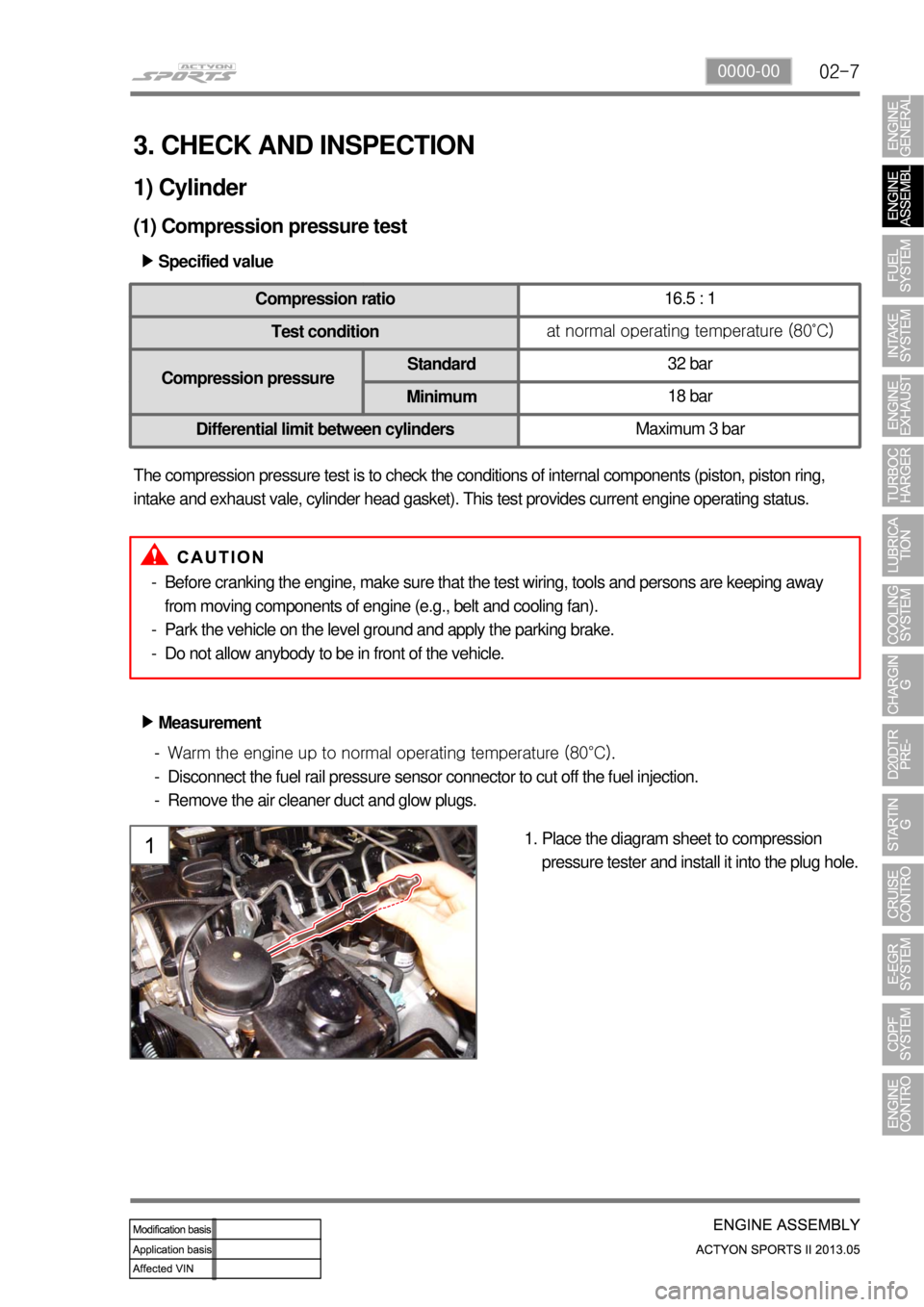

3. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping away

from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

Measurement ▶

<007e0088009900940047009b008f008c0047008c0095008e00900095008c0047009c00970047009b00960047009500960099009400880093004700960097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c00

47004f005f005700b6006a00500055>

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug hole. 1.

Page 44 of 751

02-130000-00

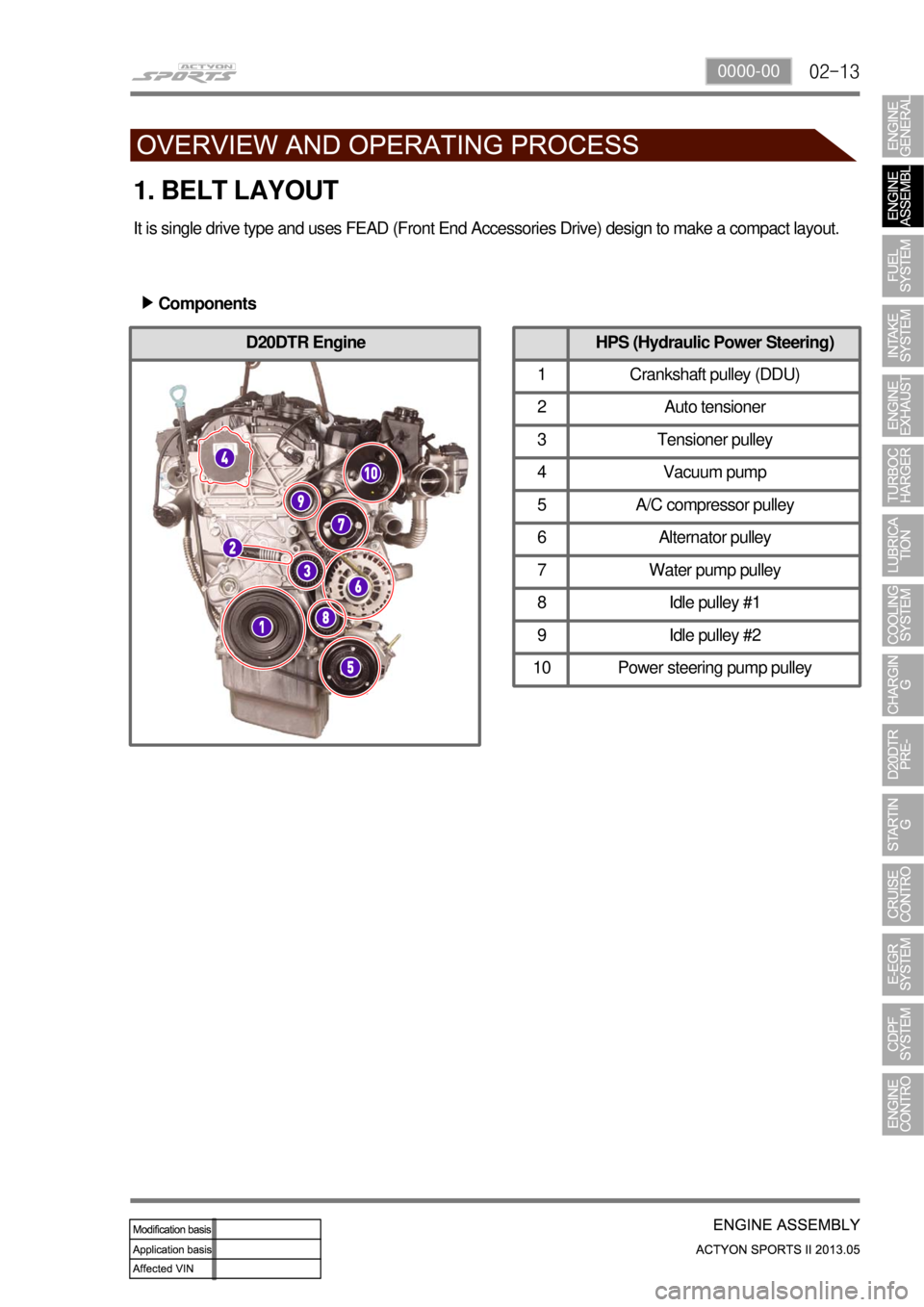

D20DTR Engine

1. BELT LAYOUT

It is single drive type and uses FEAD (Front End Accessories Drive) design to make a compact layout.

Components ▶

HPS (Hydraulic Power Steering)

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pump

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 Idle pulley #1

9 Idle pulley #2

10 Power steering pump pulley

Page 45 of 751

02-14

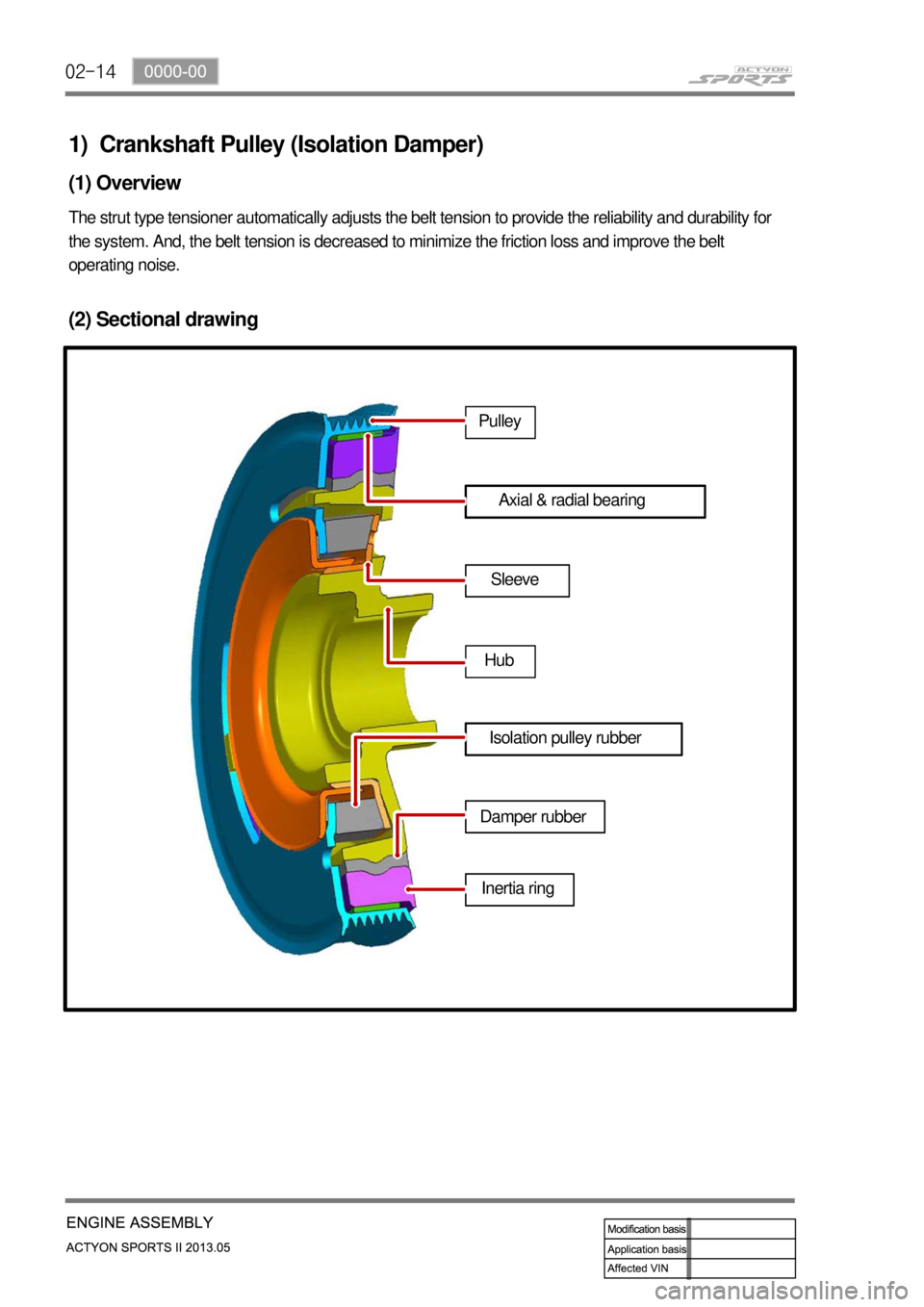

The strut type tensioner automatically adjusts the belt tension to provide the reliability and durability for

the system. And, the belt tension is decreased to minimize the friction loss and improve the belt

operating noise.

1) Crankshaft Pulley (Isolation Damper)

(1) Overview

(2) Sectional drawing

Axial & radial bearing

Sleeve

Hub

Isolation pulley rubber Pulley

Damper rubber

Inertia ring

Page 46 of 751

02-150000-00

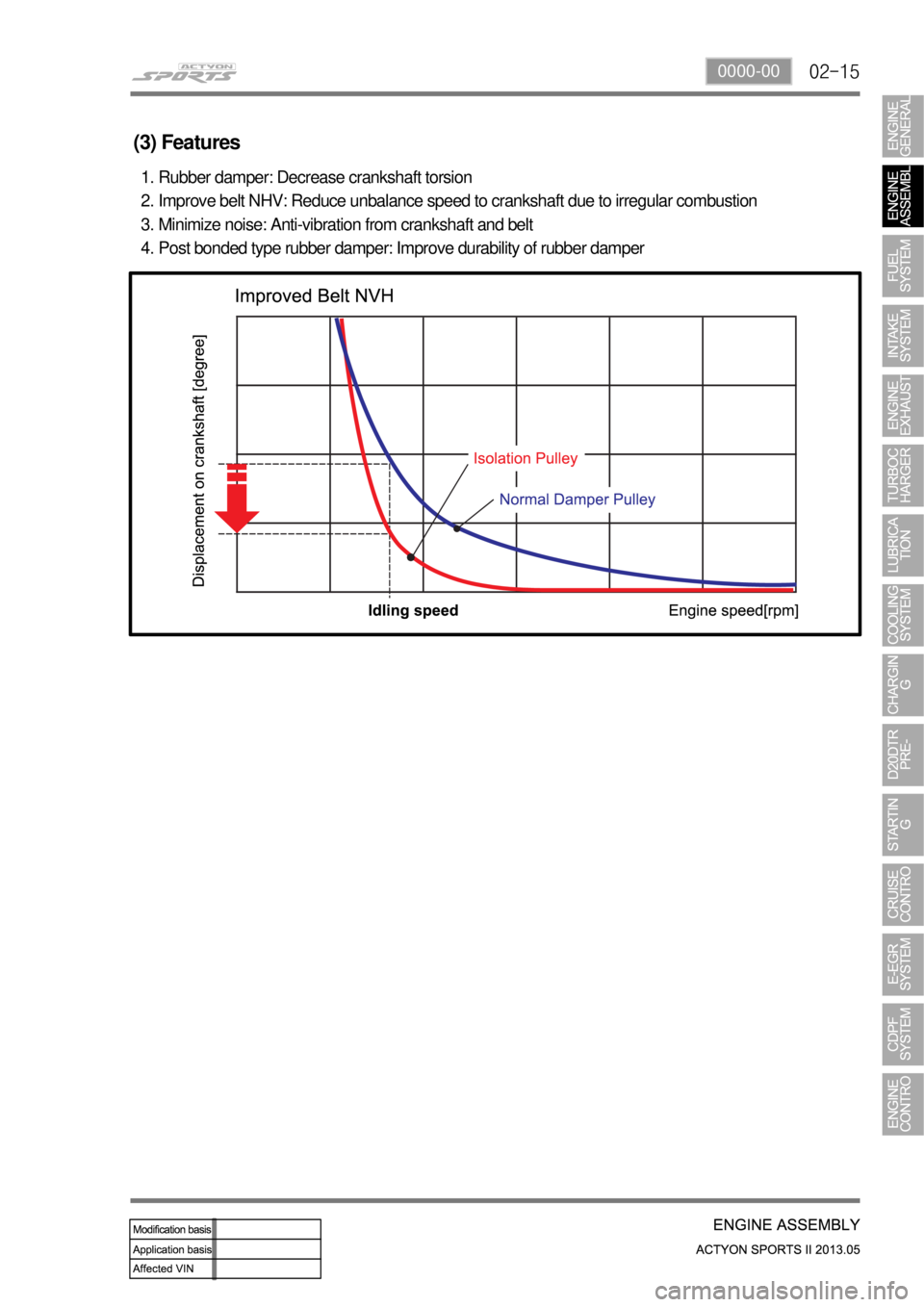

(3) Features

Rubber damper: Decrease crankshaft torsion

Improve belt NHV: Reduce unbalance speed to crankshaft due to irregular combustion

Minimize noise: Anti-vibration from crankshaft and belt

Post bonded type rubber damper: Improve durability of rubber damper 1.

2.

3.

4.

Page 47 of 751

02-16

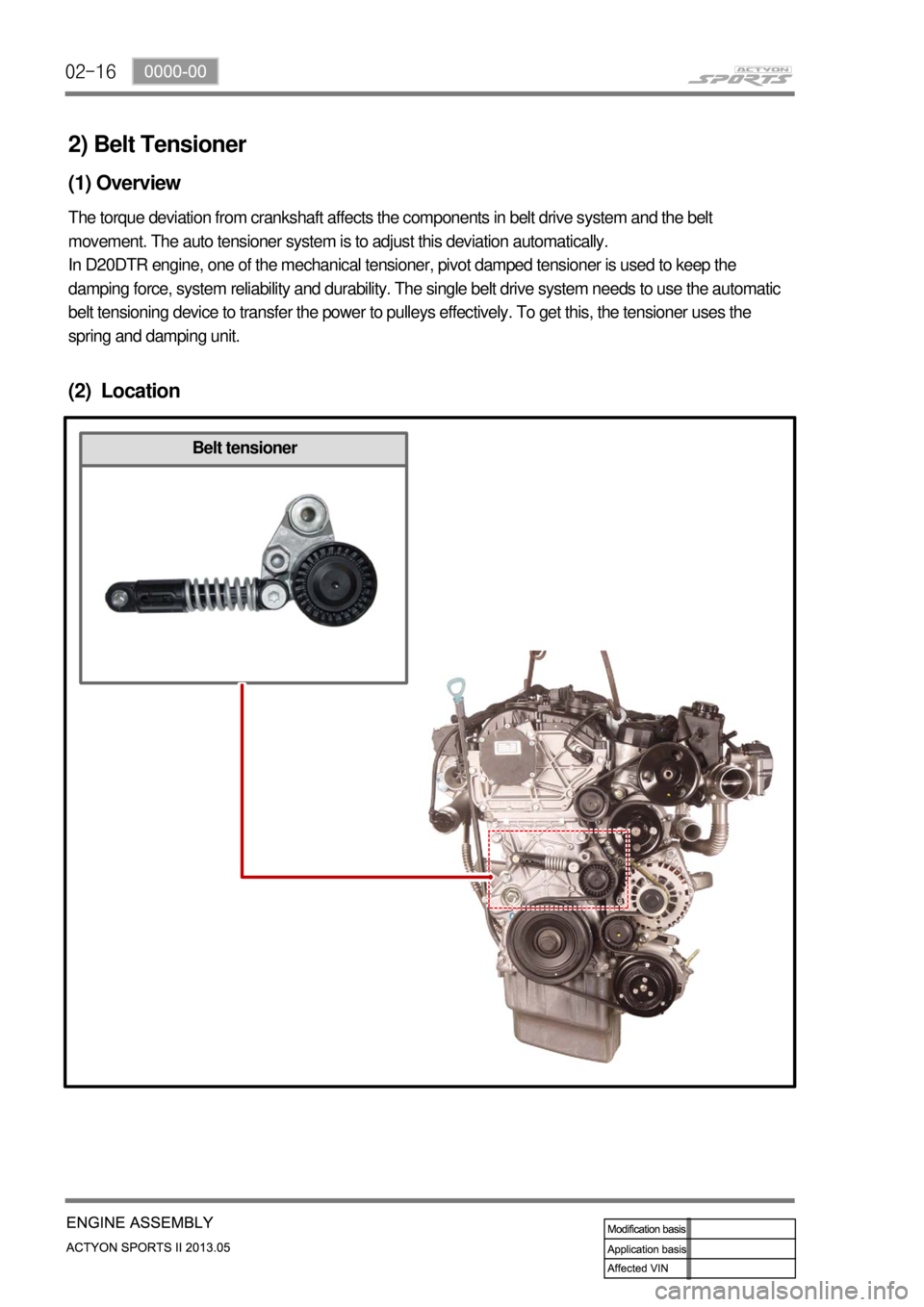

2) Belt Tensioner

(1) Overview

The torque deviation from crankshaft affects the components in belt drive system and the belt

movement. The auto tensioner system is to adjust this deviation automatically.

In D20DTR engine, one of the mechanical tensioner, pivot damped tensioner is used to keep the

damping force, system reliability and durability. The single belt drive system needs to use the automatic

belt tensioning device to transfer the power to pulleys effectively. To get this, the tensioner uses the

spring and damping unit.

(2) Location

Belt tensioner

Page 146 of 751

08-8

Oil filter module

Thermostat

When the engine coolant

reaches 90℃, the thermostat

starts to open (fully open at

100℃) and lets the coolant

flow to the radiator to maintain

the engine temperature.

Water pump

The water pump is driven by the engine drive belt and supplies

the coolant to each area of the engine.

Coolant reservoir

Long life coolant is used.

1. SYSTEM DESCRIPTION

1) Overview

Water pump

Impeller vane Sealing

Page 150 of 751

09-51451-01

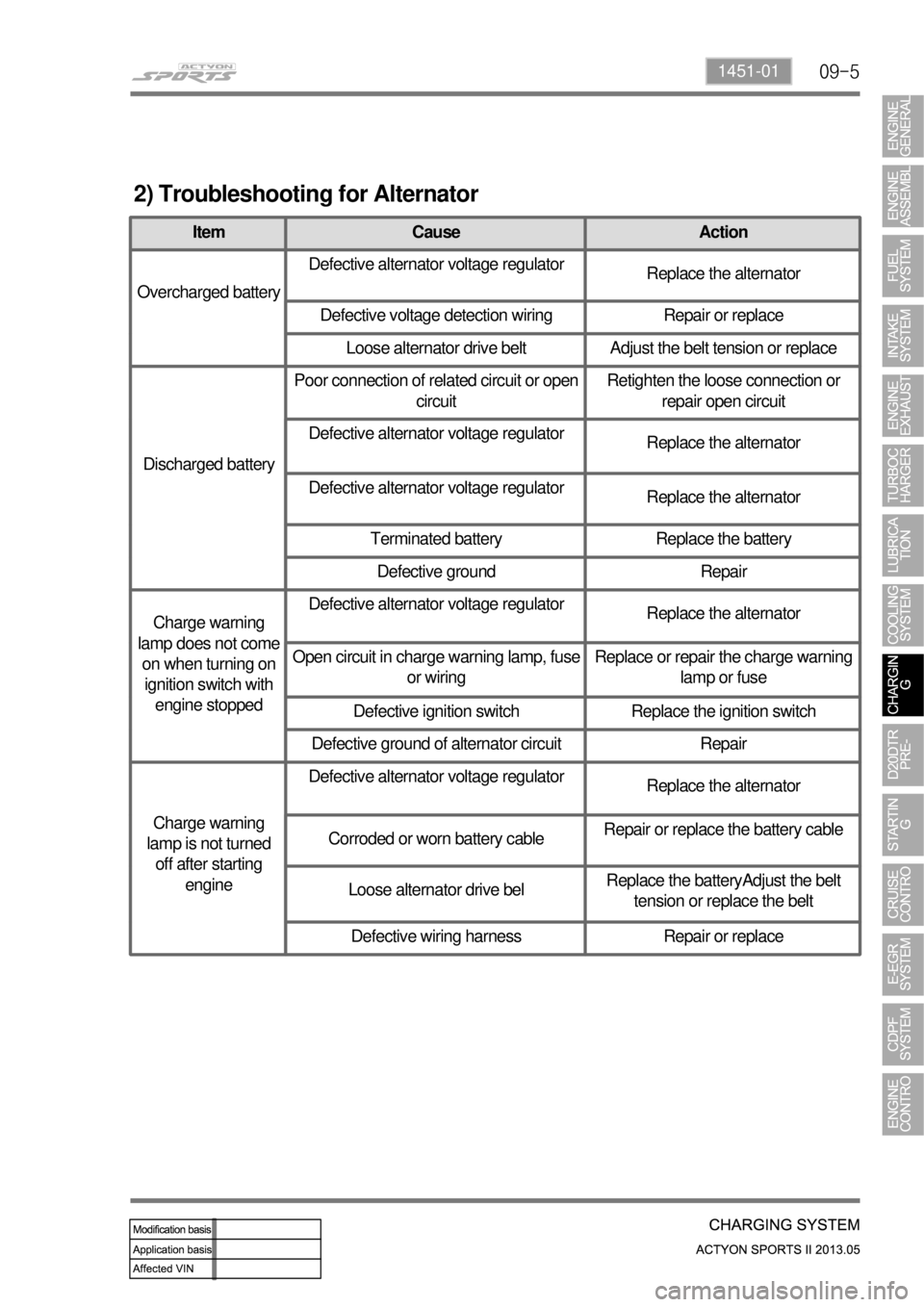

2) Troubleshooting for Alternator

Item Cause Action

Overcharged batteryDefective alternator voltage regulator

Replace the alternator

Defective voltage detection wiring Repair or replace

Loose alternator drive belt Adjust the belt tension or replace

Discharged batteryPoor connection of related circuit or open

circuitRetighten the loose connection or

repair open circuit

Defective alternator voltage regulator

Replace the alternator

Defective alternator voltage regulator

Replace the alternator

Terminated battery Replace the battery

Defective ground Repair

Charge warning

lamp does not come

on when turning on

ignition switch with

engine stoppedDefective alternator voltage regulator

Replace the alternator

Open circuit in charge warning lamp, fuse

or wiringReplace or repair the charge warning

lamp or fuse

Defective ignition switch Replace the ignition switch

Defective ground of alternator circuit Repair

Charge warning

lamp is not turned

off after starting

engineDefective alternator voltage regulator

Replace the alternator

Corroded or worn battery cableRepair or replace the battery cable

Loose alternator drive belReplace the batteryAdjust the belt

tension or replace the belt

Defective wiring harness Repair or replace

Page 286 of 751

06-6

2. DESCRIPTION AND OPERATION

1) General Description

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions.

When the engine is cold, the cooling system cools the engine slowly or not at all. This slow cooling o

f

the engine allows the engine to warm up quickly.

The cooling system includes a radiator and recovery subsystem, cooling fans, a thermostat and

housing, a water pump, and a water pump drive belt. The timing belt drives the water pump.

All components must function properly for the cooling system to operation. The water pump draws the

coolant from the radiator. The coolant then circulates through water jackets in the engine block, the

intake manifold, and the cylinder head. When the coolant reaches the operating

temperature of the thermostat, the thermostat opens. The coolant then goes back to the radiator where

it cools.

This system directs some coolant through the hoses to the heat core. This provides for heating and

defrosting.

The coolant reservoir is connected to the radiator to recover the coolant displaced by expansion from

the high temperatures. The coolant reservoir maintains the correct coolant level.

The cooling system for this vehicle has no radiator cap or filler neck. The coolant is added to the cooling

system through the coolant reservoir.

2) Radiator

This vehicle has a lightweight tube-and-fin aluminum radiator. Plastic tanks are mounted on the upper

and the lower sides of the radiator core.

On vehicles equipped with automatic transaxles, the transaxle fluid cooler lines run through the radiato

r

tank.

A radiator drain plug is on this radiator.

To drain the cooling system, open the drain plug.

3) Coolant Reservoir

The coolant reservoir is a transparent plastic reservoir, similar to the windshield washer reservoir.

The coolant reservoir is connected to the radiator by a hose and to the engine cooling system by anothe

r

hose.

As the vehicle is driven, the engine coolant heats and expands. The portion of the engine coolant

displaced by this expansion flows from the radiator and the engine into the coolant reservoir. The ai

r

trapped in the radiator and the engine is degassed into the coolant reservoir.

When the engine stops, the engine coolant cools and contracts. The displaced engine coolant is then

drawn back into the radiator and the engine. This keeps the radiator filled with the coolant to the desired

level at all times and increases the cooling efficiency.

Maintain the coolant level between the MIN and MAX marks on the coolant reservoir when the system is

cold.

Page 287 of 751

06-72112-01

4) Water Pump

The belt-driven centrifugal water pump consists of an impeller, a drive shaft, and a belt pulley.

The impeller is supported by a completely sealed bearing.

The water pump is serviced as an assembly and, therefore, cannot be disassembled.

5) Thermostat

A wax pellet-type thermostat controls the flow of the engine coolant through the engine cooling system.

The thermostat is mounted in the thermostat housing to the front of the cylinder head.

The thermostat stops the flow of the engine coolant from the engine to the radiator to provide faste

r

warm-up, and to regulate the coolant temperature. The thermostat remains closed while the engine

coolant is cold, preventing circulation of the engine coolant through the radiator. At this point, the engine

coolant is allowed to circulate only throughout the heater core to warm it quickly and evenly.

As the engine warms, the thermostat opens. This allows the engine coolant to flow through the radiato

r

wherethe heat is dissipated. This opening and closing of the thermostat permits enough engine coolant

to enter the radiator to keep the engine within proper engine temperature operating limits.

The wax pellet in the thermostat is hermetically sealed in a metal case. The wax element of the

thermostat expands when it is heated and contracts when it is cooled.

As the vehicle is driven and the engine warms, the engine coolant temperature increases. When the

engine coolant reaches a specified temperature, the wax pellet element in the thermostat expands and

exerts pressure against the metal case, forcing the valve open. This allows the engine coolant to flow

through the engine cooling system and cool the engine.

As the wax pellet cools, the contraction allows a spring to close the valve.

The thermostat begins to open at 87°C(188.6 °F) and is fully open at 102°C(215.6°F). The

thermostat closes at 85°C (187°F).

6) Electric Cooling Fan

Keep hands, tools, and clothing away from the engine cooling fans to help prevent personal injury.

This fan is electric and can turn on even when the engine is not running. -

If a fan blade is bent or damaged in any way, no attempt should be made to repair or reuse the

damaged part. A bent or damaged fan assembly should always be replaced with a new one to

prevent possible injury. -