engine SSANGYONG NEW REXTON 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 372 of 600

1914-01

Control

rangeTurbocharger driving

mechanismControl method

EffectImproved

performance

At low

speedNarrows the flow

passage for the

exhaust gas by

folding the vanesThe flow rate is

increased as the

exhaust gas passes

the narrow passage

turbine & impeller

speed, Increased

compressive forceImproved

low speed torque

4. OPERATING PRINCIPLES

The E-VGT is designed to get more improved engine power in all ranges by controlling the turbine as

follows:

1) How it Works at Low Speed

Normal turbocharger cannot get the turbo effect because the amount of exhaust gas is not enough and

the flow speed is slow in a low speed zone, but VGT allows the flow passage of exhaust to narrow,

resulting in increasing the flow speed of exhaust gas and running the turbine quickly and powerfully.

Therefore, as VGT can intake more air than normal turbocharger, it can give the benefit of the increased

output even in a low speed zone.

Turbocharger lag

The turbocharger is at idle speed when there is no load or it is in the normal driving condition. During

this period, the amount of exhaust gas passing through the turbine is not enough to turn the

compressor wheel (impeller) fast. Therefore, the intake air is not compressed as needed.

Because of this, it takes time for turbocharger to supply the additional power after the accelerator

pedal is depressed. This is called "turbocharger lag". Basic principle at low speed

At low speed, it utilizes the principle of venturi.

For example, when air flows through the venturi

tube, the flow speed is faster and the pressure is

lower at the point "A". In this case, if the inner

diameter of venturi is more narrowed, the flow

speed is so much faster (refer to the equation).

Page 374 of 600

1543-00

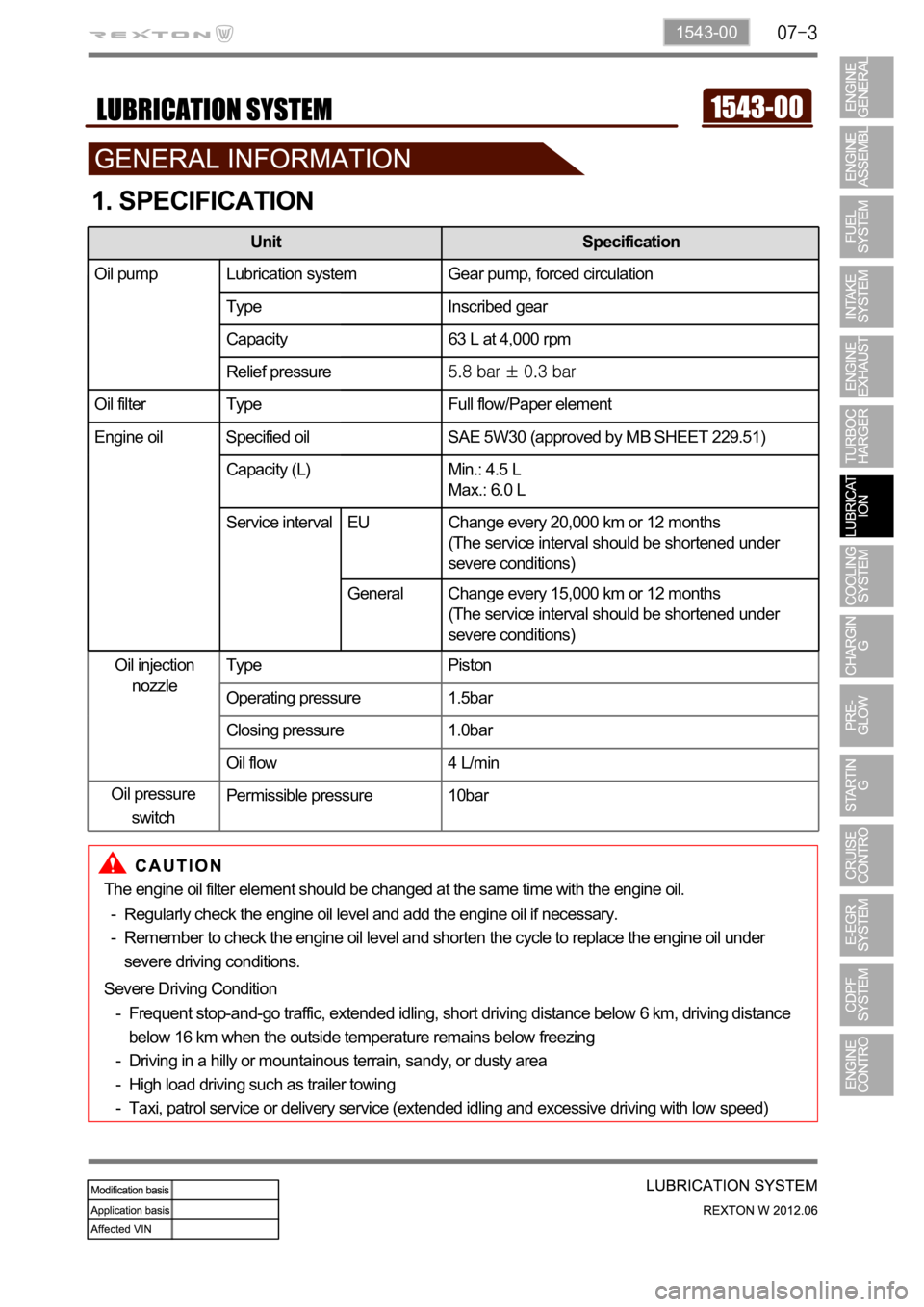

1. SPECIFICATION

The engine oil filter element should be changed at the same time with the engine oil.

Regularly check the engine oil level and add the engine oil if necessary.

Remember to check the engine oil level and shorten the cycle to replace the engine oil under

severe driving conditions. -

-

Severe Driving Condition

Frequent stop-and-go traffic, extended idling, short driving distance below 6 km, driving distance

below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) -

-

-

-

Unit Specification

Oil pump Lubrication system Gear pump, forced circulation

Type Inscribed gear

Capacity 63 L at 4,000 rpm

Relief pressure

Oil filter Type Full flow/Paper element

Engine oil Specified oil SAE 5W30 (approved by MB SHEET 229.51)

Capacity (L) Min.: 4.5 L

Max.: 6.0 L

Service interval Change every 15,000 km or 12 months (But, shorten

the service interval under severe condition)

Oil injection

nozzleType Piston

Operating pressure 1.5bar

Closing pressure 1.0bar

Oil flow 4 L/min

Permissible pressure 10bar

Unit Specification

Oil pump Lubrication system Gear pump, forced circulation

Type Inscribed gear

Capacity 63 L at 4,000 rpm

Relief pressure

Oil filter Type Full flow/Paper element

Engine oil Specified oil SAE 5W30 (approved by MB SHEET 229.51)

Capacity (L) Min.: 4.5 L

Max.: 6.0 L

Service interval EU Change every 20,000 km or 12 months

(The service interval should be shortened under

severe conditions)

General Change every 15,000 km or 12 months

(The service interval should be shortened under

severe conditions)

Oil pressure

switch

Page 375 of 600

2. MAINTENANCE

1) Level Check

Park the vehicle on a level ground and apply the parking brake. Stop the engine and wait more than 5

minutes.

Pull out the dipstick and wipe it with a clean cloth. Reinsert it all the way.

Pull out it again and check the oil level.

The oil level should be between the maximum (Max) mark and minimum (Min) mark on the oil dipstick.

Oil should be replenished before the level goes below the minimum mark. -

-

-

Operating vehicle with insufficient amount of oil can damage the engine. Make sure the engine oil

level is correct and add oil if necessary.

2) Replenishment

If the level gets to the lower point, open the filler cap on top of the cylinder block and add the genuine oil

without exceeding the level of the upper mark.

Recheck the oil level after 5 minutes.

Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary.

Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine.

The oil should not go above the upper mark on the dipstick.

The engine oil may be consumed more if the engine is new. -

-

-

-

Engine oil dipstickEngine oil filler

Page 376 of 600

1543-00

1. SYSTEM DESCRIPTION

1) Overview

The lubrication system supplies oil to each lubrication section to prevent friction and wear and to remove

heat from the friction part. As the engine runs, frictional heat is generated on each lubrication section. If

this condition persists, the bearing can be burned and stuck.

In other words, it creates an oil film on each sliding surface to convert solid friction to liquid friction in order

to minimize wear and prevent temperature increasing on the friction part.

For the D20DTF engine with no oil pressure switch, the engine ECU receives the low engine oil level

signal from the oil level sensor and communicates with the instrument cluster through the CAN

communication to turn on the warning lamp.

2) Components

Oil coolerOil dipstick gaugeOil pump

Oil filter moduleOil pressure switchOil pan

Page 377 of 600

2. FUNCTIONS OF LUBRICATION

1) Lubrication

It creates a viscous barrier between moving parts that reduces friction, which means less heat and

longer life for those parts. As a lubricant, oil must maintain a protective film to prevent metal-to-metal

contact. It must be fluid enough to allow easy starting and to circulate quickly through the engine, yet

remain thick enough at higher operating temperatures and speeds to provide adequate lubrication.

2) Cooling

Combustion heat and friction energy must be removed from the engine in order to prevent its

overheating. Most of heat energy is taken by the engine oil.

Clean oil passages, proper viscosity and low contamination provide sufficient flow rate of the engine oil

and effective cooling.

3) Sealing

It helps to seal the space between the pistons and the cylinder walls so that compression is more

effective and power is not lost during combustion.

4) Anti-corrosion

As a corrosion inhibitor, oil coats internal engine parts to prevent surface rust on the inside of the engine

which can be caused by blow-by products and water formed in combustion. It must also be capable of

neutralizing the acids that are formed by combustion blow-by and oil oxidation at high temperatures.

5) Cleaning

The small particles of dirt or other contaminants are suspended in oil and carried away to be filtered out.

As a detergent, engine oil must be able to gather and suspend dirt and other contaminants until the oil

can leave them as it passes through the filter and returns to the internal engine environment.

Page 380 of 600

1520-00

1) Coolant Level Check

Park the vehicle on level ground and apply the parking brake. Stop the engine and wait until it is

cooled down.

The coolant level should be between the MAX and MIN mark on the coolant reservoir.1.

2.

Scalding hot coolant and steam could be blown out under pressure, which could cause serious

injury. Never remove the coolant reservoir cap when the engine and radiator are hot.

Avoid any direct contact of the coolant to the painted body of the vehicle. -

-

Page 382 of 600

1520-00

3. CAUTIONS

If 100% of anti-freeze is added, the water pump vane can be damaged and thermal conductivity

can be decreased resulting in poor circulation in the cooling system which leads to overheated

engine.

Use of non-recommended coolant could cause damage to the cooling system and overheating of

the engine.

Opening the coolant reservoir cap while the engine is running or hot can cause burns by hot steam

or water.

To open the coolant reservoir cap, wrap the cap with a wet towel or thick cloth after the engine is

cooled down sufficiently.

If cool water is added to the heated engine, the engine or radiator can be deformed.

The anti-freeze in the coolant can damage the painted surface, so avoid the contact of the coolant

to the painted body.

The anti-freeze and water should be mixed in proper mixture ratio. Never add only water when

adding coolant.

If the anti-freeze content is too low, the coolant can be frozen while the engine can be overheated if

anti-freeze content is too high. -

-

-

-

-

-

-

-

Page 383 of 600

Water pump

The water pump is driven by the engine drive belt and supplies

the coolant to each area of the engine.

Coolant reservoir

Long life coolant is used.

Thermostat

When the engine coolant

starts to open (fully open at

flow to the radiator to maintain

the engine temperature.

1. SYSTEM DESCRIPTION

1) Overview

Water pump

Impeller vane Sealing

Oil filter module

Page 384 of 600

1520-00

Electric fan

Circulates the fresh air forcibly to exchange heat

with the radiator core fin.

Radiator

Releases heat through fins and cools down the hot

coolant as the coolant passes through the tube of the

radiator core.

Coolant temperature sensor

Measures the coolant

temperature and sends the

result to the engine ECU.

Page 386 of 600

2. INSPECTION

1) Alternator Output Test

Item How to check DTC set value / Action

Output

current

B terminal

current

Rotor

coil

resistance

L terminal

voltage

Disconnect the cable connected to the B

terminal on the alternator. Connect one end

of the ammeter to the B terminal and the

other end to the cable connected to the B

terminal.

Measure the maximum output value.

(Maintain the engine speed between 2,500

and 3,000 rpm.)

(Turn the headlamp and all the electrical

switches on.) 1.

2.Pass: If the measured current is 45

A or higher.

Fail: If the measured current is less

than 45 A.

Check the current of the B terminal. -

-

-

Move the gear selector lever to the neutral

position.

Maintain the engine speed at 2,500 rpm

with the vehicle unloaded.

(Turn all the electrical switches off.) 1.

2.Open circuit: If the measured

current is 5 A or higher. -

Disconnect the negative cable from the

battery.

Remove the B terminal and turn off the

ignition switch.

Measure the resistance between the L and

F terminals with an ohmmeter. 1.

2.

3.Pass: If the measured resistance is

Faulty rotor coil or slip ring: If the

measured resistance is less than

-

-

Connect the B terminal wiring.

Measure the voltage with the engine running. 1.

2.Specification: 12.5 V to 14.5 V

Faulty IC regulator or field coil: If

the measured voltage is 14.5 V or

higher. -

-

Disconnect the negative battery cable.

Connect the negative cable again after connecting the ammeter. -

-