ECU SSANGYONG NEW REXTON 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 229 of 600

1533-01

Front temperature sensor

(Measuring the temperature of

exhaust gas passedthrough

exhaust manifold)Rear temperature sensor

(Measuring the temperature of exhaust

gas passed through DOC)

Differrential pressure sensor

(Front pressure port)Differrential pressure sensor

(Rear pressure port)

The engine ECU detects the

amount of particulate material

colected by the information

from temperature sensors

and differential pressure

snesor. When the soot is

accumulated, the pressure

difference be-tween the front

and the rear side occurs.

Then, the engineECU

performs the post injec-tion to

raise the exhaust gas

temperature and burn the

collected soot at approx. The exhaust gas enters

intoCDPF assembly after

passing through the exhaust

manifold. (Normal

temperature of ex-haust gas: When the exhaust gas

enters into the CDPF

assembly, its CO, HC and

particulate mate-rial are

reduced as it is oxi-dized in

DOC. The remaining

particulate material is

filtered and collected in

DPF and the temperature

of exhaust gas is increased

Page 230 of 600

2) Fuel Injection During CDPF Regeneration

3) Warning Lamp Related To CDPF

CDPF regeneration process (warning lamp NOT illuminated)

The CDPF system enters the regeneration mode when the

driving distance becomes approx. 600 to 1,200 km (may

differ by the driving condition and driving style). Then, the

engine ECU performs the CDPF regeneration operation.

However, the driver is not in-formed with this operation by an

y

engine warning lamp or vehicle signal, so he/she may not

detect this operation. The control logic at the post-injection

dur-ing the regeneration process is to increase the fuel

injection volume and control the intake air volume (by the

throttle body) in order to increase the tem-perature of the

exhaust gas. The driver may not feel any particular difference

from the vehicle.

No illumination

Page 242 of 600

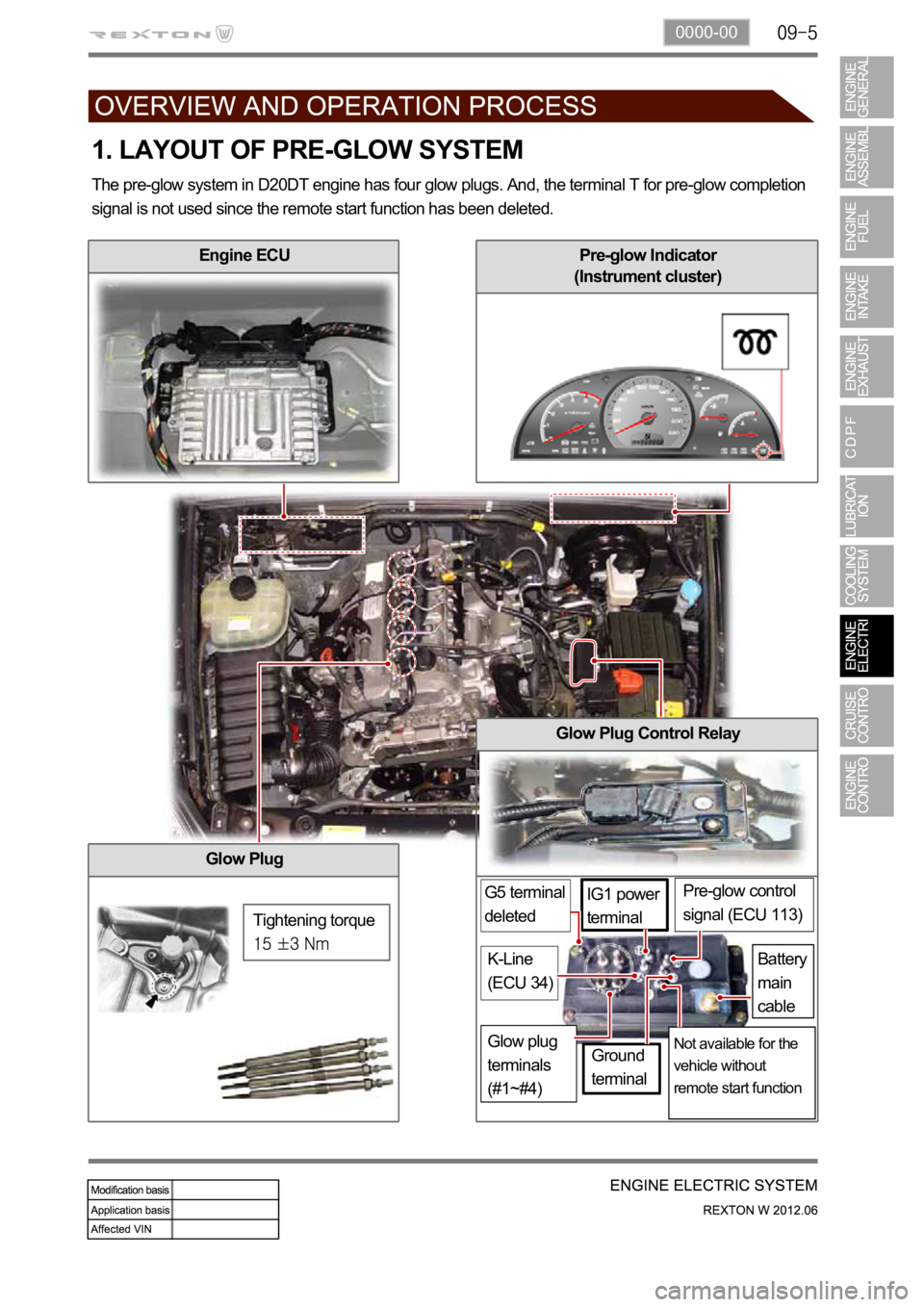

0000-00

Glow Plug

1. LAYOUT OF PRE-GLOW SYSTEM

The pre-glow system in D20DT engine has four glow plugs. And, the terminal T for pre-glow completion

signal is not used since the remote start function has been deleted.

Tightening torque

Engine ECUPre-glow Indicator

(Instrument cluster)

Ground

terminal

Pre-glow control

signal (ECU 113)IG1 power

terminal

Not available for the

vehicle without

remote start functionGlow plug

terminals

(#1~#4)

K-Line

(ECU 34)

G5 terminal

deleted

Battery

main

cable

Glow Plug Control Relay

Page 244 of 600

0000-00

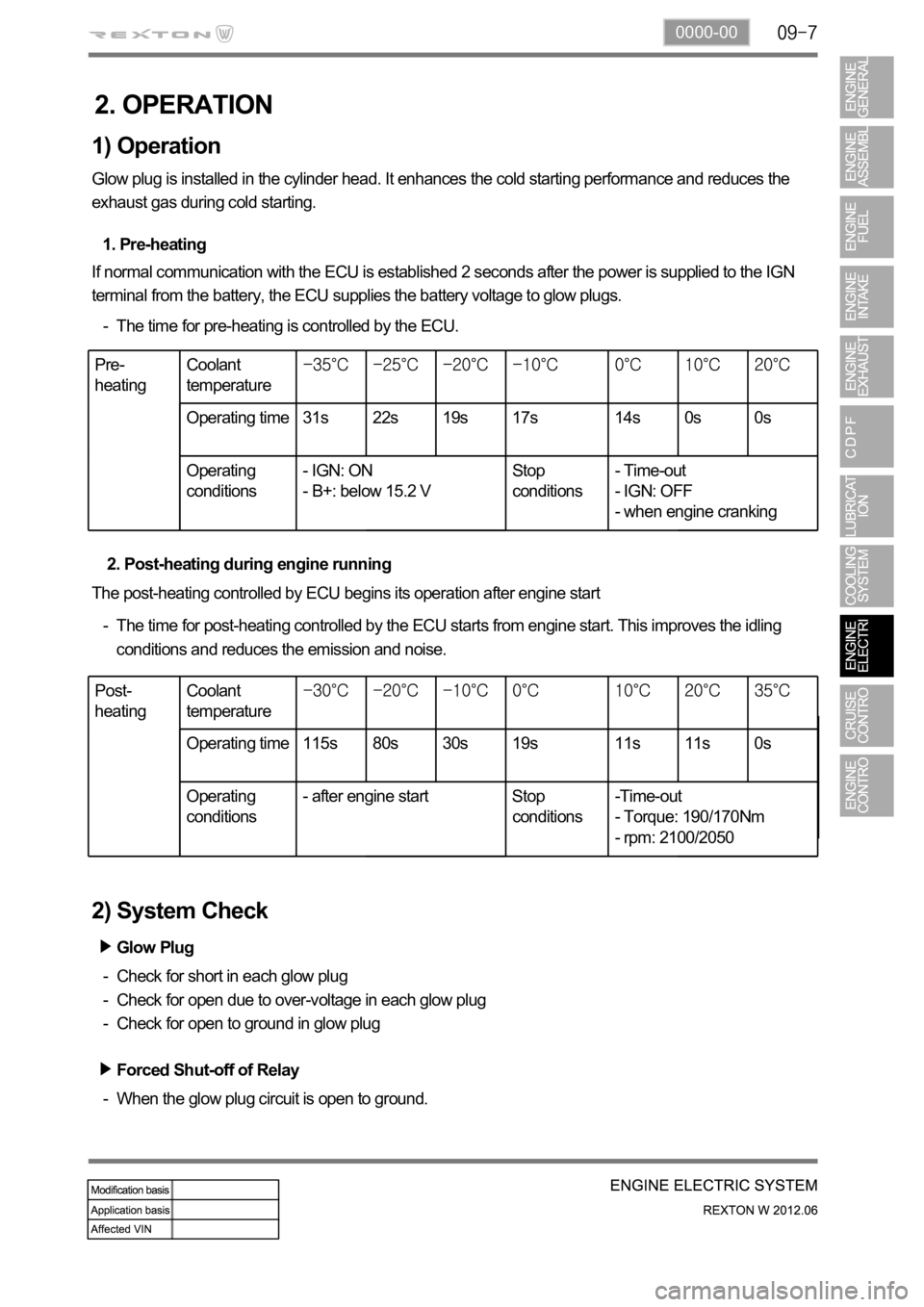

2. OPERATION

Glow plug is installed in the cylinder head. It enhances the cold starting performance and reduces the

exhaust gas during cold starting.

1. Pre-heating

2. Post-heating during engine running If normal communication with the ECU is established 2 seconds after the power is supplied to the IGN

terminal from the battery, the ECU supplies the battery voltage to glow plugs.

The post-heating controlled by ECU begins its operation after engine start The time for pre-heating is controlled by the ECU. -

The time for post-heating controlled by the ECU starts from engine start. This improves the idling

conditions and reduces the emission and noise. -

2) System Check

Glow Plug

Forced Shut-off of Relay

Check for short in each glow plug

Check for open due to over-voltage in each glow plug

Check for open to ground in glow plug -

-

-

When the glow plug circuit is open to ground. -

1) Operation

Pre-

heatingCoolant

temperature

Operating time 31s 22s 19s 17s 14s 0s 0s

Operating

conditions- IGN: ON

- B+: below 15.2 VStop

conditions- Time-out

- IGN: OFF

- when engine cranking

Post-

heatingCoolant

temperature

Operating time 115s 80s 30s 19s 11s 11s 0s

Operating

conditions- after engine start Stop

conditions-Time-out

- Torque: 190/170Nm

- rpm: 2100/2050

Page 245 of 600

K-Line Communication

ECU starts to communicate by sending the result to pre-glow timer relay through K-Line.

Pre-glow timer relay sends the message with self-diagnosis data for glow plug to ECU.

The glow plug responses only for request.

ECU starts self-diagnosis operation from 2 seconds after power input.

Communication error occurs when: -

-

-

-

-

No response from pre-glow module for a certain period of time

Checksum error

Insufficient byte

3) DTC

DTC Description Error

P1678 GCU circuit is open GCU circuit is open

P1679 GCU circuit is short GCU circuit is short

P1680 GCU circuit is short to ground GCU circuit is short to ground

P1676Communication error Communication error between ECU and

GCU

P1677Defective GCU Communication error between ECU and

GCU

P0671 GCU channel 3 opened circuit GCU channel 3 circuit is open

P0672 GCU channel 4 opened circuit GCU channel 4 circuit is open

P0674 GCU channel 1 opened circuit GCU channel 1 circuit is open

P0675 GCU channel 2 opened circuit GCU channel 2 circuit is open

Page 248 of 600

8510-23

2. CONFIGURATION

1) Circuit Diagram

The engine ECU detects the operating conditions of cruise control system, and monitors the braking

performance, vehicle speed, road conditions and ESP system operation. If the engine ECU determines

that there are not any problem to drive in cruise control mode, the vehicle can be operated by cruise

switch signals (decelerating, accelerating, cruising).

Page 278 of 600

0000-00

4. GUIDELINES ON ENGINE SERVICE

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and

unit inspection/repair and to secure optimum engine performance and safety after service works, basic

cautions and service work guidelines that can be easily forgotten during engine service works are

described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not support

the bottom of oil pan with a jack.

Engine and accessories

-

-

-

-

-

-

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working procedures in

this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there are not any interference while servicing. -

-

-

-

-

Page 285 of 600

Brake booster and naster

cylinderVacuum pump

Pump capacity: 210 cc/rev

Camshaft speed: 375 to 3,000 rpm

Lubrication temperature: -40 to

Oil: 5W30

Drive type: Driven by exhaust

Camshaft sprocket

2. VACUUM PUMP

Vacuum pump generates the vacuum pressure and supplies it to EGR cooler bypass solenoid. This

pump is single vane type and displacement is 210 cc/rev. The lubrication oil is supplied through the hole

in hollow shaft.

Components

EGR cooler bypass valve

This valve is controlled by ECU.

When the engine is cooled, the

exhaust gas goes to combustion

chamber without passing through

EGR cooler because the valve is

closed by vacuum pressure.

Page 333 of 600

2210-01

2) Cleanness

(1) Cleanness of DI engine fuel system

Cleanness of DI engine fuel system and service procedures

The fuel system for DI engine consists of transfer (low pressure) line and high pressure line.

Its highest pressure reaches over 1,800 bar.

preciseness.

The pressure regulation and injector operation are done by electric source from engine ECU.

Accordingly, if the internal valve is stuck due to foreign materials, injector remains open.

Even in this case, the HP pump still operates to supply high pressurized fuel. This increases the

pressure to combustion chamber (over 250 bar) and may cause fatal damage to engine.

You can compare the thickness of injector nozzle hole and hair as shown in below figure (left side). The

below figure shows the clearance between internal operating elements.

The core elements of fuel system has very high preciseness that is easily affected by dust or very small

foreign material. Therefore, make sure to keep the preliminary works and job procedures in next pages.

If not, lots of system problems and claims may arise.

Hair

Nozzle holeValve actuator lift - 0.028 mm

Diameter

0.04 mm

Operating

clearance

0.002 mm

Diameter

2.0 mm

Page 334 of 600

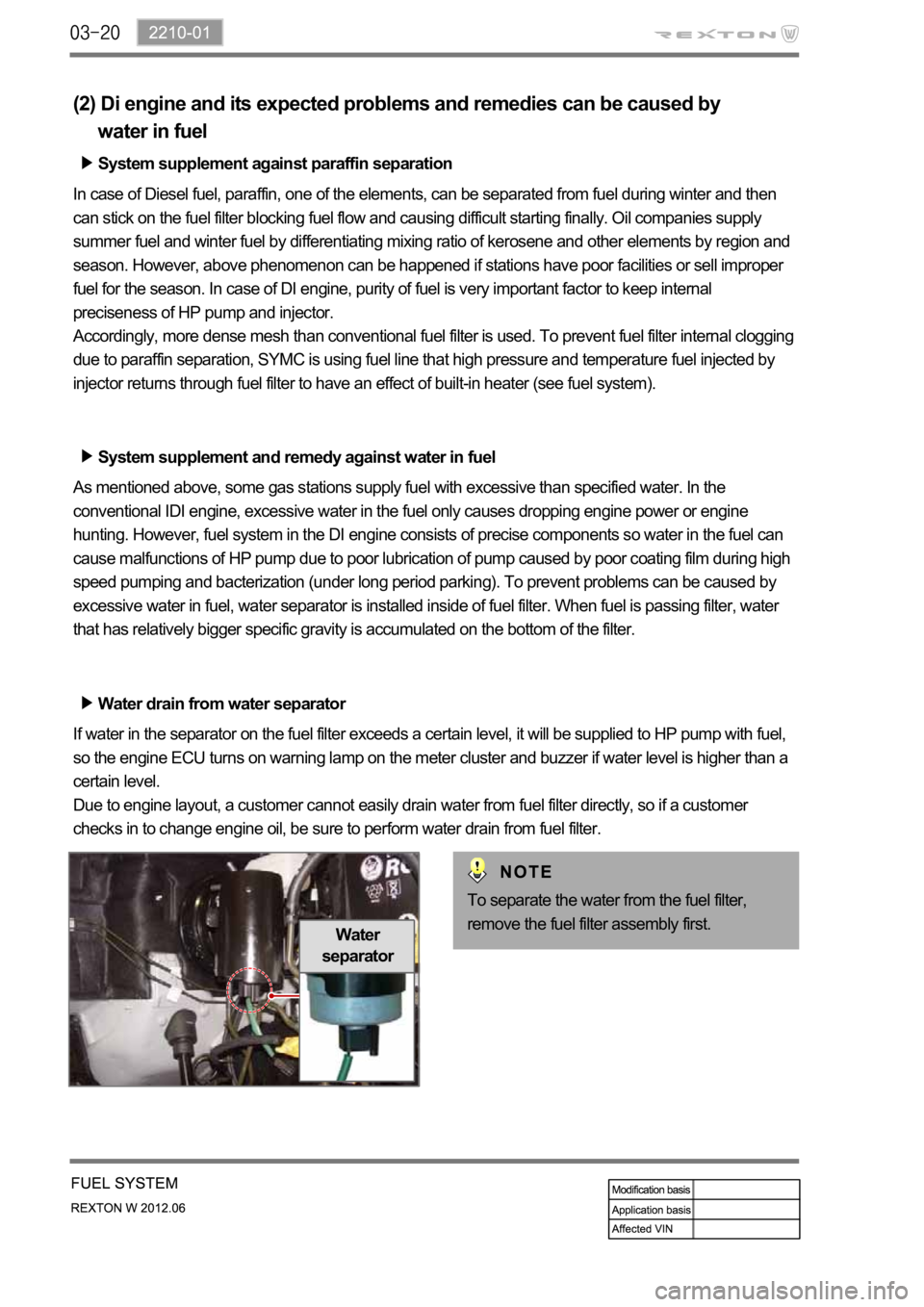

(2) Di engine and its expected problems and remedies can be caused by

water in fuel

System supplement against paraffin separation

In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and then

can stick on the fuel filter blocking fuel flow and causing difficult starting finally. Oil companies supply

summer fuel and winter fuel by differentiating mixing ratio of kerosene and other elements by region and

season. However, above phenomenon can be happened if stations have poor facilities or sell improper

fuel for the season. In case of DI engine, purity of fuel is very important factor to keep internal

preciseness of HP pump and injector.

Accordingly, more dense mesh than conventional fuel filter is used. To prevent fuel filter internal clogging

due to paraffin separation, SYMC is using fuel line that high pressure and temperature fuel injected by

injector returns through fuel filter to have an effect of built-in heater (see fuel system).

System supplement and remedy against water in fuel

As mentioned above, some gas stations supply fuel with excessive than specified water. In the

conventional IDI engine, excessive water in the fuel only causes dropping engine power or engine

hunting. However, fuel system in the DI engine consists of precise components so water in the fuel can

cause malfunctions of HP pump due to poor lubrication of pump caused by poor coating film during high

speed pumping and bacterization (under long period parking). To prevent problems can be caused by

excessive water in fuel, water separator is installed inside of fuel filter. When fuel is passing filter, water

that has relatively bigger specific gravity is accumulated on the bottom of the filter.

Water drain from water separator

If water in the separator on the fuel filter exceeds a certain level, it will be supplied to HP pump with fuel,

so the engine ECU turns on warning lamp on the meter cluster and buzzer if water level is higher than a

certain level.

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a customer

checks in to change engine oil, be sure to perform water drain from fuel filter.

Water

separator

To separate the water from the fuel filter,

remove the fuel filter assembly first.