Turbo SSANGYONG NEW REXTON 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 220 of 600

0000-00

1. COMPONENTS

1. E-EGR valve: Controlling the EGR valve electrically and sends the valve location signal to ECU

(vacuum modulator control has been deleted).

2. EGR cooler:

VGT turbochargerIntake manifold

Turbocharger intercooler

(intake air)

EGR gas (from EG

R

cooler)

E-EGR

valve

Exhaust manifoldE-EGR

valveCoolant

To intake

manifold

EGR cooler

EGR pipe

E-EGR valveDecreasing EGR gas (NOx) efficiently by cooling the EGR gas and let it flow to the

intake manifold. The components of the exhaust system consist of:

Throttle body

Exhaust manifold

Page 222 of 600

Under air cleaner in right side

of engine compartment

2. CDPF (EURO IV) SYSTEM

The CDPF system is only installed to the D27DT engine, and the major changes comparing to the

previous D27DT engine is as follows:

CDPF (Catalyst & Diesel Particulate Filter) and Sensors

Front exhaust gas

temperature sensor

CDPF Exhaust Gas Temperature Sensor

The two temperature sensors

in-side the CDPF are installed

inexhaust manifold (front

exhaustgas temperature

sensor) and inDOC (rear

exhaust gas tempera-ture

sensor), and perform the fol-

lowing functions.Front Exhaust Gas Tempera-ture

Sensor:

Measures the exhaust gas tem-

perature of the exhaust manifold. As it

is installed in front of the VGT

turbocharger, it also monitors the

exhaust gas tempera-ture coming to

the turbocharger. If the temperature of

the exhaust gas flowing to the

turbocharger is higher than the

specification, the engine lowers the

exhaust gas temperature.Rear Exhaust Gas Tempera-

ture Sensor:

Measures the increased ex-

haust gas temperature after

the oxidation process of DOC.

If the temperature is below

amount is increased to

increase the temperature.

As the soot is filtered in the CDPF, the pressure between the front side and the rear side of the filter is

different from each other. If the amount of soot is over 28 g, the soot is burnt in the CDPF. The

combustion is determined depending on the pressure difference, temperature of exhaust gas and

Page 223 of 600

1533-01

Throttle Body

CDPF system controls the amount of intake air by controlling the

electronic throttle body. The electronic throttle body has the

following main functions.

CDPF control - added a function that increases the exhaust gas

temperature by closing the throttle valve flap to minimize the intake

air amount by the fuel injection amount during the CDPF

regeneration range with the low engine load range.

ON/OFF control - prevents the engine from turning off with

vibration and noise by closing the throttle body flap to block the

intake air when the engine is stopped.

Duty control - controls the valve inside the throttle body to burn

more EGR gas in the EGR valve operating range.

VGT Turbocharger and Front Exhaust Gas Temperature Sensor

Turbocharger may become weaker if high tem-

perature exhaust gas passes through the tur-

bocharger for DPF regeneration process.

The front exhaust gas temperature sensor moni-tors

the temperature of the exhaust gas that flows into the

turbocharger.

If the temperature of the exhaust gas that passes

through the exhaust manifold is higher than the

specification, the ECU decreases the fuel injection

amount and increases the EGR gas intake amount to

decrease the exhaust gas temperature.Front exhaust gas

temperature sensor

Page 259 of 600

0000-00

Right view

Front exhaust gas temperature

sensor

Oil dipstick tube &

gauge assembly

E-VGT actuator

E-VGT turbocharger

Coolant screw plug

Oil drain plug

Left view

Thermostat assembly

Variable swirl valve assembly

E-EGR valve

E-EGR solenoid valve

EGR cooler

Electronic throttle body

Oil cooler assembly

Page 267 of 600

0000-00

Hot water inlet pipe2 -

1 -

1 -

4 25~2.5Nm -

4 -

2 -

6 -

6 -

1 -

2 -

2 -

1 10~14Nm -

1 -

M8 10

-

M8 3

-

1

-

M8 1

-

T/C oil supply pipe M6(to block) 1

-

M6

(to turbocharger)1

-

T/C oil return pipe

2 -

(to turbocharger)2

-

EGR valve

3 -

EGR pipe bolt (to exhaust

manifold)

2 -

EGR pipe bolt (to EGR

cooler)

2 -

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Hot water inlet pipe

2 -

Alternator

1 -

1 -

Air conditioner

compressor

4 25~2.5Nm -

Air conditioner bracket

4 -

Intake manifold

2 -

6 -

Oil filter module

6 -

1 -

2 -

Knock sensor

2 -

Camshaft position sensor

1 10~14Nm -

T-MAP pressure sensor

1 -

Exhaust manifold M8 10

-

Turbocharger M8 3

-

T/C support bolt M8 1

-

Page 272 of 600

0000-00

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Hot water inlet pipe

2 -

Alternator

1 -

1 -

A/C bracket

4 7.8~11.8Nm -

A/C sub bracket

4 -

Intake manifold

2 -

6 -

Oil filter module

6 -

1 -

2 -

Knock sensor

2 -

Cam position sensor

1 10~14Nm -

Booster pressure sensor

2 -

Exhaust manifold M8 10

-

Turbocharger M8 3

-

Support bolt 1

-

Support nut M8 1

-

T/C oil supply pipe M6(block side) 1

-

M6(turbo side) 1

-

T/C oil return pipe

2 -

2 -

EGR valve

2 -

EGR pipe bolt

(Intake side)

2 -

EGR pipe bolt

(EGR cooler side)

2 -

EGR combination bolt

4 -

16 -

Idle pulley/Tensioner

pulley1

-

Page 342 of 600

2. INSPECTION

1) Troubleshooting

When Abnormal Noises are Heard from the Engine Room

For the vehicle equipped with DI engine, if a learning noise occurs in each range or other noises

occur, the major cause of it is a faulty turbocharger assembly. But an interference issue, poor

tightness or loose in the intake and exhaust system also can cause those noises. This is mainly

because the operator didn't follow the instruction exactly when reconnecting the intake hoses and

pipes which were disconnected to check the system or replace the air cleaner. If the intake system is

free of any faults, check the EGR and PCV oil separator connected to the intake system.

The figure may be different from the actual engine. Therefore, read thoroughly below before replacing

the parts.

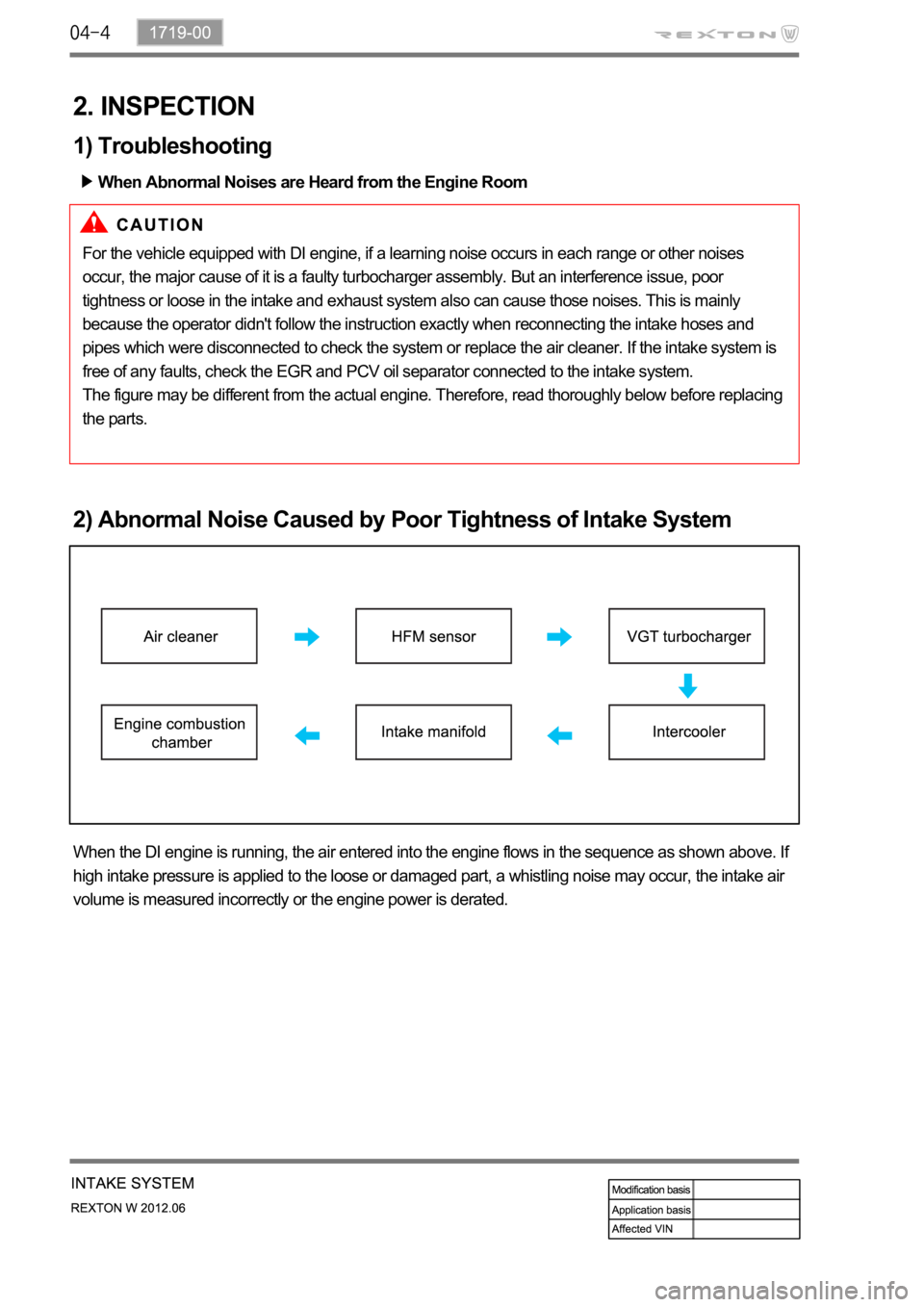

2) Abnormal Noise Caused by Poor Tightness of Intake System

When the DI engine is running, the air entered into the engine flows in the sequence as shown above. If

high intake pressure is applied to the loose or damaged part, a whistling noise may occur, the intake air

volume is measured incorrectly or the engine power is derated.

Page 354 of 600

1914-01

1. SPECIFICATION

Unit Description Specification

TurbochargerMax. expansion coefficient 4.0

Max. turbine speed 226,000rpm

Max. temperature of turbine housing

Weight 6.5kg

E-VGT actuator Operation duty cycle 250Hz

Page 355 of 600

2. INSPECTION

1) Cautions During Driving

The following lists cautions to take during test drive and on the turbocharger vehicle, which must be

considered during the operation.

It's important not to drastically increase the engine rpm starting the engine. It could make rotation at

excessive speed even before the journal bearing is lubricated and when the turbocharger rotates in

poor oil supply condition, it could cause damage of bearing seizure within few seconds.

If the engine is running radically after replacing the engine oil or oil filter brings poor oil supply

condition. To avoid this, it's necessary to start off after idling the engine for about 1 minute allowing oil

to circulate to the turbocharger after the replacement.

When the engine is stopped abruptly after driving at high speed, the turbocharger continues to rotate

in condition where the oil pressure is at '0'. In such condition, an oil film between the journal bearing

and the housing shaft journal section gets broken and this causes abrasion of the journal bearing due

to the rapid contact. The repeat of such condition significantly reduces life of the turbocharger.

Therefore, the engine should be stopped possibly in the idle condition. 1.

2.

3.

After string for long period of time during winter season or in the low temperature condition where the

fluidity of engine oil declines, the engine, before being started, should be cranked to circulate oil and

must drive after checking the oil pressure is in normal condition by idling the engine for few minutes.

Page 356 of 600

1914-01

2) Inspection of Turbocharger

When problem occurs with the turbocharger, it could cause engine power decline, excessive discharge of

exhaust gas, outbreak of abnormal noise and excessive consumption of oil.

On-board Inspection 1.

Check the bolts and nuts foe looseness or missing

Check the intake and exhaust manifold for looseness or damage

Check the oil supply pipe and drain pipe for damages

Check the housing for crack and deterioration -

-

-

-

Inspection of turbine 2.

Remove the exhaust pipe at the opening of the turbine and check, with a lamp, the existence of

interference of housing and wheel, oil leakage and contamination (at blade edge) of foreign materials.

Interference: In case where the oil leak sign exists, even the small traces of interferences on the

turbine wheel mean, most of times, that abrasion has occurred on the journal bearing. Must inspect

after overhauling the turbocharger.

Oil Leakage: Followings are the reasons for oil leakage condition -

-

Idling for long period of time can cause oil leakage to the turbine side due to low pressure of exhaust

gas and the rotation speed of turbine wheel. Please note this is not a turbocharger problem.

Oil Drain Pipe Defect

In case where oil flow from the turbocharger sensor housing to the crank case is not smooth would

become the reason for leakage as oil builds up within the center housing. Also, oil thickens (sludge) at

high temperature and becomes the indirect reason of wheel hub section. In such case, clogging and

damage of the oil drain pipe and the pressure of blow-by gas within the crank case must be inspected.

Damages due to Foreign Materials

When the foreign materials get into the system, it could induce inner damage as rotating balance of

the turbocharger gets out of alignment. -

-Problems in engine: In case where the oil is smeared on inner wall section of the exhaust gas

opening.

Problems in turbocharger: In case where the oil is smeared on only at the exhaust gas

outlet section. *

*