fuel SSANGYONG NEW REXTON 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 184 of 600

0000-00

Knock sensor (one) and

water temperature sensor

Fuel rail sensor (common

rail)

1. LOCATION OF MAJOR SENSORS ON ENGINE

Major sensors and devices

InjectorGlow plugCommon rail

Camshaft position sensorBoost pressure sensor

Crankshaft position

sensor

HP pumpCommon rail

Injector

Turbocharger vacuum

modulator

Page 186 of 600

0000-00

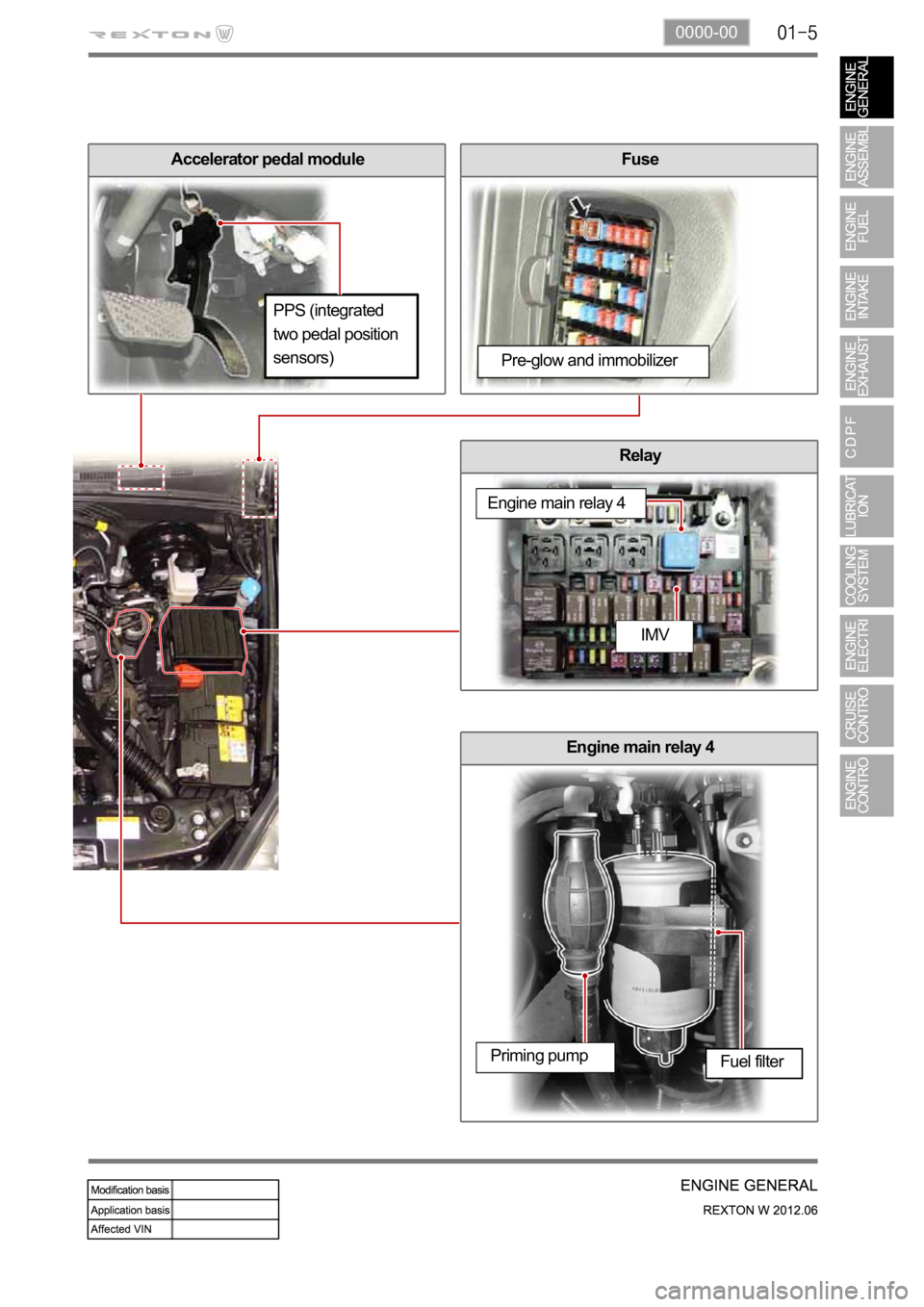

Accelerator pedal moduleFuse

Relay

Engine main relay 4

PPS (integrated

two pedal position

sensors)

Pre-glow and immobilizer

Engine main relay 4

IMV

Priming pumpFuel filter

Page 195 of 600

InjectorFuel filter and priming pump

8. LAYOUT OF FUEL SYSTEM

Components

IMV connector

Pressure sensor

in fuel rail

High pressure

fuel pipe

Fuel pipe

Common rail IMV connector

HP pump

Priming pumpFuel filter

Connector

Returned fuel

from HP pumpFuel filter

Fuel tank

HP pump

Fuel tank

Fuel return port

Low pressure fuel supply portVenturi

Fuel return portFuel temperature

sensor

IMV valve

IMV connectorHigh pressure fuel

supply port

(with orifice)

Page 201 of 600

Injector washer puller

2. SPECIAL SERVICE TOOLS

1) Using the Special Service Tools on Engine

Injector pullerGlow plug socket

HP remover/installerHigh pressure pipe

remover/installerCylinder head bolt wrench

Sealing caps

(fuel line)

Page 206 of 600

0000-00

(4) Lubrication system

Prolonged exposure to the engine oil make cause a skin cancer or an irritation.

Used engine cotains the hazardous material that may cause the skin cancer. Do not allow the used

engine to make contact with your skin.

Make sure to wear the protection gloves and goggle when handling the engine oil. If contact happens,

rinse affected areas immediately with plenty of water. Do not wash it with gasoline or solvent. If

irritation persists, consult a doctor.

Improperly disposed engine oil can pollute the environment. Dispose used engine oil in accordance

with local environmental regulations. -

-

-

(5) Tightening the fastener

Clean the mating surfaces before tightening.

Place the marks with paint to tighten by angle if the angle wrench is not available. -

-

3) Fuel and Oil System

If work on the fluid system such as fuel and oil, working area should be well ventilated and smoking

should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and nuts

should be tightened as specified. -

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious damages

between HP pump and injectors. So, be sure to cover removed fuel system components with cap

and protect removed parts not to be contaminated with dirt. (Refer to cleanness in this manual

while working on DI engine fuel system)

When working on the fuel line between priming pump and injector (including return line), always

plug the openings with caps to prevent foreign materials or dust from entering to the openings and

connections.

The HP fuel supply pipe (HP pump to fuel rail) and HP fuel pipe (Fuel rail to injector)

should be replaced with new ones when removed. 1.

2.

3.

Page 211 of 600

0000-00

Injector (7-way Injection and C3I Coding)

1. FUEL SYSTEM - K2006

The C3I injector system is used in D20DT engine.

Injector

C3I Label

Two nozzle holes are added (currently 7) to the tip of the injector to increase the amount of fuel

injection and to improve injection efficiency according to the increased engine power.

The existing C2I coding (16 digits) is changed to C3I coding (20 digits) to monitor fuel injection and

follow the target value.

For the D20DT engine, the injector MDP (minimum current for the solenoid in the injector to lift the

nozzle) is leaned only when the engine is running. However, for the D20DT (EURO 4) engine, it is

learned when the vehicle is in motion and the engine is at idle speed. -

-

C3I Label

C3I Code

Fuel nozzle

holes (7)

C3I

Fuel nozzle

holes (7)

C3I Code (20 digits)

Page 212 of 600

1. FUEL FLOW OF D20DT (EURO 4) ENGINE

According to input signals from various sensors, engine ECU calculates driver's demand (position of the

accelerator pedal) and then controls overall operating performance of engine and vehicle on that time. ECU

receives the signals from sensors via data line and then performs effective engine air-fuel ratio controls

based on those signals. Engine speed is measured by crankshaft speed (position) sensor and camshaft

speed (position) sensor determines injection order and ECU detects driver's pedal position (driver's

demand) through electrical signal that is generated by variable resistance changes in accelerator pedal

sensor. HFM (Hot Film Air Mass) sensor detects intake air volume and sends the signals to ECU.

Especially, the engine ECU controls the air-fuel ratio by recognizing instant air volume changes from air flow

sensor to decrease the emissions (EGR valve control). Furthermore, ECU uses signals from coolant

temperature sensor and air temperature sensor, booster pressure sensor and atmospheric pressure sensor

as compensation signal to respond to injection starting, pilot injection set values, various operations and

variables.

Page 213 of 600

0000-00

HP PumpFuel Line

Injector (7-way Injection and C3I Coding)Fuel filter Priming Pump

Common Rail

2. COMPONENTS OF FUEL SYSTEM

Fuel nozzle

holes (7)

Injector

Fuel pipe

High pressure fuel pip Fuel rail pressure sensor

Fuel filter

Connector

Priming

pump

Fuel from

HP pumpFuel filter

HP pumpFuel tank

Fuel tank

Common rail

Fuel return

port

Low pressure

fuel supply port

Venturi

High pressure

fuel supply port

(orifice included)

Fuel

temperature

sensor

IMV valve

Fuel return

port

IMV

connector

Page 214 of 600

3. HYDRAULIC CYCLE IN FUEL LINE

(TRANSFER AND HIGH PRESSURE LINE)

Page 223 of 600

1533-01

Throttle Body

CDPF system controls the amount of intake air by controlling the

electronic throttle body. The electronic throttle body has the

following main functions.

CDPF control - added a function that increases the exhaust gas

temperature by closing the throttle valve flap to minimize the intake

air amount by the fuel injection amount during the CDPF

regeneration range with the low engine load range.

ON/OFF control - prevents the engine from turning off with

vibration and noise by closing the throttle body flap to block the

intake air when the engine is stopped.

Duty control - controls the valve inside the throttle body to burn

more EGR gas in the EGR valve operating range.

VGT Turbocharger and Front Exhaust Gas Temperature Sensor

Turbocharger may become weaker if high tem-

perature exhaust gas passes through the tur-

bocharger for DPF regeneration process.

The front exhaust gas temperature sensor moni-tors

the temperature of the exhaust gas that flows into the

turbocharger.

If the temperature of the exhaust gas that passes

through the exhaust manifold is higher than the

specification, the ECU decreases the fuel injection

amount and increases the EGR gas intake amount to

decrease the exhaust gas temperature.Front exhaust gas

temperature sensor