SSANGYONG NEW REXTON 2012 Service Manual

NEW REXTON 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57514/w960_57514-0.png

SSANGYONG NEW REXTON 2012 Service Manual

Page 189 of 600

E-EGR Valve

EGR cooler

PCV oil separator

The first separation will happen when blow-by

gas passes through baffle plates in cylinde

r

head cover. Then oil and gas will be separated

due to cyclone effect after entering the oil

separator inlet port. Separated oil returns to oil

pan via oil drain port and the gas will be burnt

again after entering the combustion chambe

r

through air duct hose via PCV valve that

opens/closes due to pressure differences

between the intake side and crankcase.Blow-by gas (air

duct hose)

Oil (oil gauge pipe) Cylinder head cover (oil + gas)

Inlet port

5. LAYOUT OF EXHAUST SYSTEM

VGT Turbocharger

Vacuum

modulator

To exhaust

pipe (DOC)

From exhaust manifold

Page 192 of 600

0000-00

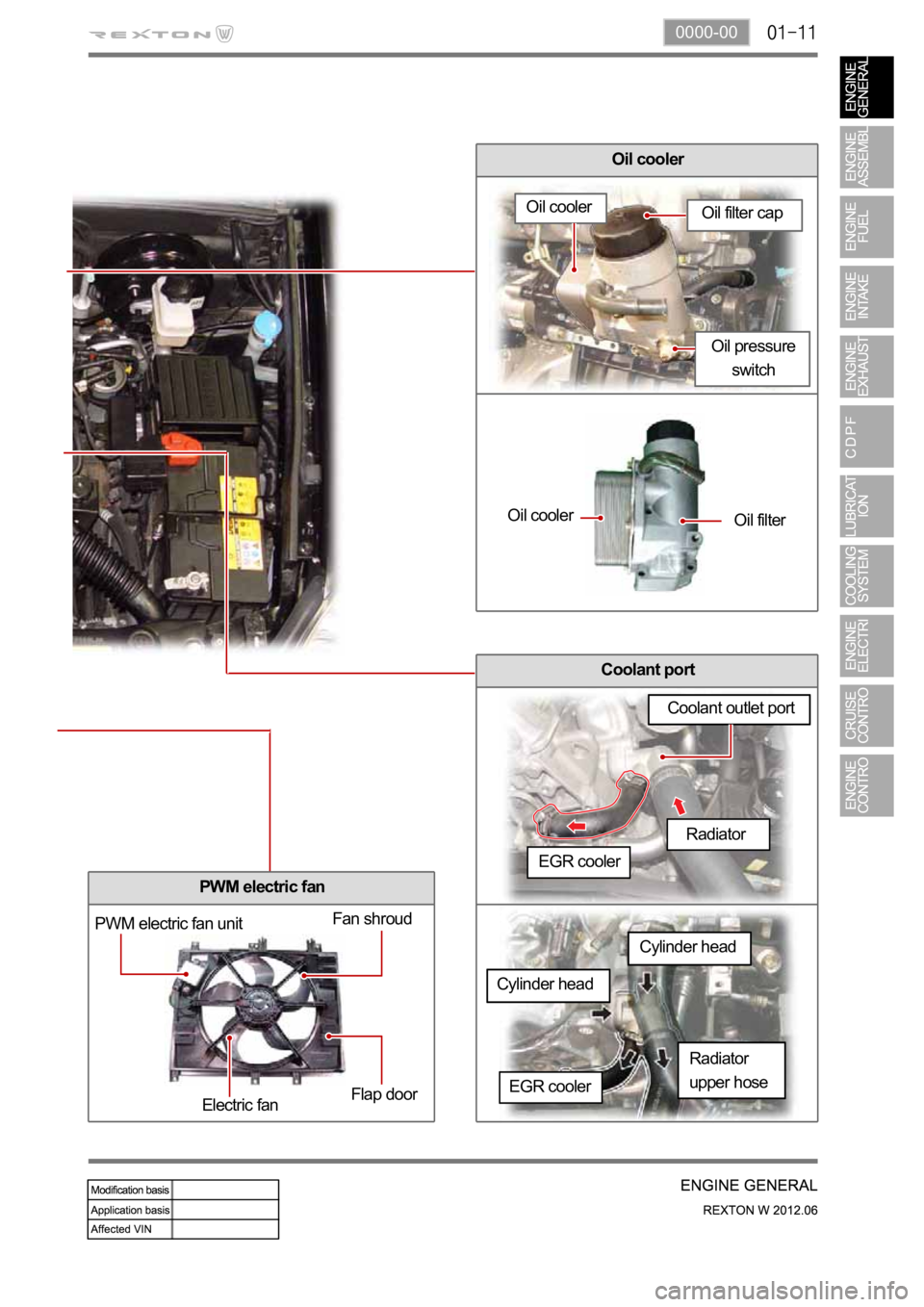

Coolant port

Oil cooler

Oil filter capOil cooler

Oil cooler

Oil filter

PWM electric fan unitFan shroud

Electric fanFlap door

Cylinder headCylinder head

EGR coolerRadiator

upper hose

EGR cooler

Radiator

Oil pressure

switch

PWM electric fan

Coolant outlet port

Page 193 of 600

Oil pan and baffle plate (integrated type) Oil strainer

Heavy-duty PCV oil separator

7. LAYOUT OF LUBRICATION SYSTEM

The first separation will happen when blow-by gas

passes through baffle plates in cylinder head

cover. Then oil and gas will be separated due to

cyclone effect after entering the oil separator inlet

port. Separated oil returns to oil pan via oil drain

port and the gas will be burnt again after entering

the combustion chamber through air duct hose

via PCV valve that opens/closes due to pressure

differences between the intake side and

crankcase.

Cylinder head

cover (oil + gas)Intake air

duct hose

(blow-by gas)

Baffle plate

Oil gauge pipe

Oil dipstick gauge

Page 194 of 600

0000-00

Cylinder head cover

Low oil pressure warning lamp (on

instrument cluster)

Oil filter and oil cooler

Oil

coolerOil

filter

Page 200 of 600

0000-00

Oil Temperature/Pressure and Boost Pressure

Page 205 of 600

4. CAUTION WHEN SERVICING THE ENGINE

1) Cleaness

Engine has a lot of precisely machined (grinding, polishing, lapping) surfaces. Thus, there should be

great cautions for cleaness when servicing the engine components. Apply the engine oil on the sliding

surfaces when assemblying the components. Every component should be disassembled and

reassembled in accordance with the correct sequences. Before servicing the engine, the negative cable

should be diconnected from the battery. Otherwise, some electric or electronic components could be

damaged.

2) Servicing

Before service work, be sure to disconnect battery negative (-) terminal to prevent damages by bad

wire and short.

To prevent the foreign material from getting into engine cylinder, cover the inlet of air cleaner if the

air cleaner has been removed.

(1) Lifting up the vehicle

Always keep the safety precautions.

To prevent the vehicle from rolling down, put the chocks under the tires (when using a 4-post lift).

Make sure to support the correct lifting points (when using a 2-post lift) -

-

-

(2) Exhaust system

Wear the safety glove when removing the exhaust pipe.

Make sure that the exhaust pipe is cooled before removing it. -

-

(3) Cautions before service

Scalding hot coolant and steam could be blown out under pressure, which could cause serious injury.

Never remove the coolant reservoir cap when the engine and radiator are hot.

Page 233 of 600

0000-00

1. SPECIFICATIONS

Frequent stop-and-go traffic, extended idling, short driving distance below 6 km, driving distance

below 16 km when the outside temperature remains below freezing

Driving in a hilly or mountainous terrain, sandy, or dusty area

High load driving such as trailer towing

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed) *

-

-

-

-

Engine Oil Quality classSsangyong genuine engine oil (Approved by MB

Sheet 229.1 or 229.3 or 229.31 for DSL/GSL ENG

without CDPF)

(Approved by MB Sheet 229.31 for DSL ENG with

CDPF)

Viscosity: MB sheet No. 224.1

Capacity

Service

intervalEUInitial check: 5,000 km, and replenish if necessary,

change every 20,000 km or 12 months (But,

shorten the service interval under severe condition)

GeneralInitial change: 5,000 km, change every 15,000 km

or 12 months (But, shorten the service interval

under severe conditions)

Engine oil filterSame interval with the engine oil

Oil filter relief valve opening pressure

Page 234 of 600

PCV Oil Separator

Oil Pan & Baffle Plate (Integrated type) Oil Strainer

The first separation will happen when blow-by gas

passes through baffle plates in cylinder head cover.

Then oil and gas will be separated due to cyclone

effect after entering the oil separator inlet port.

Separated oil returns to oil pan via oil drain port and

the gas will be burnt again after entering the

combustion chamber through air duct hose via

PCV valve that opens/closes due to pressure

differences between the intake side and crankcase.

Cylinder head cover (oil + gas)

Oil (gauge pipe)

Oil (gauge pipe) Inlet port

Oil dipstick gauge

1. LAYOUT OF LUBRICATION SYSTEM

Page 235 of 600

0000-00

Low Oil Pressure Warning Lamp (Instrument

Cluster)

Oil Pressure SwitchCylinder Head Cover

Oil coolerOil filter

Oil Filter & Oil Cooler

Page 258 of 600

2. MAJOR COMPONENTS

Front view

Vacuum pump

Camshaft position sensor

Oil filter assembly

Power steering pump pulley

Oil pressure switch

Idler pulley No. 2

Water pump pulley

Alternator pulley

Auto tensioner

Idler pulley No. 1

A/C compressor pulley

Rear view

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

IMV valve Crankshaft position sensor

Isolation damper