oil SSANGYONG RODIUS 2005 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2005, Model line: RODIUS, Model: SSANGYONG RODIUS 2005Pages: 502, PDF Size: 70.43 MB

Page 136 of 502

0-3

ENGINE LUBRICATION SYSTEM

RODIUS 2005.07

9210-01

0000LUBRICATION SYSTEM

1. ENGINE OIL SPECIFICATION

1) components

1. Drain plug .................................... 25 Nm (18 lb-ft)

2. Oil filter3. Engine oil filler cap

4. Dipstick gauge

2) Specifications

Page 137 of 502

0-4

RODIUS 2005.07

9210-01

ENGINE LUBRICATION SYSTEM

3) Replacement

Install the socket wrench A9910 0050A

(103 589 02 09 00) on the oil filter cover (2).

1.

Tighten the bolts on the socket wrench to

remove the screw cover.

Set a wrench on the bolt on the top of

socket wrench and turn it to remove the

oil filter cover.

Remove the oil filter element.

2.

3.

Wrap the used filter element with a shop

cloth so that the oil cannot drop on the floor.

Remove the drain plug (1) and drain the

engine oil completely.

4.

To drain the oil easily, remove the oil filler

cap (3).

Clean the drain plug and reinstall it.

5.

Replace the seal washer with new one.

Replace the O-ring (5) on the oil filter

cover with new one.

6.

When replacing, apply the engine oil on the

O-ring.

Insert new oil filter element into the oil

filter housing.

Temporarily tighten the oil filter cover (2)

by hands and then tighten it with the

socket wrench A9910 0050A

(103 589 02 09 00).

7.

8.

Pour the engine oil through the engine oil

filler hole. Run the engine and check for oil leakage

at normal operating temperature.

Stop the engine and wait for 5 minutes.

Check the oil level and add if necessary.

9.

10.

11.

Page 140 of 502

0-7

ENGINE LUBRICATION SYSTEM

RODIUS 2005.07

9210-01

1. OIL CIRCULATION

1. Oil pump

2. Oil gallery (to oil filter)

3. Oil filter

4. Oil pressure switch

5. Main oil gallery

6. Cylinder head closing cover

7. Oil gallery (at chain tensioner)

8. Oil non-return valve

9. Chain tensioner

10. Vent (chain tensioner)

11. Front closing cover (φ 17 mm)

12. Oil gallery (perpendicular to the shaft)

13. Ball (φ 6 mm)

14. Oil spray nozzle (timing chain)

15. Oil gallery (at cylinder head)

16. Ball (φ 15mm)

17. Oil restriction inner (φ 4mm)

18. Oil supply (to exhaust camshaft)19. Oil supply (to intake camshaft)

20. Oil supply (to exhaust camshaft bearing)

21. Oil supply (to intake camshaft bearing)

22. Oil gallery (oil supply to exhaust valve tappet)

23. Oil gallery (oil supply to intake valve tappet)

24. Camshaft closing cover

25. Ball (φ 8 mm)

26. Screw plug

27. Camshaft adjuster

28. Front closing cover (intake camshaft)

29. Front treaded bushing (exhaust camshaft)

30. Valve tappet

a. Oil gallery (from oil pump to oil filter)

b. Main oil gallery

c. Oil return line (oil returns to the oil pan when

replacing the filter element)

Page 147 of 502

08-9

ENGINE ELECTRIC SYSTEM

RODIUS 2005.07

1452-01

8) STARTER

Wound field starter motors have pole pieces, arranged around the armature, which are

energized by wound field coils.

Enclosed shift lever cranking motors have the shift lever mechanism and the solenoid plunge

r

enclosed in the drive housing, protecting them from exposure to dirt, icy conditions, and

splashes. In the basic circuit, solenoid windings are energized when the switch is closed. The

resulting plunger and shift lever movement causes the pinion to engage the engine flywheel

ring gear. The solenoid main contacts close. Cranking then takes place.

When the engine starts, pinion overrun protects the armature from excessive speed until the

switch is opened, at which time the return spring causes the pinion to disengage.

To prevent excessive overrun, the switch should be released immediately after the engine

starts.

9) STARTING SYSTEM

The engine electrical system includes the battery, the ignition, the starter, the alternator, and all

the related wiring.

Diagnostic tables will aid in troubleshooting system faults.

When a fault is traced to a particular component, refer to that component section of the service

manual.

The starting system circuit consists of the battery, the starter motor, the ignition switch, and all

the related electrical wiring. All of these components are connected electrically.

Page 154 of 502

09-8

RODIUS 2005.07

0452-01

ENGINE CONTROL SYSTEM

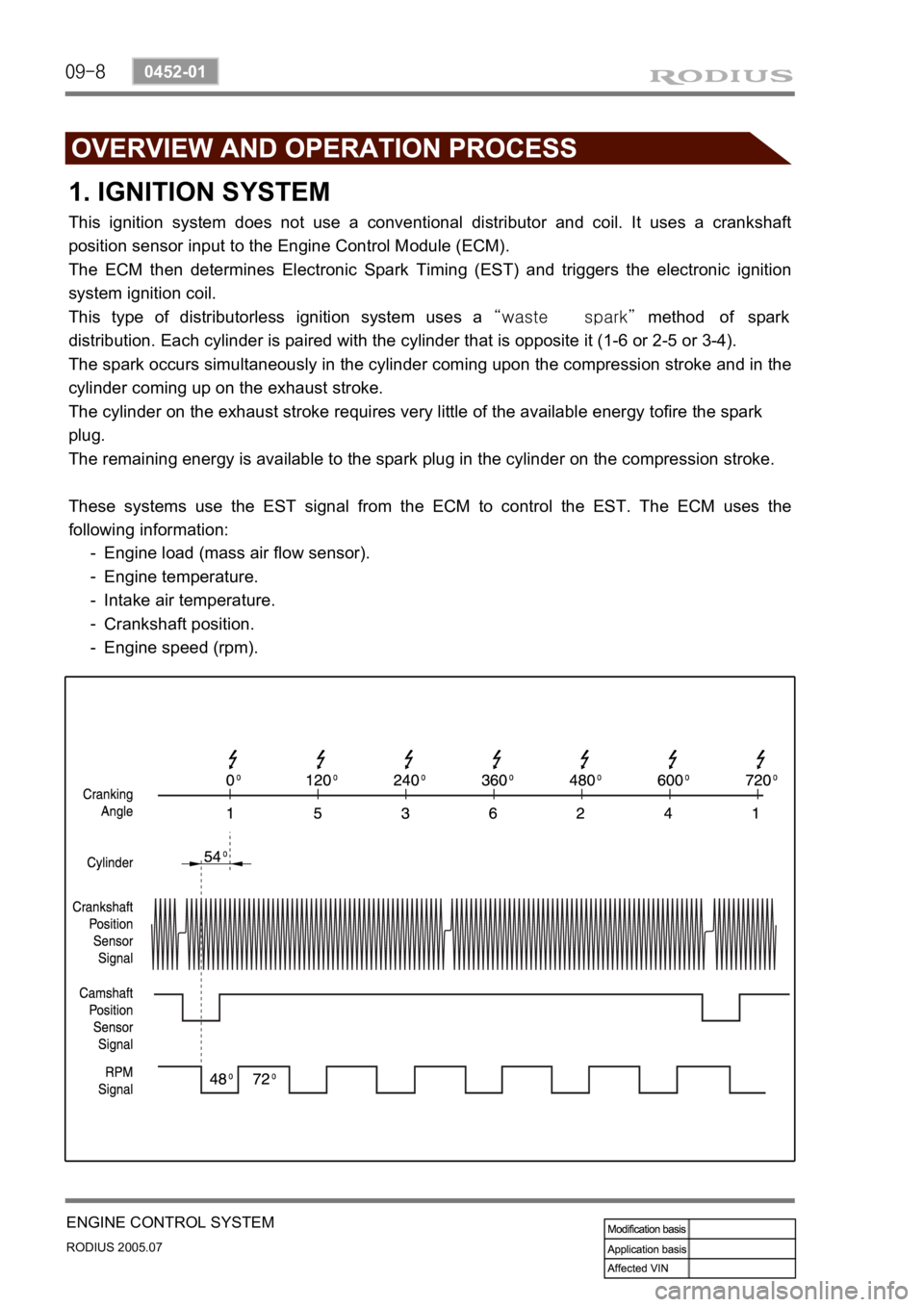

1. IGNITION SYSTEM

This ignition system does not use a conventional distributor and coil. It uses a crankshaft

position sensor input to the Engine Control Module (ECM).

The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition

system ignition coil.

This type of distributorless ignition system uses a “waste spark” method of spark

distribution. Each cylinder is paired with the cylinder that is opposite it (1-6 or 2-5 or 3-4).

The spark occurs simultaneously in the cylinder coming upon the compression stroke and in the

cylinder coming up on the exhaust stroke.

The cylinder on the exhaust stroke requires very little of the available energy tofire the spark

plug.

The remaining energy is available to the spark plug in the cylinder on the compression stroke.

These systems use the EST signal from the ECM to control the EST. The ECM uses the

following information:

Engine load (mass air flow sensor).

Engine temperature.

Intake air temperature.

Crankshaft position.

Engine speed (rpm). -

-

-

-

-

Page 161 of 502

09-15

ENGINE CONTROL SYSTEM

RODIUS 2005.07

0452-01

2) ECU (GSL G32)

IGN COIL, CPS, AIR FLOW SENSOR, THROTTLE SENSOR, TPS ▶

Page 165 of 502

0-4

RODIUS 2005.07

3650-01

DC 5-SPEED AUTOMATIC TRANSMISSION

2. STRUCTURE

Torque converter

Oil pump

Input shaft

Disc brake B1

Disc clutch C1

Disc clutch C2 1.

2.

3.

4.

5.

6.Disc brake B3

Disc clutch C3

Disc brake B2

Output shaft

Parking lock gear

Intermediate shaft 7.

8.

9.

10.

11.

12.Freewheel F2

Center planetary gear set

Electric control unit (valve body)

Freewheel F1

Stator shaft

Converter lockup clutch 13.

14.

15.

16.

17.

18.

Page 173 of 502

0-12

RODIUS 2005.07

3650-01

DC 5-SPEED AUTOMATIC TRANSMISSION

Name and Part Number Application

128 589 04 31 00

Measuring bridge

W 208 589 00 21 00

Compressor

W 140 589 15 21 00

Pipstick guage Compressing clutch and disc brake

Measuring the oil levelMeasuring the clearance between ball

bearing and parking lock gear

Page 191 of 502

0-9

TRANSFER CASE

RODIUS 2005.07

3410-01

Ring, snap

Ring, snap

Ring, snap

Bearing

Hub, circular

Asm. -shaft, input

Plate, thrust

Gear, sun

Snap ring

Asm. -carrier (complete)

Hub reduction

Asm. -shaft, main

Clamp hose

Hose

Filter

Asm. -coil, electric

Asm. -cam/coil hsg.

Ring, snap

Armature

Hub, lockup

Spring, sleeve return

Collar, lockup

Sprocket, driving

Spring, return

Rail, shift

Fork, shift

Asm. -fork, shift

Cam, electric shift

Spring, torsion

Spacer

Shaft, shift

Ring, retaining

Asm. -case, transfer

Barb, breather 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.Decal

Shaft, output

Deflector, dust

Magnet

Ring snap

Sprocket lower

Spacer

Chain

Ring retaining

Bearing

Bearing

Cover

Bendable clip

Bolt, Metric

Seal, oil

Washer

Nut, Metric

Flange, companion

Seal, oil

Spacer

Tone wheel (upper)

Nut, Metric

Clip, “J”

Bolt, hex head

Bracket, relay mounting

Locking clip

Connector

Bolt, hex head

Capscrew, hex head

Asm. -motor, electric

Seal, oil

Plug, pipe

Sealing Compound 35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

Page 215 of 502

0-8

RODIUS 2005.07

3240-01

TORQUE ON DEMAND

(3) Electro Magnetic Clutch (EMC)

EMC consists of coil and housing. TOD control unit controls EMC by controlling duty cycle

according to the road and driving conditions. These controls use the continuity time and amount

of electric current to determine the torque to be transmitted to front wheels.

Basic controls in EMC ▶