wiring SSANGYONG RODIUS 2006 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2006, Model line: RODIUS, Model: SSANGYONG RODIUS 2006Pages: 444, PDF Size: 56.32 MB

Page 223 of 444

0-11

CLUSTER

RODIUS 2007.07

8010-10

4) Coolant Temperature Gauge

The coolant temperature gauge displays the coolant temperature with a pointer. The angle of

pointer that changes by coolant temperature is as shown below.

Measurement of coolant temperature sensor resistance

Measure the resistance between the terminal and the ground with an ohmmeter and replace i

f

the resistance is out of specified range.

Resistance value by coolant temperature:

20°C : 2449 Ω ±5 %

50°C : 826 Ω ±5 %

80°C : 321 Ω ±5 %

100°C : 112 Ω ±5 %

When the resistance value by coolant temperature is within the specified range, check

thermostat, water pump, radiator related coolant circuit for normal operation. Also, check the

wiring harnesses and connectors for proper connection.

-40 040° °°

Page 329 of 444

0-11

ABS SYSTEM

RODIUS 2007.07

4892-01

Use only DOT-3 equivalent hydraulic brake fluid. The use of DOT-5 (silicone) brake fluid is

not recommended. Reduced brake performance or durability may result.

Avoid spilling brake fluid on any the vehicle’s painted surfaces, wiring, cables or

electrical connectors. Brake fluid will damage paint and electrical connections. If any fluid is

spilled on the vehicle, flush the area with water to lessen the damage.

Page 334 of 444

0-16

RODIUS 2007.07

4892-01

ABS SYSTEM

Service precautions ▶

Observe the following general precautions during any ABS/TCS service. Failure to adhere to

these precautions may result in ABS/TCS system damage.

Disconnect the EBCM harness connector before performing the electric welding procedures.

Carefully note the routing of the ABS/TCS wiring and wiring components during removal.

The ABS/ TCS components are extremely sensitive to EMI (eletromagnetic interference).

Proper mounting is critical during component service.

Disconnect the EBCM connector with the ignition OFF.

Do not hang the suspension components from the wheel speed sensor cables. The cables

may be damaged.

Do not use petroleum based fluids in the master cylinder. Do not use any containers

previously used for petroleum based fluids. Petroleum causes swelling and distortion of the

rubber components in the hydraulic brake system, resulting in water entering the system

and lowering the fluid boiling point. 1.

2.

3.

4.

5.

Page 361 of 444

0-10

RODIUS 2007.07

6810-20

AIR CONDITIONING SYSTEM

2. AIR CONDITIONER MODULE WIRING AND LAYOUT

1) Front Air Conditioner Module

Wiring layout

Components

Air source selection

door actuatorAir conditioner filterEvaporator

Blower

motor

Blower high

speed relay

Heater core

Page 362 of 444

0-11

AIR CONDITIONING SYSTEM

RODIUS 2007.07

6810-20

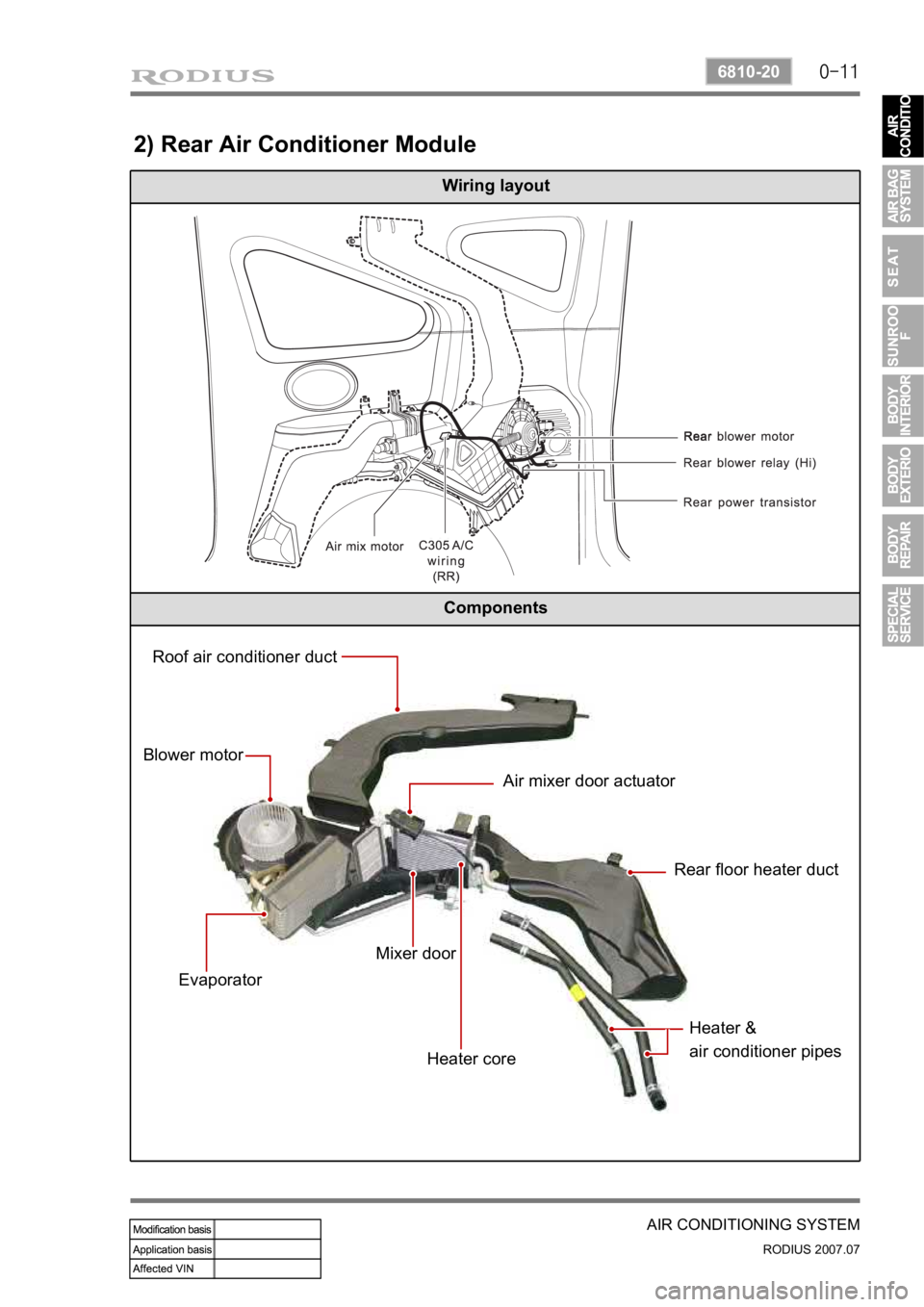

2) Rear Air Conditioner Module

Wiring layout

Components

Roof air conditioner duct

Blower motor

EvaporatorAir mixer door actuator

Rear floor heater duct

Mixer door

Heater coreHeater &

air conditioner pipes

Page 366 of 444

0-15

AIR CONDITIONING SYSTEM

RODIUS 2007.07

6810-20

(3) Inspection

If the active incar sensor defect code (DTC 1) and the humidity sensor defect code (DTC 10)

are set, check as below:

Air conditioner controller

Air conditioner controller connector (based on wiring) AIH sensor (based on sensor)

Active incar sensor

▶

Remove the integrated AIH sensor and measure the resistance between terminal No. 5 and

6 on the sensor connector. (standard: approx. 25°C, 2.2 kΩ)

If the measured value is out of the specified range, replace the AIH sensor. If the measured

values are within the specified range, check as below.

Turn the ignition switch to ON position and measure the voltage to active incar sensor from

the FATC controller connector. (standard: approx. 2 V at 25°C)

If the voltage value cannot be measured, check the circuit for open. If the measured value is

within the specified range, replace the FATC controller.

1.

2.

3.

4.

Page 387 of 444

0-8

RODIUS 2007.07

8810-01

AIR BAG SYSTEM

6) Contact Coil

The contact coil is installed between the steering wheel and the steering column and contains a

coil that enables to contact electrically between the airbag wiring harness, the driver airbag

module and the horn switch.

Turning the steering wheel more than three and onequarter turns may damage the clock

spring. The contact coil should never be disassembled and must be replaced if the airbag

have been deployed. -

Turn the label of the clock spring clockwise to lock and turn the label of the clock spring

counterclockwise approximately 2.9 ± 0.2 turns to the neutral positions with the front

wheels ahead.

Align the pointed marks “43”. -

7) Accelometer Sensor

The accelerometer sensor electronically represents the acceleration or deceleration of the

vehicle during a frontal impact.

In this electronic representation, the electrical signal is proportional to the acceleration o

r

deceleration of the vehicle.

8) Safety Sensor

The safety sensor is safety device made up of a dualcontact, electro-mechanical switch that:

Acts independently of the electronic components.

Connects the acceleration sensor in series in order to make up for the weak points in the

current electronic sensor. 1.

2.

Page 389 of 444

0-10

RODIUS 2007.07

8810-01

AIR BAG SYSTEM

11) Wiring Harness Connectors

If the sensing and diagnostic module (SDM) electrical connector is not attached properly, a built

in shorting bar will connect the wire from airbag warning lamp with the SDM ground wire. This

turns on the AIRBAG indicator.

To prevent deployment during servicing, additional shorting bars are located in following

locations:

Driver airbag module connector

Passenger airbag module connector

Driver and passenger side airbag module connector

SDM wiring harness connector

Contact coil connector to airbag wiring harness ·

·

·

·

·

The shorting bar is only a backup safety device. Always disable the supplemental restraints

system (SRS) before beginning any service procedure.

12) Belt Pretensioner

The belt pretensioner enables to retract the driver and the passenger seat belt webbing to

reduce any personal impact when accounted a frontal collision.

Page 410 of 444

0-21

SEAT

RODIUS 2007.07

7410-01

3) Seat electrical equipment check

Disconnect the seat wiring connector and check if the power is supplied (Refer to the wiring

diagram)

·

1) If the power supply has no problem, remove the seat.

2) Check the motor and wiring if damaged.

3) Connect the battery to the seat connector.

4) Control the seat switch and check the opration.

- Electrical parts are not supplied by a part separately.