SSANGYONG RODIUS 2006 Service Manual

RODIUS 2006

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57523/w960_57523-0.png

SSANGYONG RODIUS 2006 Service Manual

Trending: catalytic converter, gas mileage, air condition, timing belt, warning light, audio, ESP

Page 281 of 444

0-8

RODIUS 2007.07

3240-01

TORQUE ON DEMAND

(3) Electro Magnetic Clutch (EMC)

EMC consists of coil and housing. TOD control unit controls EMC by controlling duty cycle

according to the road and driving conditions. These controls use the continuity time and amount

of electric current to determine the torque to be transmitted to front wheels.

Basic controls in EMC ▶

Page 282 of 444

0-9

TORQUE ON DEMAND

RODIUS 2007.07

3240-01

3) Signal Flow

Page 283 of 444

0-10

RODIUS 2007.07

3240-01

TORQUE ON DEMAND

4) Power Flow

(1) 4H Mode (4WD Drive - High Speed)

Page 284 of 444

0-11

TORQUE ON DEMAND

RODIUS 2007.07

3240-01

(2) 4H Mode (4WD Drive - Low Speed)

Page 285 of 444

0-12

RODIUS 2007.07

3240-01

TORQUE ON DEMAND

3. OPERATION

1) System Layout

Page 286 of 444

0-13

TORQUE ON DEMAND

RODIUS 2007.07

3240-01

2) 4WD Operation Overview

To make the mode shift easier, stop the vehicle, depress the brake pedal, select the mode

switch, and move the selector lever with the sequence of [N-P-N].

3) Mode Switch

Selection Mode ▶

The TOD system has 2 selectable mode, 4H and 4L.

4H is the normal operating mode when drive of which gear ratio is 1:1 and 4L mode distributes

power to front and rear wheels 50:50 of which gear ratio is 2.48:1.

4L Mode ▶

When selecting 4L mode, EMC is locked to apply maximum torque into front and rear propelle

r

shafts (when the wheel speed is more than 87Hz).

Shift motor rotates also 4L position by rotation of cam thus propeller shaft torque changes from

1:1 to 2.48:1 by planetary gear set.

Releasing the 4L Mode ▶

When selecting 4H mode, 4L drive mode is

released and 4H mode is resumed.

“4H” switch: Self-return type

“4L” switch: Push lock type ·

·

Page 287 of 444

0-14

RODIUS 2007.07

3240-01

TORQUE ON DEMAND

4. CIRCUIT DIAGRAM

Page 288 of 444

0-33310-01

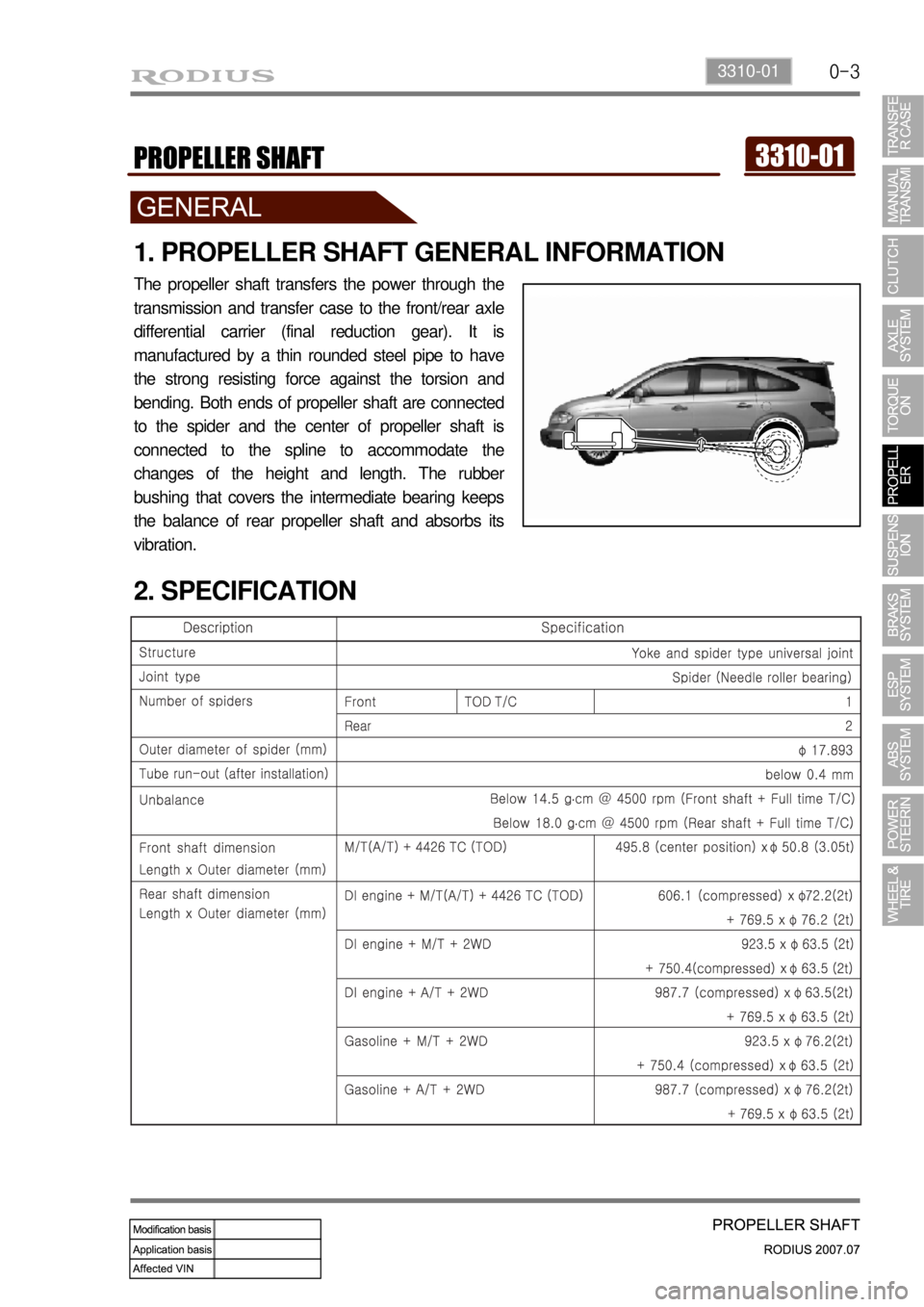

1. PROPELLER SHAFT GENERAL INFORMATION

The propeller shaft transfers the power through the

transmission and transfer case to the front/rear axle

differential carrier (final reduction gear). It is

manufactured by a thin rounded steel pipe to have

the strong resisting force against the torsion and

bending. Both ends of propeller shaft are connected

to the spider and the center of propeller shaft is

connected to the spline to accommodate the

changes of the height and length. The rubbe

r

bushing that covers the intermediate bearing keeps

the balance of rear propeller shaft and absorbs its

vibration.

2. SPECIFICATION

Page 289 of 444

0-4

RODIUS 2007.07

3310-01

PROPELLER SHAFT

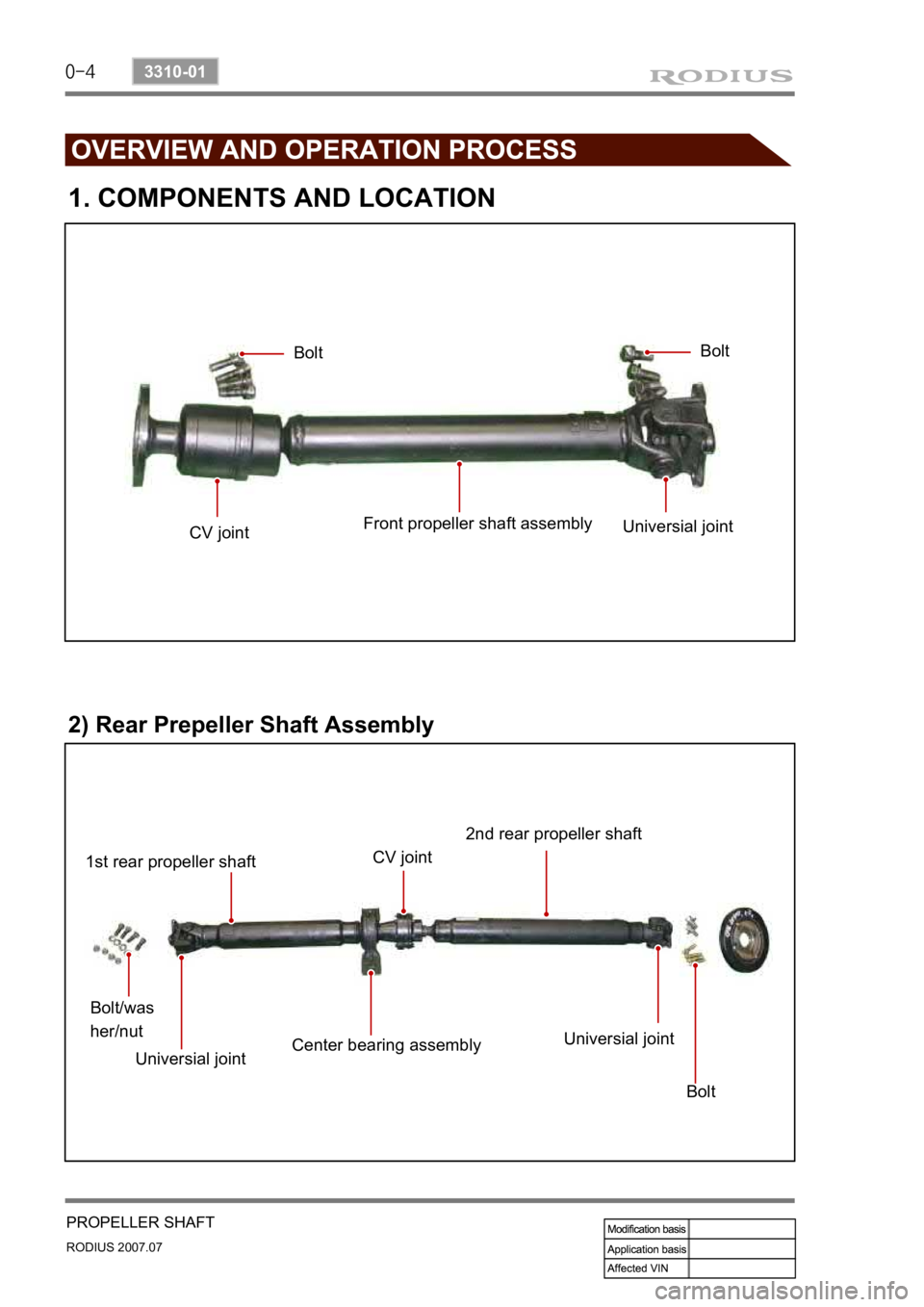

1. COMPONENTS AND LOCATION

1) Front Prepeller Shaft Assembly

2) Rear Prepeller Shaft Assembly

Bolt Bolt

CV joint Front propeller shaft assembly

Universial joint

Bolt/was

her/nut

Universial joint

1st rear propeller shaft

Center bearing assembly

CV joint

2nd rear propeller shaft

Universial joint

Bolt

Page 290 of 444

0-3

SUSPENSION SYSTEM

RODIUS 2007.07

4111-01

4410-01SUSPENSION SYSTEM

1. FRONT SUSPENSION SPECIFICATION

Trending: jack points, fuel pump, odometer, octane, traction control, differential, ELECTRICAL