change time SSANGYONG RODIUS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 513 of 715

09-6

Gear shift lever

- Sends the back-up signal to PAS

unit.

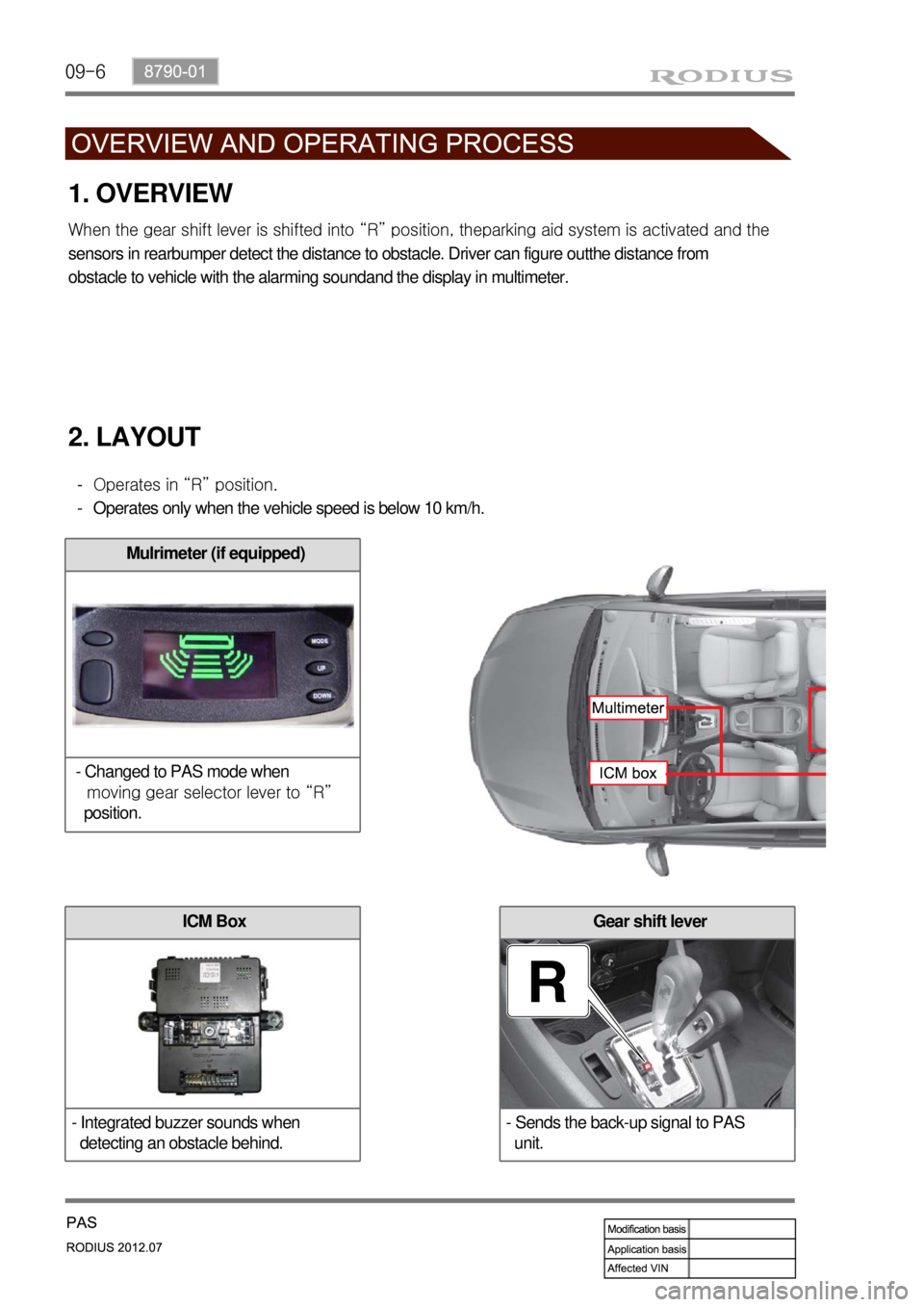

1. OVERVIEW

<007e008f008c00950047009b008f008c0047008e008c008800990047009a008f0090008d009b00470093008c009d008c009900470090009a0047009a008f0090008d009b008c008b004700900095009b0096004702c8007902c9004700970096009a009000

9b00900096009500530047009b008f008c0097008800990092>ing aid system is activated and the

sensors in rearbumper detect the distance to obstacle. Driver can figure outthe distance from

obstacle to vehicle with the alarming soundand the display in multimeter.

2. LAYOUT

Operates in “R” position.

Operates only when the vehicle speed is below 10 km/h. -

-

Mulrimeter (if equipped)

- Changed to PAS mode when

moving gear selector lever to “R”

position.

ICM Box

- Integrated buzzer sounds when

detecting an obstacle behind.

Page 541 of 715

02-33170-01

Description Specification

Basic structure 2-shaft, 6-speed (directly connected 4 gears)

Gear ratio 1st 4.489 : 1

2nd 2.337 : 1

3rd 1.350 : 1

4th 1.000 : 1

5th 0.784 : 1

6th 0.679 : 1

Reverse 4.253 : 1

Synchronizer

ring type1st T: Triple-cone

2nd T: Triple-cone

3rd T: Triple-cone

4th S: Single-cone

5th D: Double-cone

6th S: Single-cone

Reverse T: Triple-cone

Shifting Type Floor change type

Gear selector

lever position

Transmission

fluidType HD MTF 75W/85 (SHELL) or HK MTF 75W/85(SK)

Capacity2.2 ℓ

Sercive interval Inspect and replenish every 60000 km or 3 years (under

severe driving conditions, change every 120,000 km)

1. SPECIFICATION

Reversing:

High-force type

What’s the severe conditions?

Towing a trailer or off-road driving (Inspect the leak of fluid at any time, occasionlly)

Taxi, patrol service or delivery service (extended idling and excessive driving with low speed)

Frequent stop-and-go traffic, extended idling, short driving distance

Driving in a hilly or mountainous terrain, sandy, or dusty area

Driving frequently at high speed over 170 km/hour

<006b00990090009d00900095008e0047008d0099008c0098009c008c0095009b009300a0004700900095004700880099008c00880047009e008f008c0099008c0047008f008c0088009d00a00047009b00990088008d008d0090008a0047009c0095008b00

8c00990047009b008f008c00470088009400890090008c0095>t temperature above 30°C -

-

-

-

-

-

Page 564 of 715

03-73010-00

1. OVERVIEW

The hydraulic clutch transmits the force required to operate the clutch pedal to the concentric

slave cylinder fitted to the clutch housing as a hydraulic pressure.

(The hydraulic pressure is transmitted in the following order: Clutch pedal - Clutch master cylinder

- Clutch pipe - Clutch damper - Clutch pipe and hose - Concentric slave cylinder - Pressure

plate - Flywheel.)

If a driver depress the clutch pedal, the hydraulic pressure is generated in the master cylinder. It is

transmitted to the concentric slave cylinder through the pipe, resulting in the cylinder being forced

out. At this time, the clutch disc is forced against the cylinder by pushing the cover. This, in turn,

remove the flywheel from the pressure plate. As a consequence, the power from the engine will be

cut off and the gear change can be carried out.

Page 571 of 715

05-4

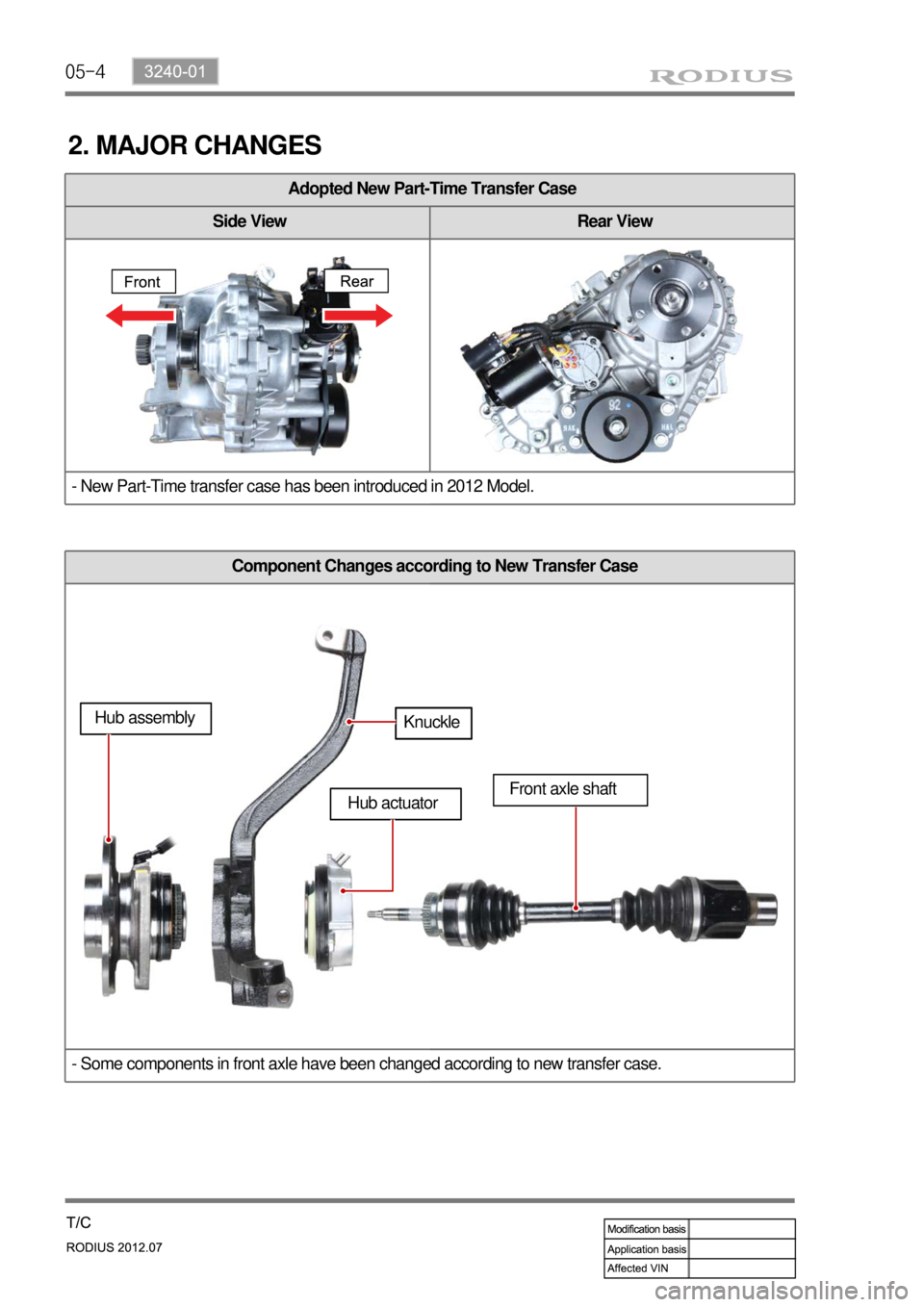

Component Changes according to New Transfer Case

- Some components in front axle have been changed according to new transfer case.

2. MAJOR CHANGES

Adopted New Part-Time Transfer Case

Side View Rear View

- New Part-Time transfer case has been introduced in 2012 Model.

Hub assembly

Knuckle

Front axle shaft

Hub actuator

Page 587 of 715

07-4

3. MAJOR CHANGES

Front Sub Frame

Old New

The engine mounting insulators (A) have been changed according to newly equipped engine

(D20DTR). It improves the durability and NVH.

Front Knuckle Assembly

Old New

The front knuckle assembly has been changed according to new 4WD system (Part-time T/C).

Hub bearingLocking hub

actuator

Page 602 of 715

08-114850-03

Let the engine run for 1 to 2 minutes and

stop it. If the brake pedal stroke is

shortened as pumping the brake pedal,

the system is normal. If not, the system is

defective.

Depress the brake pedal several times with

engine off. If the brake goes down when

starting engine with pedal depressed, the

system is normal. If not, the system is

defective. 1.

2.

Depress the brake pedal when the engine

is running. If the pedal height is not

changed for 30 seconds after stopping the

engine, the system is normal. If not, the

system is defective. 3.

If the above three checks are OK, the system

is normal. If any condition is not met, check

the valve, vacuum hose and brake booster.

3) Brake Booster

OK

NG

Engine stopped

Engine running

Page 623 of 715

09-154891-01

4. SCHEMATIC DIAGRAM

When equipped with ABS, the braking force at each wheel will be controlled with 3-channel 4-

sensor method. And when equipped with ESP, 4 wheels will be controlled independently with 4-

channel method. (When controlling ABS system only, it will be operated with 3-channel method.)

When compared to the vehicle equipped with ABS/EBD only, the internal hydraulic circuit has a

normally-open separation valve and a shuttle valve in primary circuit and in secondary circuit.

When the vehicle brakes are not applied during engine running or when applying the non-ABS

operating brakes, the normally-open separation valve and the inlet valve are open, whereas the

normally-closed shuttle valve and the outlet valve are closed. When the ESP system is operating,

the normally-open separation valve will be closed by the solenoid valve operation and the hydraulic

circuit will be established by the shuttle valve. Then, the inlet and outlet valves will be

closed or open depending on the braking pressure increase, decrease or unchanged conditions.

▶The warning lamp comes on and warning beep sounds when the ESP is operating

Driving feeling when the ESP is operating ▶

▶Noise and vibration that driver senses when the ESP is operating

1) Hydraulic Circuit Diagram

When the ESP operates during vehicle movement, the ESP warning lamp on the instrument

panel flickers and beep comes on every 0.1 seconds. The ESP operation shows that the vehicle

stability is extremely unstable and it is used to warn the driver. The ESP system is just a

supplementary system for the vehicle motion and it cannot control the vehicle when it exceeds

the physical limits. Do not solely rely on the system but be advised to drive the vehicle safely.

When the ESP system activates, the driving feeling can be different depending on vehicle

driving conditions. For example, you will feel differently when the ESP system is activated during

when ABS is operating with the brakes applied and when brakes are not applied on a curve.

Thus, the ESP system would make the driver feel more abruptly when the brakes are applied

during the ESP system activation.

The ESP system may transfer noise and vibration to the driver due to the pressure changes

caused by the motor and valve operations in a very short period of time. Extreme cornering will

trigger the ESP operation and this will make the driver feel noise and vibration due to sudden

brake application. Also, the ESP system controls the engine output. So, the driver may notice

the engine output decrease even when the accelerator pedal is being applied.

Page 646 of 715

11-8

Oil Level Check ▶

Check the fluid level on a level ground with the

engine turned off. The fluid level should be

between the MIN and MAX marks on the

reservoir cap gauge.

Place the vehicle on a level ground and start

the engine and let it run at idle speed.

Turn the steering wheel several times so that

the oil temperature reaches to normal

operating level (75~85˚C).

Place the steering wheel at straight ahead

direction.

Check the oil level in the power steering oil

reservoir. Adjust the oil level between MAX

and MIN. A.

B.

C.

D.

Oil Change ▶

If the difference between two measurements

is below 5 mm and the level is between MAX

and MIN level, it's normal. If it is over 5 mm,

bleed air from the system.

Open the power fluid reservoir cap and drain

the fluid completely with oil suction device.

To make it easy, turn the steering wheel to its

both ends several times.

Fill up the specified fluid into fluid reservoir

and bleed air from the steering system. A.

B.

Oil typeS-PSF3

Capacityapprox. 1.1ℓ

(including reservoir)

below 5

mm

Engine running Engine idling

Page 652 of 715

12-4

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct

line from one bead to the other across the tread. In addition, a radial tire has a belt overwrap

under the tread surface to provide greater structural stability. The belt overwrap of a radial tire

distortion while the radial structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

<009d008c008f0090008a0093008c02c5009a004700940096009d008c0094008c0095009b0055004700700095004700960099008b008c00990047009b00960047008a0096009400970093008c009b008c0047009a009c008a008f0047009b0088009a009200

9a0053004700880047009b00900099008c00470094009c009a>t be structured to be a resilient

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6

mm from the groove bottom. This wear limit mark is not seen from the outside so there is

additional "▲" mark on the shoulder to let the driver find the wear mark easily. To measure the tire

groove depth, measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire

inflation pressure, changed tire location, etc.

1) Structure of Tire

Tread

This thick layer of rubber provides the

interface between the tire and the road.

Wear-resistant rubber is used to protect the

carcass and belt against fractures and

impacts and to deliver a long driving life.

Shoulder

Located between the tread and sidewall, the

shoulder rubber is the thickest so that the

design must allow for the easy diffusion of

heat generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the

flexible sidewall protects the carcass and

enhances the ride. A tire’s type, size,

structure, pattern, manufacturing company,

product name and various characters are

indicated here. Bead

The bead attaches the tire to the rim and

wraps the end of the cord fabric. Comprised

of the bead wire, core, flipper and other parts,

the bead is generally designed to be slightly

tight around the rim so that in the case of a

sudden drop in inflation pressure, the tire will

not fall off the rim.

Carcass

As the most important framework of a tire, the

entire inner layer of cord fabric is called the

carcass. The carcass acts to support air

pressure, vertical load and absorb shocks.

Valve

Belt

Bead core