steering SSANGYONG RODIUS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 612 of 715

09-4

2) Sensor Cluster

3) Steering Wheel Angle Sensor

Air gap between sensor and rotorFront 0.335 ~ 0.945mm

Rear 0.309 ~ 0.958mm

Current (at 2.75 km/h)IHIGH : 14mA

ILOW : 7mA

Voltage (when turning the steering wheel one turn per second) 7.5 ~ 20V

4) Active Wheel Speed Sensor

Operating voltage 9~16V

Maximum output current 10mA

Maximum detection angle speed 1500˚/s

Operating temperature -30~75℃

Supplying voltage 9 to 16 V (battery voltage)

Output voltage (HI) approx. 3.50V (3.0 to 4.1V)

Output voltage (LO) approx. 1.50V (1.3 to 2.0V)

Description Specification

Description Specification

Description Specification

Supplying voltage approx. 5V (4.75~5.25V)

Output voltage while in stationary approx. 2.5V (Ignition ON)

Output range 0.2~4.8V

Operating start speed4˚/s

Page 613 of 715

09-54891-01

1. ESP (Electronic Stability Program)

ESP system contains the ABS (Anti-Lock Brake System), ABD (Automatic Braking Differential),

ASR (Acceleration Slip Regulation), Cornering Control and HBA (Hydraulic Brake Assist System)

functions.

▶Cornering Control (Understeer and Overersteer) Function

This function controls the vehicle stability by applying the braking pressure on each wheel

according to the yaw rate, lateral sensing value and driver’s steering wheel control.

▶HBA (Hydraulic Brake Assist System) Function

HBA (Hydraulic Brake Assist) system helps in an emergency braking situation when the driver

applies the brake fast, but not with sufficient pressure, which leads to dangerously long braking

distance. ECU recognizes the attempt at full braking and transmits the signal calling for full brake

pressure from the hydraulic booster.

Page 614 of 715

09-6

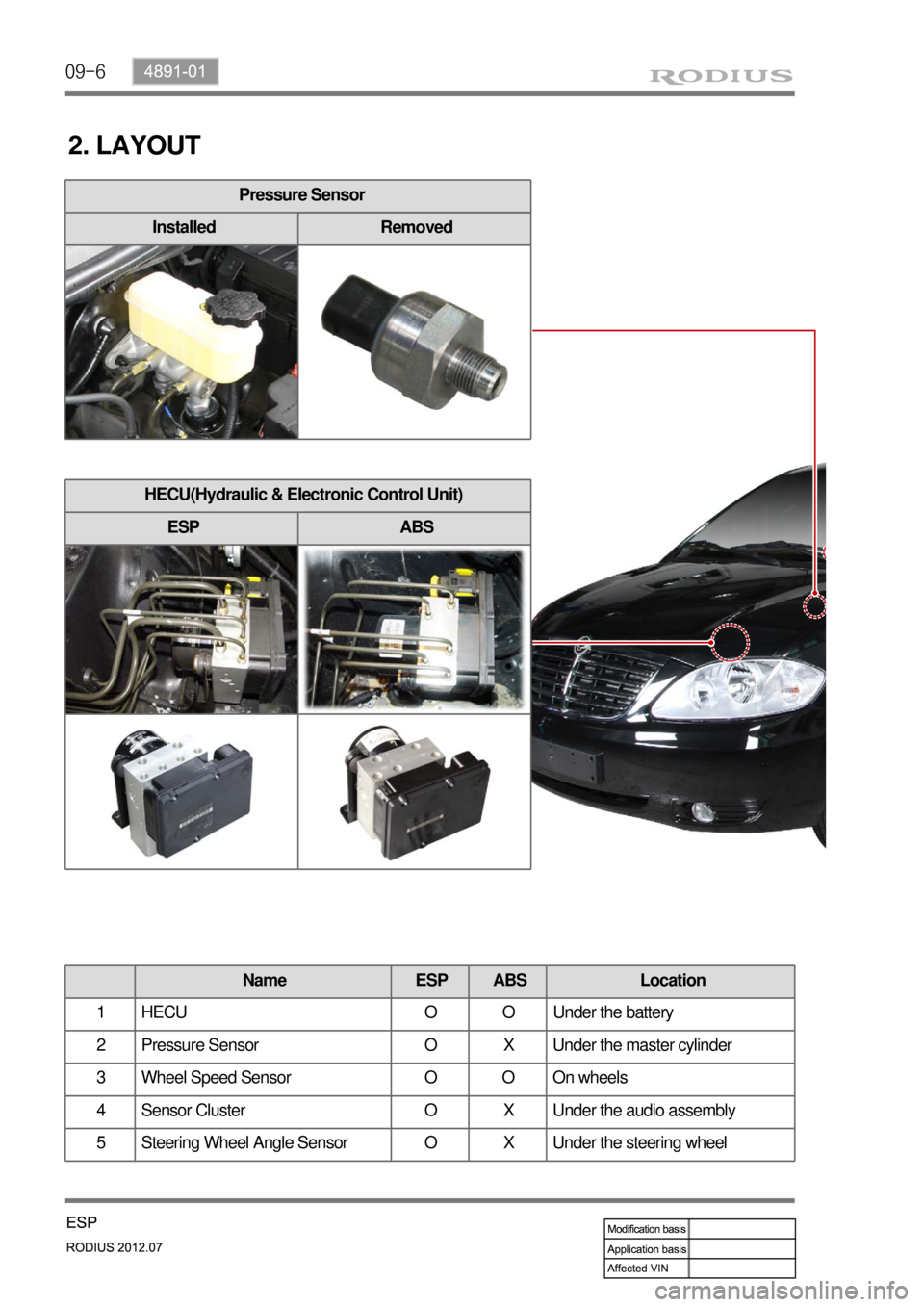

HECU(Hydraulic & Electronic Control Unit)

ESP ABS

2. LAYOUT

Name ESP ABS Location

1 HECU O O Under the battery

2 Pressure Sensor O X Under the master cylinder

3 Wheel Speed Sensor O O On wheels

4 Sensor Cluster O X Under the audio assembly

5 Steering Wheel Angle Sensor O X Under the steering wheel

Pressure Sensor

Installed Removed

Page 615 of 715

09-74891-01

1. ESP Indicator2. Steering Wheel Angle

Sensor

3. ESP OFF Switch 4. Sensor Cluster

Front Wheel Speed Sensor

4WD 2WDRear Wheel Speed

Sensor

Page 617 of 715

09-94891-01

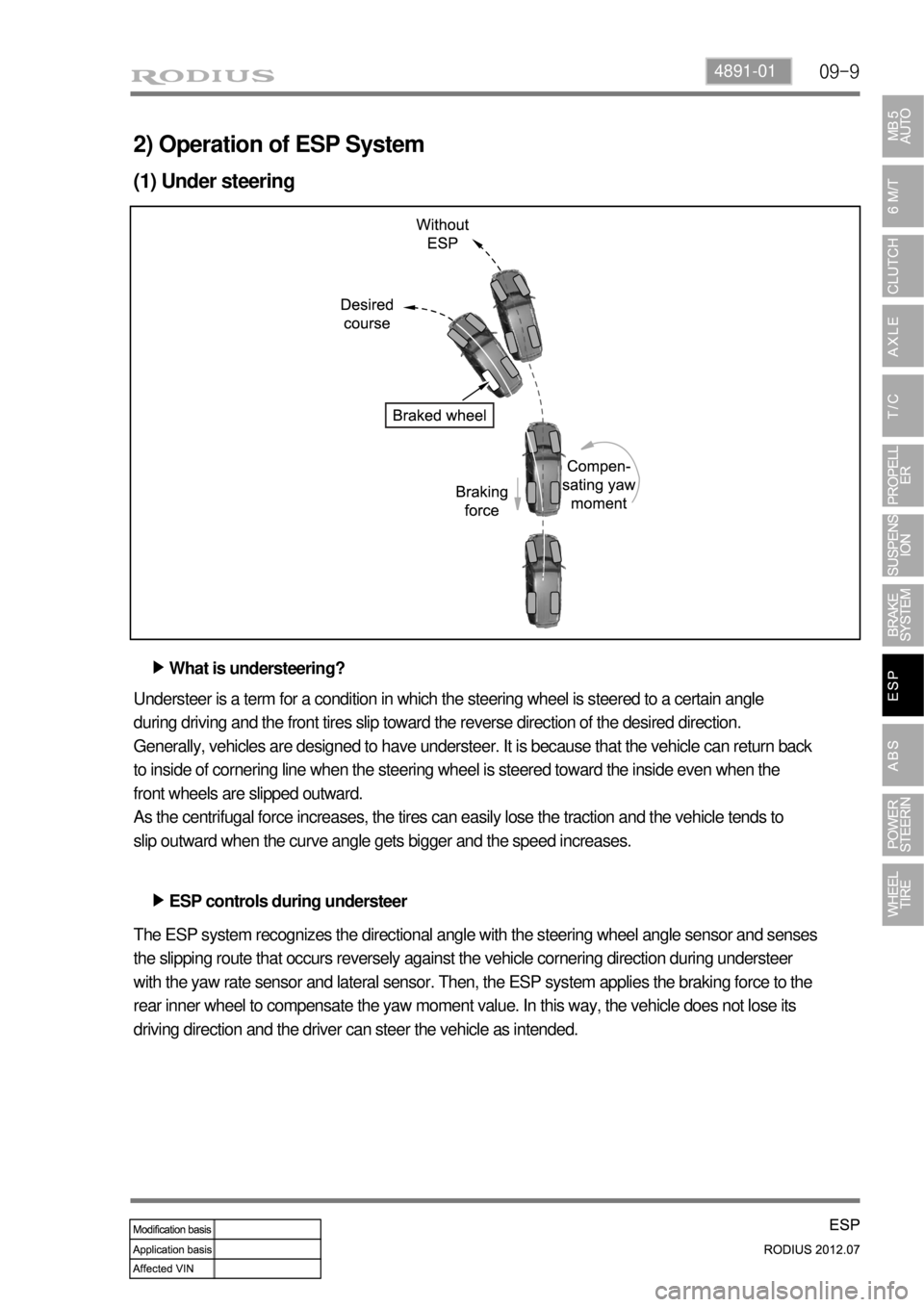

2) Operation of ESP System

(1) Under steering

What is understeering? ▶

ESP controls during understeer ▶ Understeer is a term for a condition in which the steering wheel is steered to a certain angle

during driving and the front tires slip toward the reverse direction of the desired direction.

Generally, vehicles are designed to have understeer. It is because that the vehicle can return back

to inside of cornering line when the steering wheel is steered toward the inside even when the

front wheels are slipped outward.

As the centrifugal force increases, the tires can easily lose the traction and the vehicle tends to

slip outward when the curve angle gets bigger and the speed increases.

The ESP system recognizes the directional angle with the steering wheel angle sensor and senses

the slipping route that occurs reversely against the vehicle cornering direction during understeer

with the yaw rate sensor and lateral sensor. Then, the ESP system applies the braking force to the

rear inner wheel to compensate the yaw moment value. In this way, the vehicle does not lose its

driving direction and the driver can steer the vehicle as intended.

Page 618 of 715

09-10

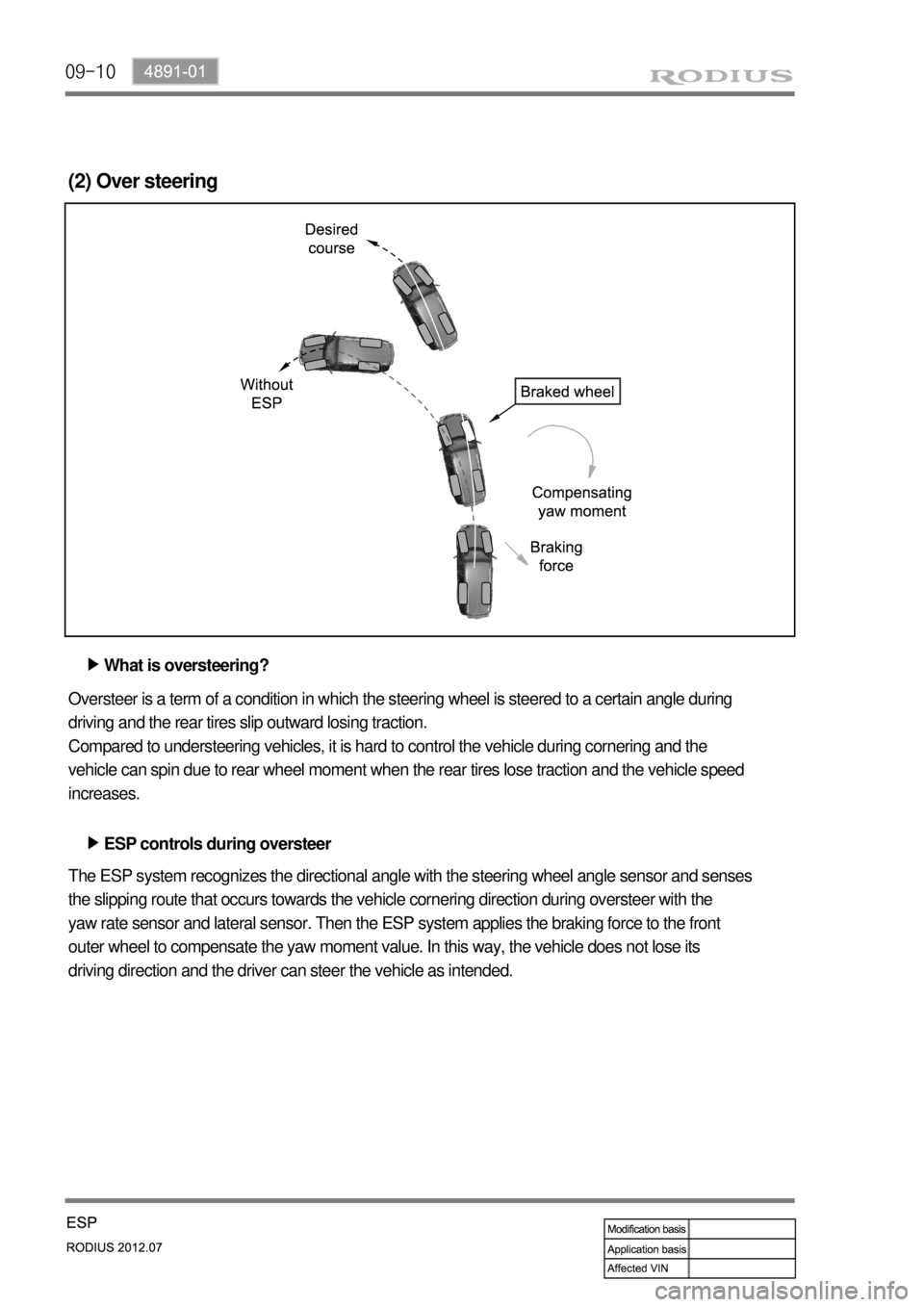

(2) Over steering

What is oversteering? ▶

ESP controls during oversteer ▶ Oversteer is a term of a condition in which the steering wheel is steered to a certain angle during

driving and the rear tires slip outward losing traction.

Compared to understeering vehicles, it is hard to control the vehicle during cornering and the

vehicle can spin due to rear wheel moment when the rear tires lose traction and the vehicle speed

increases.

The ESP system recognizes the directional angle with the steering wheel angle sensor and senses

the slipping route that occurs towards the vehicle cornering direction during oversteer with the

yaw rate sensor and lateral sensor. Then the ESP system applies the braking force to the front

outer wheel to compensate the yaw moment value. In this way, the vehicle does not lose its

driving direction and the driver can steer the vehicle as intended.

Page 619 of 715

09-114891-01

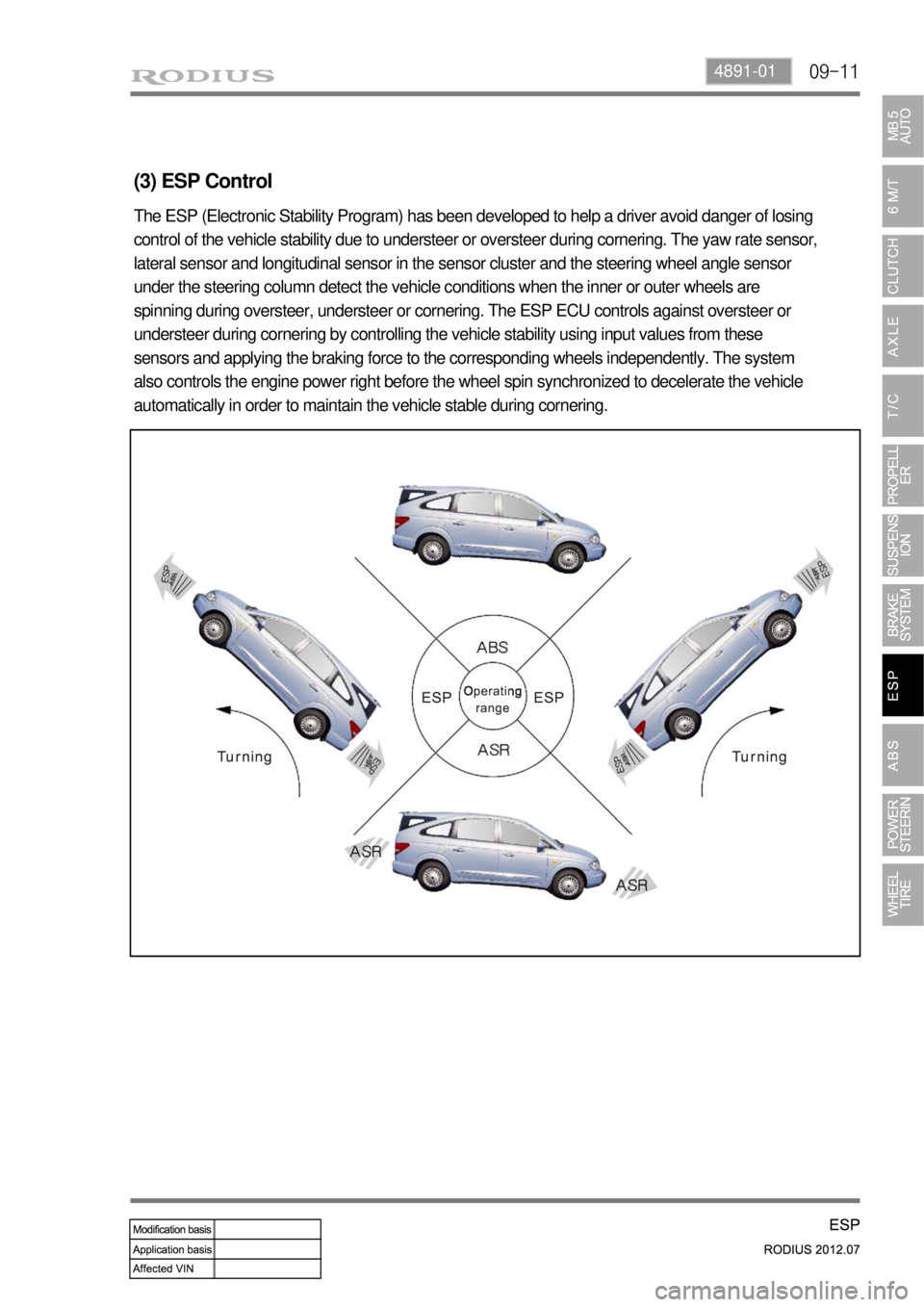

(3) ESP Control

The ESP (Electronic Stability Program) has been developed to help a driver avoid danger of losing

control of the vehicle stability due to understeer or oversteer during cornering. The yaw rate sensor,

lateral sensor and longitudinal sensor in the sensor cluster and the steering wheel angle sensor

under the steering column detect the vehicle conditions when the inner or outer wheels are

spinning during oversteer, understeer or cornering. The ESP ECU controls against oversteer or

understeer during cornering by controlling the vehicle stability using input values from these

sensors and applying the braking force to the corresponding wheels independently. The system

also controls the engine power right before the wheel spin synchronized to decelerate the vehicle

automatically in order to maintain the vehicle stable during cornering.

Page 632 of 715

10-34891-01

1. SYSTEM OVERVIEW

When braking suddenly or braking on slippery roads, the vehicle keeps moving forward but the wheels

are locking and not rotating. If these happen, the vehicle may lose stability or rotate resulting in an

accident. ABS helps to maintain directional stability and control of the vehicle. ABS is designed to secure

more safety and increase the control of steering wheel during emergency braking situation. But, ABS

does not guarantee perfect safety beyond its physical limit. ABS in this vehicle contains EBD function. In

normal driving conditions, the brake system operates without ABS function.

1) Basic Theory of ABS Function

To give you a better understanding of the tasks and functions of ABS, we will first look at the physics

principles.

▶Stopping distance

The stopping distance depends on the vehicle weight and initial speed when braking starts. This also

applies for vehicle with ABS, where ABS always tries to set an optimum brake force on each wheel. As

great forces are exerted between the tires and the carriageway when braking, even with ABS the wheels

may scream and rubber is left on the road. With an ABS skid mark one may be able to clearly recognize

the tire profile. The skid mark of an ABS vehicle does not however leave any hint of the speed of the

vehicle in the case of an accident, as it can only be clearly drawn at the start of braking.

▶Brake force on a wheel

The maximum possible brake force on a wheel depends on the wheel load and the adhesion coefficient

between tire and carriageway. With a low adhesion coefficient the brake force, which can be obtained is

very low. You are bound to know the result already from driving on winter roads. With a high adhesion

coefficient on a dry road, the brake force, which can be obtained, is considerably higher. The brake

force, which can be obtained, can be calculated from below formula:

Page 641 of 715

11-34610-00

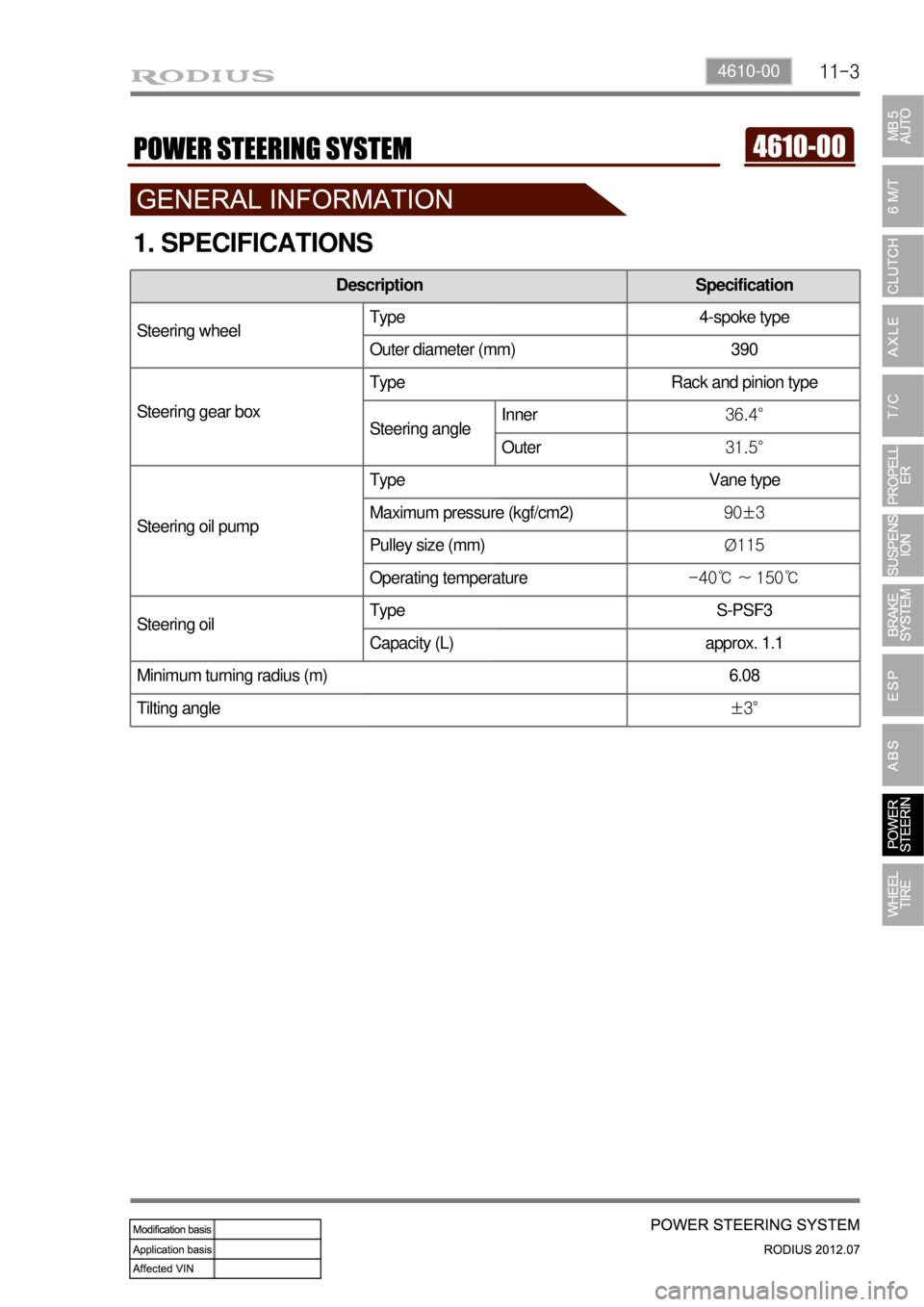

1. SPECIFICATIONS

Description Specification

Steering wheelType 4-spoke type

Outer diameter (mm) 390

Steering gear boxType Rack and pinion type

Steering angleInner36.4°

Outer31.5°

Steering oil pumpType Vane type

Maximum pressure (kgf/cm2)90±3

Pulley size (mm)Ø115

Operating temperature-40℃ ~ 150℃

Steering oilType S-PSF3

Capacity (L) approx. 1.1

Minimum turning radius (m) 6.08

Tilting angle±3°

Page 642 of 715

11-4

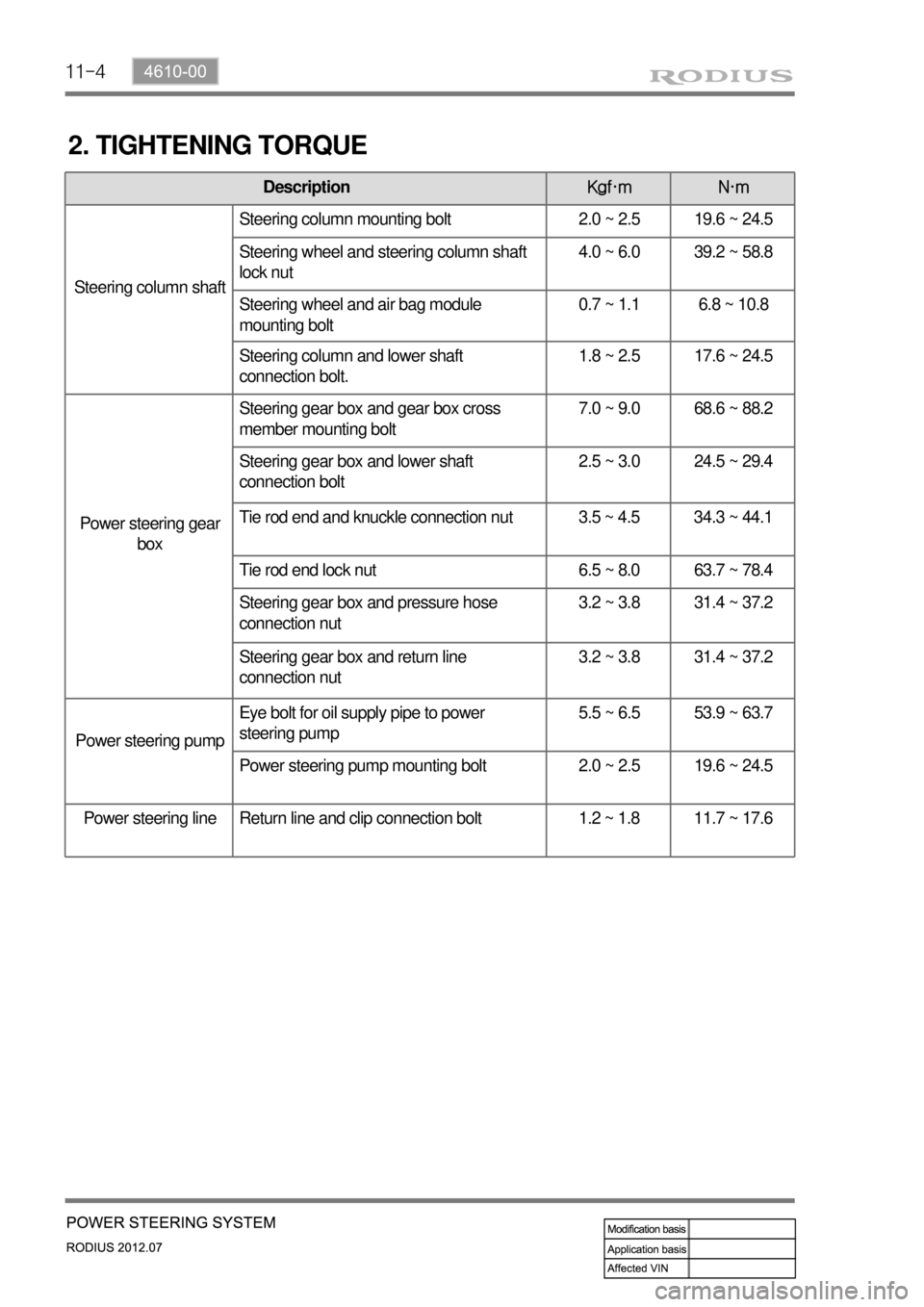

2. TIGHTENING TORQUE

DescriptionKgf·m N·m

Steering column shaftSteering column mounting bolt 2.0 ~ 2.5 19.6 ~ 24.5

Steering wheel and steering column shaft

lock nut4.0 ~ 6.0 39.2 ~ 58.8

Steering wheel and air bag module

mounting bolt0.7 ~ 1.1 6.8 ~ 10.8

Steering column and lower shaft

connection bolt.1.8 ~ 2.5 17.6 ~ 24.5

Power steering gear

boxSteering gear box and gear box cross

member mounting bolt7.0 ~ 9.0 68.6 ~ 88.2

Steering gear box and lower shaft

connection bolt2.5 ~ 3.0 24.5 ~ 29.4

Tie rod end and knuckle connection nut 3.5 ~ 4.5 34.3 ~ 44.1

Tie rod end lock nut 6.5 ~ 8.0 63.7 ~ 78.4

Steering gear box and pressure hose

connection nut3.2 ~ 3.8 31.4 ~ 37.2

Steering gear box and return line

connection nut3.2 ~ 3.8 31.4 ~ 37.2

Power steering pumpEye bolt for oil supply pipe to power

steering pump5.5 ~ 6.5 53.9 ~ 63.7

Power steering pump mounting bolt 2.0 ~ 2.5 19.6 ~ 24.5

Power steering line Return line and clip connection bolt 1.2 ~ 1.8 11.7 ~ 17.6