wiring SSANGYONG RODIUS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 402 of 715

08-51452-01

1. CHARGING SYSTEM OPERATION

Alternators use a new type of regulator that incorpo-rates a diode trio. A Delta stator, a rectifier

bridge, and a rotor with slip rings and brushes are electrically similar to earlier alternators.

A conventional pulley and fan are used. There is no test hole.

1) Charging Time Required

The time required to charge a battery will vary depending upon the following factors:

Size of Battery ▶

A Completely discharged large heavy-duty battery required more than twice the

recharging time as a completely discharged small passenger car battery. -

Temperature ▶

A longer time will be needed to charge any battery at -18°C (0°F) than at 27°C (80°F).

When a fast charger is connected to a cold battery, the current accepted by the battery

will be very low at first. The battery will accept a higher current rate as the battery warms. -

Charger Capacity ▶

A charger which can supply only 5 amperes will require a much longer charging period

than a charger that can supply 30 amperes or more. -

State-of-Charge ▶

A completely discharged battery requires more than twice as much charge as a onehalf

charged battery. Because the electrolyte is nearly pure water and a poor conductor in a

completely discharged battery, the current accepted by the battery is very low at first.

Later, as the charging current causes the electrolyte acid content to increase, the charging

current will likewise increase. -

2. STARTING SYSTEM OPERATION

The engine electrical system includes the battery, the ignition, the starter, the alternator, and all

the related wiring. Diagnostic tables will aid in troubleshooting system faults. When a fault is

traced to a particular component, refer to that component section of the service manual. The

starting system circuit consists of the battery, the starter motor, the ignition switch, and all the

related electrical wiring. All of these components are connected electrically.

Page 418 of 715

01-4

Make sure a connector is connected

securely. Loose connection results in

malfunction. -

When inspecting the airbag system, make

sure to use a diagnostic device, not a

circuit tester.When disconnecting a connector equipped

with a lock, press it down to the direction in

the below figure. -

When checking voltage or continuity of the

connector terminal with a circuit tester,

connect the tester probe to the terminal at

the harness side. For a sealed type

connector, connect the probe to the

terminal through the hole in the rubber cap

of the wiring. Take care not to damage the

insulation of the wires. Insert the probe until

it contacts the terminal completely. -

Page 419 of 715

01-58410-02

2. CHECKING CABLES AND WIRES

Check for loose connection or rust.

Check terminals and wires for corrosion due to electrolyte leakage.

Check terminals and wires for open circuit.

Check the wire insulation and coat for damage, cracks or deterioration.

Check if the conductive parts of the terminals do not contact with vehicle body or other metal

parts.

Check that the grounding part has continuity with mounting bolts and vehicle body.

Check that wires are properly routed.

Make sure that wires are securely fixed to avoid contact with sharp body parts and

hightemperature

parts, such as the exhaust manifold and exhaust pipes.

The rotating parts, such as fan pulley and fan belt, perturbative parts and wiring should be

secured tightly at regular intervals.

Secure the wiring between the fixed parts, such as the vehicle body, and vibrating parts, such

as the engine, after slackening it slightly to prevent it from being damaged. -

-

-

-

-

-

-

-

-

Page 552 of 715

02-14

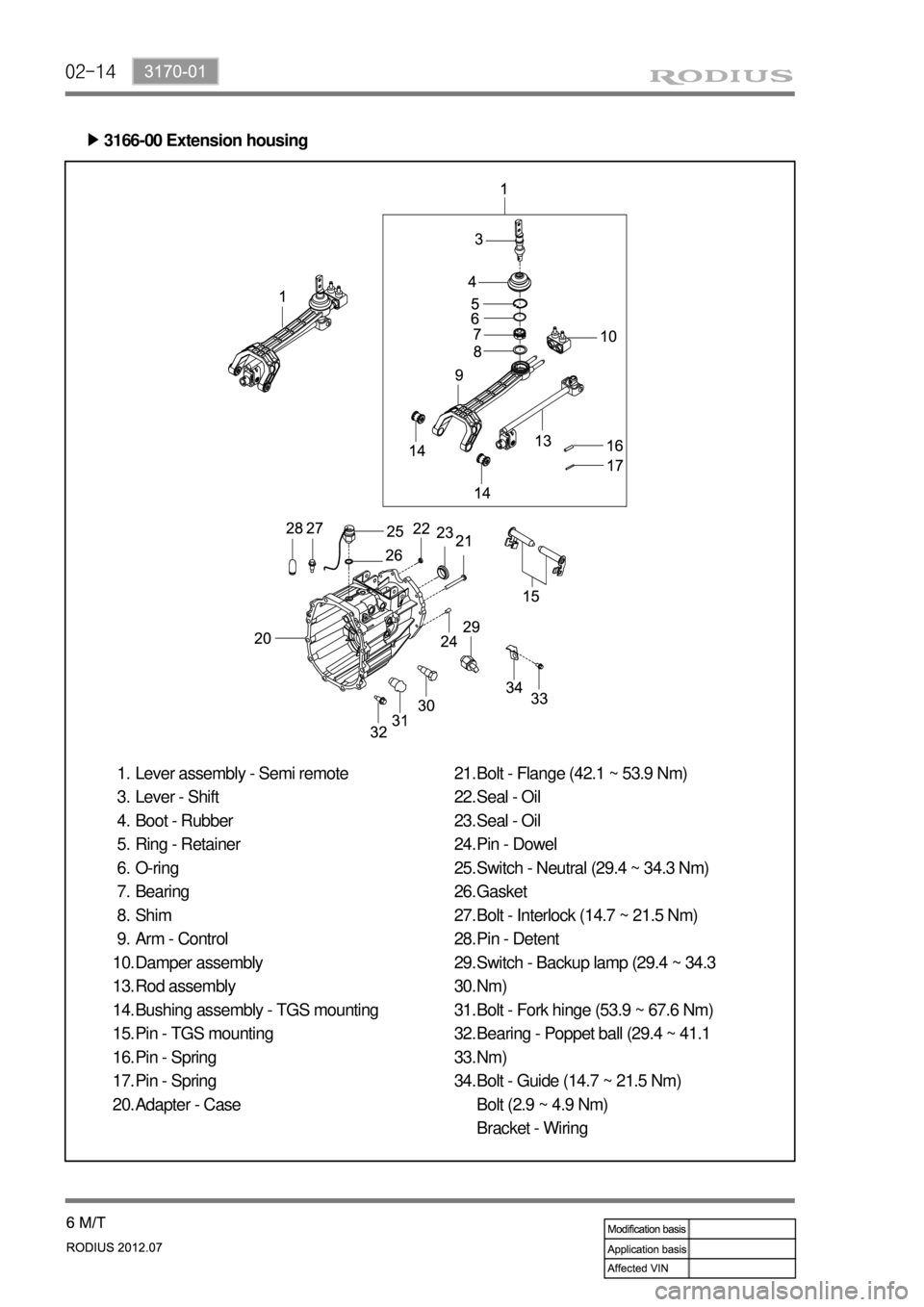

3166-00 Extension housing ▶

Lever assembly - Semi remote

Lever - Shift

Boot - Rubber

Ring - Retainer

O-ring

Bearing

Shim

Arm - Control

Damper assembly

Rod assembly

Bushing assembly - TGS mounting

Pin - TGS mounting

Pin - Spring

Pin - Spring

Adapter - Case 1.

3.

4.

5.

6.

7.

8.

9.

10.

13.

14.

15.

16.

17.

20.Bolt - Flange (42.1 ~ 53.9 Nm)

Seal - Oil

Seal - Oil

Pin - Dowel

Switch - Neutral (29.4 ~ 34.3 Nm)

Gasket

Bolt - Interlock (14.7 ~ 21.5 Nm)

Pin - Detent

Switch - Backup lamp (29.4 ~ 34.3

Nm)

Bolt - Fork hinge (53.9 ~ 67.6 Nm)

Bearing - Poppet ball (29.4 ~ 41.1

Nm)

Bolt - Guide (14.7 ~ 21.5 Nm)

Bolt (2.9 ~ 4.9 Nm)

Bracket - Wiring 21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

Page 657 of 715

01-2

Front air conditioner module assembly - inside instrument panel

Compressor - engine rightAQS/Air source selection

switch

Sun load sensor - instrument

panel upper left

1. SYSTEM LAYOUT AND COMPONENTS

Type Air cindotioner controller

FATC

Manual air

conditioner

It change sun load coming through

front windshield into current to input to

FATC controller. *

Air mix door

actuator

PTC (If equipped)

Duct temperature

sensor

Mode door

actuator

Air conditioner wiring

Thermo AMP

Air source door

actuator

Air conditioner

filter

Bloewr motor

Blower high speed relayPower transistor

Page 661 of 715

01-6

2) AIR CONDITIONER MODULE WIRING AND LAYOUT

(1) Front Air Conditioner Module

Air source selection

door actuator

Air conditioner

filterEvaporator

Blower motor

Blower high

speed relay

Heater core

Wiring layout

Components

Page 662 of 715

01-76810-30

(2) Rear Air Conditioner Module

Roof air conditioner duct

Blower motor

Evaporator

Mixer door

Heater core

Air mixer door actuator

Rear floor

heater duct

Heater &

air conditioner

pipes

Wiring layout

Components

Page 675 of 715

02-78810-03

Do not put the seat cover on the front seatbacks. It may interfere with the side air bag inflation.

When sitting in the rear seat, do not hold onto the seatback of the front seat. If the side air bag

inflates, the occupant may get seriously injured.

Do not lean on the door. When the side air bag inflates, the occupant may get seriously injured.

Do not place any objects such as an umbrella or a bag between the side air bag and the door.

Do not place the part of your body near the side air bag. You may obstruct the side air bag or

get injured by the inflation impact.

Do not slam the front doors. It may lead to an unintended inflation of the side air bag.

Do not move your seat too close to the steering wheel or dashboard. If you lower your head,

the air bag can hit your head during inflation and can cause severe injury or even death.

Hold only the outer rim of the steering so that the air bag can inflate without any hindrances.

Do not place your face or chest near the steering wheel and dashboard. Also, do not allow

anyone to place their hands, leg or face on the dashboard. The air bag cannot work properly.

Do not hold and operate the steering wheel by crossing your arms. You could get seriously

injured when the air bag deploys.

When the air bag inflates, it makes a loud noise and smoke. However, the smoke is a non-

toxic nitrogen gas.

When the air bag is deployed, non-toxic gas will come out. This gas may cause skin, eyes or

nose irritation.

Wash it out with cold and clean water and consult the doctor if irritation continues.

When any repairs are needed for the steering wheel, or when an accident occurred without the

air bag deployment, have the air bag system checked by Ssangyong Dealer or Ssangyong

Authorized Service Operation.

The windshield glass may be broken when the passenger's air bag is deployed.

The air bag deployment can cause abrasion on your hands and face. -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

4) Major Replacement Parts after Air Bag Deployment

In Case Of Front Air Bag Deployment ▶

Instrument panel, deployed air bag module, air bag unit, seat belt pre-tensioner, wirings

(including connectors), damaged trim and components

In Case Of Curtain Air Bag Deployment ▶

Deployed side bag, air bag unit, side air bag sensor, wirings (including connectors), damaged

trim and seat components