engine SSANGYONG RODIUS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 169 of 715

02-12

Electrical equipment ▶

Electric devices should be handled more carefully.

Currently, the engine has a lot of electric devices. there could be poor engine performance,

incomplete combustion and other abnormal symptoms due to short circuit or poor contact.

Before work on engine and each electrical equipment, be sure to disconnect battery negative

(-) terminal.

When replacing the electric device, use only genuine part and check the conditions of

connections and grounds. Loosened connection or ground make cause a fire and personal

injury. -

-Fuel and lubrication system ▶

Do not allow the fluid and engine oil to make contact with the body paintwork and hoses.

If work on the fluid system such as fuel and oil, working area should be well ventilated and

smoking should be prohibited.

Gasket or seal on the fuel/lubrication system should be replaced with new ones and bolts and

nuts should be tightened as specified.

After removal/installation works, be sure to check whether there is leak on the connecting

section. -

-

-

-

If fine dust or foreign material enters into DI engine's fuel system, there can be serious damages

in HP pump and injectors. Thus, be sure to plug the inlets of removed fuel line components with

cap and protect removed parts not to be contaminated with dirt. (Refer to cleanness in this

manual while working on DI engine fuel system)

Page 170 of 715

02-130000-00

D20DTR Engine

1. BELT LAYOUT

It is single drive type and uses FEAD (Front End Accessories Drive) design to make a compact

layout.

Components ▶

HPS

(Hydraulic Power Steering)

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pump

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 Idle pulley #1

9 Idle pulley #2

10 Power steering pump pulley

Page 173 of 715

02-16

2) Belt Tensioner

(1) Overview

The torque deviation from crankshaft affects the components in belt drive system and the belt

movement. The auto tensioner system is to adjust this deviation automatically.

In D20DTR engine, one of the mechanical tensioner, pivot damped tensioner is used to keep the

damping force, system reliability and durability. The single belt drive system needs to use the

automatic belt tensioning device to transfer the power to pulleys effectively. To get this, the

tensioner uses the spring and damping unit.

(2) Location

Belt tensioner

Page 174 of 715

02-170000-00

Vacuum pump

Pump capacity: 210 cc/rev

Camshaft speed:

375 to 3,000 rpm

Lubrication temperature:

-40 to 155°C

Oil: 5W30

Drive type: Driven by exhaust

Camshaft sprocket

EGR cooler bypass valve

This valve is controlled by ECU. When the

engine is cooled, the exhaust gas goes to

combustion chamber without passing through

EGR cooler because the valve is closed by

vacuum pressure.

2. VACUUM PUMP

Vacuum pump generates the vacuum pressure and supplies it to EGR cooler bypass solenoid.

This pump is single vane type and displacement is 210 cc/rev. The lubrication oil is supplied

through the hole in hollow shaft.

Components ▶

Brake booster and naster

cylinder

Page 176 of 715

02-190000-00

Rear mounting insulator

2WD M/T 2WD A/T 4WD A/T

P/N: 31900-21M20 P/N: 31900-21A20 P/N: 31900-21A40

3. ENGINE MOUNTING

D20DTR engine uses 3-point mounting type that supports the engine and transmission

simultaneously.

Components ▶

Front mounting insulator (Left side)

Location InsulatorFront mounting insulator (Right side)

Location Insulator

Page 180 of 715

02-230000-00

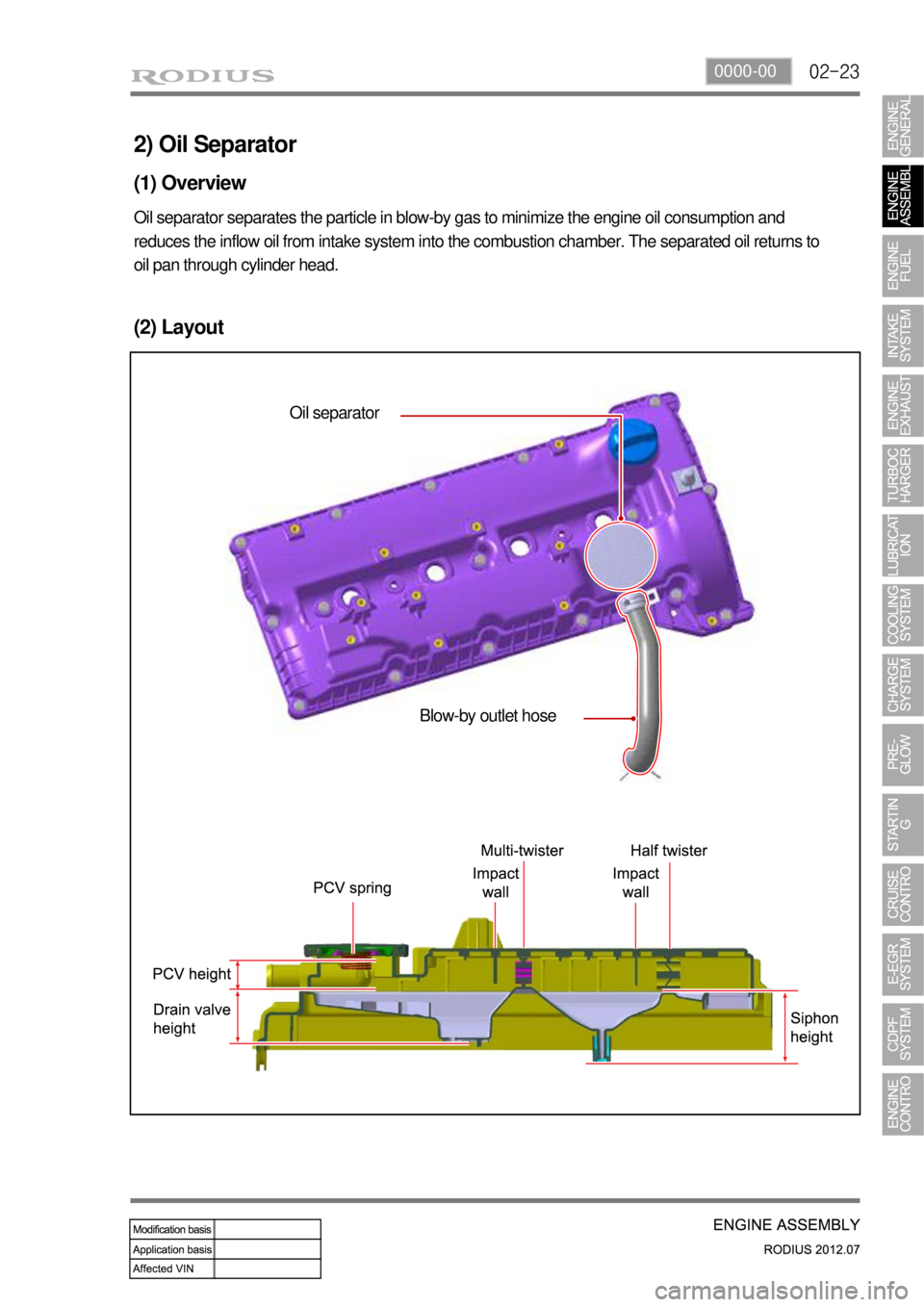

2) Oil Separator

Oil separator separates the particle in blow-by gas to minimize the engine oil consumption and

reduces the inflow oil from intake system into the combustion chamber. The separated oil returns to

oil pan through cylinder head.

Oil separator

Blow-by outlet hose

(1) Overview

(2) Layout

Page 183 of 715

02-26

Intake/Exhaust Camshafts

2) Camshaft

(1) Overview

Hollow type camshaft contains cam, octagon cam, HP pump gear and intake/exhaust gears.

Camshaft operates the intake/exhaust valves, vacuum pump and HP pump, and transfers the

engine oil to vacuum pump through the internal oil passage.

(2) Location

Exhaust CamshaftExhaust Camshaft

Thrust journalIntake Camshaft

Closed flow type water jacket (improving cooling performance) ▶

Octagon cam

(for tooling)

Connected to

vacuum pump

Page 185 of 715

02-28

4) Cylinder Head Gasket

(1) Features

Sealing the cylinder gas pressure - Peak pressure: 190 bar

Minimizing the distortion of engine structure (cylinder head, block): profile stopper, backland

stopper

Material: MLS (Multi Layer Steel), Gasket (3 layers)

Thickness of gasket: 3 types (1.2 /1.3 /1.4 mm) 1.

2.

3.

4.

(2) Thickness of cylinder head gasket

There are three types of gasket to managing the compression ratio.

Piston protrusion ▶

Piston protrusion Thickness

0.475 to 0.540 mm 1.2t

0.541 to 0.649 mm 1.3t

0.650 to 0.745 mm 1.4t

Thickness marking

Ex: 1.3t

Page 186 of 715

02-290000-00

1) Chain Drive

(1) Overview

The drive chain is single chain drive system with simple design and variable performance, and it

utilizes the hydraulic tensioner to reduce the wave impact generated by the chain. This chain is light

weight and has high durability through single bush chain. Shoulder bolts are used for better NHV.

7. CHAIN AND GEAR DRIVE SYSTEM

D20DTR engine uses single stage chain drive system. Timing chain drives the exhaust side and

gear drive the intake side. Timing chain is single bush type. Upper chain drives HP pump

connected to intake Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil

pump to lubricate the engine.

Page 188 of 715

02-310000-00

2) Timing Chain and Gear

(1) Timing chain

Simple layout: optimized timing, enhanced

NVH

Single stage layout: minimized chain load

The brass link on crankshaft is at

symmetric position of that on camshaft. -

-

-

Chain upper bush

- Single bush type (112 EA)

Chain lower bush

- Single bush type (60 EA)

(2) Tensioner

Tensioner adjusts the chain tension to keep it tight during engine running. This reduces the wear

in guide rail and spoke.

Operating principle

- Use the spring tension in tensioner and hydraulic pressure

Tensioner type

- Compensation and impact absorbing

Static and dynamic force

- Spring + Hydraulic pressure 1.

2.

3.

Plunger

HousingSpring

Check valve

Hydraulic tensioner assembly ▶