lock SSANGYONG RODIUS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 269 of 715

08-4

2. INSPECTION

Possible Cause Action

Coolant level

is

too low- Leak from the radiator

- Leak from the coolant auxiliary tank

- Leak from the heater core- Change the radiator

- Change the coolant auxiliary tank

- Change the heater

- Leak from the coolant hose

connections

- Damaged coolant hose - Reconnect the hose or replace

the clamp

- Change the hose

- Leak from the water pump gasket

- Leak from the water pump internal

seal- Change the gasket

- Change the water pump

- Leak from the water inlet cap

- Leak from the thermostat housing- Change the water inlet cap

gasket

- Change the thermostat sealing

- Incorrect tightening torque of the

cylinder head bolts

- Damaged cylinder head gasket- Tighten the bolts to the specified

torque

- Change the cylinder head gasket

Coolant

temperature is

too high- Coolant leakage (Coolant level is low)

- Improper coolant mixture ratio

- Kinked coolant hose- Add coolant

- Check the coolant concentration

(Anti-freeze)

- Repair or replace the hose

- Defective thermostat

- Defective water pump

- Defective radiator

- Defective coolant auxiliary tank or tank

cap- Change the thermostat

- Change the water pump

- Change the radiator

- Change the coolant auxiliary tank

or tank cap

- Cracks on the cylinder block or

cylinder head

- Clogged coolant passages in the

cylinder block or cylinder head- Change cylinder block or cylinder

head

- Clean the coolant passage

- Clogged radiator core - Clean the radiator core

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or

faulty wiring- Replace the sensor or repair the

related wiring

Coolant

temperature is

too low- Thermostat is stuck open - Change the thermostat

- Improper operation of cooling fan - Replace the cooling fan or repair

the related circuit

- Defective temperature sensor or faulty

wiring- Replace the sensor or repair the

related wiring

Page 280 of 715

09-8

(3) Starting with jumper cable

If the battery is weak or terminated, the battery from another vehicle can be used with jumper

cables to start the engine.

Connecting order ▶

The positive (+) terminal of the discharged battery

The positive (+) terminal of the booster battery

The negative (-) terminal of the booster battery

Connect one end of the other jumper cable to the body of the discharged vehicle, such as the

engine block or a front towing hook. 1.

2.

3.

4.

Starting ▶

Prepare a set of jumper cables.

Place another vehicle that has the same 12 V of power near to the discharged vehicle.

Switch off all electrical accessories for the discharged vehicle.

Apply the parking brake and shift the transaxle to the P position (automatic transaxle) or neutral

(N) position (manual transaxle).

Connect the jumper cables.

Try to start the discharged vehicle while accelerating the engine rpm in the booster vehicle.

Attempt to start the engine with the discharged battery.

After starting the engine, carefully disconnect the jumper cables in the reverse sequence of

connection. 1.

2.

3.

4.

5.

6.

7.

8.

Page 294 of 715

11-31461-01

1. SPECIFICATION

Description Specification

Capacity 12V 2.3kW

Engagement Meshed type

Rotating direction Clockwise

Pinion gear manufacturing Cooled forging

Solenoid operating voltage Max. 8 V

Weight 2.5 kg

Bracket manufacturing Aluminum die casting

Page 333 of 715

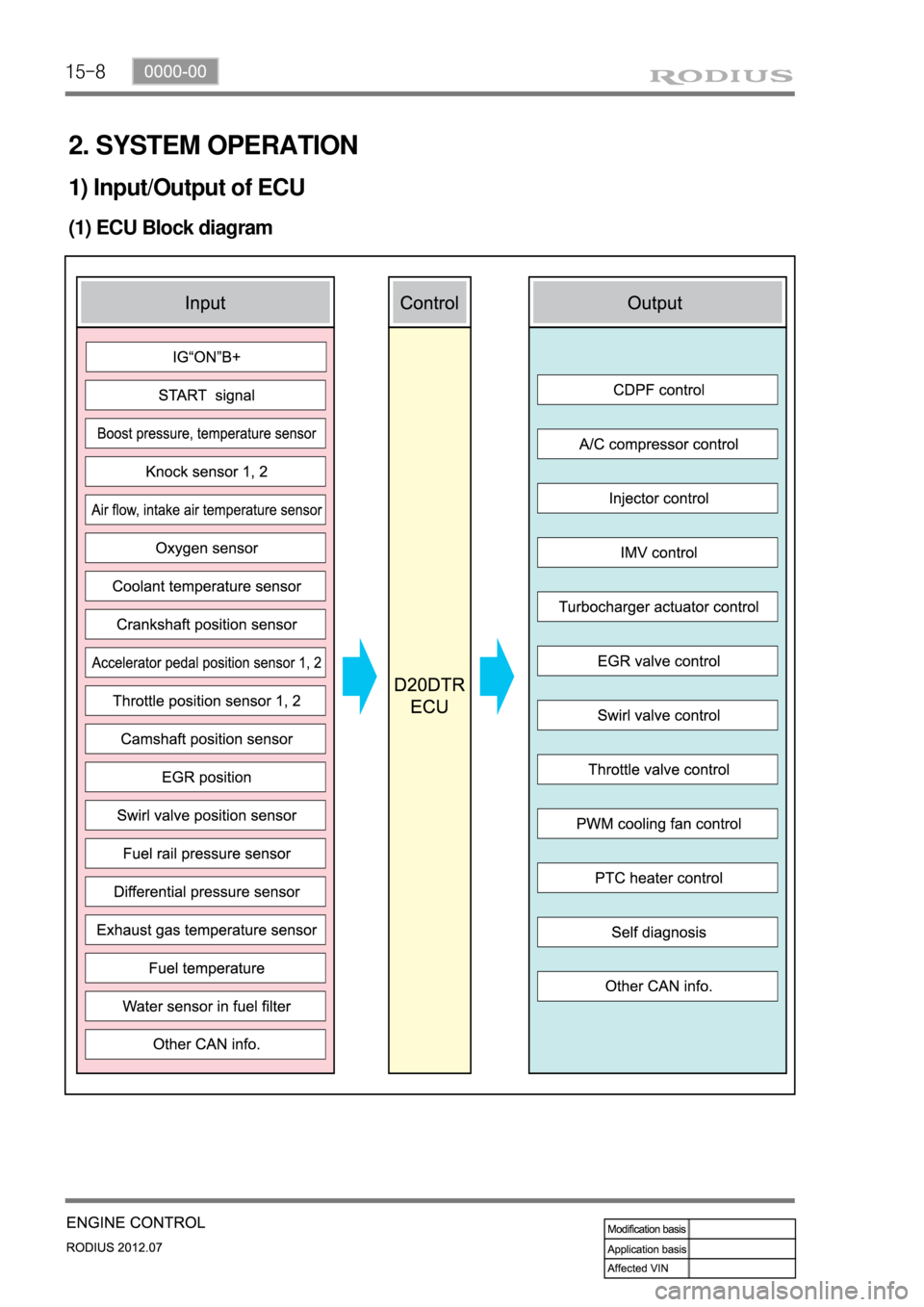

15-8

2. SYSTEM OPERATION

1) Input/Output of ECU

(1) ECU Block diagram

Page 349 of 715

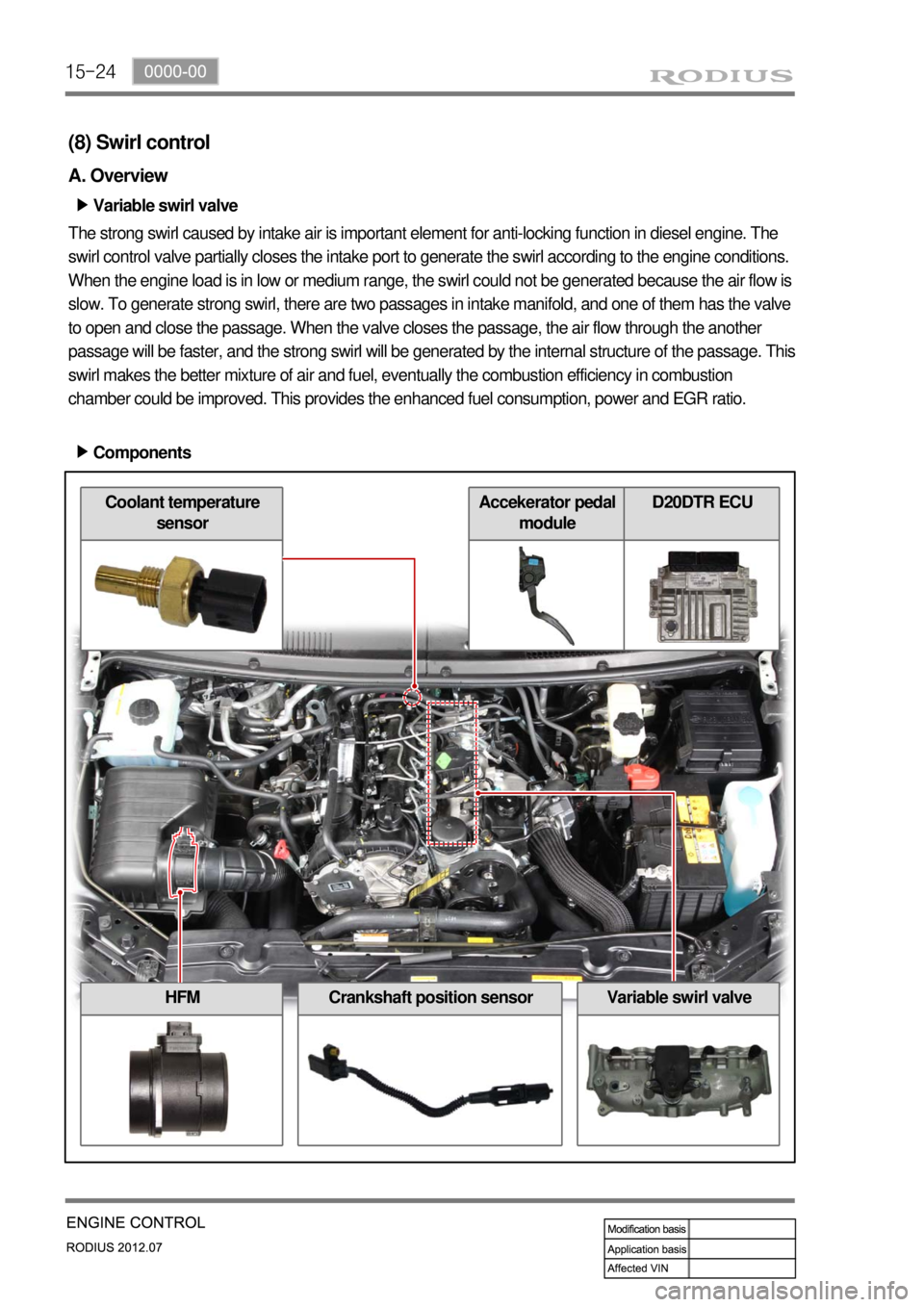

15-24

(8) Swirl control

A. Overview

Variable swirl valve ▶

The strong swirl caused by intake air is important element for anti-locking function in diesel engine. The

swirl control valve partially closes the intake port to generate the swirl according to the engine conditions.

When the engine load is in low or medium range, the swirl could not be generated because the air flow is

slow. To generate strong swirl, there are two passages in intake manifold, and one of them has the valve

to open and close the passage. When the valve closes the passage, the air flow through the another

passage will be faster, and the strong swirl will be generated by the internal structure of the passage. This

swirl makes the better mixture of air and fuel, eventually the combustion efficiency in combustion

chamber could be improved. This provides the enhanced fuel consumption, power and EGR ratio.

Components ▶

HFMCrankshaft position sensorVariable swirl valve

Coolant temperature

sensorAccekerator pedal

moduleD20DTR ECU

Page 363 of 715

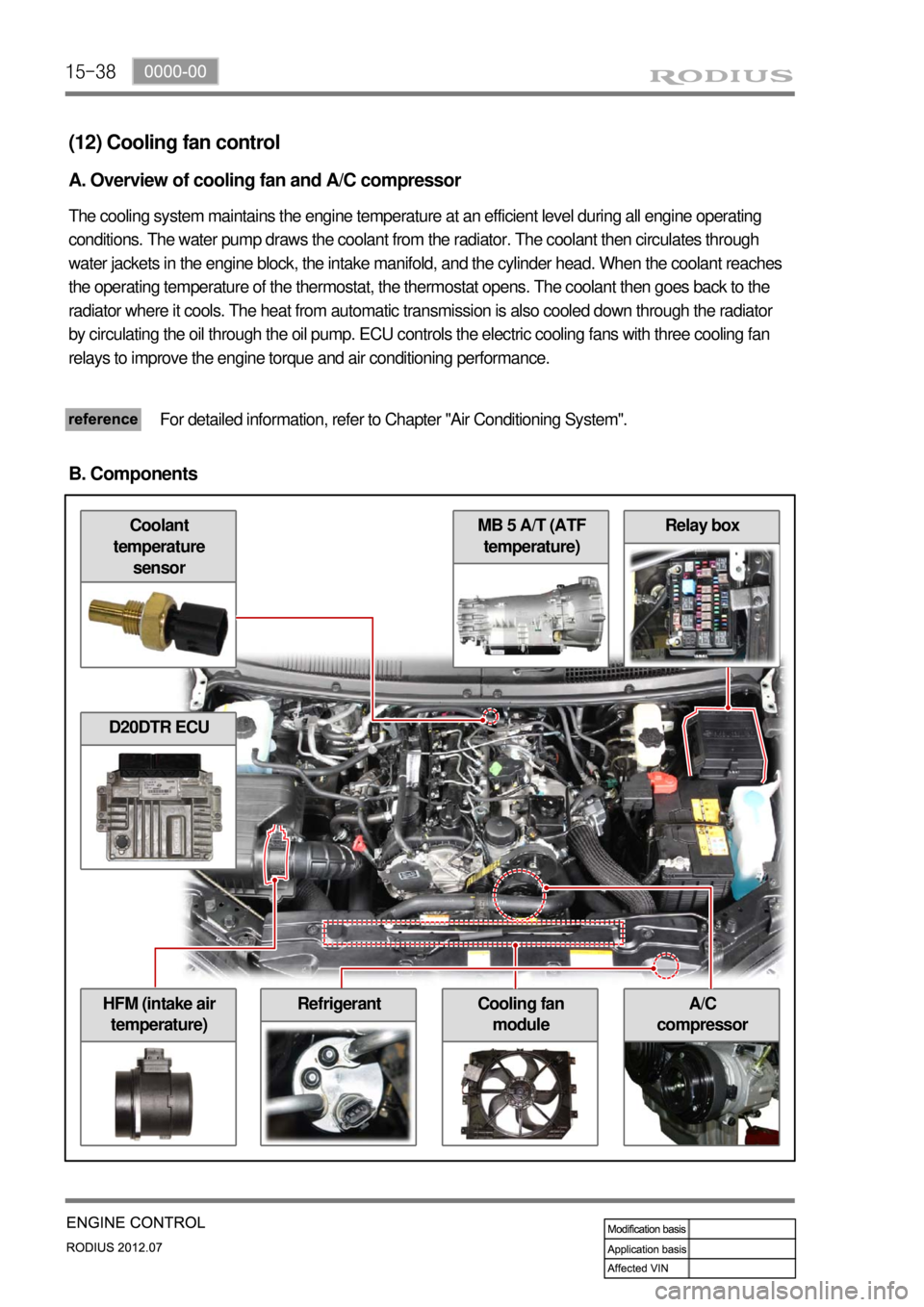

15-38

Relay box

A/C

compressorHFM (intake air

temperature)Cooling fan

module

MB 5 A/T (ATF

temperature)Coolant

temperature

sensor

(12) Cooling fan control

A. Overview of cooling fan and A/C compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transmission is also cooled down through the radiator

by circulating the oil through the oil pump. ECU controls the electric cooling fans with three cooling fan

relays to improve the engine torque and air conditioning performance.

For detailed information, refer to Chapter "Air Conditioning System".

B. Components

D20DTR ECU

Refrigerant

Page 374 of 715

15-490000-00

E. Cautions

Use only specified Engine Oil (approved by MB Sheet 229.51) for CDPF. -

Use only specified engine oil (Low Ash Oil) ▶

The vehicle equipped with CDPF should use specific engine oil to improve the engine performance

and fuel economy, and ensure the service life of CDPF. -

Issue with normal engine oil ▶

Sulfur, one of the contents of engine oil is burned and generates soot that is not regenerated by the

DPF. This remains on the filter as ashes and keeps accumulating. Eventually, this ashes will block

the filter. -

Benefit for specified engine oil ▶

Minimized the sulfur content of engine oil which reduces the service life.

Improved fuel economy and emission level of CO2 with high performance and low viscosity.

Increased service life of engine oil with high resistance to temperature. -

-

-

Problems when using unspecified engine oil ▶

The service life of filter may be reduced by 30% or more by the ashes accumulated on the filter.

The fuel economy may be reduced because of engine rolling resistance, frequent regeneration of

DPF. -

-

These problems are also caused by oil with high sulfur content, such as tax exemption oil and

heating oil, etc. *

Page 379 of 715

01-70000-00

2. DESCRIPTION AND OPERATION

1) Cleanliness and Care

An automobile engine is a combination of many machined, honed, polished and lapped surfaces

with tolerances that are measured in the ten-thousanths of an inch. When any internal engine

parts are serviced, care and cleanliness are important. A liberal coating of enigne oil should be

applied to friction areas during assembly, to protect and lubricate the surfaces on initial operation.

Proper cleaning and protection of machined surfaces and friction areas is part of the repair

procedure. This is considered standard shop practice even if not specifically stated.

Whenever valve train components are removed for service, they should be kept in order.

They should be installed in the same locations, and with the same mating surfaces, as when they

were removed. Battery cables should be disconnected before any major work is performed on the

engine. Failure to disconnect cables may result in damage to wire harness or other electrical

parts.

2) On-Engine Service

Disconnect the negative battery cable before removing or installing any electrical unit, or

when a tool or equipment could easily come in contact with exposed electrical terminals.

Disconnecting this cable will help prevent personal injury and damage to the vehicle.

The ignition must also be in LOCK unless otherwise noted.

Notice Any time the air cleaner is removed, the intake opening -

Any time the air cleaner is removed, the intake opening should be covered. This will protect

against accidental entrance of foreign material, which could follow the intake passage into

the cylinder and cause extensive damage when the engine is started.g -

Page 397 of 715

07-6

1. GENERAL DESCRIPTION

The cooling system maintains the engine temperature at an efficient level during all engine

operating conditions. When the engine is cold, the cooling system cools the engine slowly or not

at all. This slow cooling of the engine allows the engine to warm up quickly. The cooling system

includes a radiator and recovery subsystem, cooling fans, a thermostat and housing, a water

pump, and a water pump drive belt. The timing belt drives the water pump. All components must

function properly for the cooling system to operation. The water pump draws the coolant from the

radiator.

The coolant then circulates through water jackets in the engine block, the intake manifold, and

the cylinder head. When the coolant reaches the operating temperature of the thermostat, the

thermostat opens. The coolant then goes back to the radiator where it cools. This system directs

some coolant through the hoses to the heat core. This provides for heating and defrosting. The

coolant reservoir is connected to the radiator to recover the coolant displaced by expansion from

the high temperatures. The coolant reservoir maintains the correct coolant level. The cooling

system for this vehicle has no radiator cap or filler neck. The coolant is added to the cooling

system through the coolant reservoir.

Page 418 of 715

01-4

Make sure a connector is connected

securely. Loose connection results in

malfunction. -

When inspecting the airbag system, make

sure to use a diagnostic device, not a

circuit tester.When disconnecting a connector equipped

with a lock, press it down to the direction in

the below figure. -

When checking voltage or continuity of the

connector terminal with a circuit tester,

connect the tester probe to the terminal at

the harness side. For a sealed type

connector, connect the probe to the

terminal through the hole in the rubber cap

of the wiring. Take care not to damage the

insulation of the wires. Insert the probe until

it contacts the terminal completely. -