torque SSANGYONG RODIUS 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 328 of 715

15-30000-00

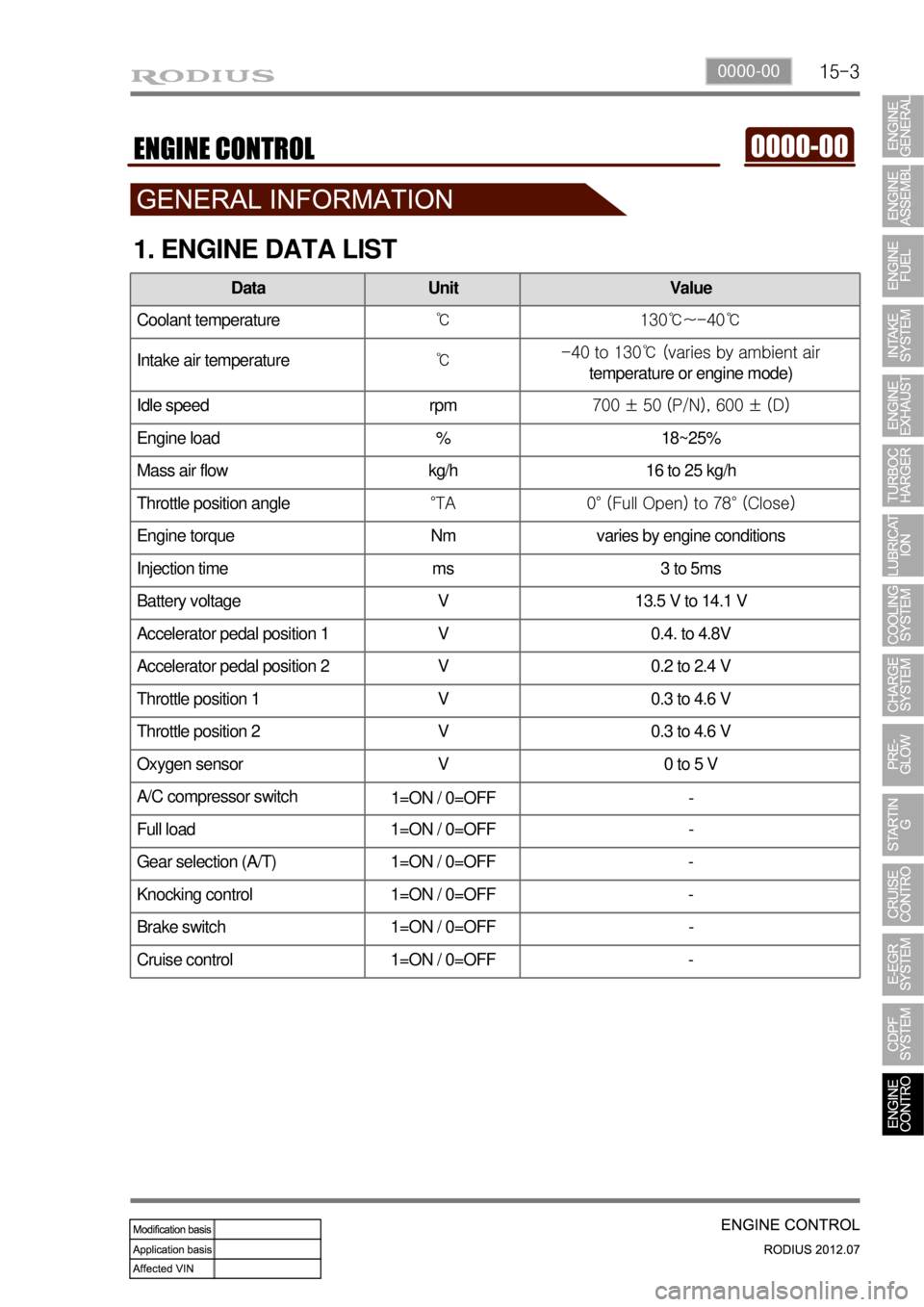

1. ENGINE DATA LIST

Data Unit Value

Coolant temperature℃ 130℃~-40℃

Intake air temperature℃ -40 to 130℃ (varies by ambient air

temperature or engine mode)

Idle speed rpm 700 ± 50 (P/N), 600 ± (D)

Engine load % 18~25%

Mass air flow kg/h 16 to 25 kg/h

Throttle position angle°TA 0° (Full Open) to 78° (Close)

Engine torque Nm varies by engine conditions

Injection time ms 3 to 5ms

Battery voltage V 13.5 V to 14.1 V

Accelerator pedal position 1 V 0.4. to 4.8V

Accelerator pedal position 2 V 0.2 to 2.4 V

Throttle position 1 V 0.3 to 4.6 V

Throttle position 2 V 0.3 to 4.6 V

Oxygen sensor V 0 to 5 V

A/C compressor switch

1=ON / 0=OFF -

Full load 1=ON / 0=OFF -

Gear selection (A/T) 1=ON / 0=OFF -

Knocking control 1=ON / 0=OFF -

Brake switch 1=ON / 0=OFF -

Cruise control 1=ON / 0=OFF -

Page 343 of 715

15-18

C. Idle Speed Controller

The idle speed controller consists of 2 principal modules:

The first module determines the required idle speed according to:

* The operating conditions of the engine (coolant temperature, gear engaged)

* Any activation of the electrical consumers (power steering, air conditioning, others)

* The battery voltage

* The presence of any faults liable to interface with the rail pressure control or the injection control. In

this case, increase the idle speed to prevent the engine from stalling.

The second module is responsible for providing closed loop control of the engine's idle speed by

adapting the minimum fuel according to the difference between the required idle speed and the

engine speed. -

-

D. Flow Limitation

The flow limitation strategy is based on the following strategies:

The flow limitation depending on the filling of the engine with air is determined according to the

engine speed and the air flow. This limitation allows smoke emissions to be reduced during

stabilized running.

The flow limitation depending on the atmospheric pressure is determined according to the engine

speed and the atmospheric pressure. It allows smoke emissions to be reduced when driving at

altitude.

The full load flow curve is determined according to the gear engaged and the engine speed. It

allows the maximum torque delivered by the engine to be limited.

A performance limitation is introduced if faults liable to upset the rail pressure control or the

injection control are detected by the system. In this case, and depending on the gravity of the fault,

the system activates: -

-

-

-

Reduced fuel logic 1: Guarantees 75 % of the performance without limiting the engine speed.

Reduced fuel logic 2: Guarantees 50 % of the performance with the engine speed limited to

3,000 rpm.

Reduce fuel logic 3: Limits the engine speed to 2,000 rpm.

The system chooses the lowest of all values.

A correction depending on the coolant temperature is added to the flow limitation. This correction makes

it possible to reduce the mechanical stresses while the engine is warming up.

The correction is determined according to the coolant temperature, the engine speed and the time which

has passed since starting.

E. Superchager Flow Demand

The supercharge flow is calculated according to the engine speed and the coolant temperature. A

correction depending on the air temperature and the atmospheric pressure is made in order to increase

the supercharge flow during cold starts. It is possible to alter the supercharge flow value by adding a flow

offset with the aid of the diagnostic tool

Page 363 of 715

15-38

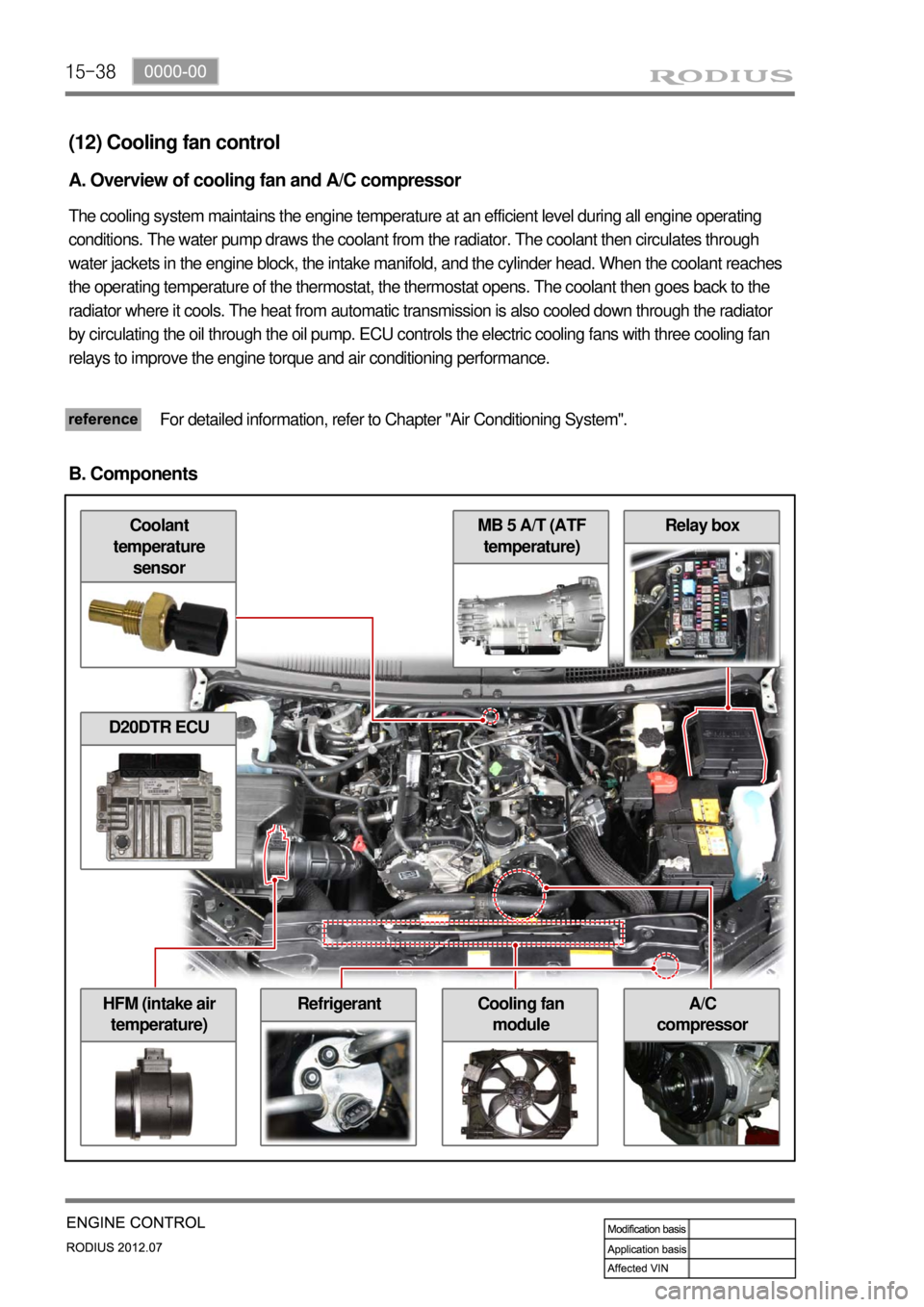

Relay box

A/C

compressorHFM (intake air

temperature)Cooling fan

module

MB 5 A/T (ATF

temperature)Coolant

temperature

sensor

(12) Cooling fan control

A. Overview of cooling fan and A/C compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transmission is also cooled down through the radiator

by circulating the oil through the oil pump. ECU controls the electric cooling fans with three cooling fan

relays to improve the engine torque and air conditioning performance.

For detailed information, refer to Chapter "Air Conditioning System".

B. Components

D20DTR ECU

Refrigerant

Page 522 of 715

01-33650-01

Diameter( Torque converter) 270mm

Lockup function Yes

Gear ratios 1st 3.595

2nd 2.186

3rd 1.405

4th 1.000

5th 0.831

Reverse:

S mode / W mode3.167/1.926

Driving type 2WD(4WD)

Fluid specification Shell ATF 134

Fluid capacityapprox. 8ℓ

Selected lever

indicationP.R.N.D Mechanical

D+/D- Electrical

Parking lock systemBrake switch(signal) → TGS lever

Reverse lock systemCAN → TGS lever

Selected lever

indicationP.R.N.D Lever position

1, 2, 3, 4, 5 CAN

Oil temperature

sensorResistance: R, D0.5 ~ 2.5kΩ

Resistance: P, N20kΩ

TCU EGS 52

Shift solenoid

valve(25℃)Resistance3.8 ± 0.2Ω

Operating distance 0.2mm

Operating current 1.5 ~ 2A

Item W5A580(2WD) / W5A400(4WD)

Input torque 450Nm

1. SPECIFICATIONS

Page 524 of 715

01-53650-01

2. SPECIAL SERVICE TOLLS

Part Name/Part Number Description

W126 589 62 00

HandleInstall and remove the torque converter

W116 589 06 59 00

SupportSupport the transmission

W140 589 12 15 00

DriftInstall the seal ring

W001 589 50 33 00

PullerInstall and remove the transmission housing ball bearing

Page 527 of 715

01-8

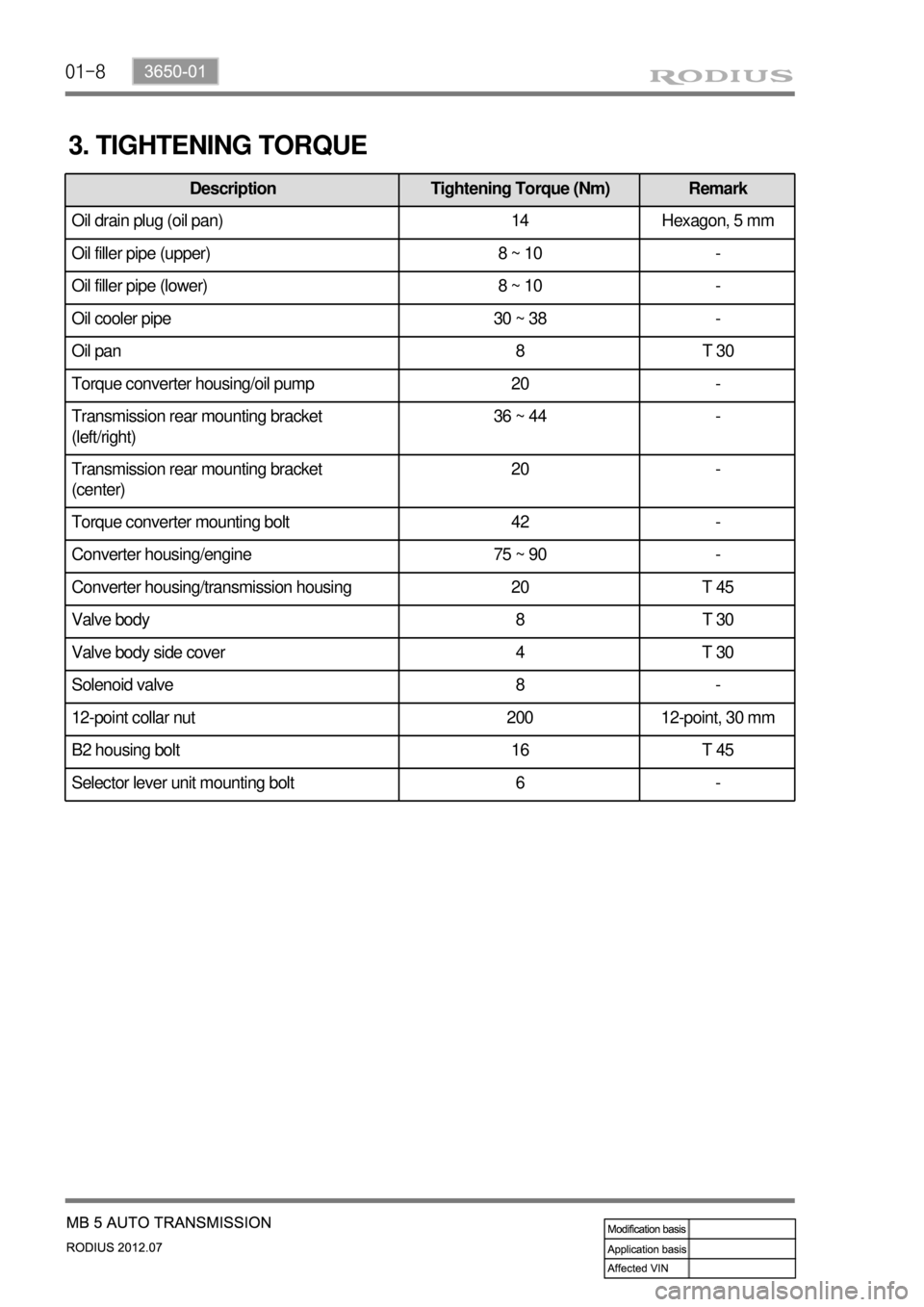

3. TIGHTENING TORQUE

Description Tightening Torque (Nm) Remark

Oil drain plug (oil pan) 14 Hexagon, 5 mm

Oil filler pipe (upper) 8 ~ 10 -

Oil filler pipe (lower) 8 ~ 10 -

Oil cooler pipe 30 ~ 38 -

Oil pan 8 T 30

Torque converter housing/oil pump 20 -

Transmission rear mounting bracket

(left/right)36 ~ 44 -

Transmission rear mounting bracket

(center)20 -

Torque converter mounting bolt 42 -

Converter housing/engine 75 ~ 90 -

Converter housing/transmission housing 20 T 45

Valve body 8 T 30

Valve body side cover 4 T 30

Solenoid valve 8 -

12-point collar nut 200 12-point, 30 mm

B2 housing bolt 16 T 45

Selector lever unit mounting bolt 6 -

Page 528 of 715

01-93650-01

Torque Converter

Old New

The capacity of torque converter has been increased to optimize the output from D20DTR engine.

4. MJOR CHANGES

Torsional damper

Introduced Torsion Damper in Torque Converter

The torsional damped has been newly installed in the torque converter.

The torsional damper absorbs the shock, vibration and noise when delivering the engine driving force.

This improves NVH performance in this vehicle.

Page 529 of 715

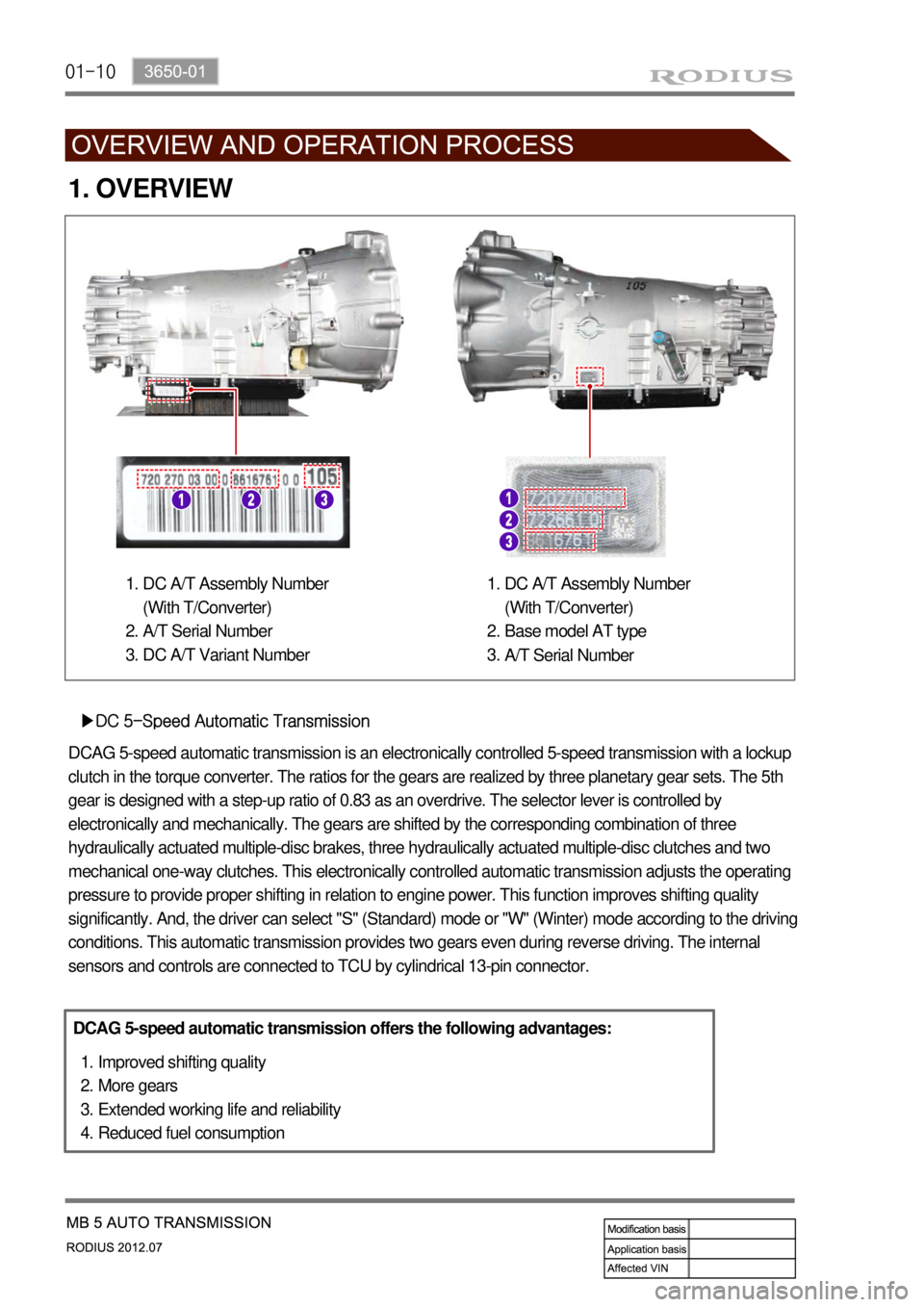

01-10

1. OVERVIEW

▶DC 5-Speed Automatic Transmission

DCAG 5-speed automatic transmission is an electronically controlled 5-speed transmission with a lockup

clutch in the torque converter. The ratios for the gears are realized by three planetary gear sets. The 5th

gear is designed with a step-up ratio of 0.83 as an overdrive. The selector lever is controlled by

electronically and mechanically. The gears are shifted by the corresponding combination of three

hydraulically actuated multiple-disc brakes, three hydraulically actuated multiple-disc clutches and two

mechanical one-way clutches. This electronically controlled automatic transmission adjusts the operating

pressure to provide proper shifting in relation to engine power. This function improves shifting quality

significantly. And, the driver can select "S" (Standard) mode or "W" (Winter) mode according to the driving

conditions. This automatic transmission provides two gears even during reverse driving. The internal

sensors and controls are connected to TCU by cylindrical 13-pin connector.

DCAG 5-speed automatic transmission offers the following advantages:

Improved shifting quality

More gears

Extended working life and reliability

Reduced fuel consumption 1.

2.

3.

4.

DC A/T Assembly Number

(With T/Converter)

A/T Serial Number

DC A/T Variant Number 1.

2.

3.DC A/T Assembly Number

(With T/Converter)

Base model AT type

A/T Serial Number 1.

2.

3.

Page 532 of 715

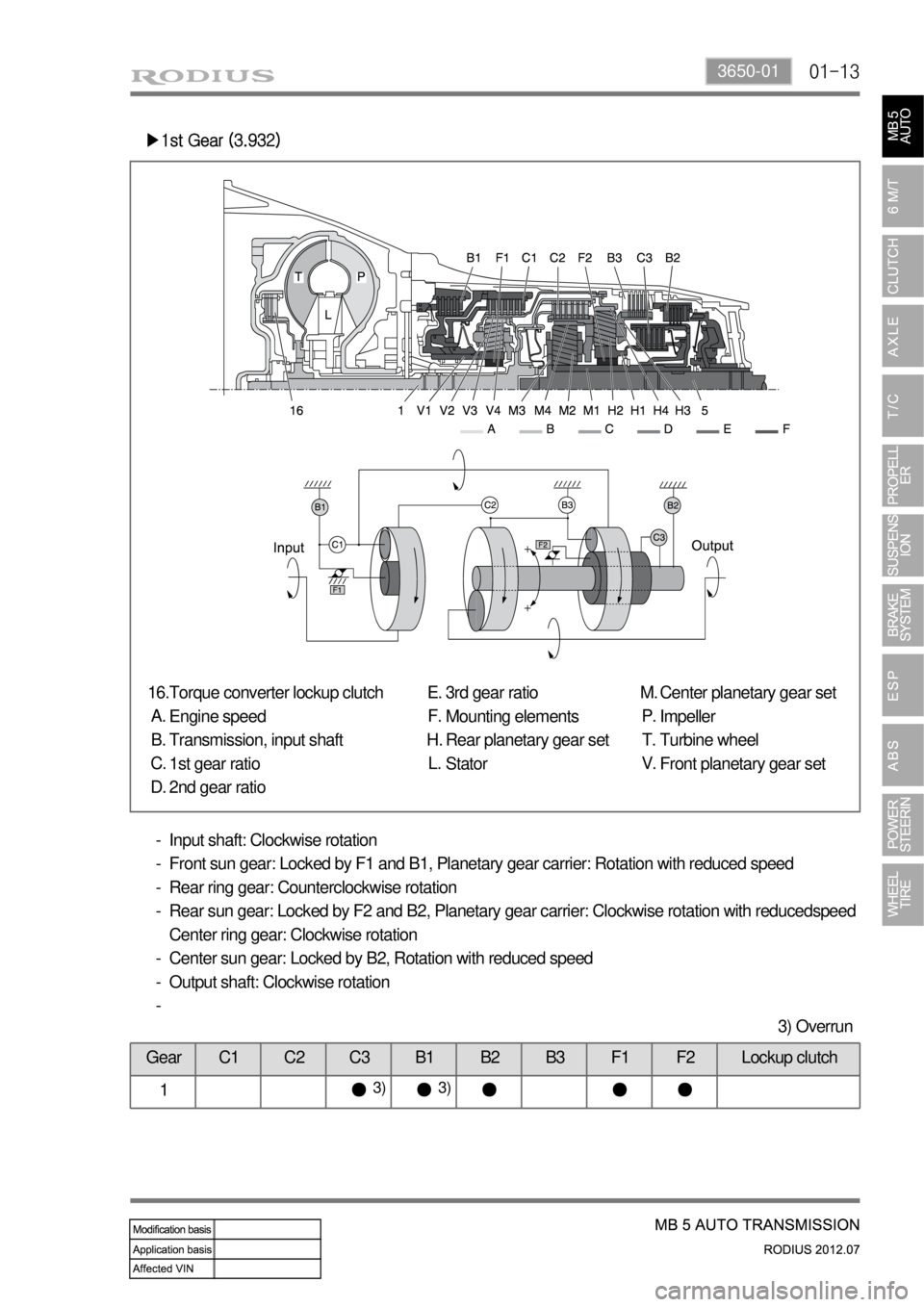

01-133650-01

▶1st Gear (3.932)

Torque converter lockup clutch

Engine speed

Transmission, input shaft

1st gear ratio

2nd gear ratio 16.

A.

B.

C.

D.3rd gear ratio

Mounting elements

Rear planetary gear set

Stator E.

F.

H.

L.Center planetary gear set

Impeller

Turbine wheel

Front planetary gear set M.

P.

T.

V.

Input shaft: Clockwise rotation

Front sun gear: Locked by F1 and B1, Planetary gear carrier: Rotation with reduced speed

Rear ring gear: Counterclockwise rotation

Rear sun gear: Locked by F2 and B2, Planetary gear carrier: Clockwise rotation with reducedspeed

Center ring gear: Clockwise rotation

Center sun gear: Locked by B2, Rotation with reduced speed

Output shaft: Clockwise rotation -

-

-

-

-

-

-

Gear C1 C2 C3 B1 B2 B3 F1 F2 Lockup clutch

1● ● ● ● ●

3) 3)

3) Overrun

Page 533 of 715

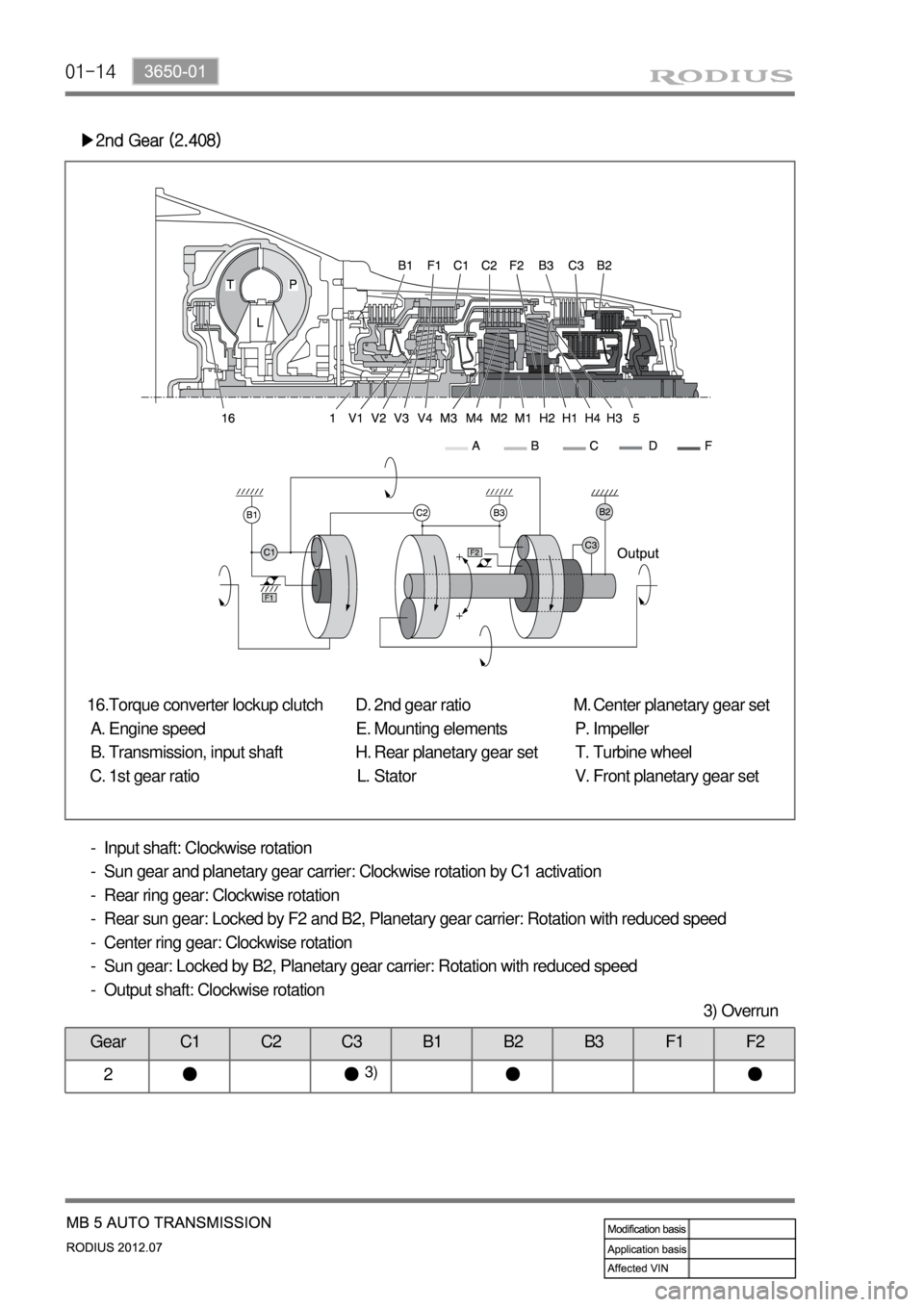

01-14

▶2nd Gear (2.408)

Torque converter lockup clutch

Engine speed

Transmission, input shaft

1st gear ratio 16.

A.

B.

C.2nd gear ratio

Mounting elements

Rear planetary gear set

Stator D.

E.

H.

L.Center planetary gear set

Impeller

Turbine wheel

Front planetary gear set M.

P.

T.

V.

Input shaft: Clockwise rotation

Sun gear and planetary gear carrier: Clockwise rotation by C1 activation

Rear ring gear: Clockwise rotation

Rear sun gear: Locked by F2 and B2, Planetary gear carrier: Rotation with reduced speed

Center ring gear: Clockwise rotation

Sun gear: Locked by B2, Planetary gear carrier: Rotation with reduced speed

Output shaft: Clockwise rotation -

-

-

-

-

-

-

Gear C1 C2 C3 B1 B2 B3 F1 F2

2 ● ● ● ●

3)

3) Overrun