drain bolt SSANGYONG RODIUS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 246 of 715

06-51914-01

2) Inspection of Turbocharger

When problem occurs with the turbocharger, it could cause engine power decline, excessive

discharge of exhaust gas, outbreak of abnormal noise and excessive consumption of oil.

On-board Inspection 1.

Check the bolts and nuts foe looseness or missing

Check the intake and exhaust manifold for looseness or damage

Check the oil supply pipe and drain pipe for damages

Check the housing for crack and deterioration -

-

-

-

Inspection of turbine 2.

Remove the exhaust pipe at the opening of the turbine and check, with a lamp, the existence of

interference of housing and wheel, oil leakage and contamination (at blade edge) of foreign

materials.

Interference: In case where the oil leak sign exists, even the small traces of interferences on

the turbine wheel mean, most of times, that abrasion has occurred on the journal bearing.

Must inspect after overhauling the turbocharger.

Oil Leakage: Followings are the reasons for oil leakage condition -

-

Problems in engine: In case where the oil is smeared on inner wall section of the exhaust

gas opening.

Problems in turbocharger: In case where the oil is smeared on only at the exhaust gas

outlet section. *

*

Idling for long period of time can cause oil leakage to the turbine side due to low pressure of

exhaust gas and the rotation speed of turbine wheel. Please note this is not a turbocharger

problem.

Oil Drain Pipe Defect

In case where oil flow from the turbocharger sensor housing to the crank case is not smooth

would become the reason for leakage as oil builds up within the center housing. Also, oil

thickens (sludge) at high temperature and becomes the indirect reason of wheel hub section.

In such case, clogging and damage of the oil drain pipe and the pressure of blow-by gas

within the crank case must be inspected.

Damages due to Foreign Materials.

When the foreign materials get into the system, it could induce inner damage as rotating

balance of the turbocharger gets out of alignment. -

-

-

Page 252 of 715

06-111914-01

3. TROUBLESHOOTING

The followings are cautions to take in handling defects of turbocharger, which must be fully aware

of.

1) Cautions

After stopping the engine, check whether the bolts on pipe connecting section are loose as

well as the connecting condition of vacuum port and modulator, which is connected to the

actuator.

During idling of the engine, check for leakage in the connecting section of pipe (hoses and

pipes, duct connections, after the turbocharger) by applying soap water. The leakage condition

in the engine block and turbine housing opening can be determined by the occurrence of

abnormal noise of exhaust.

By running the engine at idle speed, abnormal vibration and noise can be checked.

Immediately stop the engine when abnormal vibration and noise is detected and make

thorough inspection whether the turbocharger shaft wheel has any damages as well as

checking the condition of connections between pipes.

In case where the noise of engine is louder than usual, there is possibility of dampness in the

areas related with air cleaner and engine or engine block and turbocharger. And it could affect

the smooth supply of engine oil and discharge.

Check for damp condition in exhaust gas when there is sign of thermal discoloration or

discharge of carbon in connecting area of the duct.

When the engine rotates or in case where there is change in noise level, check for clogging of

air cleaner or air cleaner duct or if there is any significant amount of dust in the compressor

housing.

During the inspection of center housing, inspect inside of the housing by removing the oil drain

pipe to check for sludge generation and its attachment condition at shaft area or turbine side.

Inspect or replace the air cleaner when the compressor wheel is damaged by inflow of foreign

materials.

Inspect both side of the turbocharger wheel after removing inlet and outlet pipe of the

turbocharger. 1.

2.

3.

4.

5.

6.

7.

8.

9.

Page 527 of 715

01-8

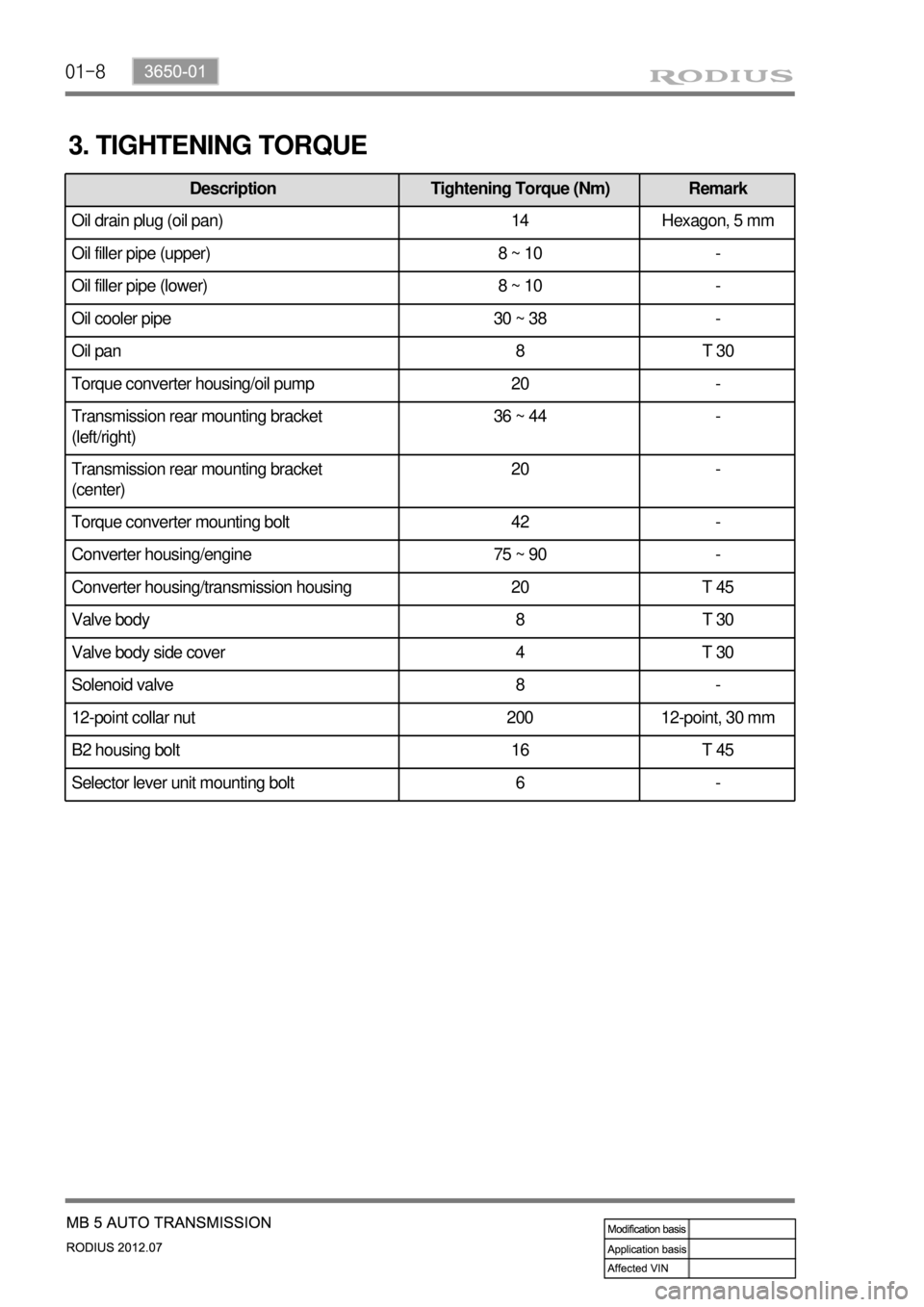

3. TIGHTENING TORQUE

Description Tightening Torque (Nm) Remark

Oil drain plug (oil pan) 14 Hexagon, 5 mm

Oil filler pipe (upper) 8 ~ 10 -

Oil filler pipe (lower) 8 ~ 10 -

Oil cooler pipe 30 ~ 38 -

Oil pan 8 T 30

Torque converter housing/oil pump 20 -

Transmission rear mounting bracket

(left/right)36 ~ 44 -

Transmission rear mounting bracket

(center)20 -

Torque converter mounting bolt 42 -

Converter housing/engine 75 ~ 90 -

Converter housing/transmission housing 20 T 45

Valve body 8 T 30

Valve body side cover 4 T 30

Solenoid valve 8 -

12-point collar nut 200 12-point, 30 mm

B2 housing bolt 16 T 45

Selector lever unit mounting bolt 6 -

Page 545 of 715

02-73170-01

4. TIGHTENING TORQUE

Part nameTightening torque

(Nm)Numbers

Adhesive

1. Seal bolt (rolling plunger and guide spring) 53.9~67.6 1EA Loctite

2. Guide bolt 14.7~21.5 1EA Loctite

3. Pocket ball bearing bolt 29.4~41.1 1EA Loctite

4. Reverse shift fork retainer bolt 53.9~67.6 2EA Loctite

5. Backup lamp switch 29.4~34.3 1EA Loctite

6. Oil drain plug 58.8~78.4 1EA Loctite

7. Interlock bolt 14.7~21.5 1EA -

8. Neutral switch 29.4~34.3 1EA Loctite

9. Oil filler plug 58.8~78.4 1EA Loctite

10. Extension housing 42.1~53.9 12EA -

11. Concentric slave cylinder bolt 9.8~15.6 3EA -

12. Front bearing retainer bolt 19.6~24.5 8EA Loctite