ABS SSANGYONG TURISMO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 616 of 796

06-53310-01

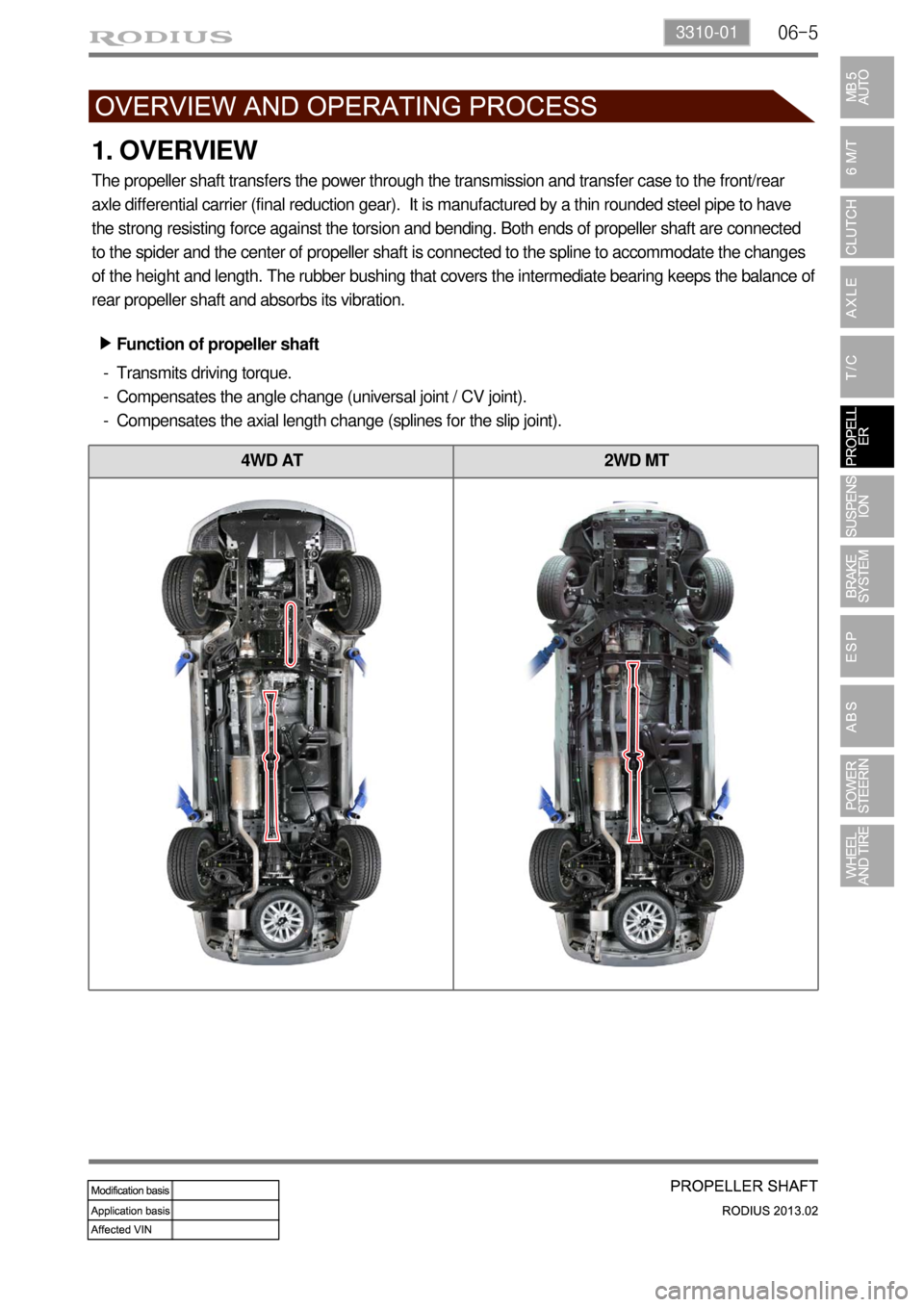

1. OVERVIEW

The propeller shaft transfers the power through the transmission and transfer case to the front/rear

axle differential carrier (final reduction gear). It is manufactured by a thin rounded steel pipe to have

the strong resisting force against the torsion and bending. Both ends of propeller shaft are connected

to the spider and the center of propeller shaft is connected to the spline to accommodate the changes

of the height and length. The rubber bushing that covers the intermediate bearing keeps the balance o

f

rear propeller shaft and absorbs its vibration.

Function of propeller shaft â–¶

Transmits driving torque.

Compensates the angle change (universal joint / CV joint).

Compensates the axial length change (splines for the slip joint). -

-

-

4WD AT 2WD MT

Page 618 of 796

07-34411-01

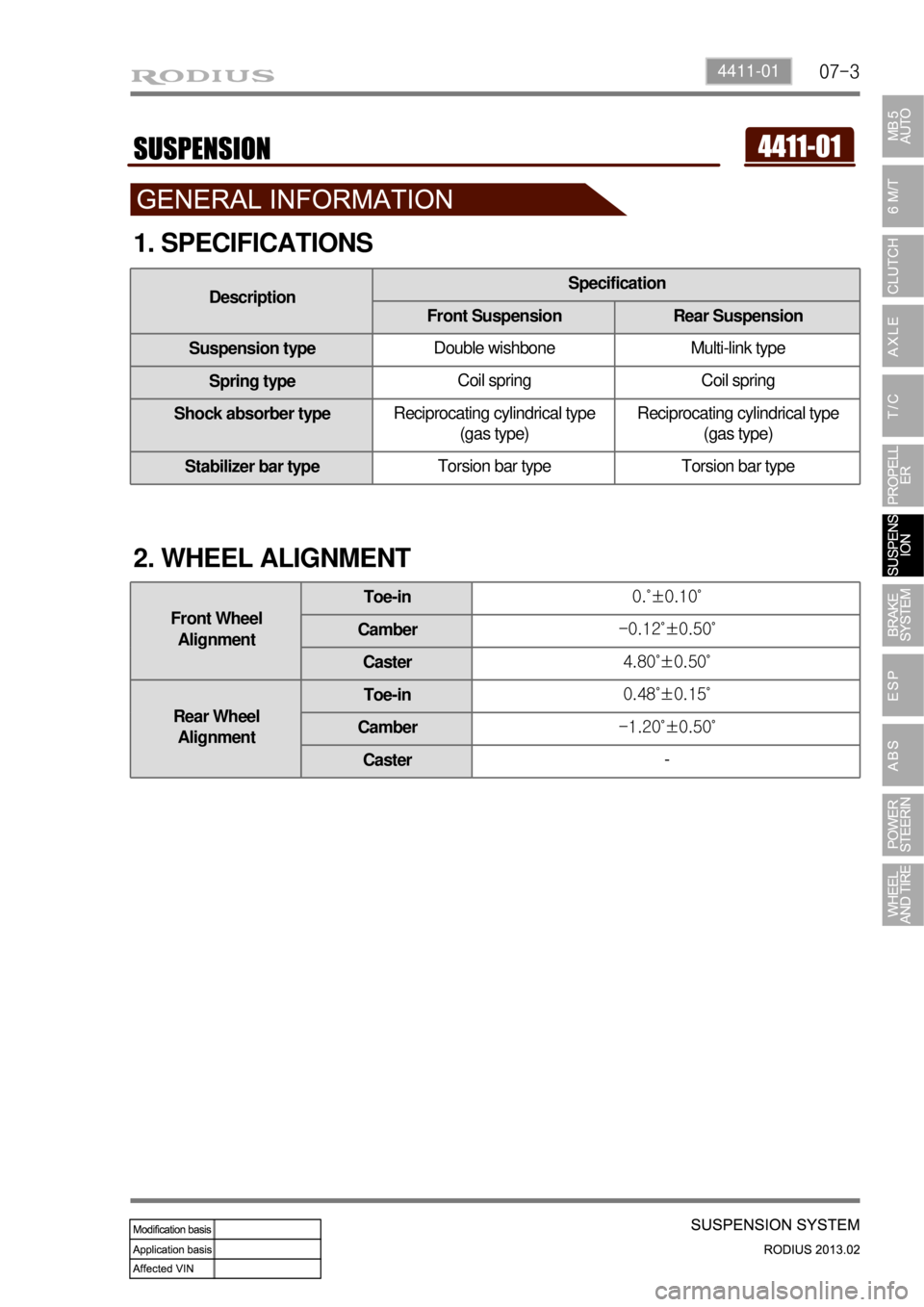

1. SPECIFICATIONS

DescriptionSpecification

Front Suspension Rear Suspension

Suspension typeDouble wishbone Multi-link type

Spring typeCoil spring Coil spring

Shock absorber typeReciprocating cylindrical type

(gas type)Reciprocating cylindrical type

(gas type)

Stabilizer bar typeTorsion bar type Torsion bar type

2. WHEEL ALIGNMENT

Front Wheel

AlignmentToe-in0.˚±0.10˚

Camber-0.12˚±0.50˚

Caster4.80˚±0.50˚

Rear Wheel

AlignmentToe-in0.48˚±0.15˚

Camber-1.20˚±0.50˚

Caster-

Page 620 of 796

07-54411-01

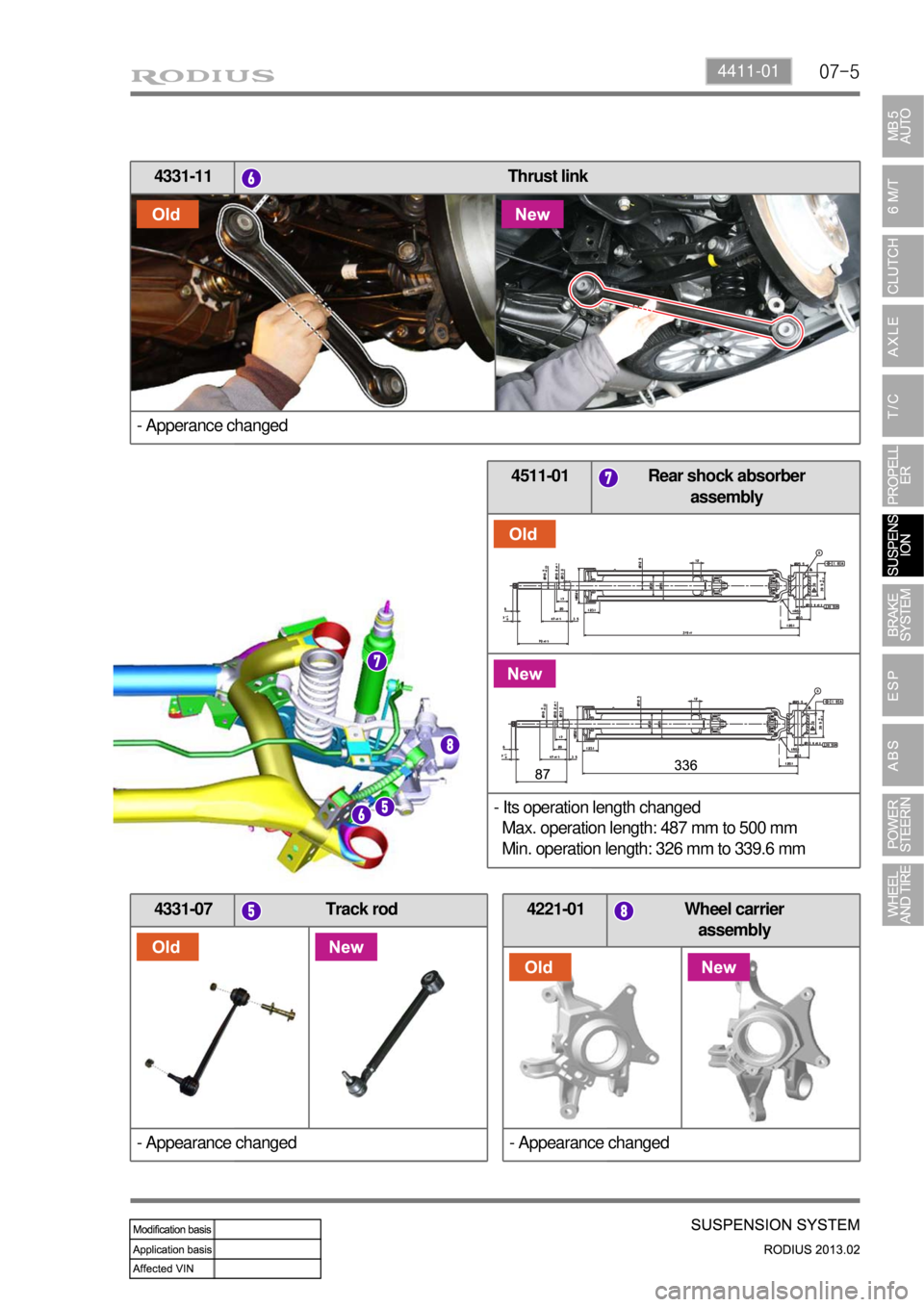

4331-07 Track rod

- Appearance changed4221-01 Wheel carrier

assembly

- Appearance changed

4331-11 Thrust link

- Apperance changed

4511-01 Rear shock absorber

assembly

- Its operation length changed

Max. operation length: 487 mm to 500 mm

Min. operation length: 326 mm to 339.6 mm

Page 621 of 796

07-6

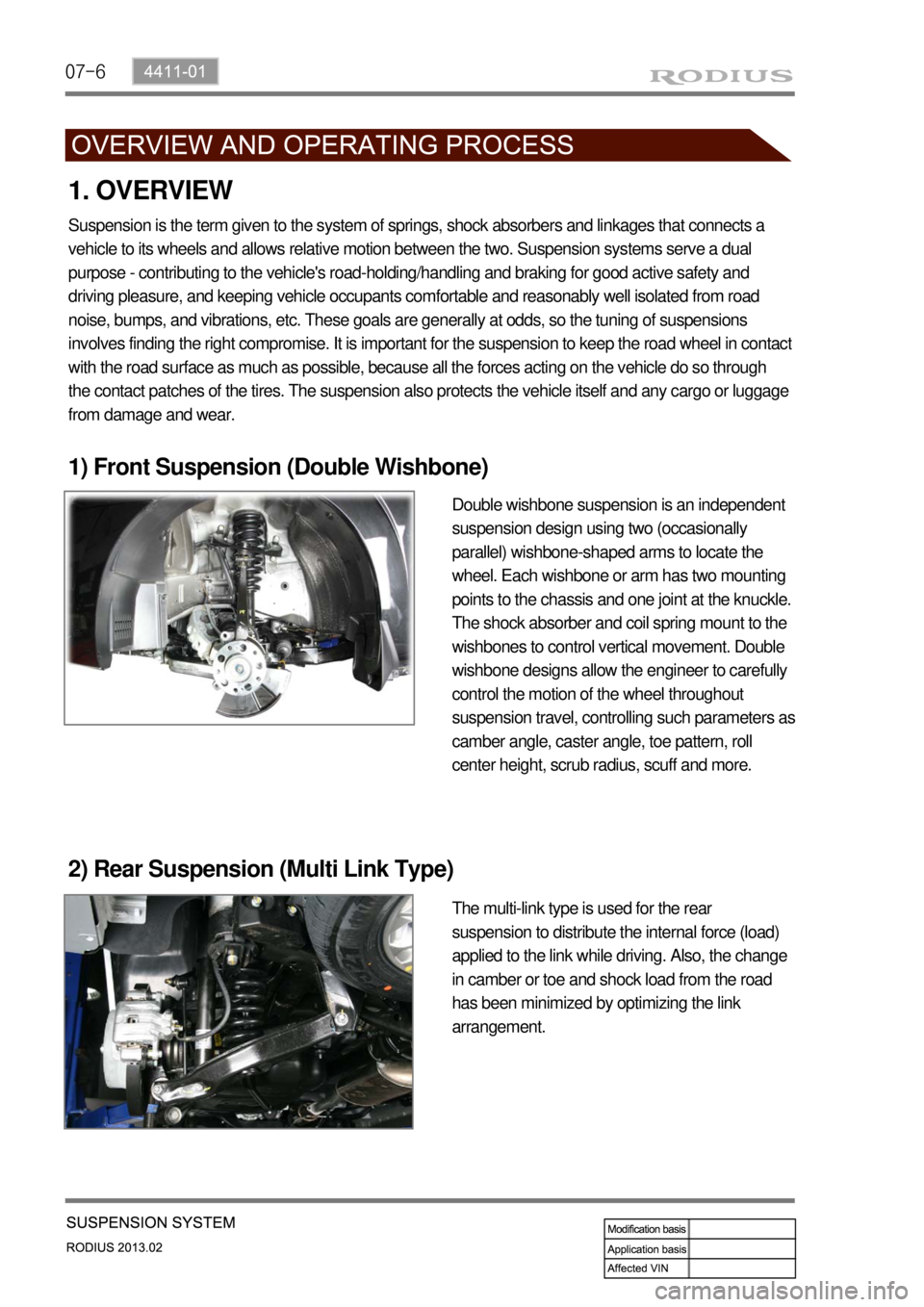

1) Front Suspension (Double Wishbone)

Suspension is the term given to the system of springs, shock absorbers and linkages that connects a

vehicle to its wheels and allows relative motion between the two. Suspension systems serve a dual

purpose - contributing to the vehicle's road-holding/handling and braking for good active safety and

driving pleasure, and keeping vehicle occupants comfortable and reasonably well isolated from road

noise, bumps, and vibrations, etc. These goals are generally at odds, so the tuning of suspensions

involves finding the right compromise. It is important for the suspension to keep the road wheel in contac

t

with the road surface as much as possible, because all the forces acting on the vehicle do so through

the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage

from damage and wear.

2) Rear Suspension (Multi Link Type)

1. OVERVIEW

Double wishbone suspension is an independent

suspension design using two (occasionally

parallel) wishbone-shaped arms to locate the

wheel. Each wishbone or arm has two mounting

points to the chassis and one joint at the knuckle.

The shock absorber and coil spring mount to the

wishbones to control vertical movement. Double

wishbone designs allow the engineer to carefully

control the motion of the wheel throughout

suspension travel, controlling such parameters as

camber angle, caster angle, toe pattern, roll

center height, scrub radius, scuff and more.

The multi-link type is used for the rear

suspension to distribute the internal force (load)

applied to the link while driving. Also, the change

in camber or toe and shock load from the road

has been minimized by optimizing the link

arrangement.

Page 623 of 796

07-8

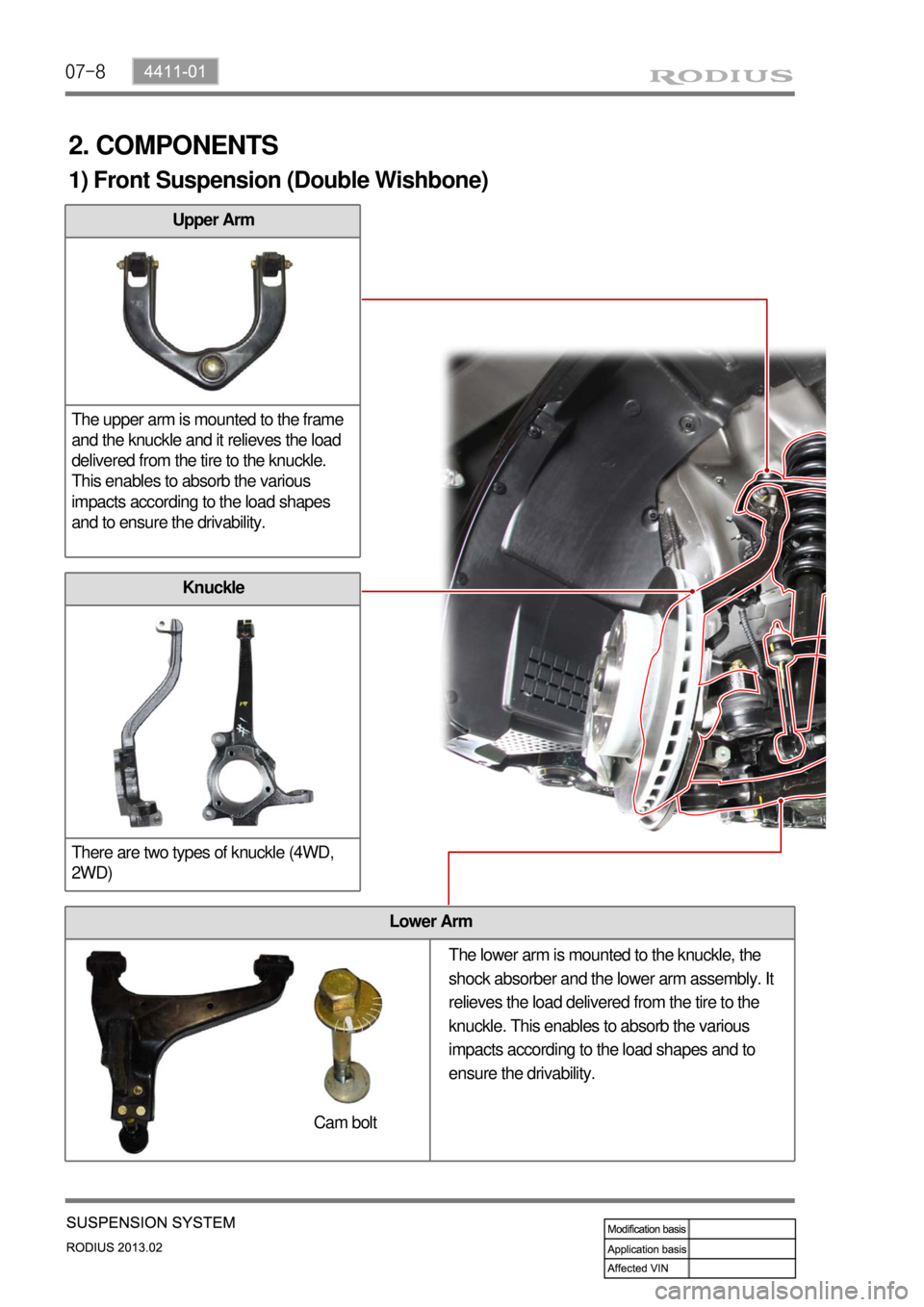

Upper Arm

The upper arm is mounted to the frame

and the knuckle and it relieves the load

delivered from the tire to the knuckle.

This enables to absorb the various

impacts according to the load shapes

and to ensure the drivability.

Lower Arm

Knuckle

There are two types of knuckle (4WD,

2WD)

Cam bolt

1) Front Suspension (Double Wishbone)

The lower arm is mounted to the knuckle, the

shock absorber and the lower arm assembly. It

relieves the load delivered from the tire to the

knuckle. This enables to absorb the various

impacts according to the load shapes and to

ensure the drivability.

2. COMPONENTS

Page 624 of 796

07-94411-01

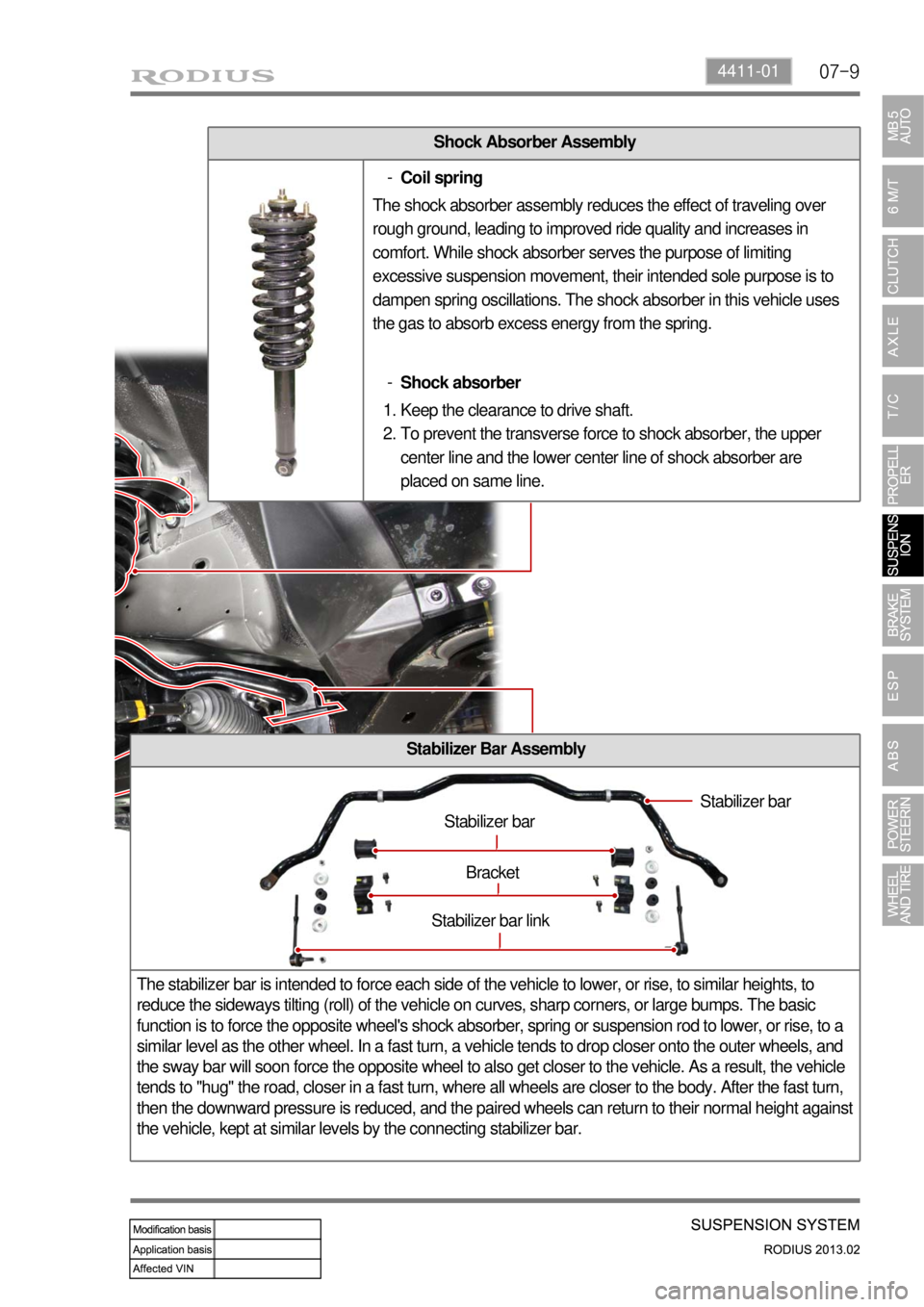

Shock Absorber Assembly

Stabilizer Bar Assembly

The stabilizer bar is intended to force each side of the vehicle to lower, or rise, to similar heights, to

reduce the sideways tilting (roll) of the vehicle on curves, sharp corners, or large bumps. The basic

function is to force the opposite wheel's shock absorber, spring or suspension rod to lower, or rise, to a

similar level as the other wheel. In a fast turn, a vehicle tends to drop closer onto the outer wheels, and

the sway bar will soon force the opposite wheel to also get closer to the vehicle. As a result, the vehicle

tends to "hug" the road, closer in a fast turn, where all wheels are closer to the body. After the fast turn,

then the downward pressure is reduced, and the paired wheels can return to their normal height against

the vehicle, kept at similar levels by the connecting stabilizer bar.

Stabilizer bar

Stabilizer bar

Bracket

Stabilizer bar link

Coil spring -

The shock absorber assembly reduces the effect of traveling over

rough ground, leading to improved ride quality and increases in

comfort. While shock absorber serves the purpose of limiting

excessive suspension movement, their intended sole purpose is to

dampen spring oscillations. The shock absorber in this vehicle uses

the gas to absorb excess energy from the spring.

Shock absorber -

Keep the clearance to drive shaft.

To prevent the transverse force to shock absorber, the upper

center line and the lower center line of shock absorber are

placed on same line. 1.

2.

Page 625 of 796

07-10

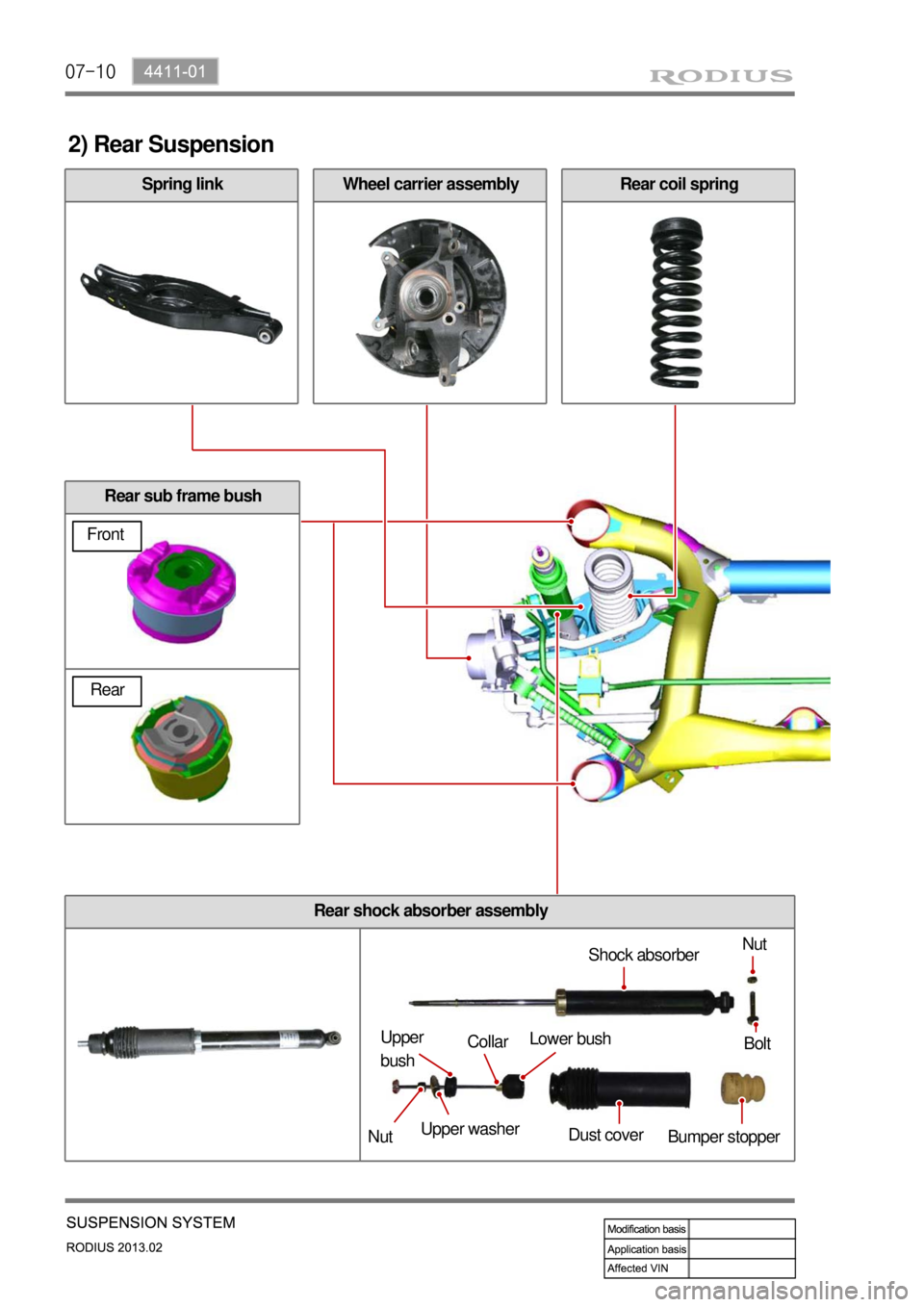

Spring link

2) Rear Suspension

Rear coil springWheel carrier assembly

Rear sub frame bush

Nut

Upper washer Upper

bush

Bumper stopper Lower bush

Dust coverShock absorber

Bolt

NutCollar

Front

Rear

Rear shock absorber assembly

Page 628 of 796

07-134411-01

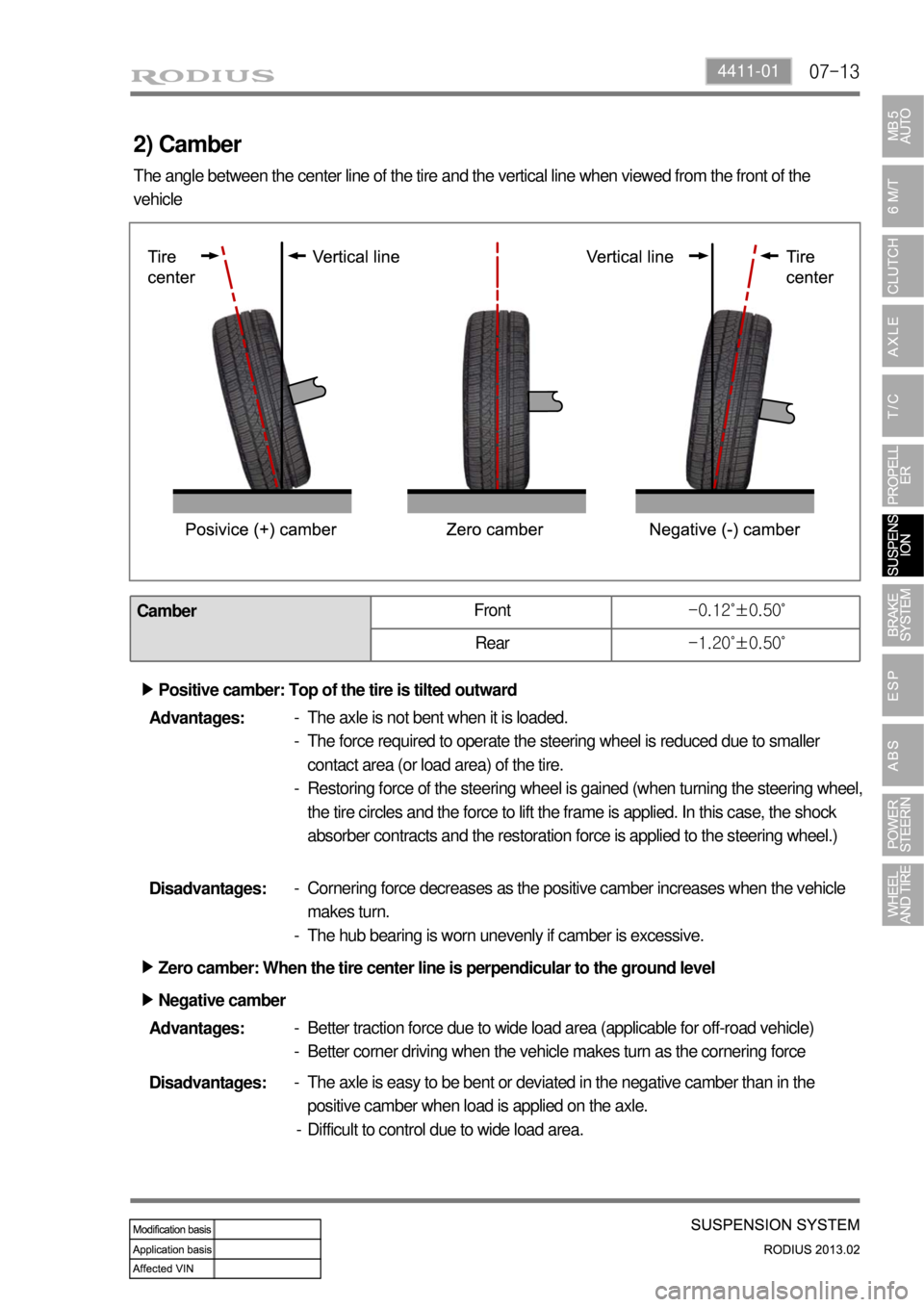

2) Camber

The angle between the center line of the tire and the vertical line when viewed from the front of the

vehicle

CamberFront-0.12˚±0.50˚

Rear-1.20˚±0.50˚

Zero camber: When the tire center line is perpendicular to the ground level â–¶

Disadvantages:The axle is easy to be bent or deviated in the negative camber than in the

positive camber when load is applied on the axle.

Difficult to control due to wide load area. -

- Advantages:Better traction force due to wide load area (applicable for off-road vehicle)

Better corner driving when the vehicle makes turn as the cornering force -

- Negative camber â–¶Disadvantages:Cornering force decreases as the positive camber increases when the vehicle

makes turn.

The hub bearing is worn unevenly if camber is excessive. -

- Advantages:The axle is not bent when it is loaded.

The force required to operate the steering wheel is reduced due to smaller

contact area (or load area) of the tire.

Restoring force of the steering wheel is gained (when turning the steering wheel,

the tire circles and the force to lift the frame is applied. In this case, the shock

absorber contracts and the restoration force is applied to the steering wheel.) -

-

- Positive camber: Top of the tire is tilted outward â–¶

Page 631 of 796

08-4

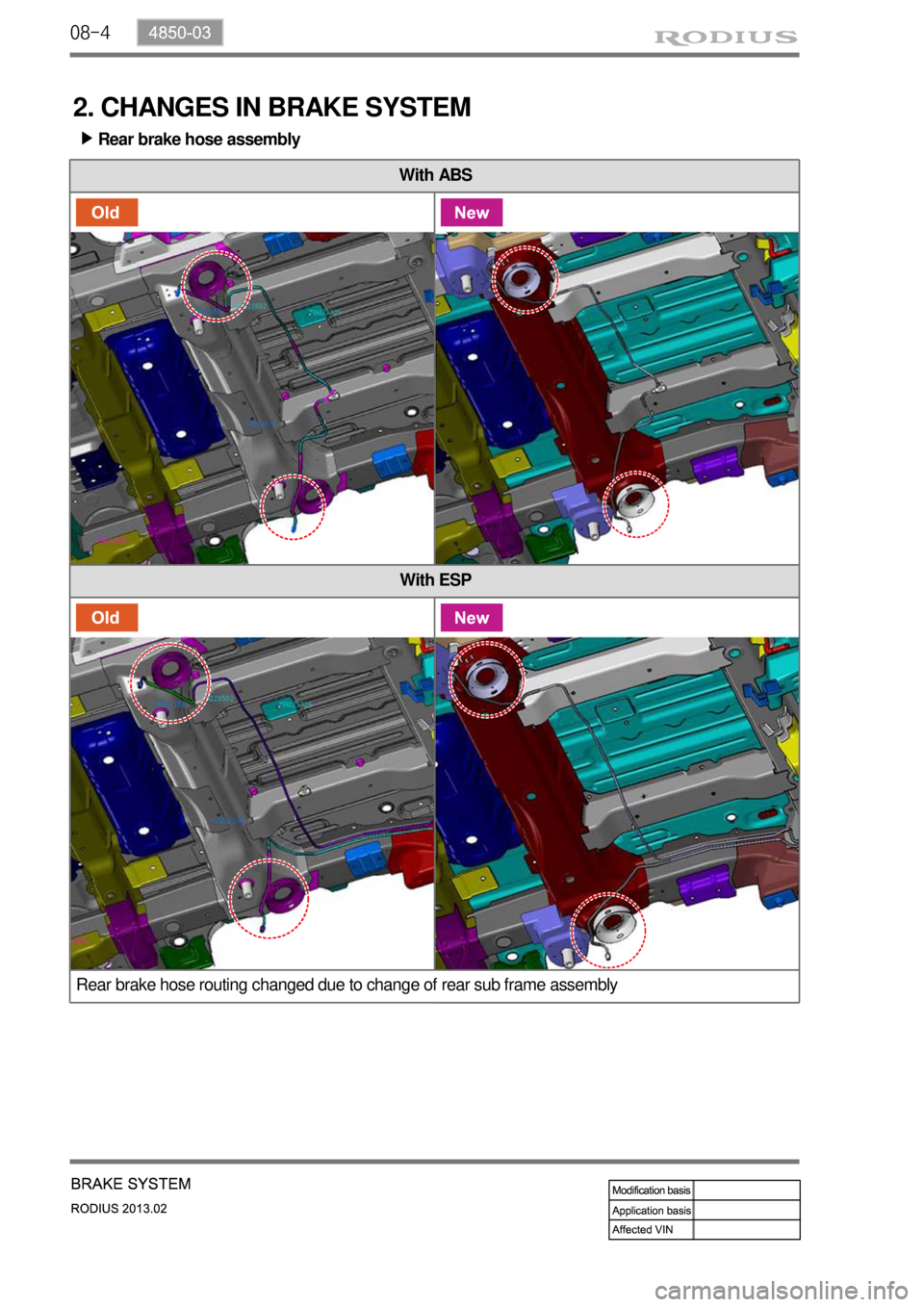

2. CHANGES IN BRAKE SYSTEM

Rear brake hose assembly â–¶

With ABS

With ESP

Rear brake hose routing changed due to change of rear sub frame assembly

Page 649 of 796

09-34891-01

1. SPECIFICATIONS

1) Pressure Sensor

UnitDescription

Location

ABS ESP

HECU

(Hydraulic &

Electronic Control

Unit) CPU:MCU60 (32bit)

Clock Frequency:

28 MHz

Memory: 128~256 KB CPU:MCU60 (32bit)

Clock Frequency:

28 MHz

Memory:256~512 KB Under the front washer

reservoir

Wheel Speed

SensorActive type wheel speed

sensorActive type wheel speed

sensorOn each wheel

Front air gap:

0.3 ~ 1.3mm,

Rear air gap:

0.3 ~ 1.3 mm

Steering Wheel

Angle SensorN/AMaximum angular speed:

1500°/sec

Operating voltage:

9~16 VUnder the steering

wheel

Sensor ClusterN/AIntegrated with yaw rate

sensor and lateral sensorUnder the audio

assembly

Pressure Sensor

N/A Analog outputUnder the master

cylinder

Description Specification

Supplying voltage approx. 5 V (4.75~5.25 V)

Max. pressure 350 bar