Axle SSANGYONG TURISMO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 627 of 796

07-12

3. WHEEL ALIGNMENT

Wheel alignment (adjustment of Camber, Caster and Toe) is part of standard automobile maintenance

that consists of adjusting the angles of the wheels so that they are set to the specification. The purpose

of these adjustments is to reduce tire wear, and to ensure that vehicle travel is straight and true (without

"pulling" to one side). Alignment angles can also be altered beyond the specifications to obtain a specific

handling characteristic.

When viewed from the top, the distance between the tire centers is smaller in the front than in

the rear. ▶

Side slip protection

Parallel front wheels rotation (straight ahead driving is ensured by toe-in to prevent the wheels from tilting

outwards by the camber while driving)

Prevention of uneven (outward) tire wear Prevention of toe-out from wearing of steering linkage -

-

-

1) Toe-in

The difference of measured distances between the front ends of the tires (A) and the rear ends of the

tires (B) along the same axle when viewed the wheels from the top.

Toe-inFront0.˚±0.10˚

Rear0.48˚±0.15˚

Necessity for Wheel Alignment ▶

Wheel alignment consists of adjusting the angles of the wheels so that they are perpendicular to the

ground and parallel to each other. The purpose of these adjustments is maximum tire life and a vehicle

that tracks straight and true when driving along a straight and level road.

The symptoms of a vehicle that is out of alignment are:

Uneven or rapid tire wear

Pulling or drifting away from a straight line

Wandering on a straight level road

Spokes of the steering wheel off to one side while driving on a straight and level road.

Page 628 of 796

07-134411-01

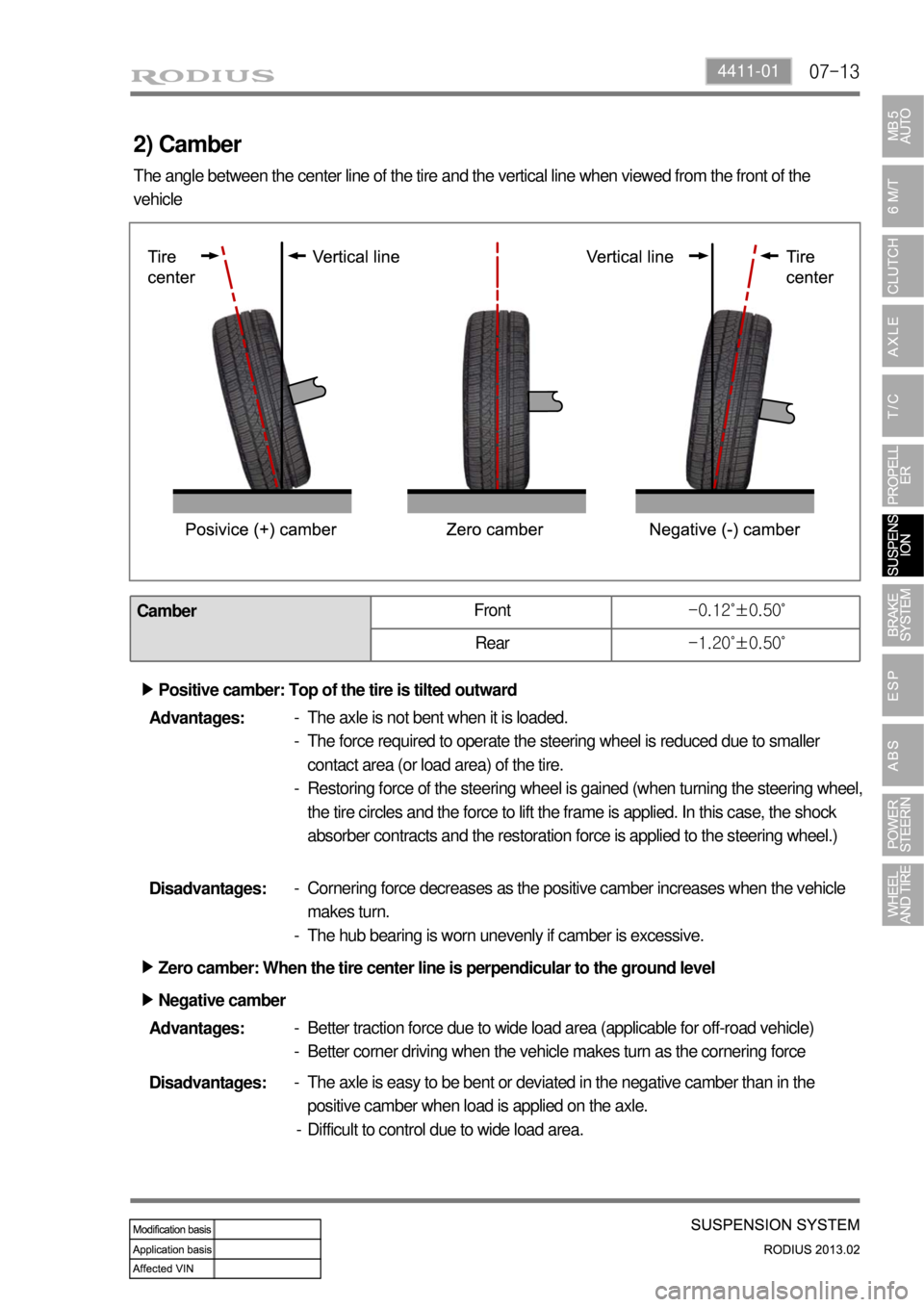

2) Camber

The angle between the center line of the tire and the vertical line when viewed from the front of the

vehicle

CamberFront-0.12˚±0.50˚

Rear-1.20˚±0.50˚

Zero camber: When the tire center line is perpendicular to the ground level ▶

Disadvantages:The axle is easy to be bent or deviated in the negative camber than in the

positive camber when load is applied on the axle.

Difficult to control due to wide load area. -

- Advantages:Better traction force due to wide load area (applicable for off-road vehicle)

Better corner driving when the vehicle makes turn as the cornering force -

- Negative camber ▶Disadvantages:Cornering force decreases as the positive camber increases when the vehicle

makes turn.

The hub bearing is worn unevenly if camber is excessive. -

- Advantages:The axle is not bent when it is loaded.

The force required to operate the steering wheel is reduced due to smaller

contact area (or load area) of the tire.

Restoring force of the steering wheel is gained (when turning the steering wheel,

the tire circles and the force to lift the frame is applied. In this case, the shock

absorber contracts and the restoration force is applied to the steering wheel.) -

-

- Positive camber: Top of the tire is tilted outward ▶

Page 629 of 796

07-14

3) Caster

The angle between the vertical line and king pin, which fixes the steering knuckle and front axle,

(steering column which connects the top and bottom ball joints in the independent axle type) when

viewed the tires from the side.

CasterFront4.80˚±0.50˚

Rear -

Disadvantages:Impact from the road is transferred to the steering wheel (steering wheel turns)

Poor straightness -

- Advantages:Directional force to go straight (following control)

Restoring force of the wheel (restored to the straight ahead direction)

Prevention of wheel shimmy (wheels wobble left and right) -

-

-

Negative caster: ▶Top of the king pin is tilted forward from the vertical line of the wheel center

when viewed the tires from the side Positive caster: ▶

With considering the height difference between the wheel centers of the front and rear

wheels. (Under standard condition that the vehicle is on a level ground) Caster: ▶

Advantages:Smaller turning radius -Top of the king pin is tilted backward from the vertical line of the wheel center

when viewed the tires from the side

Page 680 of 796

10-74891-01

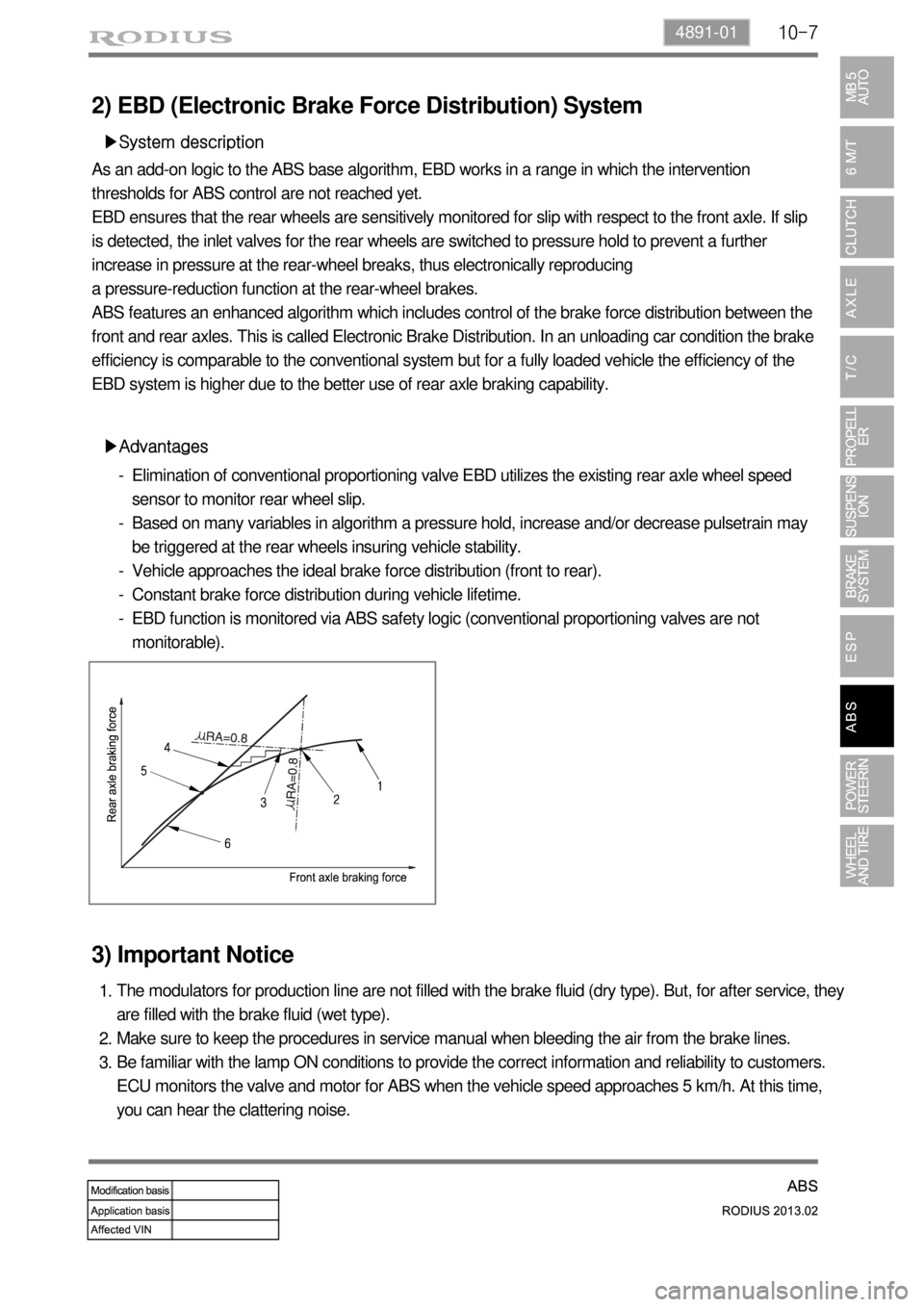

2) EBD (Electronic Brake Force Distribution) System

▶System description

As an add-on logic to the ABS base algorithm, EBD works in a range in which the intervention

thresholds for ABS control are not reached yet.

EBD ensures that the rear wheels are sensitively monitored for slip with respect to the front axle. If slip

is detected, the inlet valves for the rear wheels are switched to pressure hold to prevent a further

increase in pressure at the rear-wheel breaks, thus electronically reproducing

a pressure-reduction function at the rear-wheel brakes.

ABS features an enhanced algorithm which includes control of the brake force distribution between the

front and rear axles. This is called Electronic Brake Distribution. In an unloading car condition the brake

efficiency is comparable to the conventional system but for a fully loaded vehicle the efficiency of the

EBD system is higher due to the better use of rear axle braking capability.

▶Advantages

Elimination of conventional proportioning valve EBD utilizes the existing rear axle wheel speed

sensor to monitor rear wheel slip.

Based on many variables in algorithm a pressure hold, increase and/or decrease pulsetrain may

be triggered at the rear wheels insuring vehicle stability.

Vehicle approaches the ideal brake force distribution (front to rear).

Constant brake force distribution during vehicle lifetime.

EBD function is monitored via ABS safety logic (conventional proportioning valves are not

monitorable). -

-

-

-

-

3) Important Notice

The modulators for production line are not filled with the brake fluid (dry type). But, for after service, they

are filled with the brake fluid (wet type).

Make sure to keep the procedures in service manual when bleeding the air from the brake lines.

Be familiar with the lamp ON conditions to provide the correct information and reliability to customers.

ECU monitors the valve and motor for ABS when the vehicle speed approaches 5 km/h. At this time,

you can hear the clattering noise. 1.

2.

3.

Page 705 of 796

12-10

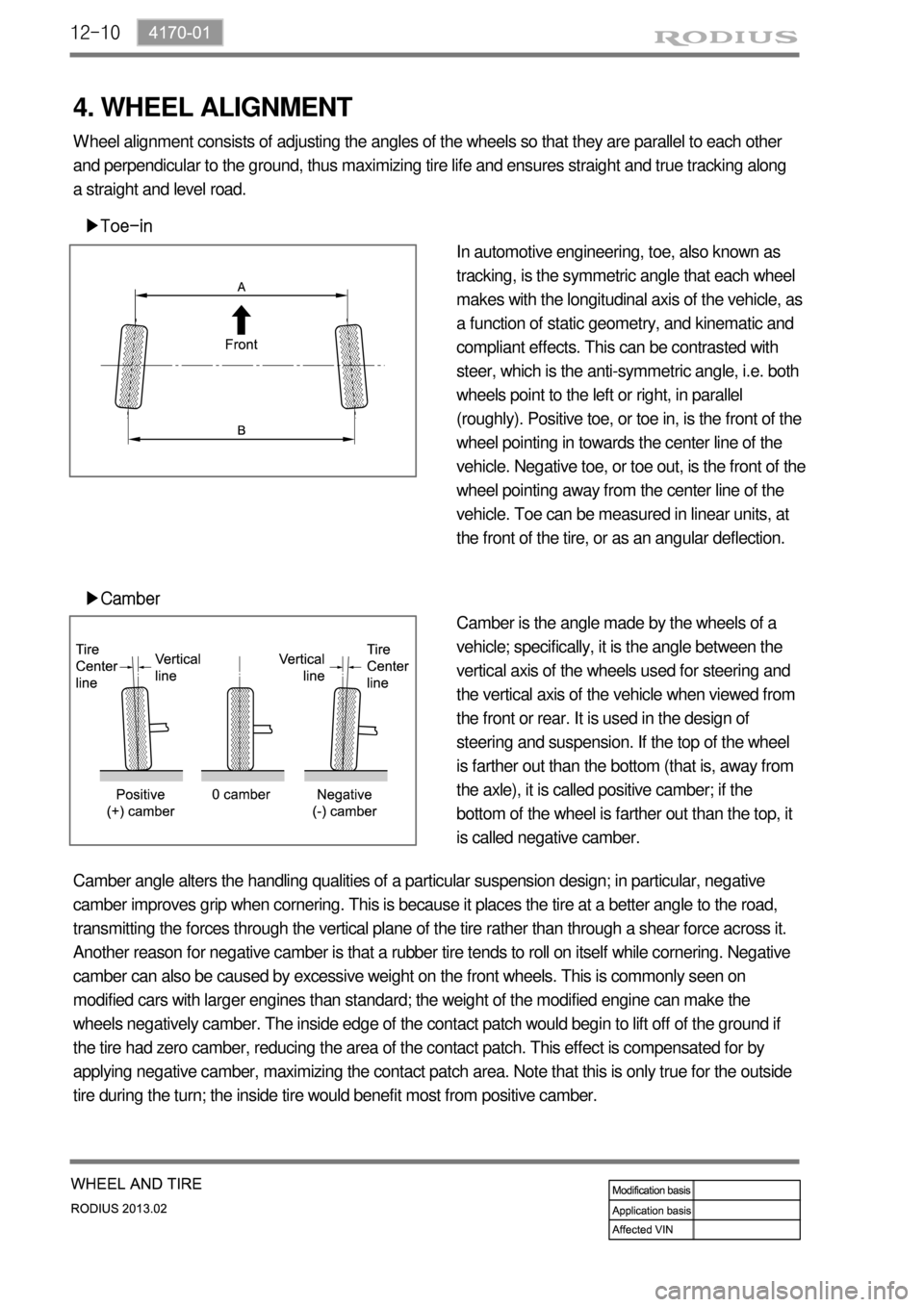

4. WHEEL ALIGNMENT

▶Toe-in

▶Camber

In automotive engineering, toe, also known as

tracking, is the symmetric angle that each wheel

makes with the longitudinal axis of the vehicle, as

a function of static geometry, and kinematic and

compliant effects. This can be contrasted with

steer, which is the anti-symmetric angle, i.e. both

wheels point to the left or right, in parallel

(roughly). Positive toe, or toe in, is the front of the

wheel pointing in towards the center line of the

vehicle. Negative toe, or toe out, is the front of the

wheel pointing away from the center line of the

vehicle. Toe can be measured in linear units, at

the front of the tire, or as an angular deflection.

Camber is the angle made by the wheels of a

vehicle; specifically, it is the angle between the

vertical axis of the wheels used for steering and

the vertical axis of the vehicle when viewed from

the front or rear. It is used in the design of

steering and suspension. If the top of the wheel

is farther out than the bottom (that is, away from

the axle), it is called positive camber; if the

bottom of the wheel is farther out than the top, it

is called negative camber. Wheel alignment consists of adjusting the angles of the wheels so that they are parallel to each other

and perpendicular to the ground, thus maximizing tire life and ensures straight and true tracking along

a straight and level road.

Camber angle alters the handling qualities of a particular suspension design; in particular, negative

camber improves grip when cornering. This is because it places the tire at a better angle to the road,

transmitting the forces through the vertical plane of the tire rather than through a shear force across it.

Another reason for negative camber is that a rubber tire tends to roll on itself while cornering. Negative

camber can also be caused by excessive weight on the front wheels. This is commonly seen on

modified cars with larger engines than standard; the weight of the modified engine can make the

wheels negatively camber. The inside edge of the contact patch would begin to lift off of the ground if

the tire had zero camber, reducing the area of the contact patch. This effect is compensated for by

applying negative camber, maximizing the contact patch area. Note that this is only true for the outside

tire during the turn; the inside tire would benefit most from positive camber.