SSANGYONG TURISMO 2013 Service Manual

TURISMO 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57526/w960_57526-0.png

SSANGYONG TURISMO 2013 Service Manual

Trending: wheel, Master cylinder clutch, run flat, wheel size, gas type, boot, ignition

Page 201 of 796

02-42

(3) Functions

Piston transfers the combustion energy from engine to connecting rod. Especially in the direct injection

engine such as D20DTF, it provides the combustion space and largely effects to the engine performance

and exhaust gas.

Piston ring

#1 ring (Top ring) : Prevents the high pressurized combustion gas from leaking into crank chamber,

and prevents the engine oil getting into combustion chamber.

#2 ring: Scrapes the engine oil on the cylinder bore, and prevents the leaked combustion gas from #1

ring from leaking into the crank chamber.

Oil ring: Scrapes the engine oil on the cylinder bore.

Piston pin

Connects the piston the connecting rod, and transfers the linear movement of piston to connecting

rod to convert it to rotating energy

Snap pin

Locks the piston pin. ▶

-

-

-

▶

-

▶

-

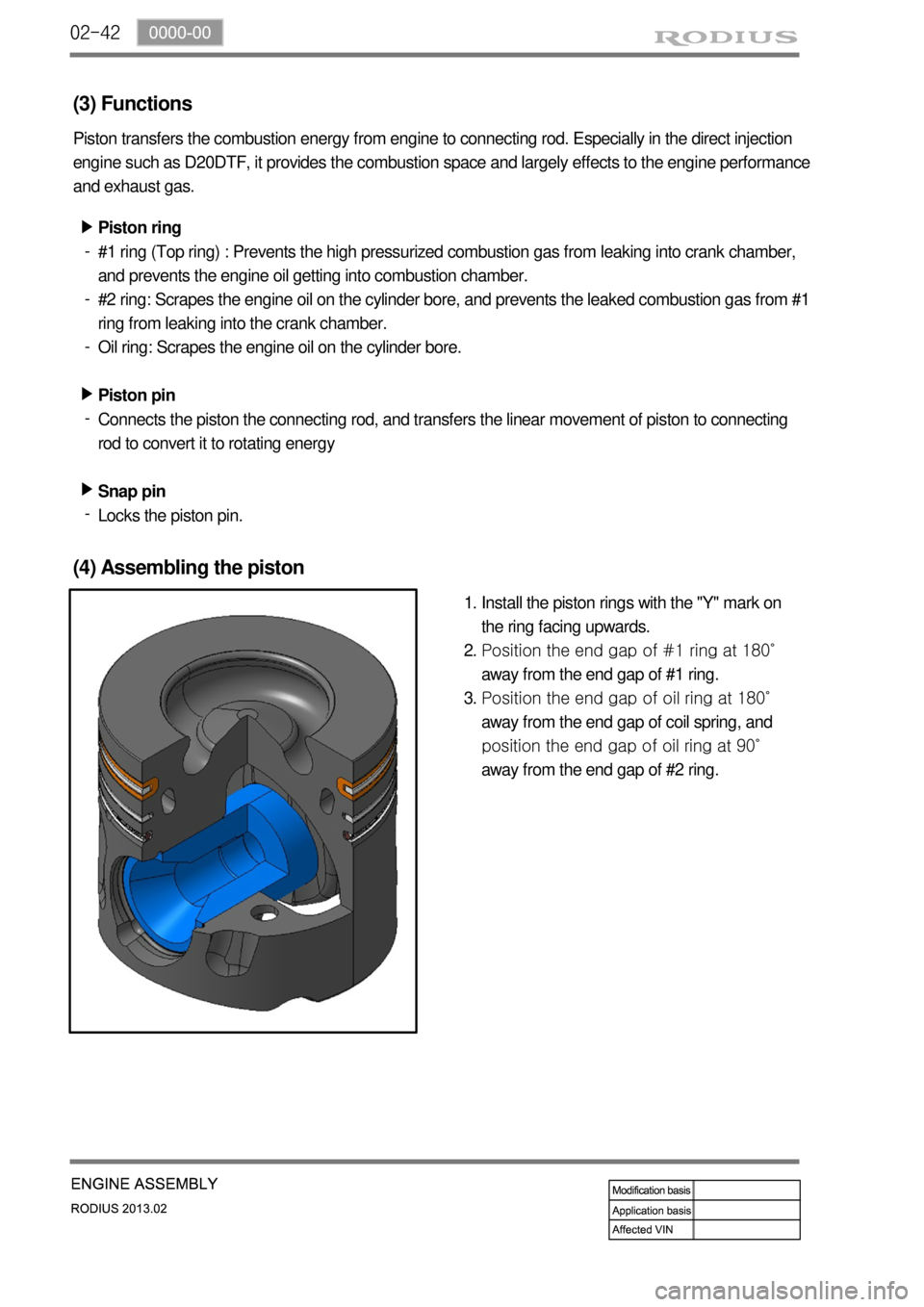

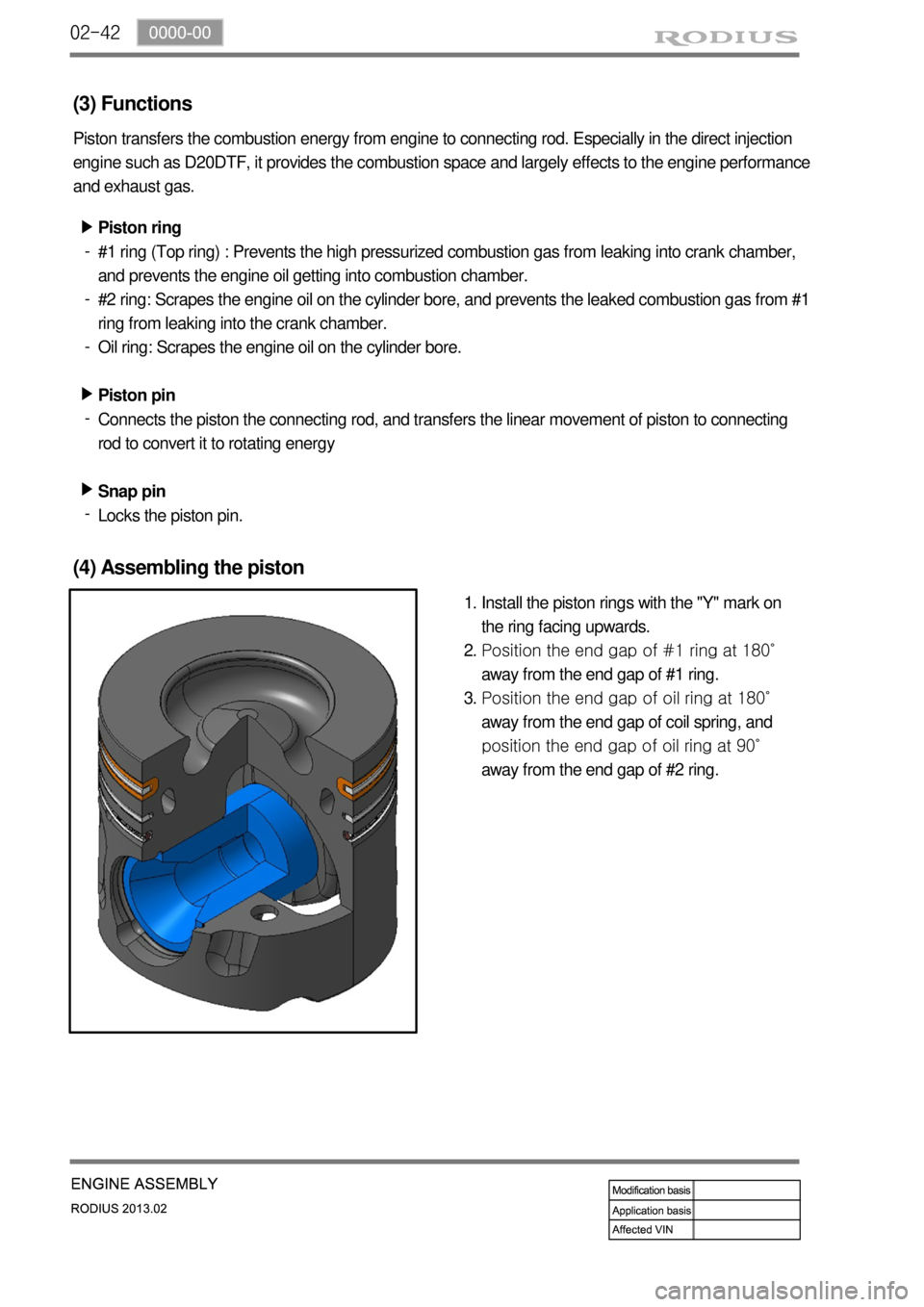

(4) Assembling the piston

Install the piston rings with the "Y" mark on

the ring facing upwards.

Position the end gap of #1 ring at 180˚

away from the end gap of #1 ring.

Position the end gap of oil ring at 180˚

away from the end gap of coil spring, and

position the end gap of oil ring at 90˚

away from the end gap of #2 ring. 1.

2.

3.

Page 202 of 796

02-430000-00

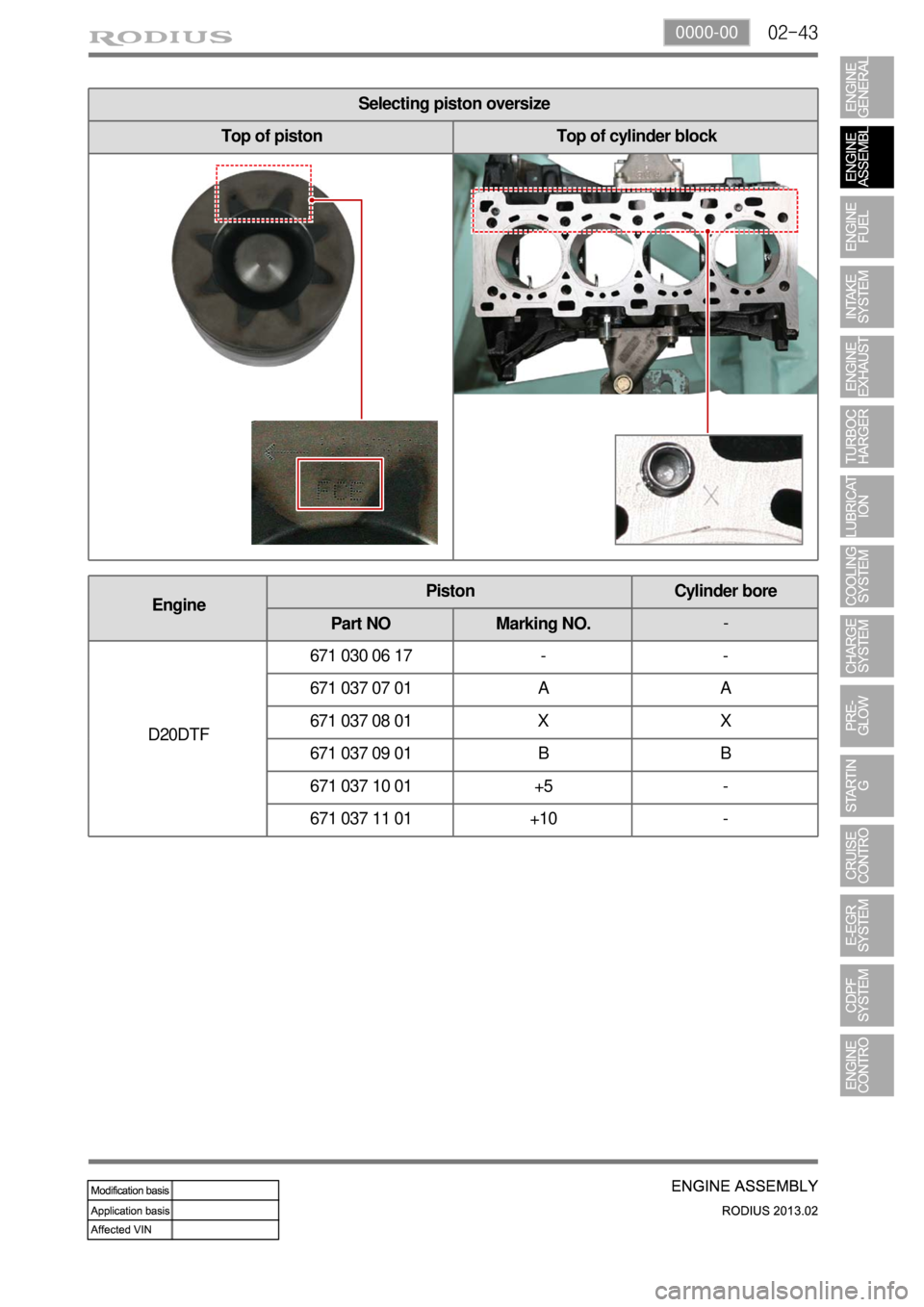

Selecting piston oversize

Top of piston Top of cylinder block

EnginePiston Cylinder bore

Part NO Marking NO.-

D20DTF 671 030 06 17 - -

671 037 07 01 A A

671 037 08 01 X X

671 037 09 01 B B

671 037 10 01 +5 -

671 037 11 01 +10 -

Page 203 of 796

02-44

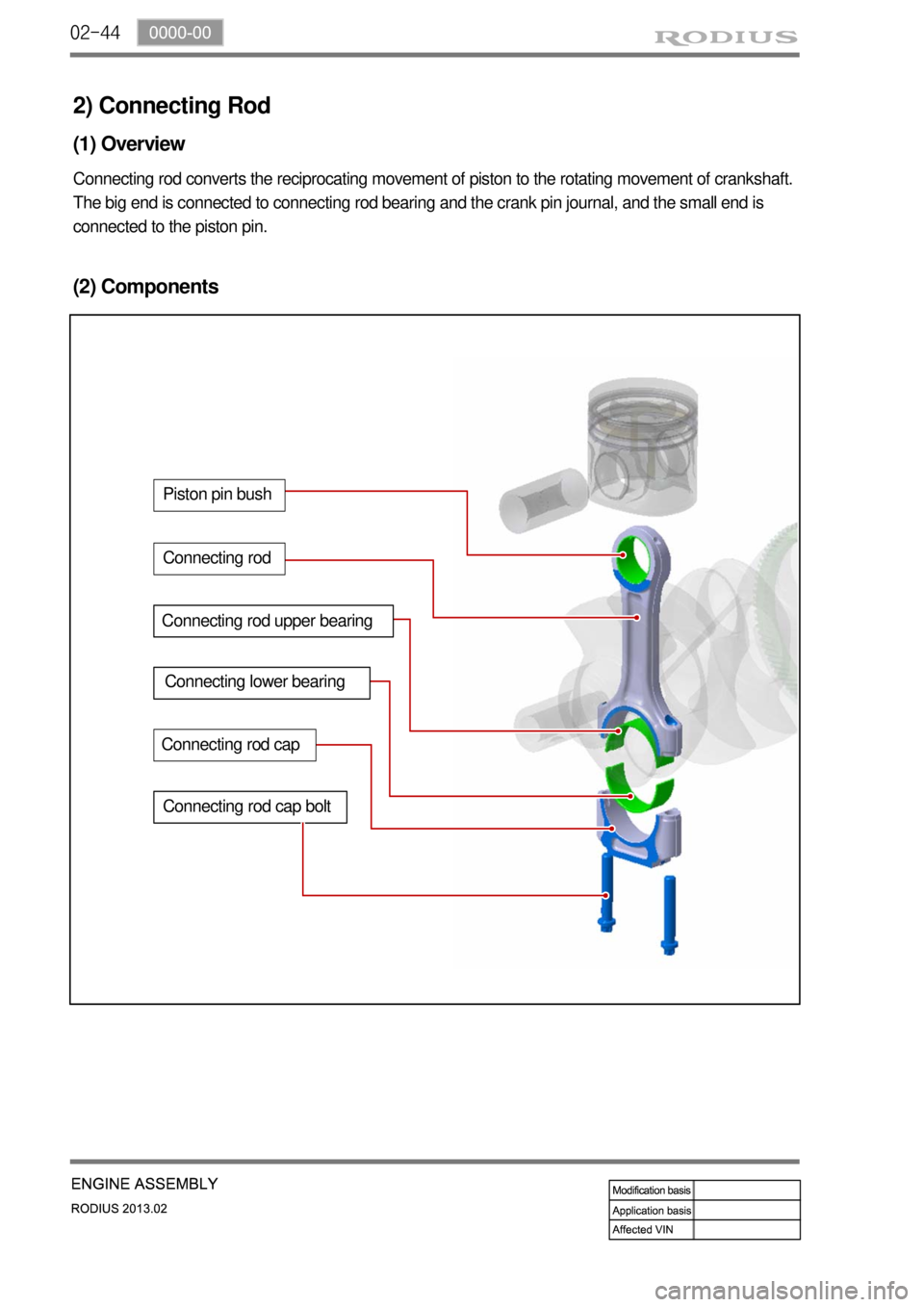

2) Connecting Rod

(1) Overview

Connecting rod converts the reciprocating movement of piston to the rotating movement of crankshaft.

The big end is connected to connecting rod bearing and the crank pin journal, and the small end is

connected to the piston pin.

(2) Components

Connecting rod cap bolt

Connecting rod upper bearing

Connecting rod

Piston pin bush

Connecting lower bearing

Connecting rod cap

Page 204 of 796

02-450000-00

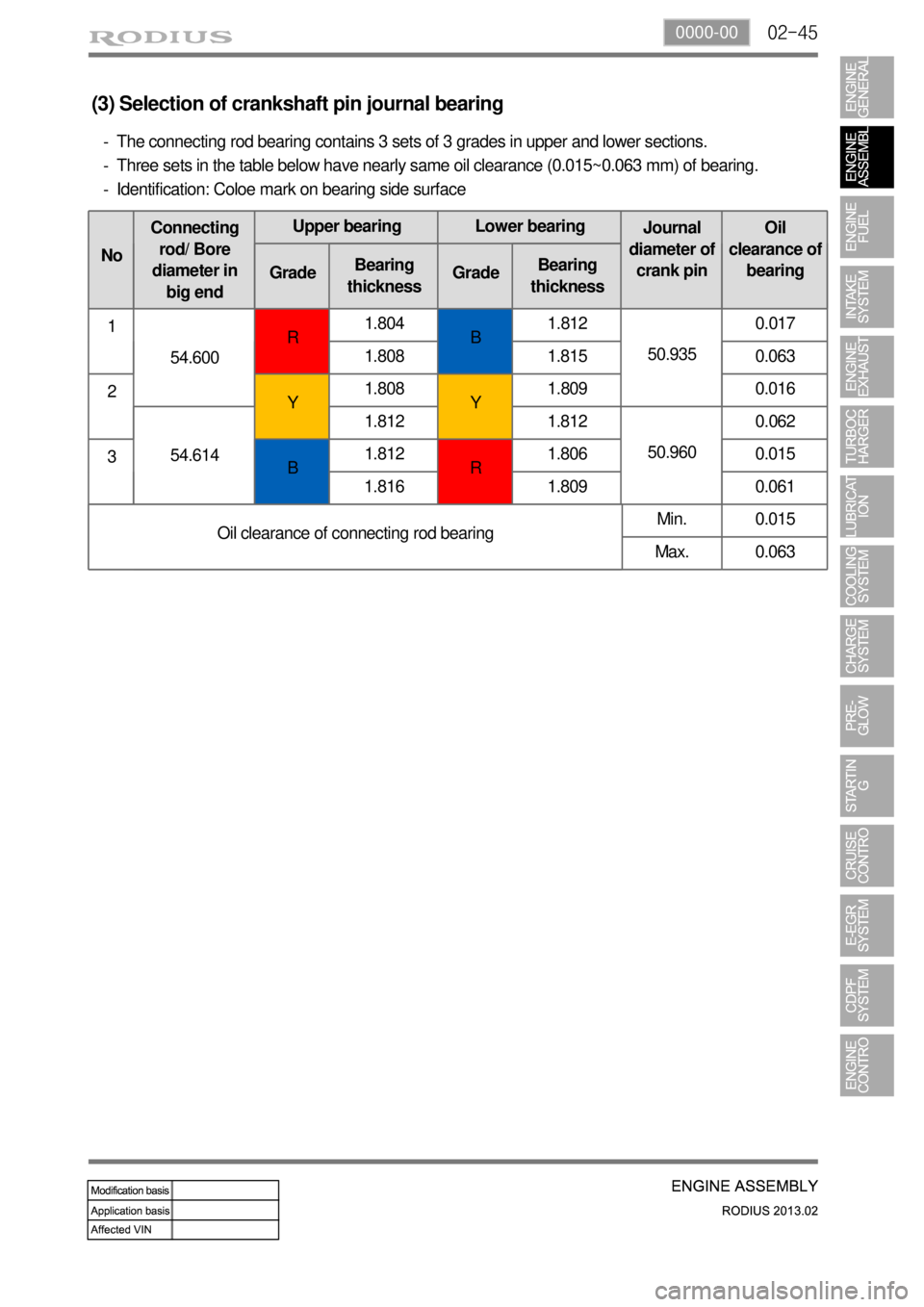

NoConnecting

rod/ Bore

diameter in

big endUpper bearing Lower bearing

Journal

diameter of

crank pinOil

clearance of

bearing

GradeBearing

thicknessGradeBearing

thickness

1

54.600 R 1.804

B 1.812

50.935 0.017

1.808 1.815 0.063

2

Y 1.808

Y 1.809 0.016

54.614 1.812 1.812

50.960 0.062

3

B 1.812

R 1.806 0.015

1.816 1.809 0.061

Min. 0.015

Max. 0.063

(3) Selection of crankshaft pin journal bearing

The connecting rod bearing contains 3 sets of 3 grades in upper and lower sections.

Three sets in the table below have nearly same oil clearance (0.015~0.063 mm) of bearing.

Identification: Coloe mark on bearing side surface -

-

-

Oil clearance of connecting rod bearing

Page 205 of 796

02-46

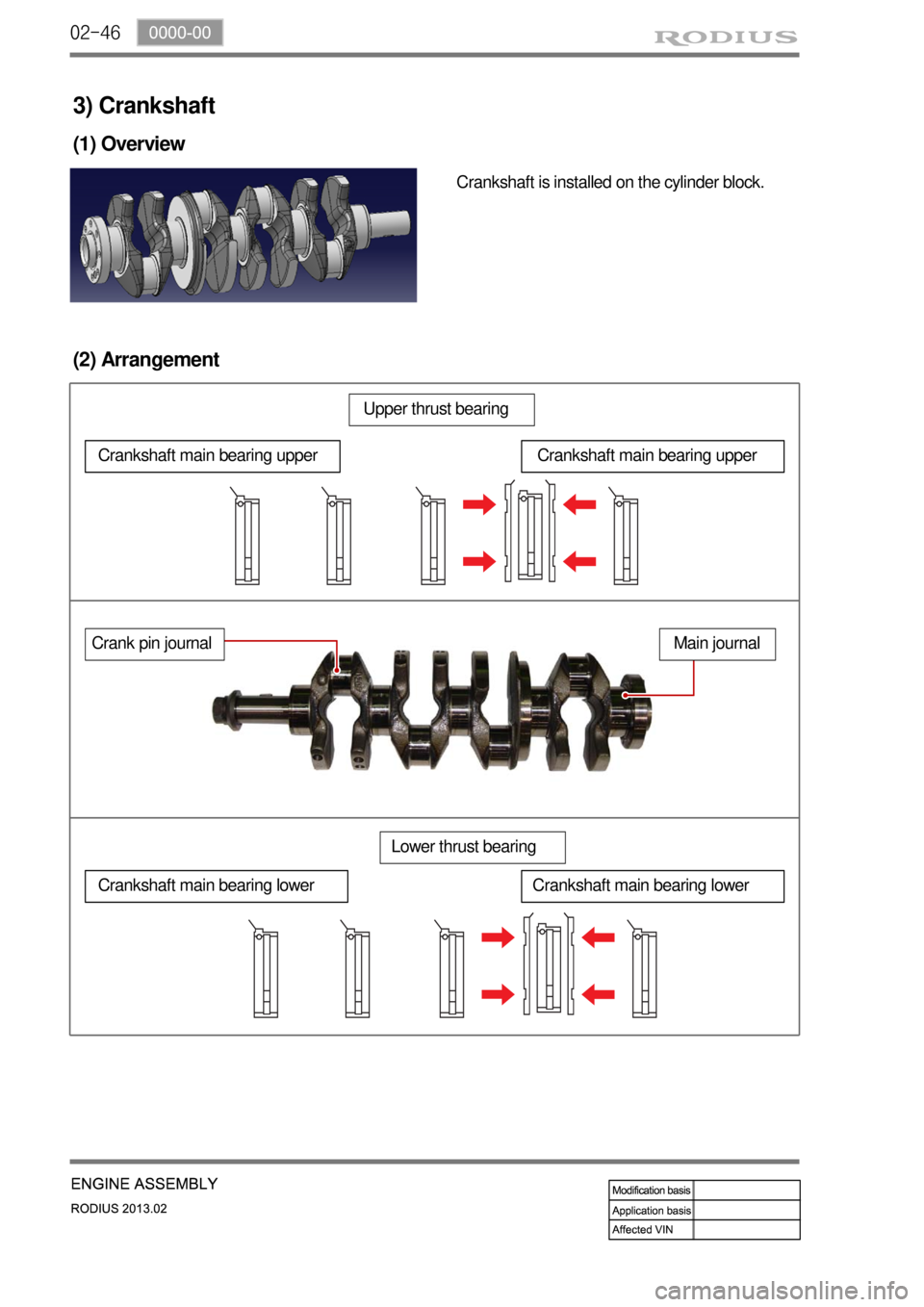

3) Crankshaft

(1) Overview

Crankshaft is installed on the cylinder block.

(2) Arrangement

Crankshaft main bearing upperCrankshaft main bearing upper

Upper thrust bearing

Crankshaft main bearing lowerCrankshaft main bearing lower

Lower thrust bearing

Crank pin journalMain journal

Page 206 of 796

02-470000-00

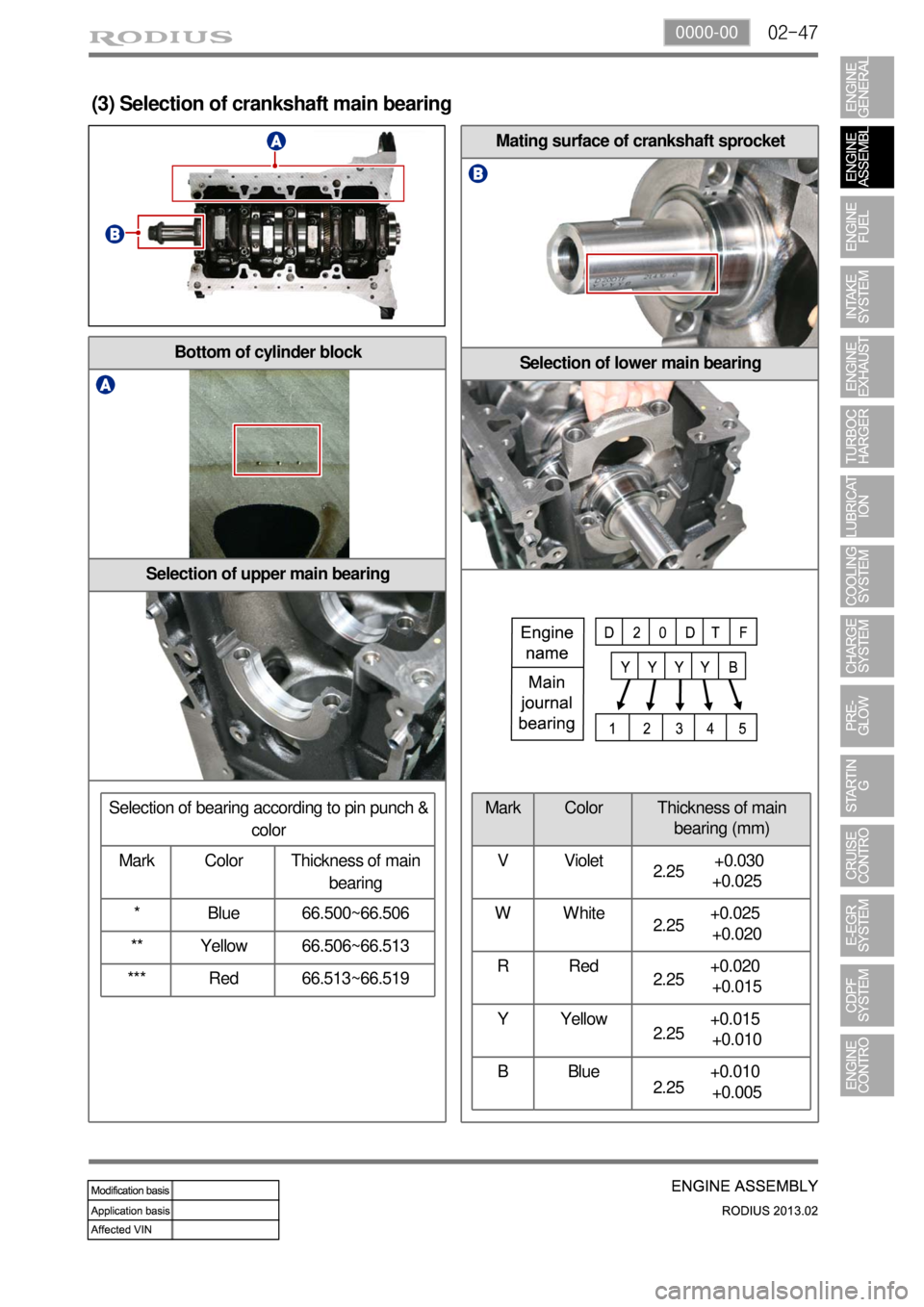

Bottom of cylinder block

Selection of upper main bearing

Mating surface of crankshaft sprocket

Selection of lower main bearing

(3) Selection of crankshaft main bearing

Mark Color Thickness of main

bearing (mm)

V Violet +0.030

+0.025

W White +0.025

+0.020

R Red +0.020

+0.015

Y Yellow +0.015

+0.010

B Blue +0.010

+0.005

2.25

2.25

2.25

2.25

2.25

Selection of bearing according to pin punch &

color

Mark Color Thickness of main

bearing

* Blue 66.500~66.506

** Yellow 66.506~66.513

*** Red 66.513~66.519

Page 207 of 796

02-48

4) Cylinder Block

(1) Overview

The major dimensions in D20DTR are similar to

D20DTR engine. It has two mounting

bosses for knock sensor and meets the

requirements for EURO5 regulation.

(2) Layout

Right sideCylindrical pin

Expansion plug

Screw plug

Page 208 of 796

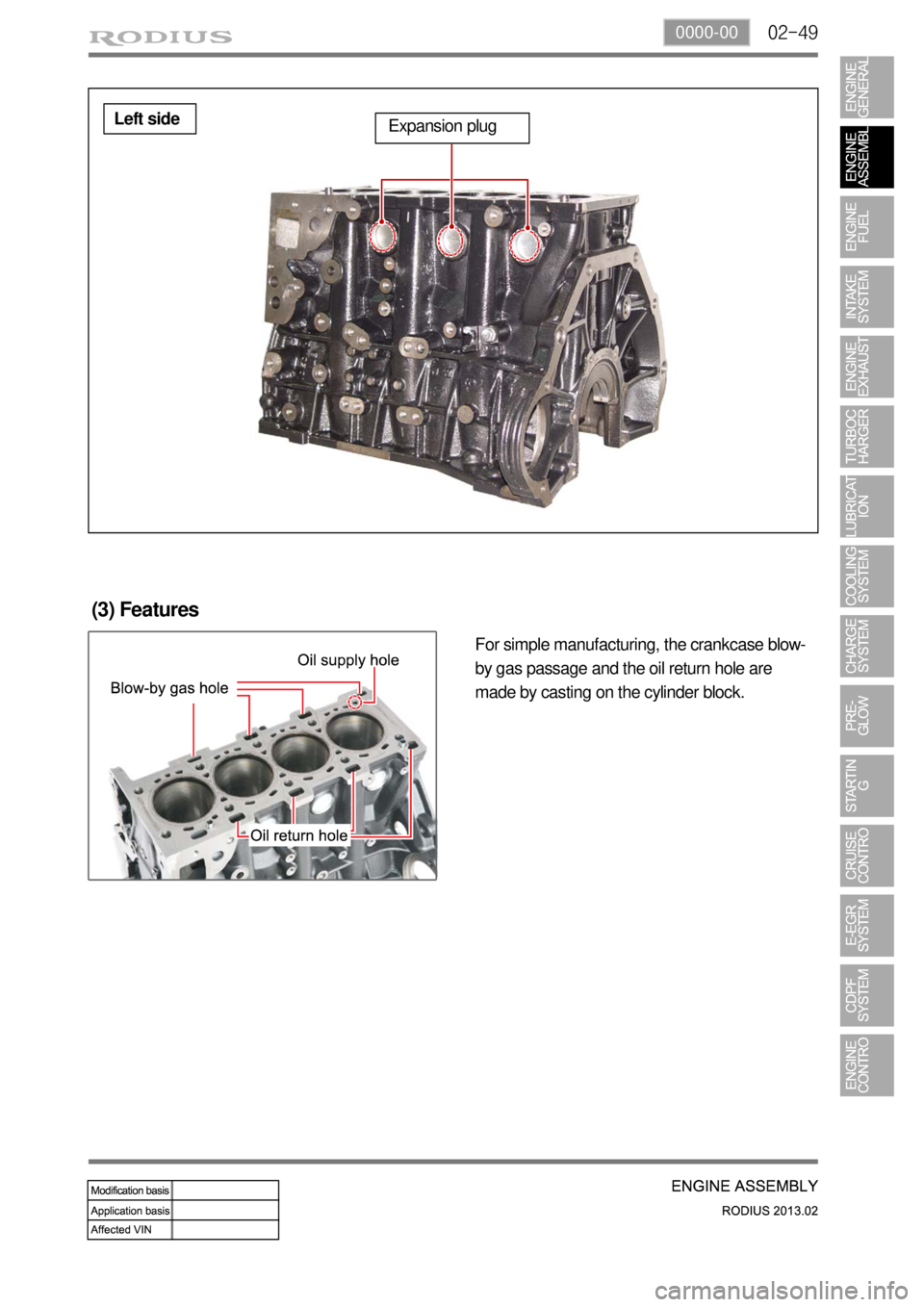

02-490000-00

Left sideExpansion plug

(3) Features

For simple manufacturing, the crankcase blow-

by gas passage and the oil return hole are

made by casting on the cylinder block.

Page 209 of 796

02-50

The bottom side of water jacket is desgined as sine wave to strengthen the structure of crankcase. The

main flow of coolant starts from outlet port of water pump and goes along the longitudinal direction of

engine. The coolant passage from cylinder head to inlet port of water pump is integrated in cylinder

head.

The engine oil from oil pump is supplied to the main oil gallery through oil channel, oil filter module and

cross bore in cylinder block without using external pipes. This oil is supplied to main bearing, cylinder

head and MBU. And, it is sprayed to the chain through the chain tensioner connected to cross bore.

Crankcase cross bore for oil supply

Water jacket core

Page 210 of 796

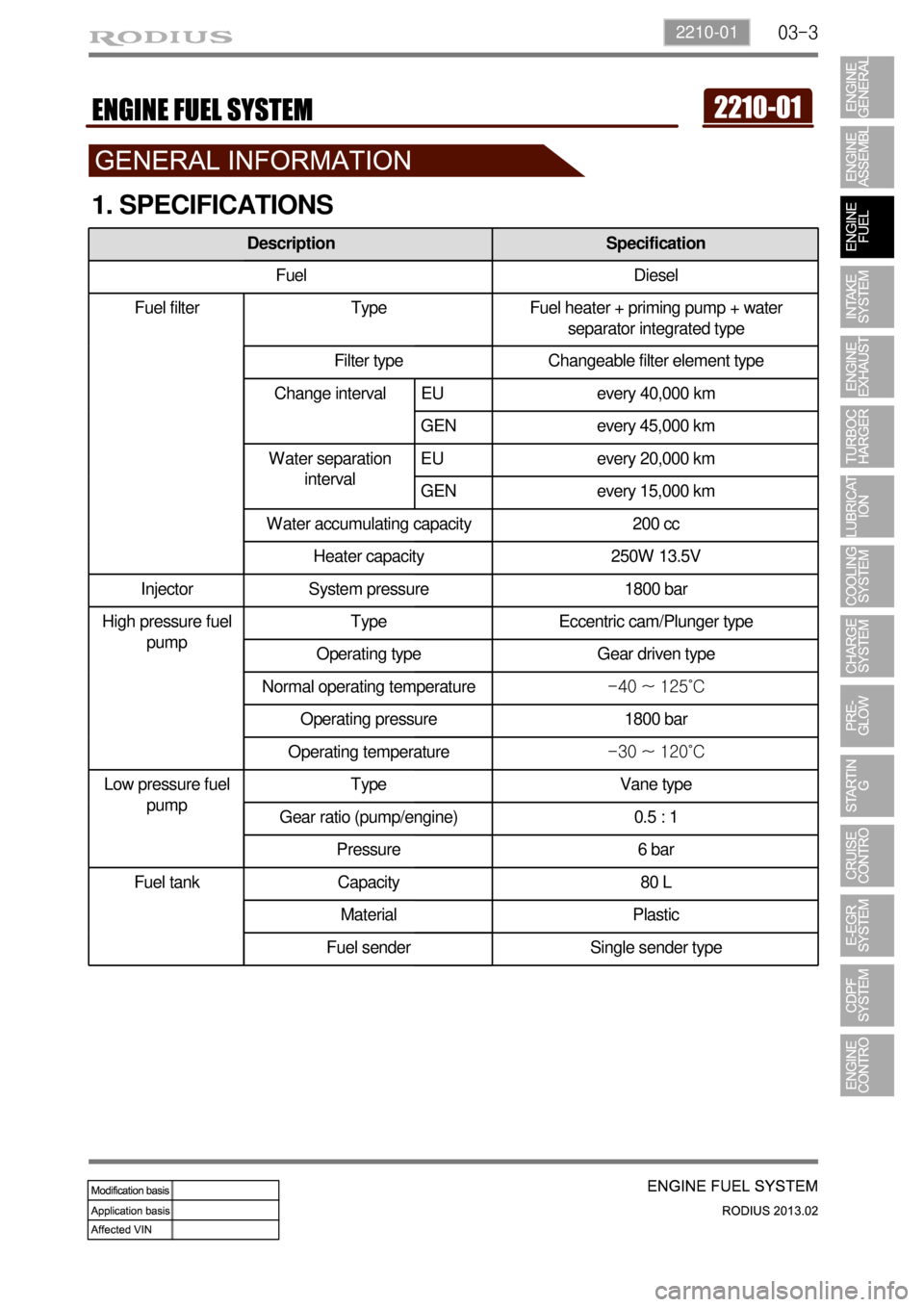

03-32210-01

1. SPECIFICATIONS

Description Specification

Fuel Diesel

Fuel filter Type Fuel heater + priming pump + water

separator integrated type

Filter type Changeable filter element type

Change interval EU every 40,000 km

GEN every 45,000 km

Water separation

intervalEU every 20,000 km

GEN every 15,000 km

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature-40 ~ 125˚C

Operating pressure 1800 bar

Operating temperature-30 ~ 120˚C

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tank Capacity 80 L

Material Plastic

Fuel sender Single sender type

Trending: pump assem, Air conditioning, oil temperature, towing capacity, lane assist, lumbar support, clutch