electrical SUBARU CROSSTREK 2018 Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2018, Model line: CROSSTREK, Model: SUBARU CROSSTREK 2018Pages: 474, PDF Size: 20.76 MB

Page 416 of 474

(429,1)

北米Model "A1320BE-C" EDITED: 2017/ 10/ 10

Pinch the upper part of the fuse puller

when removing it from the main fuse box.1) Good

2) BlownIf any lights, accessories or other electrical

controls do not operate, inspect the corre-

sponding fuse. If a fuse has blown, replace

it.

1. Turn the ignition switch to the“LOCK”/

“OFF”position and turn off all electrical

accessories.

2. Remove the cover.

3. Determine which fuse may be blown.

Look at the back side of each fuse box

cover and refer to“Fuses and circuits”

F12-10.

4. Pull out the fuse with the fuse puller.

5. Inspect the fuse. If it has blown,

replace it with a spare fuse of the same

rating.

6. If the same fuse blows again, this

indicates that its system has a problem.

Contact your SUBARU dealer for repairs.

Installation of accessoriesAlways consult your SUBARU dealer

before installing fog lights or any other

electrical equipment in your vehicle. Such

accessories may cause the electronic

system to malfunction if they are incor-

rectly installed or if they are not suited for

the vehicle.

Maintenance and service/Installation of accessories

11-35

11

Page 418 of 474

(431,1)

北米Model "A1320BE-C" EDITED: 2017/ 10/ 10

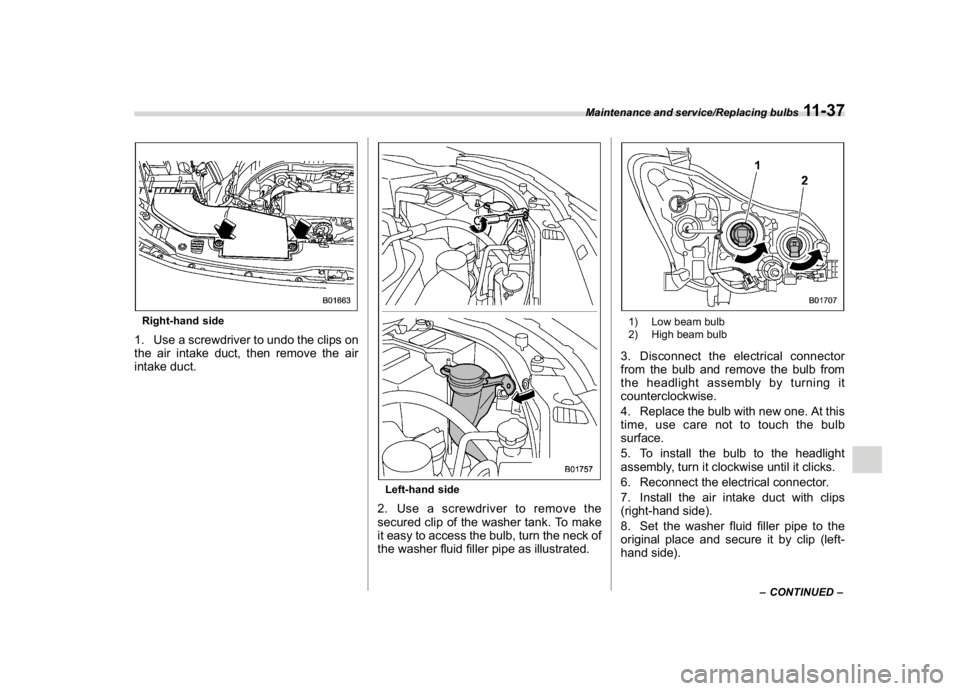

Right-hand side1. Use a screwdriver to undo the clips on

the air intake duct, then remove the air

intake duct.

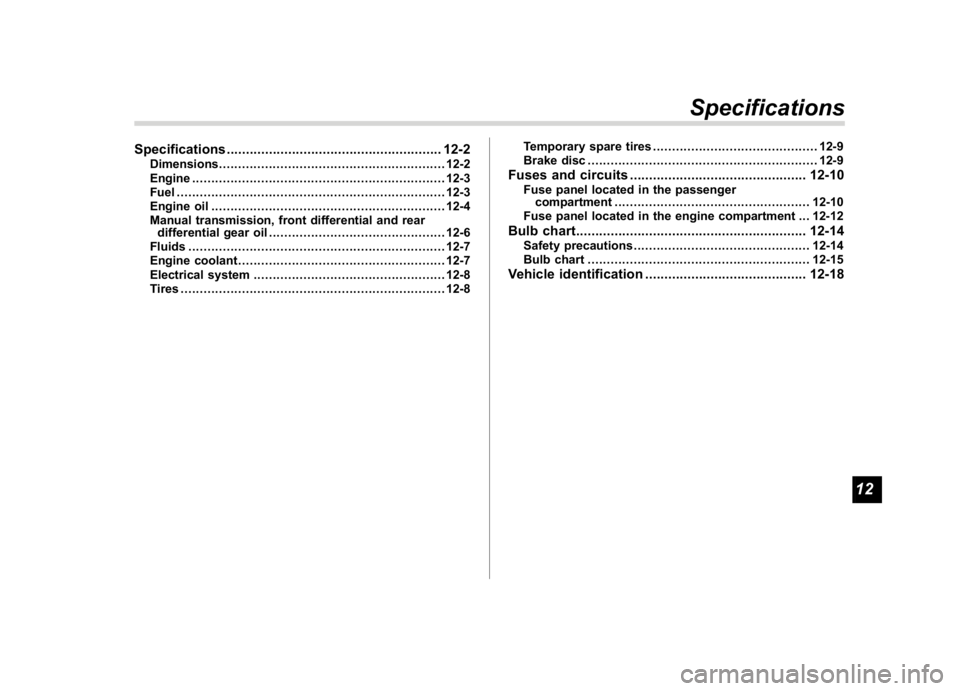

Left-hand side2. Use a screwdriver to remove the

secured clip of the washer tank. To make

it easy to access the bulb, turn the neck of

the washer fluid filler pipe as illustrated.

1) Low beam bulb

2) High beam bulb3. Disconnect the electrical connector

from the bulb and remove the bulb from

the headlight assembly by turning it

counterclockwise.

4. Replace the bulb with new one. At this

time, use care not to touch the bulb

surface.

5. To install the bulb to the headlight

assembly, turn it clockwise until it clicks.

6. Reconnect the electrical connector.

7. Install the air intake duct with clips

(right-hand side).

8. Set the washer fluid filler pipe to the

original place and secure it by clip (left-

hand side).

–CONTINUED–

Maintenance and service/Replacing bulbs

11-37

11

Page 426 of 474

(441,1)

北米Model "A1320BE-C" EDITED: 2017/ 10/ 10

Specifications........................................................12-2

Dimensions...........................................................12-2

Engine..................................................................12-3

Fuel......................................................................12-3

Engine oil.............................................................12-4

Manual transmission, front differential and rear

differential gear oil..............................................12-6

Fluids...................................................................12-7

Engine coolant......................................................12-7

Electrical system..................................................12-8

Tires .....................................................................12-8Temporary spare tires...........................................12-9

Brake disc............................................................12-9

Fuses and circuits..............................................12-10

Fuse panel located in the passenger

compartment...................................................12-10

Fuse panel located in the engine compartment ... 12-12

Bulb chart............................................................12-14

Safety precautions..............................................12-14

Bulb chart..........................................................12-15

Vehicle identification..........................................12-18

Specifications

12

Page 433 of 474

(448,1)

北米Model "A1320BE-C" EDITED: 2017/ 10/ 10

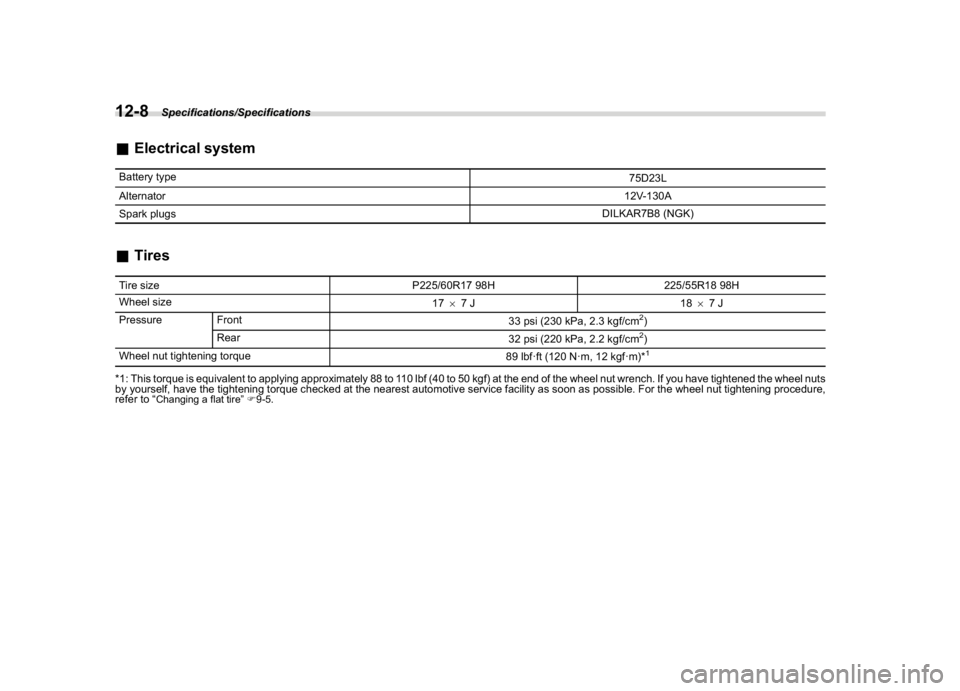

&Electrical systemBattery type

75D23L

Alternator12V-130A

Spark plugsDILKAR7B8 (NGK)&TiresTire size P225/60R17 98H 225/55R18 98H

Wheel size

1767J 1867J

Pressure Front

33 psi (230 kPa, 2.3 kgf/cm

2)

Rear

32 psi (220 kPa, 2.2 kgf/cm2)

Wheel nut tightening torque

89 lbf·ft (120 N·m, 12 kgf·m)*1

*1: This torque is equivalent to applying approximately 88 to 110 lbf (40 to 50 kgf) at the end of the wheel nut wrench. If you have tightened the wheel nuts

by yourself, have the tightening torque checked at the nearest automotive service facility as soon as possible. For the wheel nut tightening procedure,

refer to“

Changing a flat tire”F9-5.Specifications/Specifications

12-8