ground clearance SUBARU FORESTER 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 136 of 345

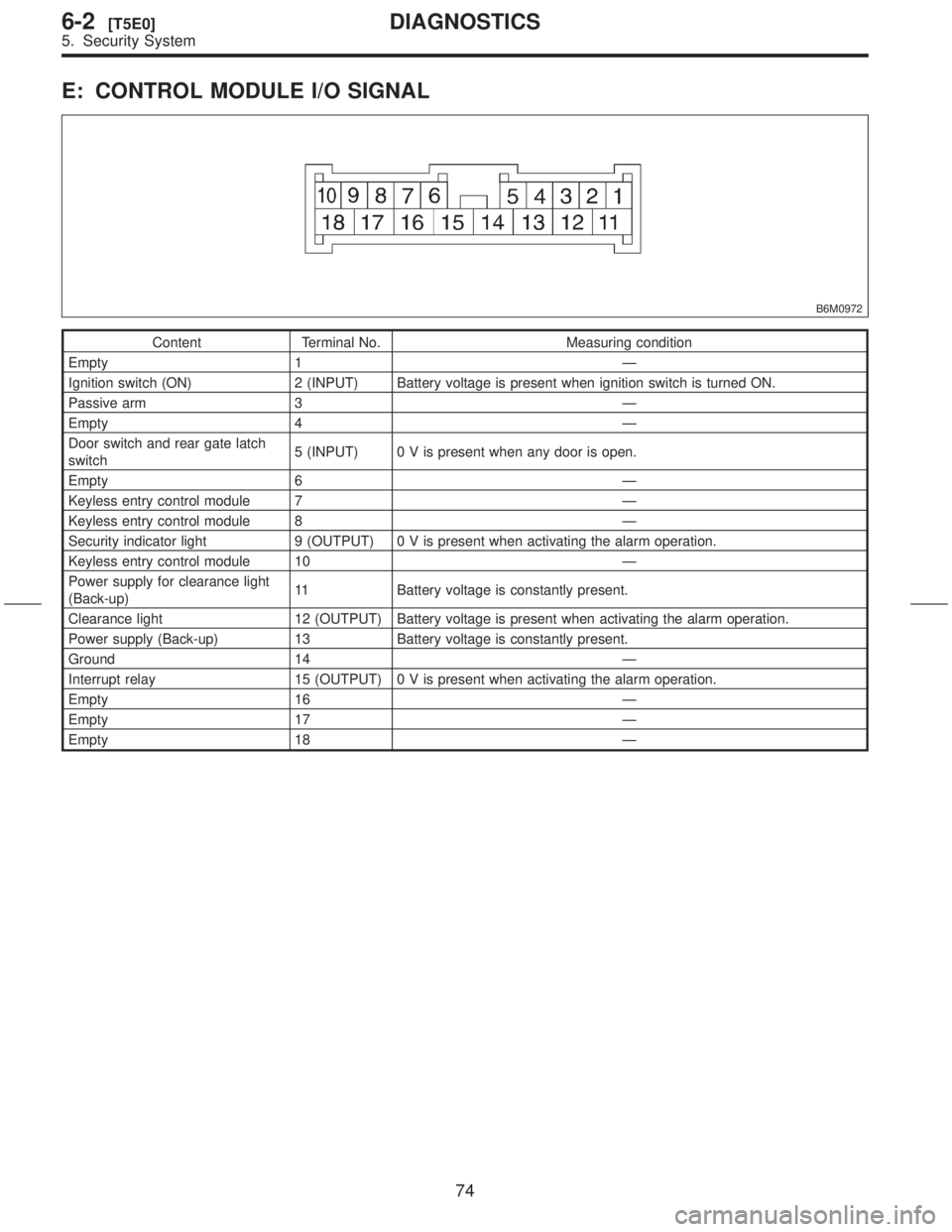

E: CONTROL MODULE I/O SIGNAL

B6M0972

Content Terminal No. Measuring condition

Empty 1 Ð

Ignition switch (ON) 2 (INPUT) Battery voltage is present when ignition switch is turned ON.

Passive arm 3 Ð

Empty 4 Ð

Door switch and rear gate latch

switch5 (INPUT) 0 V is present when any door is open.

Empty 6 Ð

Keyless entry control module 7 Ð

Keyless entry control module 8 Ð

Security indicator light 9 (OUTPUT) 0 V is present when activating the alarm operation.

Keyless entry control module 10 Ð

Power supply for clearance light

(Back-up)11 Battery voltage is constantly present.

Clearance light 12 (OUTPUT) Battery voltage is present when activating the alarm operation.

Power supply (Back-up) 13 Battery voltage is constantly present.

Ground 14 Ð

Interrupt relay 15 (OUTPUT) 0 V is present when activating the alarm operation.

Empty 16 Ð

Empty 17 Ð

Empty 18 Ð

74

6-2[T5E0]DIAGNOSTICS

5. Security System

Page 139 of 345

![SUBARU FORESTER 1999 Service Repair Manual 5F117 : CHECK PASSIVE ARM.

1) Remove the drivers side sill cover. <Ref. to 5-3

[W5A0].>

2) Connect the white connector (1-pin) at driver

side front lower pillar.

3) Close all doors and the rear gate. SUBARU FORESTER 1999 Service Repair Manual 5F117 : CHECK PASSIVE ARM.

1) Remove the drivers side sill cover. <Ref. to 5-3

[W5A0].>

2) Connect the white connector (1-pin) at driver

side front lower pillar.

3) Close all doors and the rear gate.](/img/17/57427/w960_57427-138.png)

5F117 : CHECK PASSIVE ARM.

1) Remove the driver's side sill cover.

2) Connect the white connector (1-pin) at driver

side front lower pillar.

3) Close all doors and the rear gate.

:Does the arming automatically func-

tion after 1 minute?

: Go to step5F118.

: Go to step5 F 111.

5F118 : CHECK BATTERY DISCONNECT

PROTECTION.

1) Press the UNLOCK/DISARM button.

2) Connect the white connector (1-pin) at front pil-

lar lower.

3) Install the driver's side sill cover.

4) Open the front hood.

5) Press the LOCK/ARM button.

6) Disconnect the ground cable from battery.

7) Connect the ground cable to battery.

:Does re-arming function automati-

cally?

: End of basic diagnostics procedure.

Press the UNLOCK/DISARM button,

and then close all doors and the rear

gate. Perform ignition switch position

turned LOCK to ON to LOCK.

: Replace security control module.

2. DIAGNOSTICS ITEM 1

5F21 : CHECK FUSE.

Remove and visually check fuse No. 7 (in main

fuse box).

:Is fuse No. 7 blown?

: Replace fuse (20 A).

: Go to step5F22.

5F22 : CHECK FUSE.

Remove and visually check fuse No. 5 (in fuse

box).

:Is fuse No. 5 blown?

: Replace fuse (10 A).

: Go to step5F23.

5F23 : CHECK CLEARANCE LIGHT BULB.

Remove and visually check each clearance light

bulb.

:Is the bulb blown?

: Replace clearance light bulb.

: Go to step5F24.

5F24 : CHECK POWER SUPPLY FOR

CLEARANCE LIGHT.

Measure voltage between main fuse box connec-

tor (F68) and chassis ground.

Connector & terminal

(F68) No. 4 (+) Ð Chassis ground (þ):

B6M1357A

:Is the voltage more than 10 V?

: Go to step5F25.

: Repair wiring harness between main

fuse box and battery.

77

[T5F2]6-2DIAGNOSTICS

5. Security System

Page 140 of 345

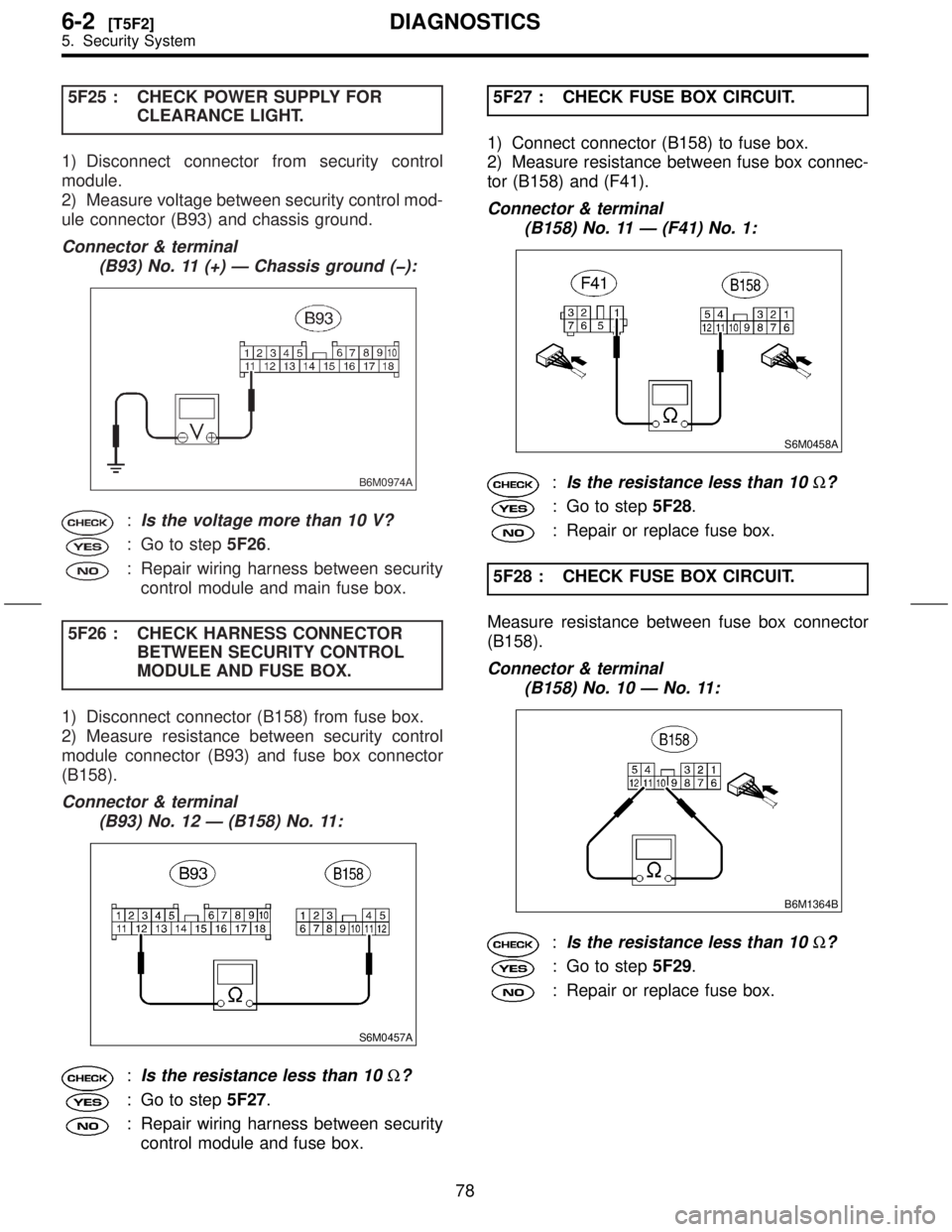

5F25 : CHECK POWER SUPPLY FOR

CLEARANCE LIGHT.

1) Disconnect connector from security control

module.

2) Measure voltage between security control mod-

ule connector (B93) and chassis ground.

Connector & terminal

(B93) No. 11 (+) Ð Chassis ground (þ):

B6M0974A

:Is the voltage more than 10 V?

: Go to step5F26.

: Repair wiring harness between security

control module and main fuse box.

5F26 : CHECK HARNESS CONNECTOR

BETWEEN SECURITY CONTROL

MODULE AND FUSE BOX.

1) Disconnect connector (B158) from fuse box.

2) Measure resistance between security control

module connector (B93) and fuse box connector

(B158).

Connector & terminal

(B93) No. 12 Ð (B158) No. 11:

S6M0457A

:Is the resistance less than 10W?

: Go to step5F27.

: Repair wiring harness between security

control module and fuse box.5F27 : CHECK FUSE BOX CIRCUIT.

1) Connect connector (B158) to fuse box.

2) Measure resistance between fuse box connec-

tor (B158) and (F41).

Connector & terminal

(B158) No. 11 Ð (F41) No. 1:

S6M0458A

:Is the resistance less than 10W?

: Go to step5F28.

: Repair or replace fuse box.

5F28 : CHECK FUSE BOX CIRCUIT.

Measure resistance between fuse box connector

(B158).

Connector & terminal

(B158) No. 10 Ð No. 11:

B6M1364B

:Is the resistance less than 10W?

: Go to step5F29.

: Repair or replace fuse box.

78

6-2[T5F2]DIAGNOSTICS

5. Security System

Page 141 of 345

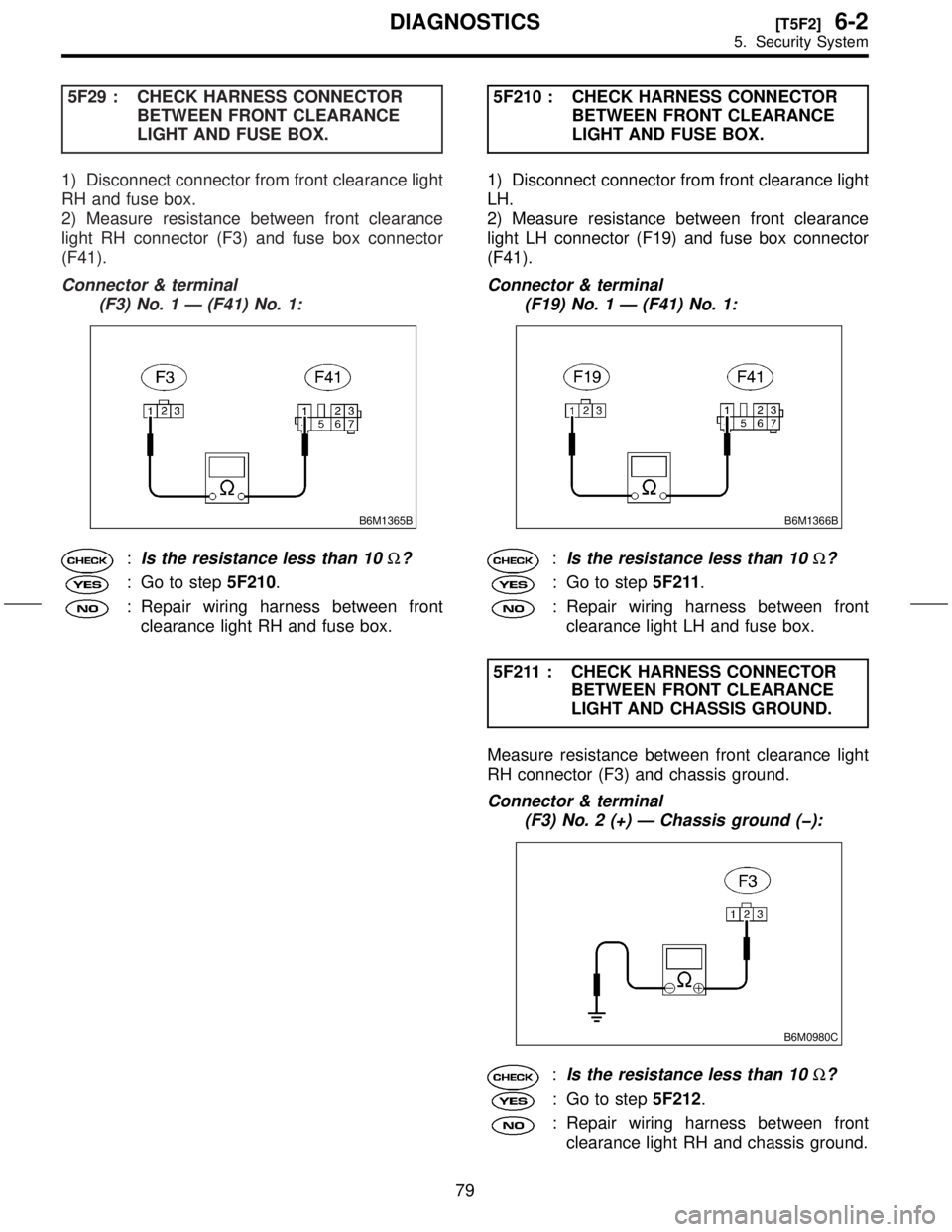

5F29 : CHECK HARNESS CONNECTOR

BETWEEN FRONT CLEARANCE

LIGHT AND FUSE BOX.

1) Disconnect connector from front clearance light

RH and fuse box.

2) Measure resistance between front clearance

light RH connector (F3) and fuse box connector

(F41).

Connector & terminal

(F3) No. 1 Ð (F41) No. 1:

B6M1365B

:Is the resistance less than 10W?

: Go to step5F210.

: Repair wiring harness between front

clearance light RH and fuse box.5F210 : CHECK HARNESS CONNECTOR

BETWEEN FRONT CLEARANCE

LIGHT AND FUSE BOX.

1) Disconnect connector from front clearance light

LH.

2) Measure resistance between front clearance

light LH connector (F19) and fuse box connector

(F41).

Connector & terminal

(F19) No. 1 Ð (F41) No. 1:

B6M1366B

:Is the resistance less than 10W?

: Go to step5F211.

: Repair wiring harness between front

clearance light LH and fuse box.

5F211 : CHECK HARNESS CONNECTOR

BETWEEN FRONT CLEARANCE

LIGHT AND CHASSIS GROUND.

Measure resistance between front clearance light

RH connector (F3) and chassis ground.

Connector & terminal

(F3) No. 2 (+) Ð Chassis ground (þ):

B6M0980C

:Is the resistance less than 10W?

: Go to step5F212.

: Repair wiring harness between front

clearance light RH and chassis ground.

79

[T5F2]6-2DIAGNOSTICS

5. Security System

Page 142 of 345

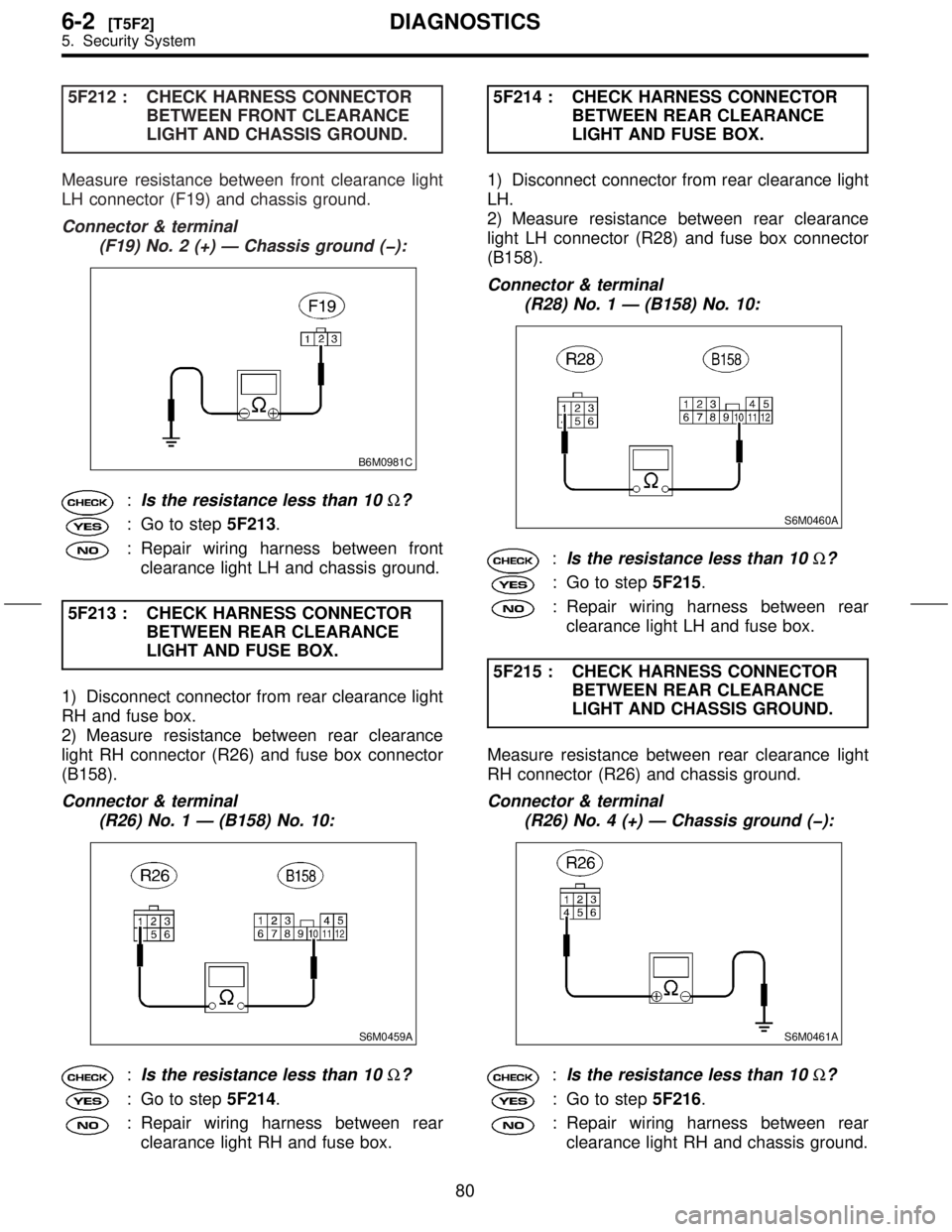

5F212 : CHECK HARNESS CONNECTOR

BETWEEN FRONT CLEARANCE

LIGHT AND CHASSIS GROUND.

Measure resistance between front clearance light

LH connector (F19) and chassis ground.

Connector & terminal

(F19) No. 2 (+) Ð Chassis ground (þ):

B6M0981C

:Is the resistance less than 10W?

: Go to step5F213.

: Repair wiring harness between front

clearance light LH and chassis ground.

5F213 : CHECK HARNESS CONNECTOR

BETWEEN REAR CLEARANCE

LIGHT AND FUSE BOX.

1) Disconnect connector from rear clearance light

RH and fuse box.

2) Measure resistance between rear clearance

light RH connector (R26) and fuse box connector

(B158).

Connector & terminal

(R26) No. 1 Ð (B158) No. 10:

S6M0459A

:Is the resistance less than 10W?

: Go to step5F214.

: Repair wiring harness between rear

clearance light RH and fuse box.5F214 : CHECK HARNESS CONNECTOR

BETWEEN REAR CLEARANCE

LIGHT AND FUSE BOX.

1) Disconnect connector from rear clearance light

LH.

2) Measure resistance between rear clearance

light LH connector (R28) and fuse box connector

(B158).

Connector & terminal

(R28) No. 1 Ð (B158) No. 10:

S6M0460A

:Is the resistance less than 10W?

: Go to step5F215.

: Repair wiring harness between rear

clearance light LH and fuse box.

5F215 : CHECK HARNESS CONNECTOR

BETWEEN REAR CLEARANCE

LIGHT AND CHASSIS GROUND.

Measure resistance between rear clearance light

RH connector (R26) and chassis ground.

Connector & terminal

(R26) No. 4 (+) Ð Chassis ground (þ):

S6M0461A

:Is the resistance less than 10W?

: Go to step5F216.

: Repair wiring harness between rear

clearance light RH and chassis ground.

80

6-2[T5F2]DIAGNOSTICS

5. Security System

Page 143 of 345

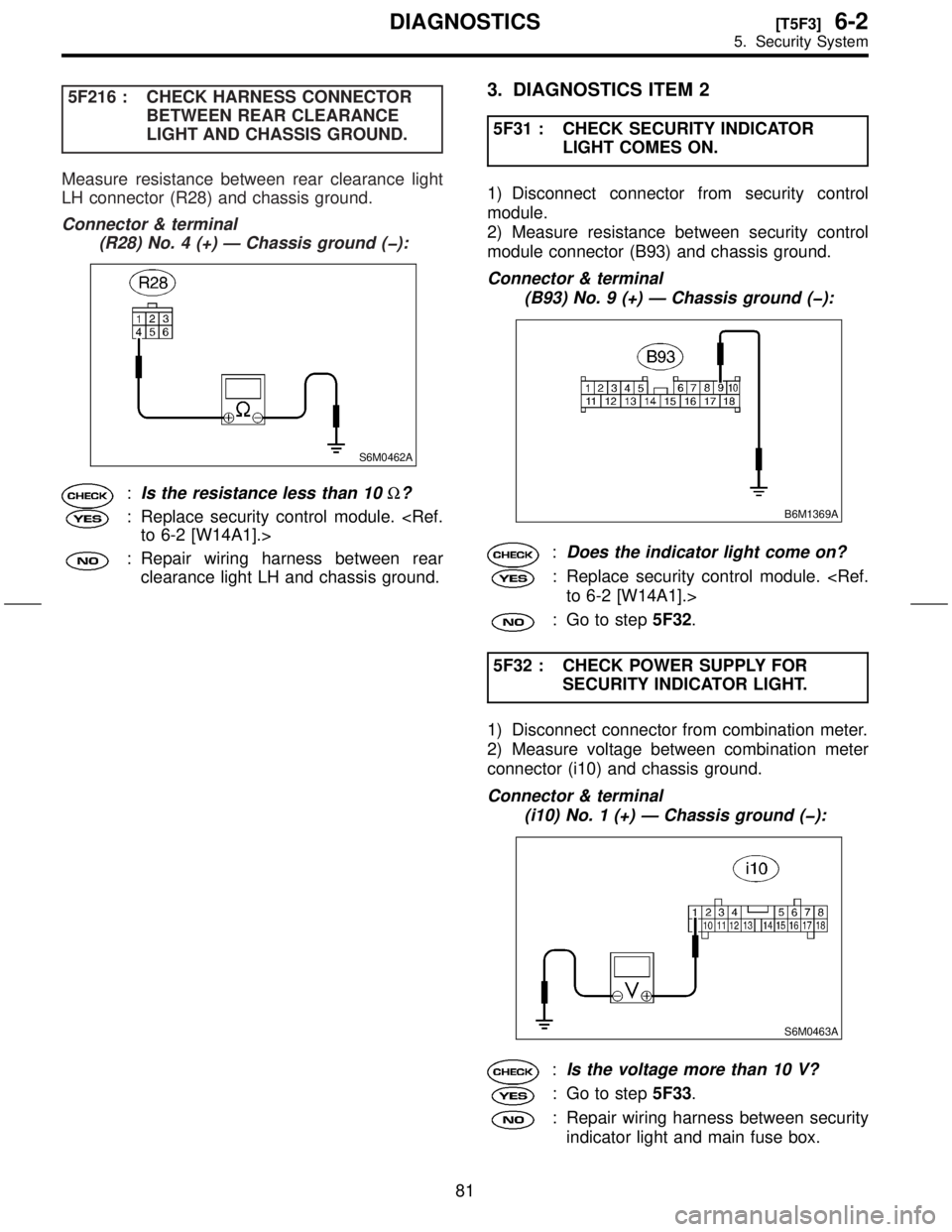

5F216 : CHECK HARNESS CONNECTOR

BETWEEN REAR CLEARANCE

LIGHT AND CHASSIS GROUND.

Measure resistance between rear clearance light

LH connector (R28) and chassis ground.

Connector & terminal

(R28) No. 4 (+) Ð Chassis ground (þ):

S6M0462A

:Is the resistance less than 10W?

: Replace security control module.

: Repair wiring harness between rear

clearance light LH and chassis ground.

3. DIAGNOSTICS ITEM 2

5F31 : CHECK SECURITY INDICATOR

LIGHT COMES ON.

1) Disconnect connector from security control

module.

2) Measure resistance between security control

module connector (B93) and chassis ground.

Connector & terminal

(B93) No. 9 (+) Ð Chassis ground (þ):

B6M1369A

:Does the indicator light come on?

: Replace security control module.

: Go to step5F32.

5F32 : CHECK POWER SUPPLY FOR

SECURITY INDICATOR LIGHT.

1) Disconnect connector from combination meter.

2) Measure voltage between combination meter

connector (i10) and chassis ground.

Connector & terminal

(i10) No. 1 (+) Ð Chassis ground (þ):

S6M0463A

:Is the voltage more than 10 V?

: Go to step5F33.

: Repair wiring harness between security

indicator light and main fuse box.

81

[T5F3]6-2DIAGNOSTICS

5. Security System

Page 187 of 345

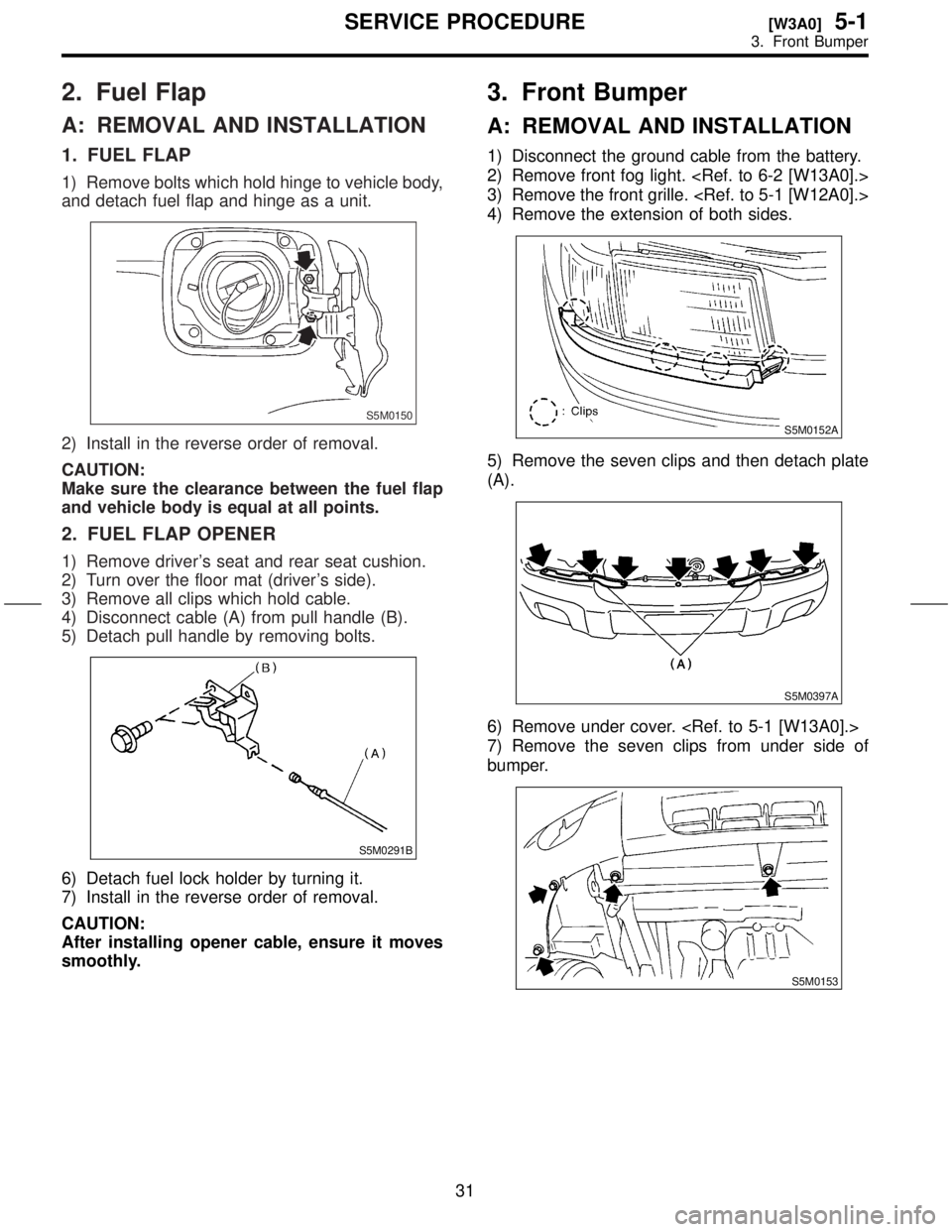

2. Fuel Flap

A: REMOVAL AND INSTALLATION

1. FUEL FLAP

1) Remove bolts which hold hinge to vehicle body,

and detach fuel flap and hinge as a unit.

S5M0150

2) Install in the reverse order of removal.

CAUTION:

Make sure the clearance between the fuel flap

and vehicle body is equal at all points.

2. FUEL FLAP OPENER

1) Remove driver's seat and rear seat cushion.

2) Turn over the floor mat (driver's side).

3) Remove all clips which hold cable.

4) Disconnect cable (A) from pull handle (B).

5) Detach pull handle by removing bolts.

S5M0291B

6) Detach fuel lock holder by turning it.

7) Install in the reverse order of removal.

CAUTION:

After installing opener cable, ensure it moves

smoothly.

3. Front Bumper

A: REMOVAL AND INSTALLATION

1) Disconnect the ground cable from the battery.

2) Remove front fog light.

3) Remove the front grille.

4) Remove the extension of both sides.

S5M0152A

5) Remove the seven clips and then detach plate

(A).

S5M0397A

6) Remove under cover.

7) Remove the seven clips from under side of

bumper.

S5M0153

31

[W3A0]5-1SERVICE PROCEDURE

3. Front Bumper

Page 188 of 345

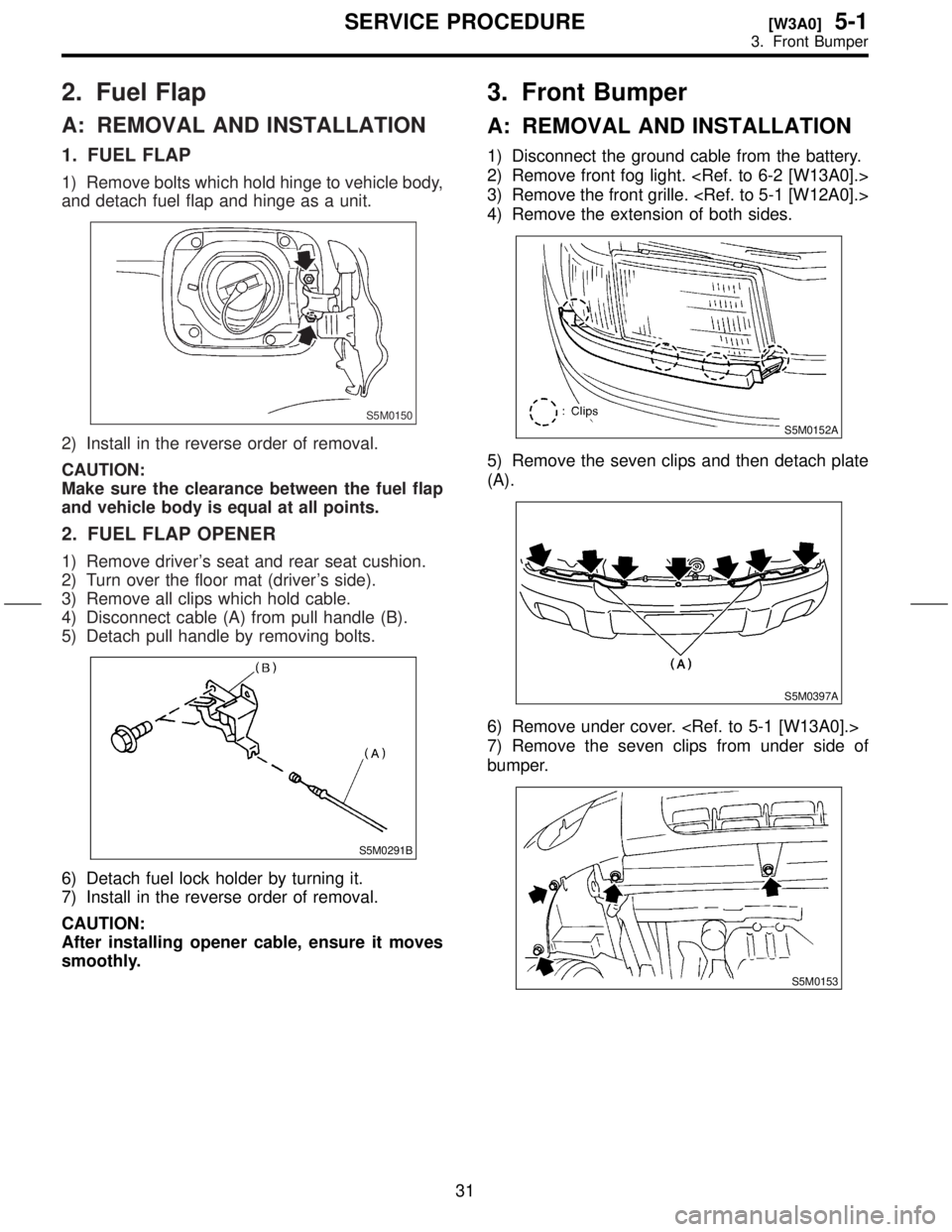

2. Fuel Flap

A: REMOVAL AND INSTALLATION

1. FUEL FLAP

1) Remove bolts which hold hinge to vehicle body,

and detach fuel flap and hinge as a unit.

S5M0150

2) Install in the reverse order of removal.

CAUTION:

Make sure the clearance between the fuel flap

and vehicle body is equal at all points.

2. FUEL FLAP OPENER

1) Remove driver's seat and rear seat cushion.

2) Turn over the floor mat (driver's side).

3) Remove all clips which hold cable.

4) Disconnect cable (A) from pull handle (B).

5) Detach pull handle by removing bolts.

S5M0291B

6) Detach fuel lock holder by turning it.

7) Install in the reverse order of removal.

CAUTION:

After installing opener cable, ensure it moves

smoothly.

3. Front Bumper

A: REMOVAL AND INSTALLATION

1) Disconnect the ground cable from the battery.

2) Remove front fog light.

3) Remove the front grille.

4) Remove the extension of both sides.

S5M0152A

5) Remove the seven clips and then detach plate

(A).

S5M0397A

6) Remove under cover.

7) Remove the seven clips from under side of

bumper.

S5M0153

31

[W3A0]5-1SERVICE PROCEDURE

3. Front Bumper

Page 208 of 345

1. Sunroof

Entry of water into compartment(1) Check roof panel and sunroof glass lid for improper or

poor sealing.

(2) Check drain tube for clogging.

(3) Check sunroof frame seal and body for improper fit.

Booming noise(1) Check sunroof glass lid and roof panel for improper clear-

ance.

(2) Check sunshade and roof trim for improper clearance.

Abnormal motor noise(1) Check motor for looseness.

(2) Check gears and bearings for wear.

(3) Check cable for wear.

(4) Check cable pipe for deformities.

Failure of sunroof to operate

(Motor operates properly.)(1) Check guide rail for foreign particles.

(2) Check guide rail for improper installation.

(3) Check parts for mutual interference.

(4) Check cable slider for improper clinching.

(5) Check cable for improper installation.

(6) Check clutch adjustment nut for improper tightness.

Motor does not rotate or rotates improperly.

(Use sunroof wrench to check operation.)(1) Check fuse for blowout.

(2) Check switch for improper function.

(3) Check motor for incorrect terminal voltage.

(4) Check relay for improper operation.

(5) Check poor grounding system.

(6) Check cords for discontinuity and terminals for poor con-

nections.

(7) Check limit switch for improper operation.

45

[K100]5-1DIAGNOSTICS

1. Sunroof