Engine mount SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 870 of 2870

MECHANICAL

ME(H4SO)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................25

3. Idle Speed .................................................................................................26

4. Ignition Timing ...........................................................................................27

5. Intake Manifold Vacuum............................................................................28

6. Engine Oil Pressure ..................................................................................29

7. Fuel Pressure ............................................................................................30

8. Valve Clearance ........................................................................................31

9. Engine Assembly ......................................................................................34

10. Engine Mounting .......................................................................................41

11. Preparation for Overhaul ...........................................................................42

12. V-belt .........................................................................................................43

13. Crank Pulley ..............................................................................................45

14. Timing Belt Cover......................................................................................47

15. Timing Belt ................................................................................................48

16. Cam Sprocket ...........................................................................................53

17. Crank Sprocket .........................................................................................55

18. Valve Rocker Assembly ............................................................................56

19. Camshaft ...................................................................................................58

20. Cylinder Head ...........................................................................................62

21. Cylinder Block ...........................................................................................69

22. Engine Trouble in General ........................................................................91

23. Engine Noise .............................................................................................96

Page 883 of 2870

ME(H4SO)-14

MECHANICAL

General Description

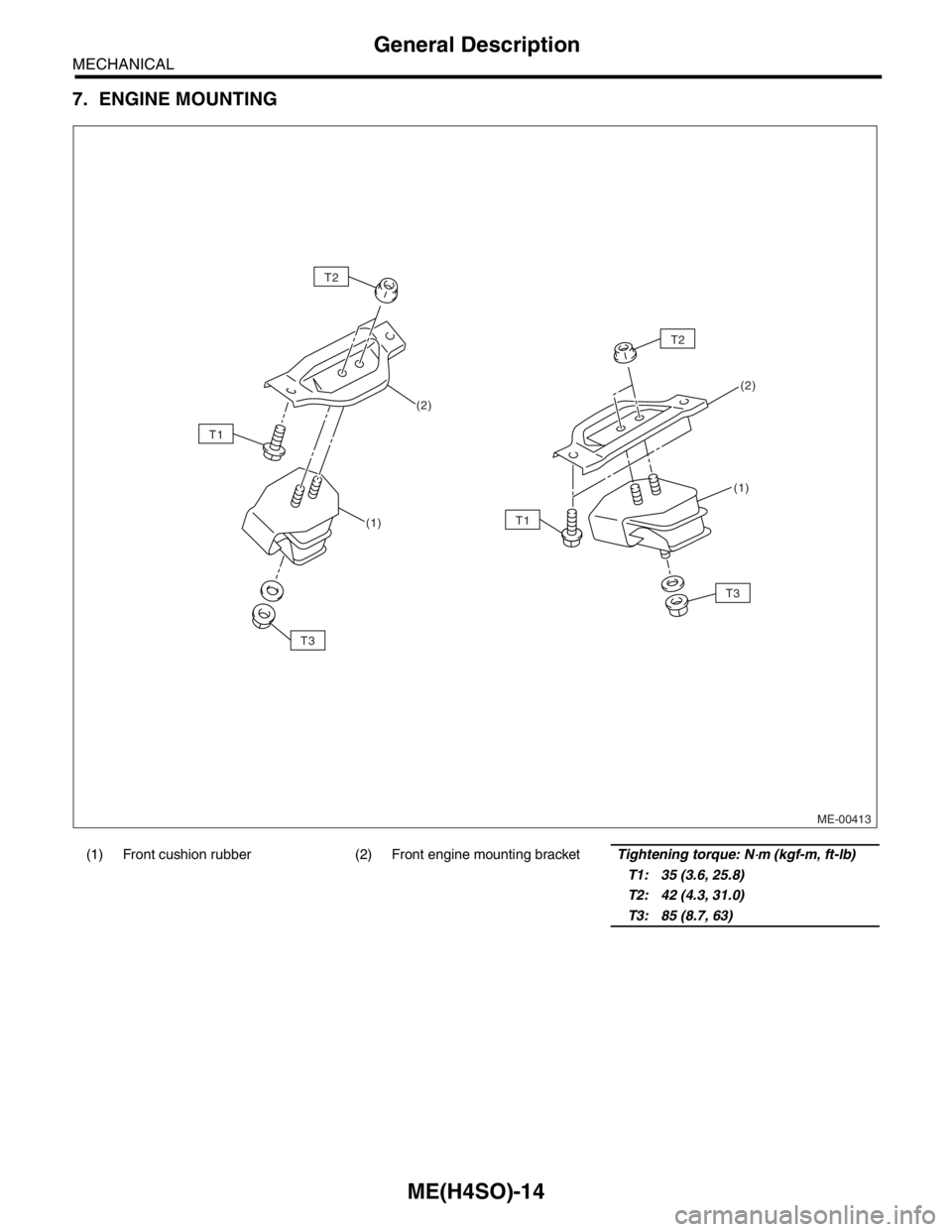

7. ENGINE MOUNTING

(1) Front cushion rubber (2) Front engine mounting bracketTightening torque: N⋅m (kgf-m, ft-lb)

T1: 35 (3.6, 25.8)

T2: 42 (4.3, 31.0)

T3: 85 (8.7, 63)

ME-00413

T2

T1

T1

T3

T3 (2)(2)

(1)(1)

T2

Page 907 of 2870

ME(H4SO)-38

MECHANICAL

Engine Assembly

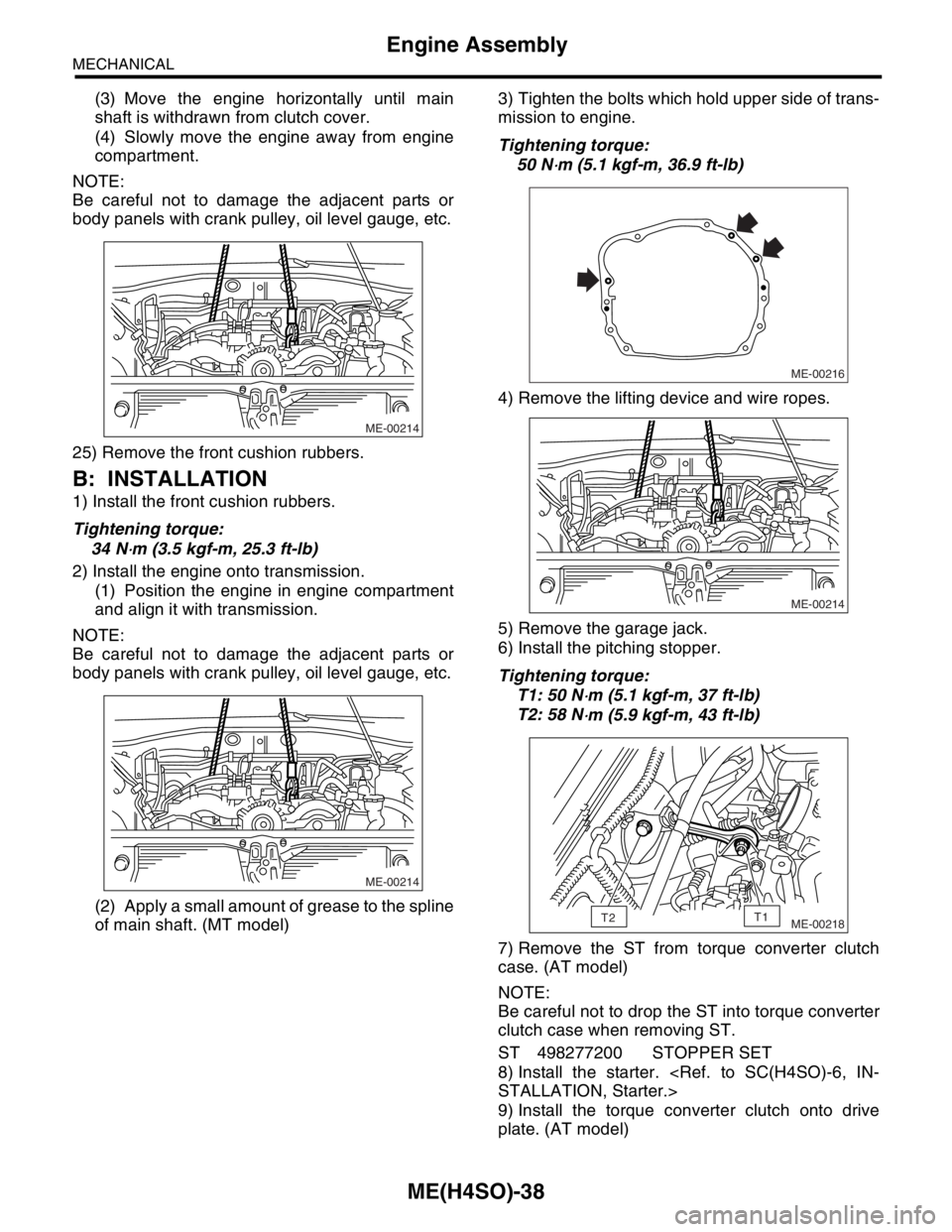

(3) Move the engine horizontally until main

shaft is withdrawn from clutch cover.

(4) Slowly move the engine away from engine

compartment.

NOTE:

Be careful not to damage the adjacent parts or

body panels with crank pulley, oil level gauge, etc.

25) Remove the front cushion rubbers.

B: INSTALLATION

1) Install the front cushion rubbers.

Tightening torque:

34 N

⋅m (3.5 kgf-m, 25.3 ft-lb)

2) Install the engine onto transmission.

(1) Position the engine in engine compartment

and align it with transmission.

NOTE:

Be careful not to damage the adjacent parts or

body panels with crank pulley, oil level gauge, etc.

(2) Apply a small amount of grease to the spline

of main shaft. (MT model)3) Tighten the bolts which hold upper side of trans-

mission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

4) Remove the lifting device and wire ropes.

5) Remove the garage jack.

6) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

7) Remove the ST from torque converter clutch

case. (AT model)

NOTE:

Be careful not to drop the ST into torque converter

clutch case when removing ST.

ST 498277200 STOPPER SET

8) Install the starter.

9) Install the torque converter clutch onto drive

plate. (AT model)

ME-00214

ME-00214

ME-00216

ME-00214

ME-00218T2T1

Page 909 of 2870

ME(H4SO)-40

MECHANICAL

Engine Assembly

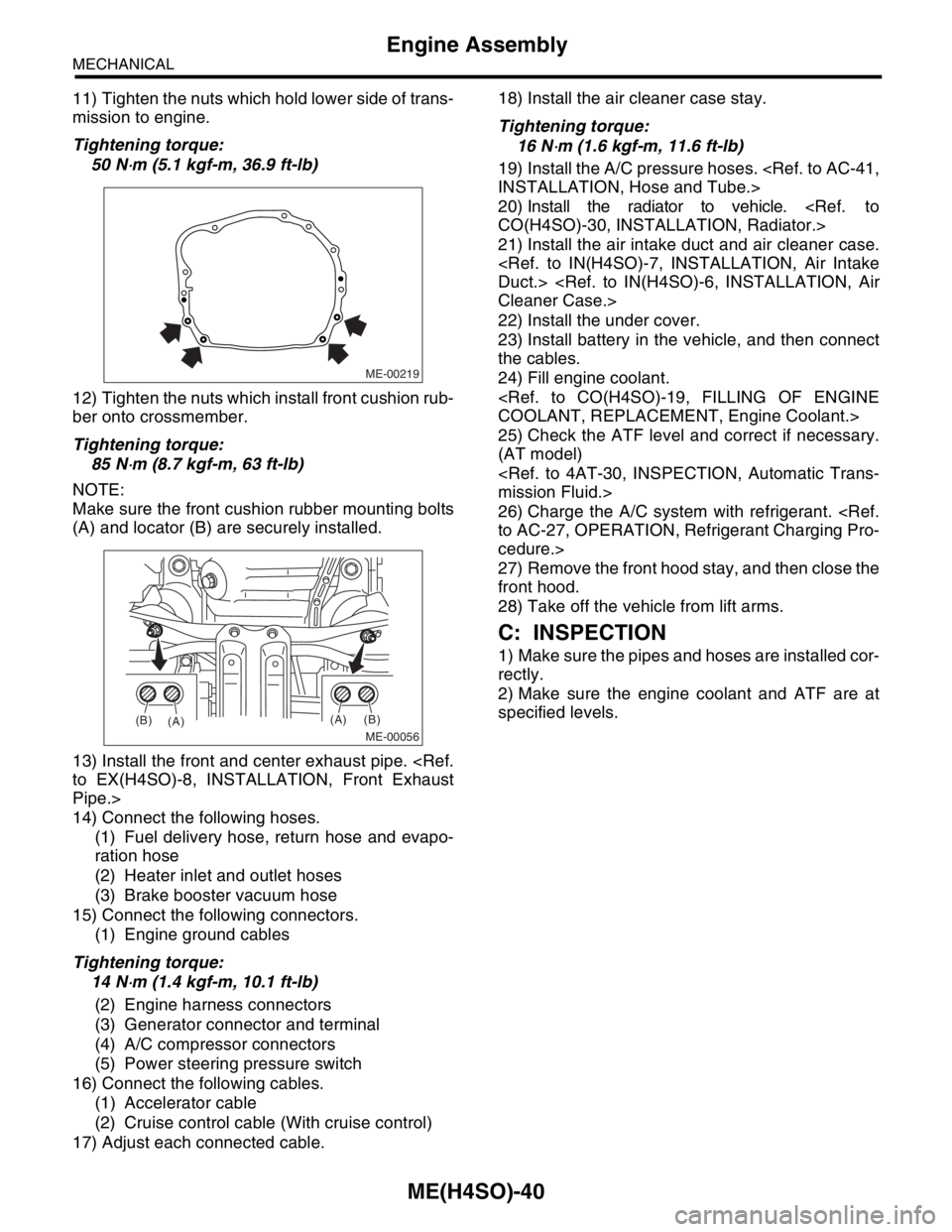

11) Tighten the nuts which hold lower side of trans-

mission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

12) Tighten the nuts which install front cushion rub-

ber onto crossmember.

Tightening torque:

85 N

⋅m (8.7 kgf-m, 63 ft-lb)

NOTE:

Make sure the front cushion rubber mounting bolts

(A) and locator (B) are securely installed.

13) Install the front and center exhaust pipe.

Pipe.>

14) Connect the following hoses.

(1) Fuel delivery hose, return hose and evapo-

ration hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

15) Connect the following connectors.

(1) Engine ground cables

Tightening torque:

14 N

⋅m (1.4 kgf-m, 10.1 ft-lb)

(2) Engine harness connectors

(3) Generator connector and terminal

(4) A/C compressor connectors

(5) Power steering pressure switch

16) Connect the following cables.

(1) Accelerator cable

(2) Cruise control cable (With cruise control)

17) Adjust each connected cable.18) Install the air cleaner case stay.

Tightening torque:

16 N

⋅m (1.6 kgf-m, 11.6 ft-lb)

19) Install the A/C pressure hoses.

20) Install the radiator to vehicle.

21) Install the air intake duct and air cleaner case.

22) Install the under cover.

23) Install battery in the vehicle, and then connect

the cables.

24) Fill engine coolant.

25) Check the ATF level and correct if necessary.

(AT model)

26) Charge the A/C system with refrigerant.

cedure.>

27) Remove the front hood stay, and then close the

front hood.

28) Take off the vehicle from lift arms.

C: INSPECTION

1) Make sure the pipes and hoses are installed cor-

rectly.

2) Make sure the engine coolant and ATF are at

specified levels.

ME-00219

ME-00056

(A)

(A)(B)

(B)

Page 910 of 2870

ME(H4SO)-41

MECHANICAL

Engine Mounting

10.Engine Mounting

A: REMOVAL

1) Remove the engine assembly.

2) Remove the engine mounting from engine as-

sembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Engine mounting:

34 N

⋅m (3.5 kgf-m, 25.3 ft-lb)

C: INSPECTION

Make sure there are no cracks or other damage.

Page 923 of 2870

MECHANICAL

ME(H4SO)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................25

3. Idle Speed .................................................................................................26

4. Ignition Timing ...........................................................................................27

5. Intake Manifold Vacuum............................................................................28

6. Engine Oil Pressure ..................................................................................29

7. Fuel Pressure ............................................................................................30

8. Valve Clearance ........................................................................................31

9. Engine Assembly ......................................................................................34

10. Engine Mounting .......................................................................................41

11. Preparation for Overhaul ...........................................................................42

12. V-belt .........................................................................................................43

13. Crank Pulley ..............................................................................................45

14. Timing Belt Cover......................................................................................47

15. Timing Belt ................................................................................................48

16. Cam Sprocket ...........................................................................................53

17. Crank Sprocket .........................................................................................55

18. Valve Rocker Assembly ............................................................................56

19. Camshaft ...................................................................................................58

20. Cylinder Head ...........................................................................................62

21. Cylinder Block ...........................................................................................69

22. Engine Trouble in General ........................................................................91

23. Engine Noise .............................................................................................96

Page 967 of 2870

ME(H4SO)-96

MECHANICAL

Engine Noise

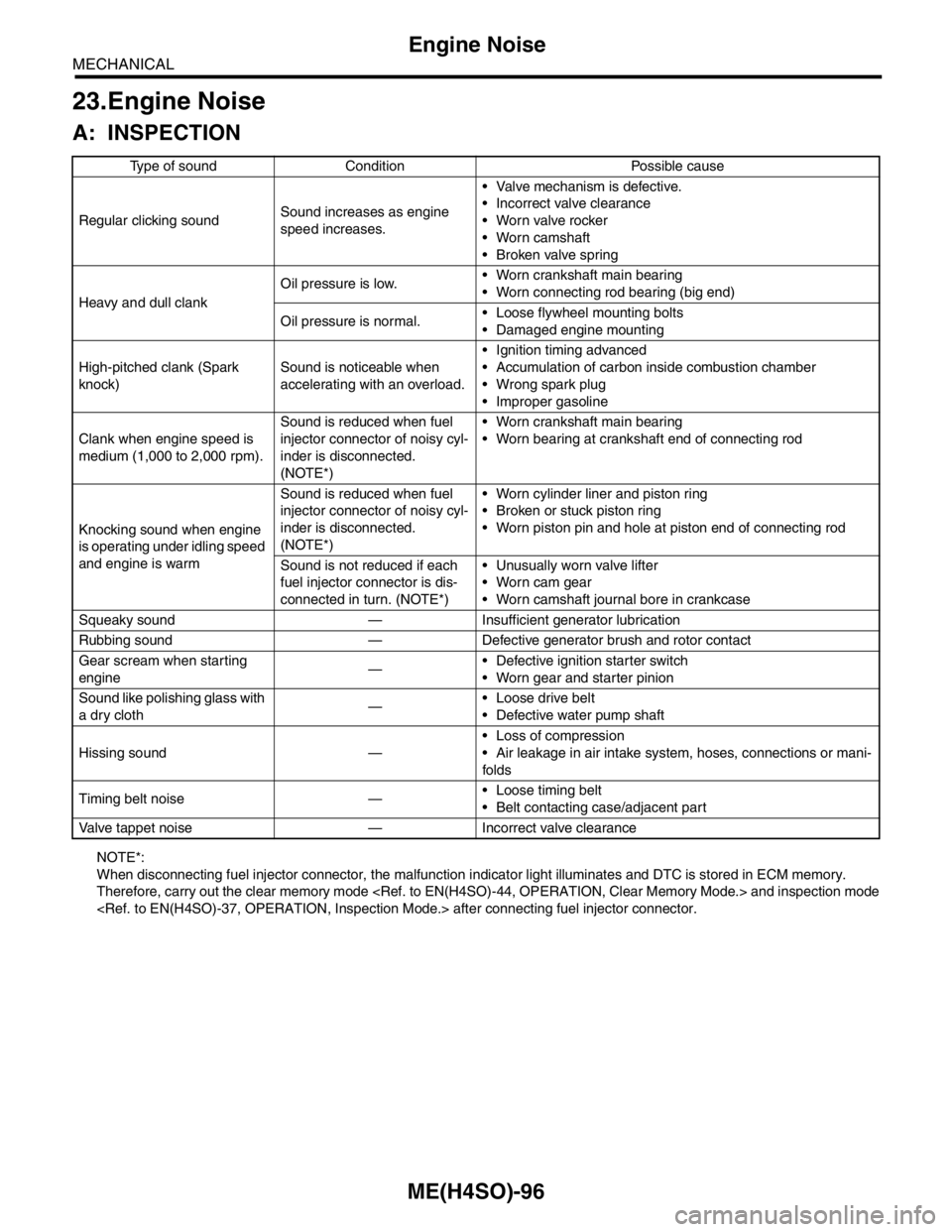

23.Engine Noise

A: INSPECTION

NOTE*:

When disconnecting fuel injector connector, the malfunction indicator light illuminates and DTC is stored in ECM memory.

Therefore, carry out the clear memory mode

Regular clicking soundSound increases as engine

speed increases. Valve mechanism is defective.

Incorrect valve clearance

Worn valve rocker

Worn camshaft

Broken valve spring

Heavy and dull clankOil pressure is low. Worn crankshaft main bearing

Worn connecting rod bearing (big end)

Oil pressure is normal. Loose flywheel mounting bolts

Damaged engine mounting

High-pitched clank (Spark

knock)Sound is noticeable when

accelerating with an overload. Ignition timing advanced

Accumulation of carbon inside combustion chamber

Wrong spark plug

Improper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm).Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*) Worn crankshaft main bearing

Worn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warmSound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*) Worn cylinder liner and piston ring

Broken or stuck piston ring

Worn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn. (NOTE*) Unusually worn valve lifter

Worn cam gear

Worn camshaft journal bore in crankcase

Squeaky sound — Insufficient generator lubrication

Rubbing sound — Defective generator brush and rotor contact

Gear scream when starting

engine— Defective ignition starter switch

Worn gear and starter pinion

Sound like polishing glass with

a dry cloth— Loose drive belt

Defective water pump shaft

Hissing sound — Loss of compression

Air leakage in air intake system, hoses, connections or mani-

folds

Timing belt noise — Loose timing belt

Belt contacting case/adjacent part

Valve tappet noise — Incorrect valve clearance

Page 1003 of 2870

CO(H4SO)-20

COOLING

Engine Coolant

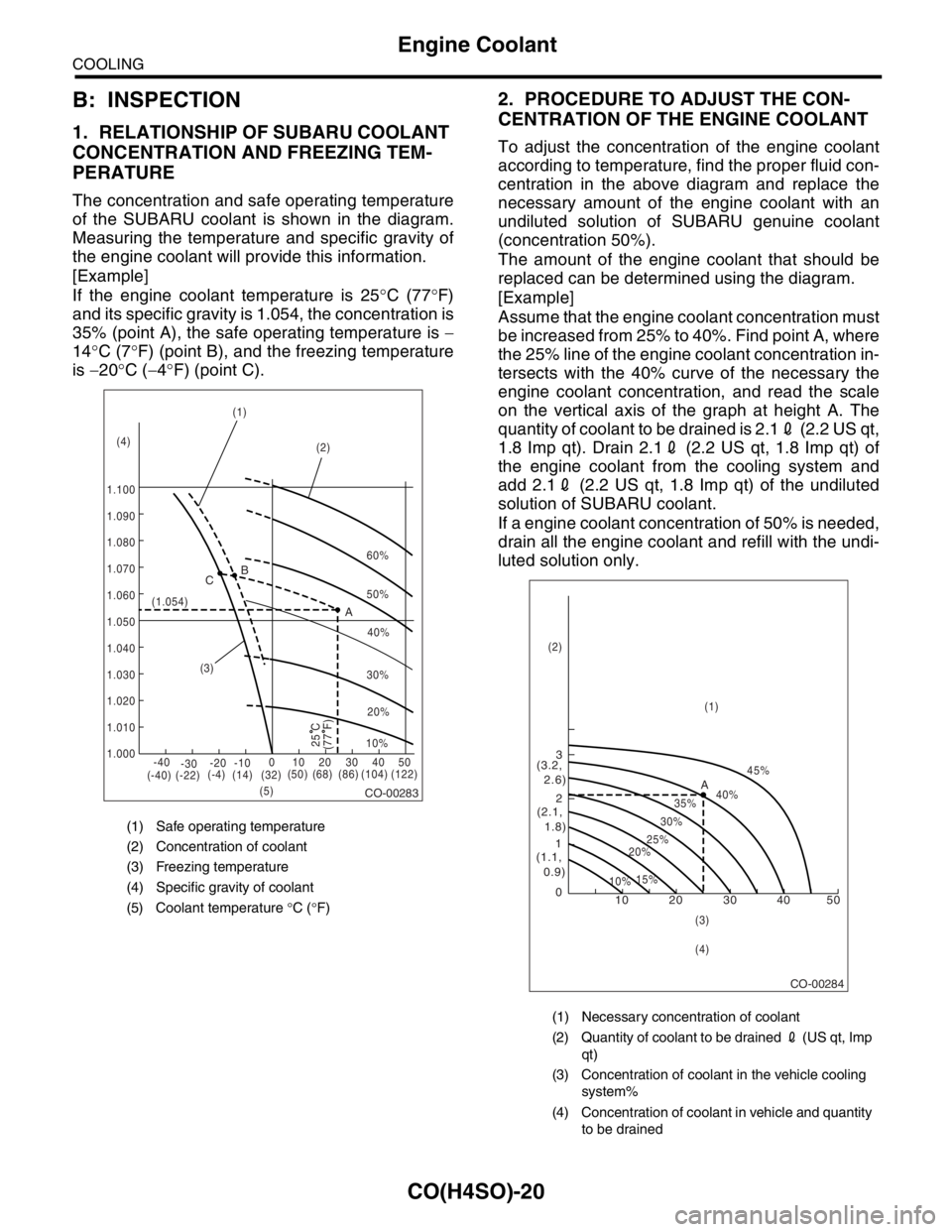

B: INSPECTION

1. RELATIONSHIP OF SUBARU COOLANT

CONCENTRATION AND FREEZING TEM-

PERATURE

The concentration and safe operating temperature

of the SUBARU coolant is shown in the diagram.

Measuring the temperature and specific gravity of

the engine coolant will provide this information.

[Example]

If the engine coolant temperature is 25°C (77°F)

and its specific gravity is 1.054, the concentration is

35% (point A), the safe operating temperature is −

14°C (7°F) (point B), and the freezing temperature

is −20°C (−4°F) (point C).

2. PROCEDURE TO ADJUST THE CON-

CENTRATION OF THE ENGINE COOLANT

To adjust the concentration of the engine coolant

according to temperature, find the proper fluid con-

centration in the above diagram and replace the

necessary amount of the engine coolant with an

undiluted solution of SUBARU genuine coolant

(concentration 50%).

The amount of the engine coolant that should be

replaced can be determined using the diagram.

[Example]

Assume that the engine coolant concentration must

be increased from 25% to 40%. Find point A, where

the 25% line of the engine coolant concentration in-

tersects with the 40% curve of the necessary the

engine coolant concentration, and read the scale

on the vertical axis of the graph at height A. The

quantity of coolant to be drained is 2.12 (2.2 US qt,

1.8 Imp qt). Drain 2.12 (2.2 US qt, 1.8 Imp qt) of

the engine coolant from the cooling system and

add 2.12 (2.2 US qt, 1.8 Imp qt) of the undiluted

solution of SUBARU coolant.

If a engine coolant concentration of 50% is needed,

drain all the engine coolant and refill with the undi-

luted solution only.

(1) Safe operating temperature

(2) Concentration of coolant

(3) Freezing temperature

(4) Specific gravity of coolant

(5) Coolant temperature °C (°F)

CO-00283

60%

(1.054)

1.000 1.010 1.020

1.030

1.040

1.050

1.060

1.070 1.080 1.090

1.100(1)

(2)

(3)

(5) (4)B

A C

-40

(-40) (-22)(-4)

(14)(32)(50) (68) (86) (104) (122) -30-20 -1001020304050

(77 F)

50%

40%

30%

20%

25 C10%

(1) Necessary concentration of coolant

(2) Quantity of coolant to be drained 2 (US qt, Imp

qt)

(3) Concentration of coolant in the vehicle cooling

system%

(4) Concentration of coolant in vehicle and quantity

to be drained

CO-00284

10 0 12 3

(1.1,

0.9)(2.1,

1.8) (3.2,

2.6)

10%15%25%

20%30%35%40%45%

A

20 30 40 50

(1) (2)

(3)

(4)

Page 1018 of 2870

CO(H4SO)-35

COOLING

Radiator Main Fan and Fan Motor

8. Radiator Main Fan and Fan

Motor

A: REMOVAL

1. NON-TURBO MODEL

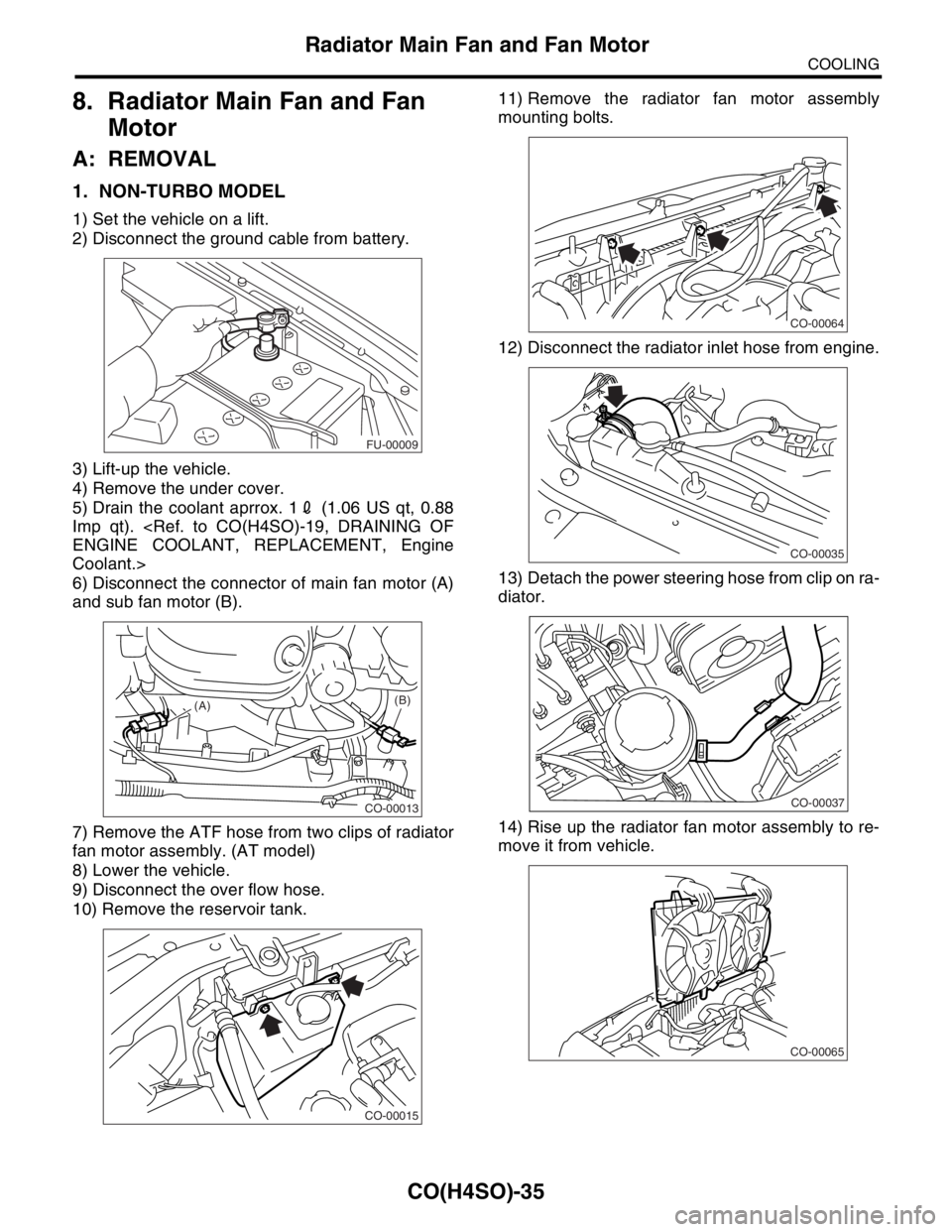

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Lift-up the vehicle.

4) Remove the under cover.

5) Drain the coolant aprrox. 12 (1.06 US qt, 0.88

Imp qt).

Coolant.>

6) Disconnect the connector of main fan motor (A)

and sub fan motor (B).

7) Remove the ATF hose from two clips of radiator

fan motor assembly. (AT model)

8) Lower the vehicle.

9) Disconnect the over flow hose.

10) Remove the reservoir tank.11) Remove the radiator fan motor assembly

mounting bolts.

12) Disconnect the radiator inlet hose from engine.

13) Detach the power steering hose from clip on ra-

diator.

14) Rise up the radiator fan motor assembly to re-

move it from vehicle.

FU-00009

CO-00013

(A)(B)

CO-00015

CO-00064

CO-00035

CO-00037

CO-00065

Page 1022 of 2870

CO(H4SO)-39

COOLING

Radiator Main Fan and Fan Motor

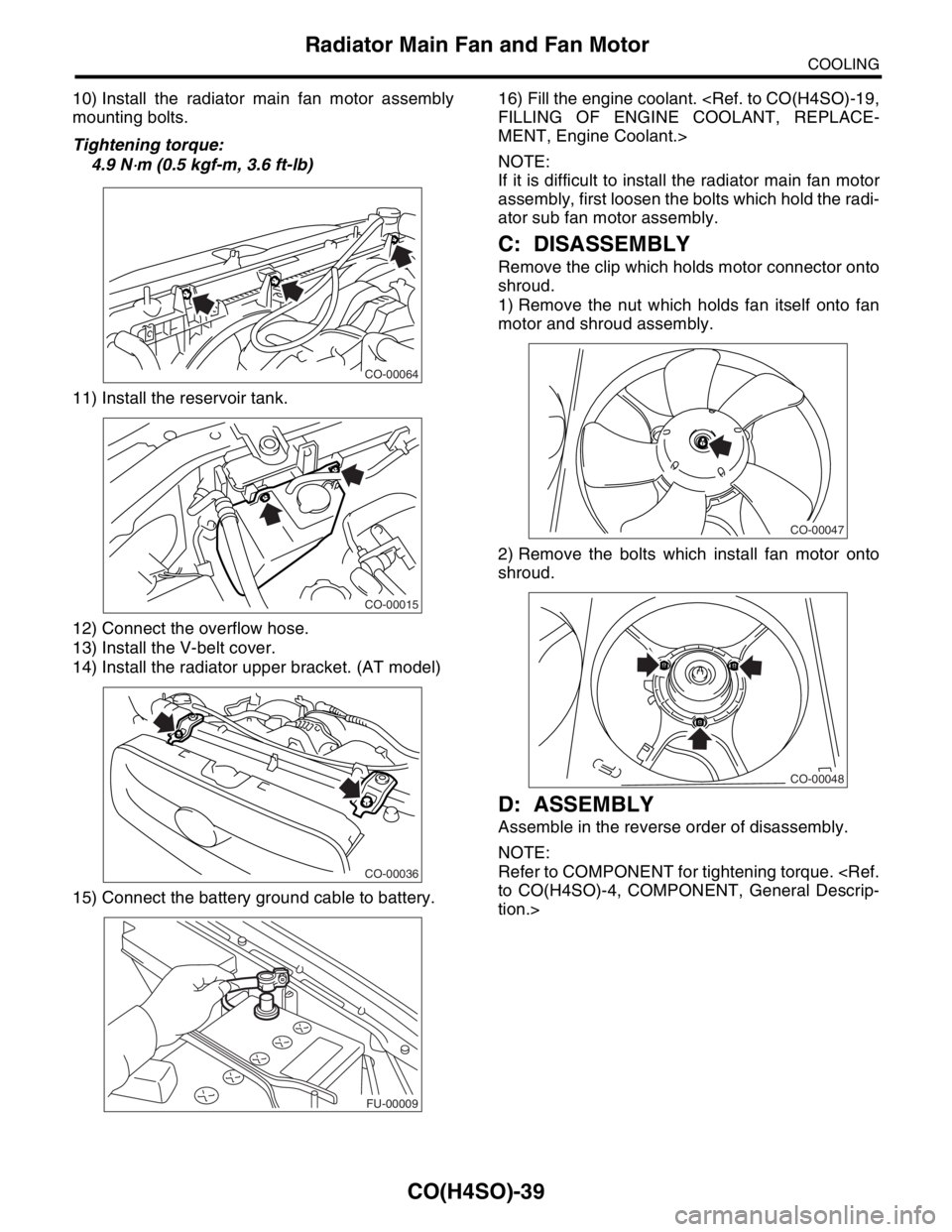

10) Install the radiator main fan motor assembly

mounting bolts.

Tightening torque:

4.9 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

11) Install the reservoir tank.

12) Connect the overflow hose.

13) Install the V-belt cover.

14) Install the radiator upper bracket. (AT model)

15) Connect the battery ground cable to battery.16) Fill the engine coolant.

MENT, Engine Coolant.>

NOTE:

If it is difficult to install the radiator main fan motor

assembly, first loosen the bolts which hold the radi-

ator sub fan motor assembly.

C: DISASSEMBLY

Remove the clip which holds motor connector onto

shroud.

1) Remove the nut which holds fan itself onto fan

motor and shroud assembly.

2) Remove the bolts which install fan motor onto

shroud.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

NOTE:

Refer to COMPONENT for tightening torque.

tion.>

CO-00064

CO-00015

CO-00036

FU-00009

CO-00047

CO-00048