automatic transmission fluid SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2347 of 2870

4AT-35

AUTOMATIC TRANSMISSION

Time Lag Test

6. Time Lag Test

A: INSPECTION

NOTE:

If the select lever is shifted while the engine is

idling, there will be a certain time elapse or lag be-

fore the shock can be felt. This is used for checking

the condition of the low clutch, reverse clutch, low &

reverse brake and one-way clutch.

Perform the test at normal operation fluid tem-

perature 70 — 80°C (158 — 176°F).

Be sure to allow a one minute interval between

tests.

Perform measurement for three times and take

the average value.

1) Fully apply the parking brake.

2) Start the engine.

Check the idling speed (A/C OFF).

3) Shift the select lever from “N” to “D” range.

Using a stop watch, measure the time it takes from

shifting the lever until the shock is felt.

Time lag: Less than 1.2 seconds

If “N” → “D” time lag is longer than specified:

Line pressure too low

Low clutch worn

One-way clutch not operating properly

D-ring worn

4) In the same manner, measure the time lag for

“N” → “R”.

Time lag: Less than 1.5 seconds

If “N” → “R” time lag is longer than specified:

Line pressure too low

Reverse clutch worn

Low & reverse brake worn

D-ring worn

Page 2352 of 2870

4AT-40

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

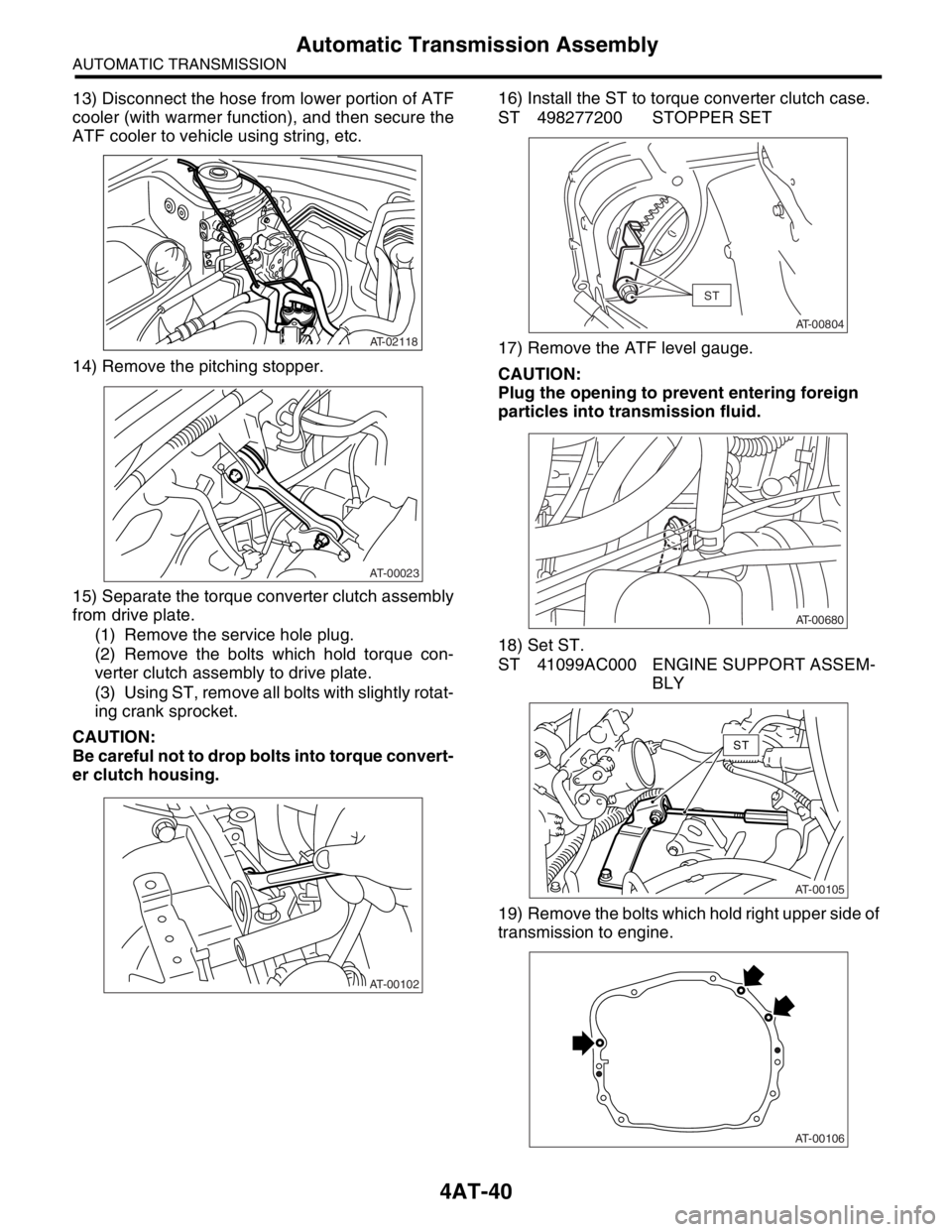

13) Disconnect the hose from lower portion of ATF

cooler (with warmer function), and then secure the

ATF cooler to vehicle using string, etc.

14) Remove the pitching stopper.

15) Separate the torque converter clutch assembly

from drive plate.

(1) Remove the service hole plug.

(2) Remove the bolts which hold torque con-

verter clutch assembly to drive plate.

(3) Using ST, remove all bolts with slightly rotat-

ing crank sprocket.

CAUTION:

Be careful not to drop bolts into torque convert-

er clutch housing.16) Install the ST to torque converter clutch case.

ST 498277200 STOPPER SET

17) Remove the ATF level gauge.

CAUTION:

Plug the opening to prevent entering foreign

particles into transmission fluid.

18) Set ST.

ST 41099AC000 ENGINE SUPPORT ASSEM-

BLY

19) Remove the bolts which hold right upper side of

transmission to engine.

AT-02118

AT-00023

AT-00102

AT-00804

ST

AT-00680

AT-00105

ST

AT-00106

Page 2358 of 2870

4AT-46

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

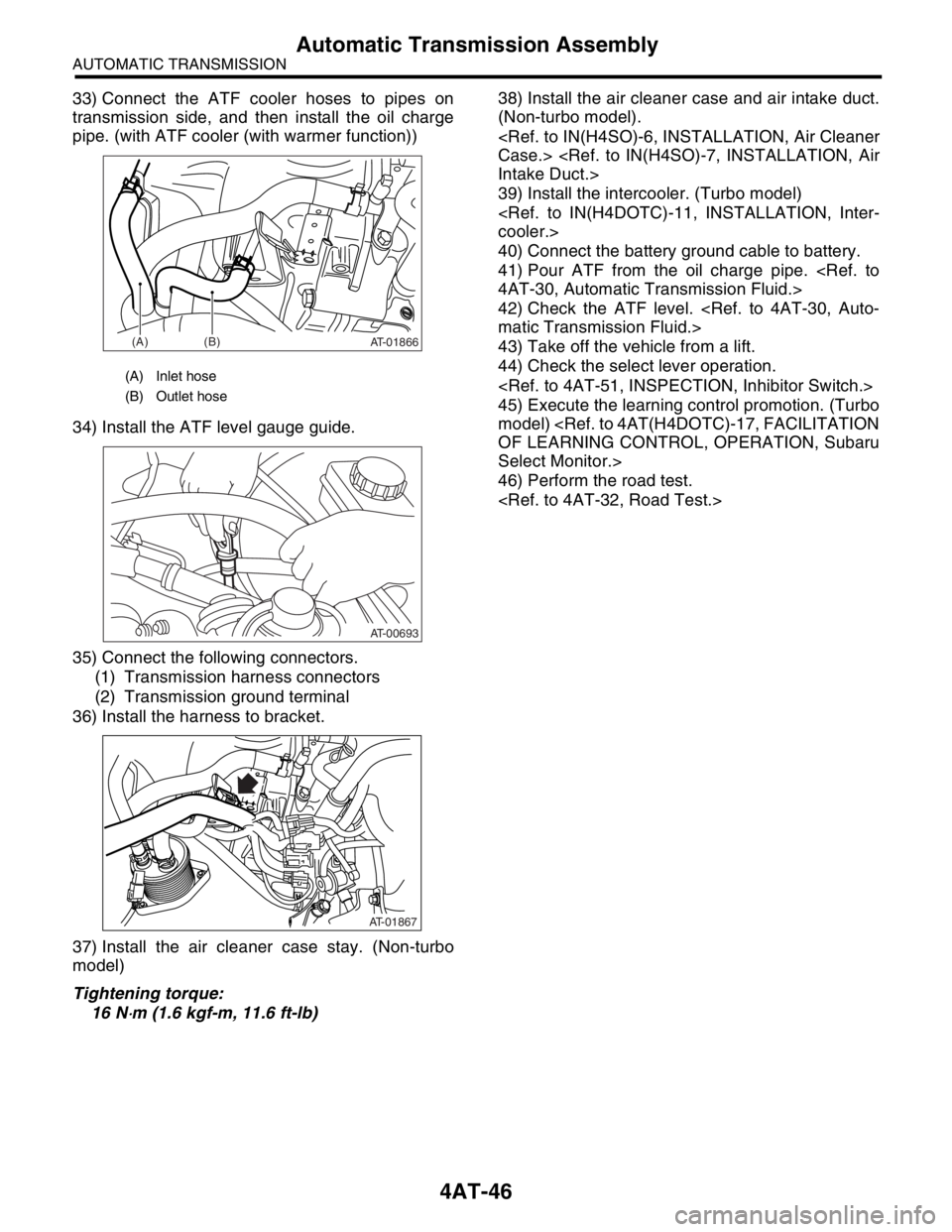

33) Connect the ATF cooler hoses to pipes on

transmission side, and then install the oil charge

pipe. (with ATF cooler (with warmer function))

34) Install the ATF level gauge guide.

35) Connect the following connectors.

(1) Transmission harness connectors

(2) Transmission ground terminal

36) Install the harness to bracket.

37) Install the air cleaner case stay. (Non-turbo

model)

Tightening torque:

16 N

⋅m (1.6 kgf-m, 11.6 ft-lb)38) Install the air cleaner case and air intake duct.

(Non-turbo model).

39) Install the intercooler. (Turbo model)

40) Connect the battery ground cable to battery.

41) Pour ATF from the oil charge pipe.

42) Check the ATF level.

43) Take off the vehicle from a lift.

44) Check the select lever operation.

45) Execute the learning control promotion. (Turbo

model)

Select Monitor.>

46) Perform the road test.

(A) Inlet hose

(B) Outlet hose

AT-01866(A)(B)

AT-00693

AT-01867

Page 2362 of 2870

4AT-49

AUTOMATIC TRANSMISSION

Extension Case Oil Seal

11.Extension Case Oil Seal

A: INSPECTION

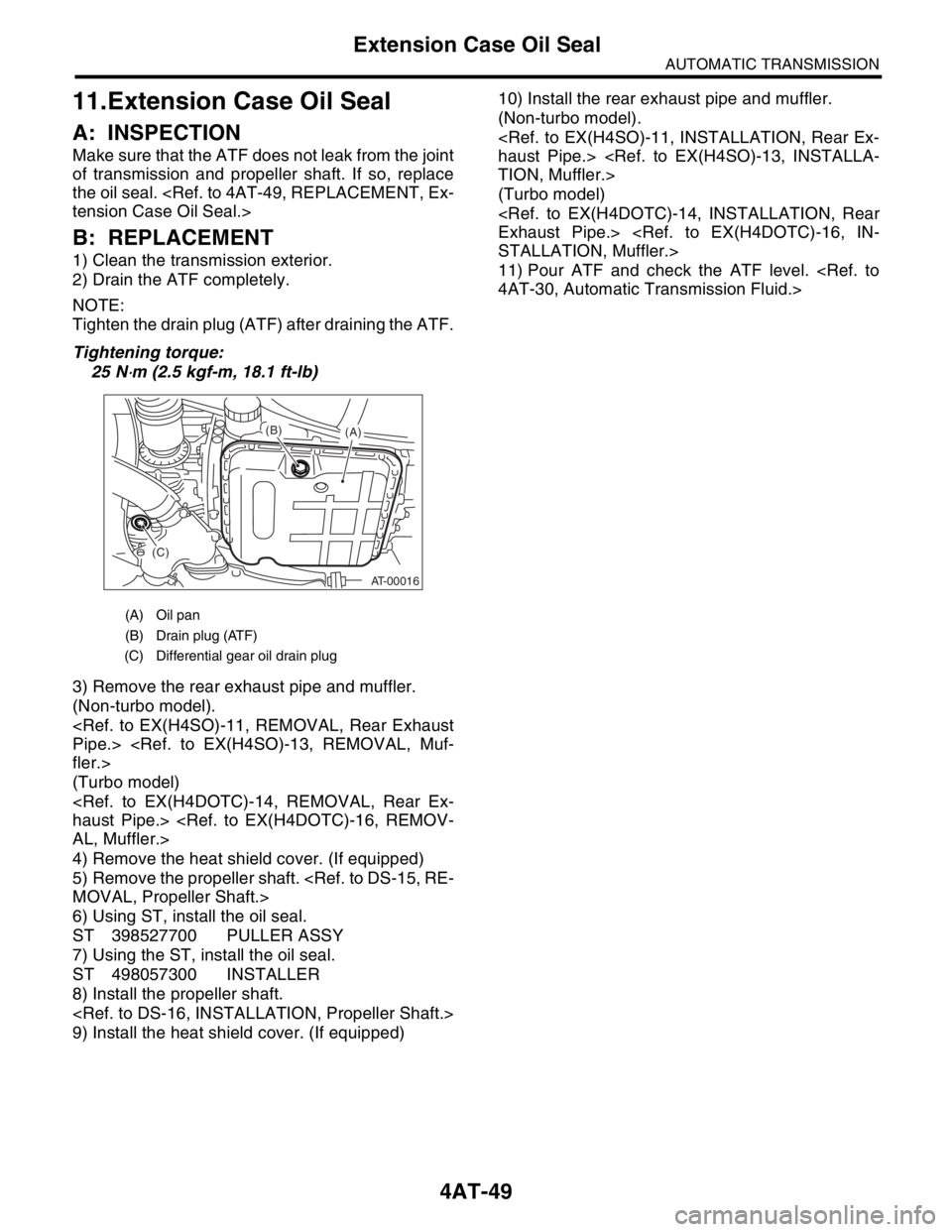

Make sure that the ATF does not leak from the joint

of transmission and propeller shaft. If so, replace

the oil seal.

B: REPLACEMENT

1) Clean the transmission exterior.

2) Drain the ATF completely.

NOTE:

Tighten the drain plug (ATF) after draining the ATF.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

3) Remove the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

4) Remove the heat shield cover. (If equipped)

5) Remove the propeller shaft.

6) Using ST, install the oil seal.

ST 398527700 PULLER ASSY

7) Using the ST, install the oil seal.

ST 498057300 INSTALLER

8) Install the propeller shaft.

9) Install the heat shield cover. (If equipped)10) Install the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

11) Pour ATF and check the ATF level.

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2377 of 2870

4AT-64

AUTOMATIC TRANSMISSION

Control Valve Body

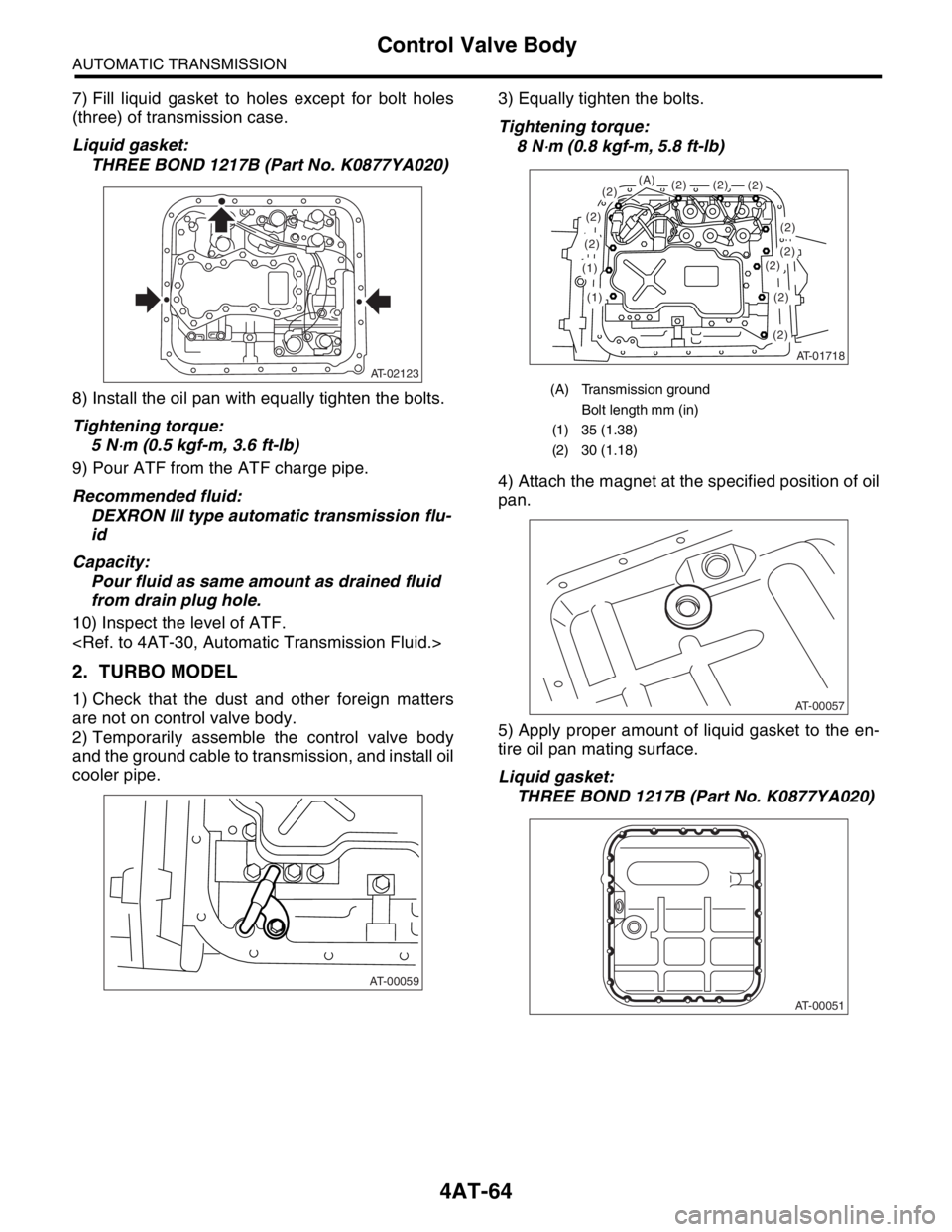

7) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

8) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

9) Pour ATF from the ATF charge pipe.

Recommended fluid:

DEXRON III type automatic transmission flu-

id

Capacity:

Pour fluid as same amount as drained fluid

from drain plug hole.

10) Inspect the level of ATF.

2. TURBO MODEL

1) Check that the dust and other foreign matters

are not on control valve body.

2) Temporarily assemble the control valve body

and the ground cable to transmission, and install oil

cooler pipe.3) Equally tighten the bolts.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

4) Attach the magnet at the specified position of oil

pan.

5) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

AT-02123

AT-00059

(A) Transmission ground

Bolt length mm (in)

(1) 35 (1.38)

(2) 30 (1.18)

AT-01718

(1)

(1)

(2)

(2)

(2)(2)

(2)

(2)(2)(2)(2)

(2)

(2)

(A)

AT-00057

AT-00051

Page 2378 of 2870

4AT-65

AUTOMATIC TRANSMISSION

Control Valve Body

6) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

7) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

8) Pour ATF from the ATF charge pipe.

Recommended fluid:

DEXRON III type automatic transmission flu-

id

Capacity:

Pour fluid as same amount as drained fluid

from drain plug hole.

9) Bleed the air of control valve.

10) Check the ATF level.

11) Execute the learning control promotion.

ING CONTROL, OPERATION, Subaru Select

Monitor.>

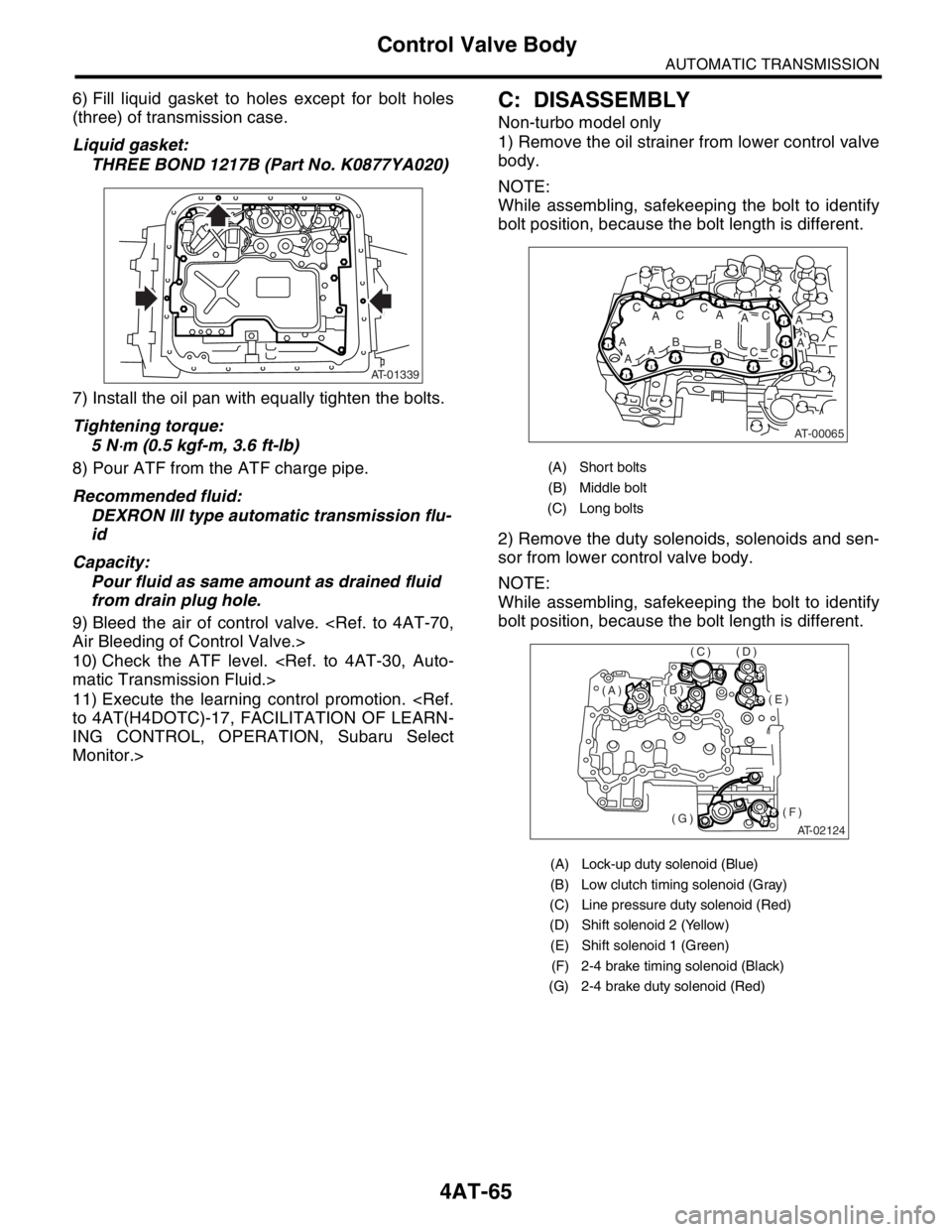

C: DISASSEMBLY

Non-turbo model only

1) Remove the oil strainer from lower control valve

body.

NOTE:

While assembling, safekeeping the bolt to identify

bolt position, because the bolt length is different.

2) Remove the duty solenoids, solenoids and sen-

sor from lower control valve body.

NOTE:

While assembling, safekeeping the bolt to identify

bolt position, because the bolt length is different.

AT-01339

(A) Short bolts

(B) Middle bolt

(C) Long bolts

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

AT-00065

A

ABAA

AC

ACC

AB

AC

CC

AT-02124

(E)

(F)(G)

(D)(C)

(B)(A)

Page 2385 of 2870

4AT-72

AUTOMATIC TRANSMISSION

Shift Solenoids, Duty Solenoids and ATF Temperature Sensor

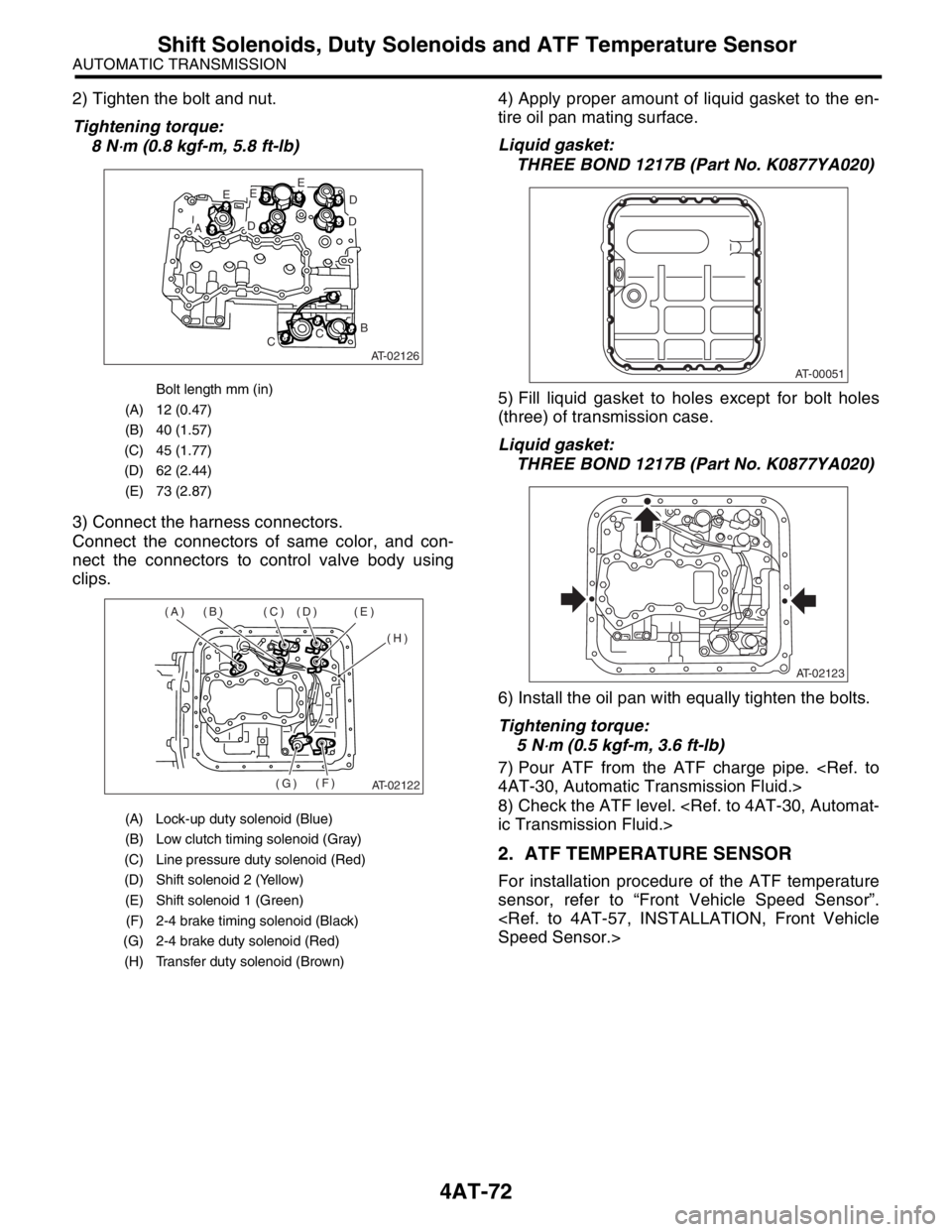

2) Tighten the bolt and nut.

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

3) Connect the harness connectors.

Connect the connectors of same color, and con-

nect the connectors to control valve body using

clips.4) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

5) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

6) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

7) Pour ATF from the ATF charge pipe.

8) Check the ATF level.

2. ATF TEMPERATURE SENSOR

For installation procedure of the ATF temperature

sensor, refer to “Front Vehicle Speed Sensor”.

Bolt length mm (in)

(A) 12 (0.47)

(B) 40 (1.57)

(C) 45 (1.77)

(D) 62 (2.44)

(E) 73 (2.87)

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) Transfer duty solenoid (Brown)

AT-02126

E

AD

EE

D

D

B

CC

AT-02122

(A) (B) (C) (D) (E)

(H)

(F)

(G)

AT-00051

AT-02123

Page 2388 of 2870

4AT-75

AUTOMATIC TRANSMISSION

Transfer Duty Solenoid and Valve Body

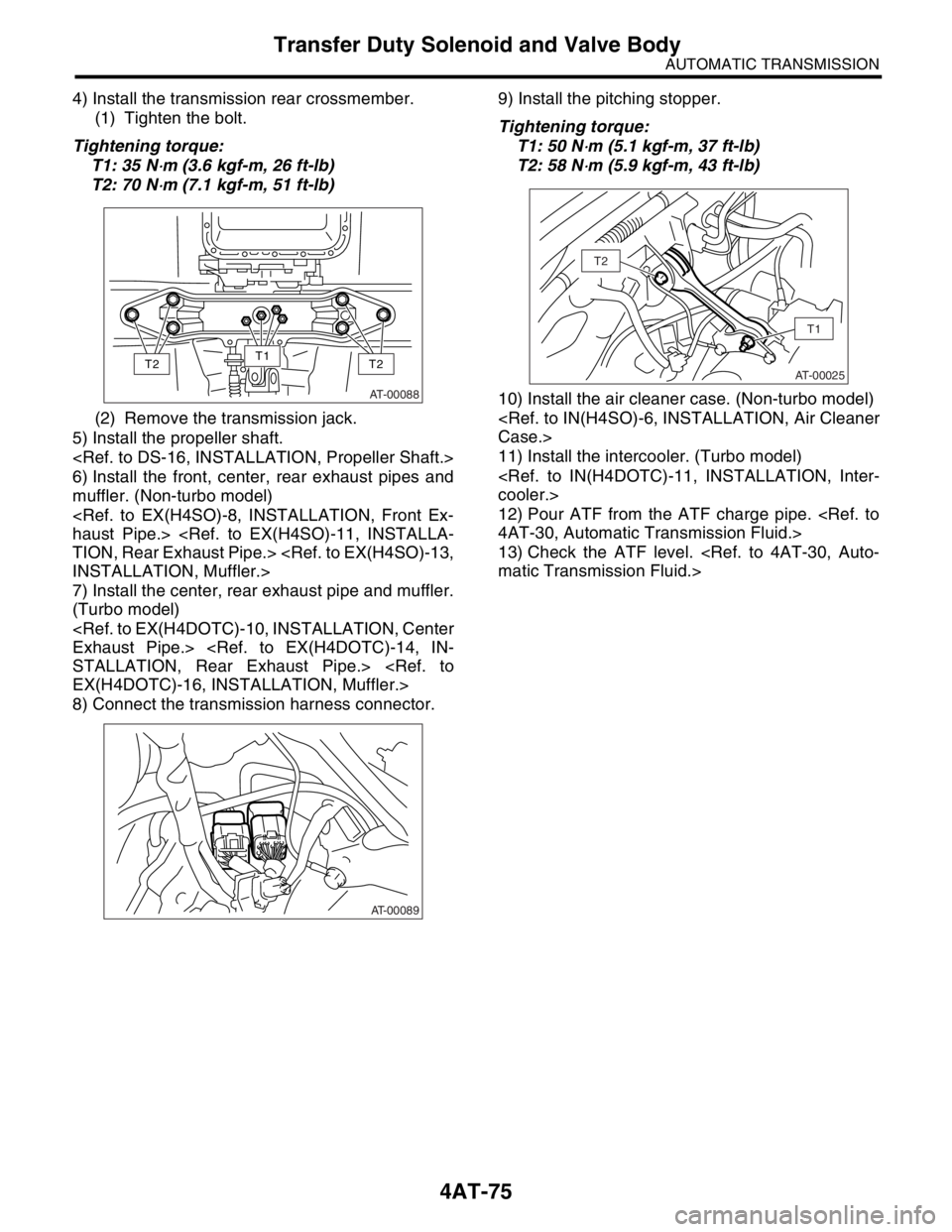

4) Install the transmission rear crossmember.

(1) Tighten the bolt.

Tightening torque:

T1: 35 N

⋅m (3.6 kgf-m, 26 ft-lb)

T2: 70 N

⋅m (7.1 kgf-m, 51 ft-lb)

(2) Remove the transmission jack.

5) Install the propeller shaft.

6) Install the front, center, rear exhaust pipes and

muffler. (Non-turbo model)

7) Install the center, rear exhaust pipe and muffler.

(Turbo model)

8) Connect the transmission harness connector.9) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

10) Install the air cleaner case. (Non-turbo model)

11) Install the intercooler. (Turbo model)

12) Pour ATF from the ATF charge pipe.

13) Check the ATF level.

AT-00088

T2T2T1

AT-00089

AT-00025

T1

T2

Page 2389 of 2870

4AT-76

AUTOMATIC TRANSMISSION

ATF Filter

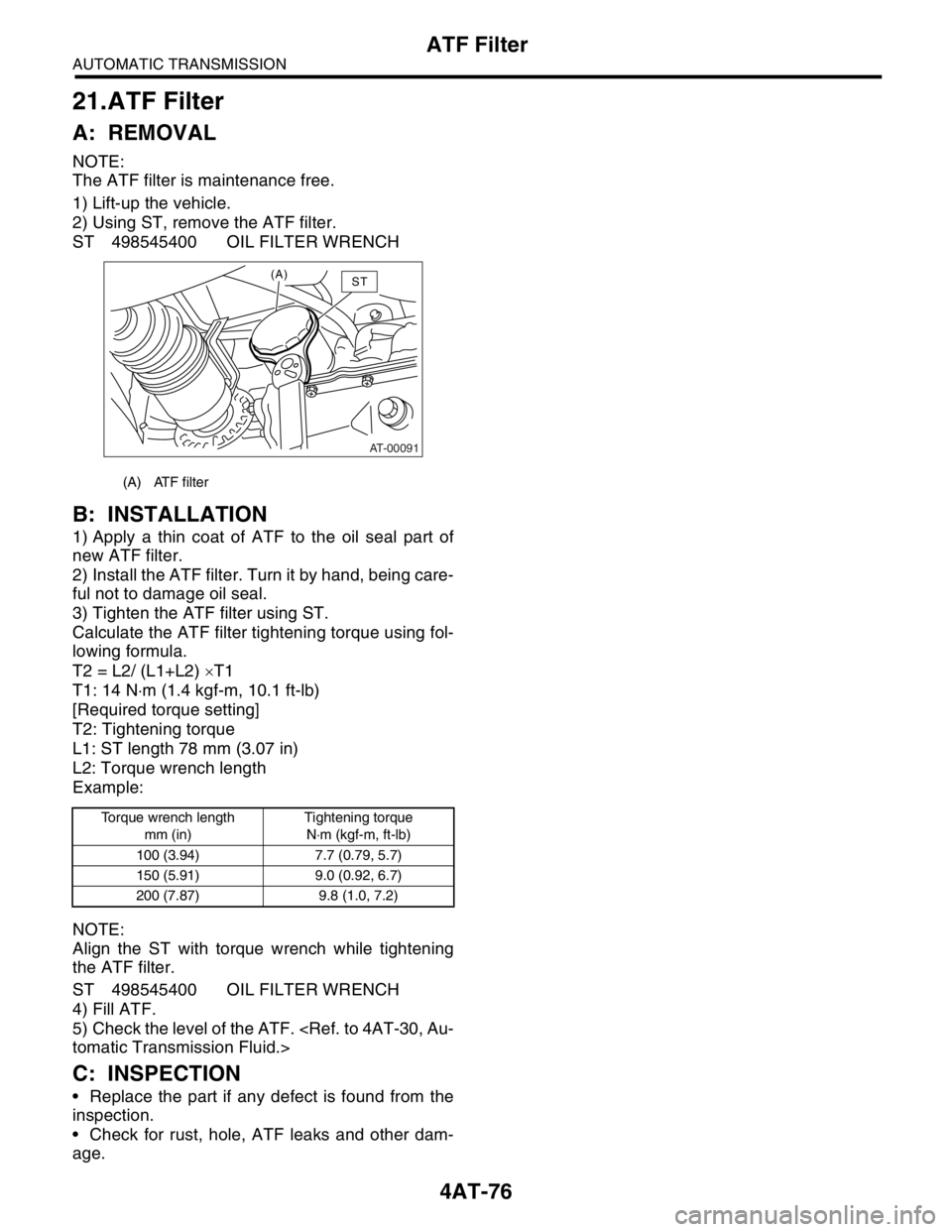

21.ATF Filter

A: REMOVAL

NOTE:

The ATF filter is maintenance free.

1) Lift-up the vehicle.

2) Using ST, remove the ATF filter.

ST 498545400 OIL FILTER WRENCH

B: INSTALLATION

1) Apply a thin coat of ATF to the oil seal part of

new ATF filter.

2) Install the ATF filter. Turn it by hand, being care-

ful not to damage oil seal.

3) Tighten the ATF filter using ST.

Calculate the ATF filter tightening torque using fol-

lowing formula.

T2 = L2/ (L1+L2) ×T1

T1: 14 N⋅m (1.4 kgf-m, 10.1 ft-lb)

[Required torque setting]

T2: Tightening torque

L1: ST length 78 mm (3.07 in)

L2: Torque wrench length

Example:

NOTE:

Align the ST with torque wrench while tightening

the ATF filter.

ST 498545400 OIL FILTER WRENCH

4) Fill ATF.

5) Check the level of the ATF.

C: INSPECTION

Replace the part if any defect is found from the

inspection.

Check for rust, hole, ATF leaks and other dam-

age.

(A) ATF filter

Torque wrench length

mm (in)Tightening torque

N⋅m (kgf-m, ft-lb)

100 (3.94) 7.7 (0.79, 5.7)

150 (5.91) 9.0 (0.92, 6.7)

200 (7.87) 9.8 (1.0, 7.2)

AT-00091

(A)ST

Page 2394 of 2870

4AT-81

AUTOMATIC TRANSMISSION

ATF Cooler Pipe and Hose

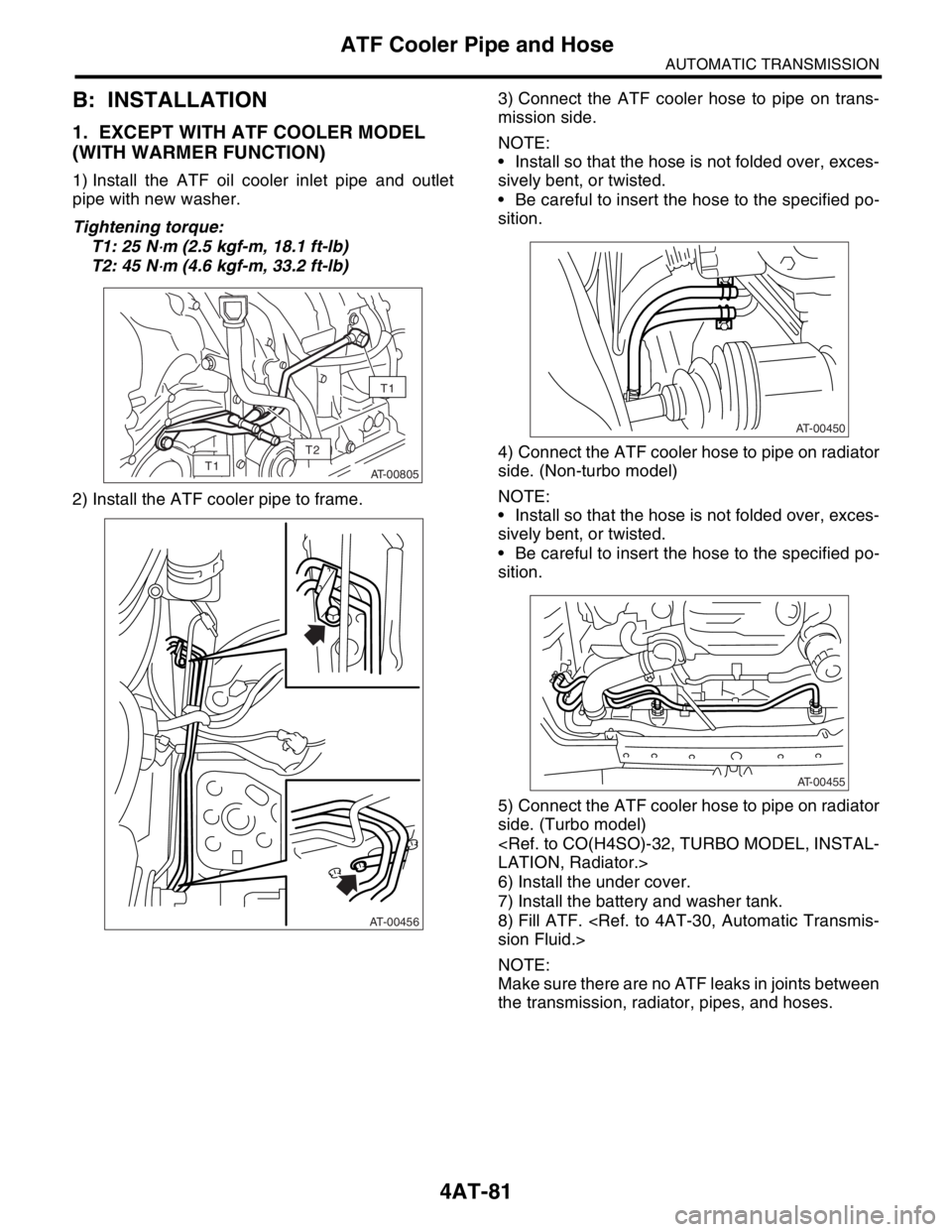

B: INSTALLATION

1. EXCEPT WITH ATF COOLER MODEL

(WITH WARMER FUNCTION)

1) Install the ATF oil cooler inlet pipe and outlet

pipe with new washer.

Tightening torque:

T1: 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

T2: 45 N

⋅m (4.6 kgf-m, 33.2 ft-lb)

2) Install the ATF cooler pipe to frame.3) Connect the ATF cooler hose to pipe on trans-

mission side.

NOTE:

Install so that the hose is not folded over, exces-

sively bent, or twisted.

Be careful to insert the hose to the specified po-

sition.

4) Connect the ATF cooler hose to pipe on radiator

side. (Non-turbo model)

NOTE:

Install so that the hose is not folded over, exces-

sively bent, or twisted.

Be careful to insert the hose to the specified po-

sition.

5) Connect the ATF cooler hose to pipe on radiator

side. (Turbo model)

6) Install the under cover.

7) Install the battery and washer tank.

8) Fill ATF.

NOTE:

Make sure there are no ATF leaks in joints between

the transmission, radiator, pipes, and hoses.

AT-00805

T1

T1

T2

AT-00456

AT-00450

AT-00455