clock SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 901 of 2870

ME(H4SO)-32

MECHANICAL

Valve Clearance

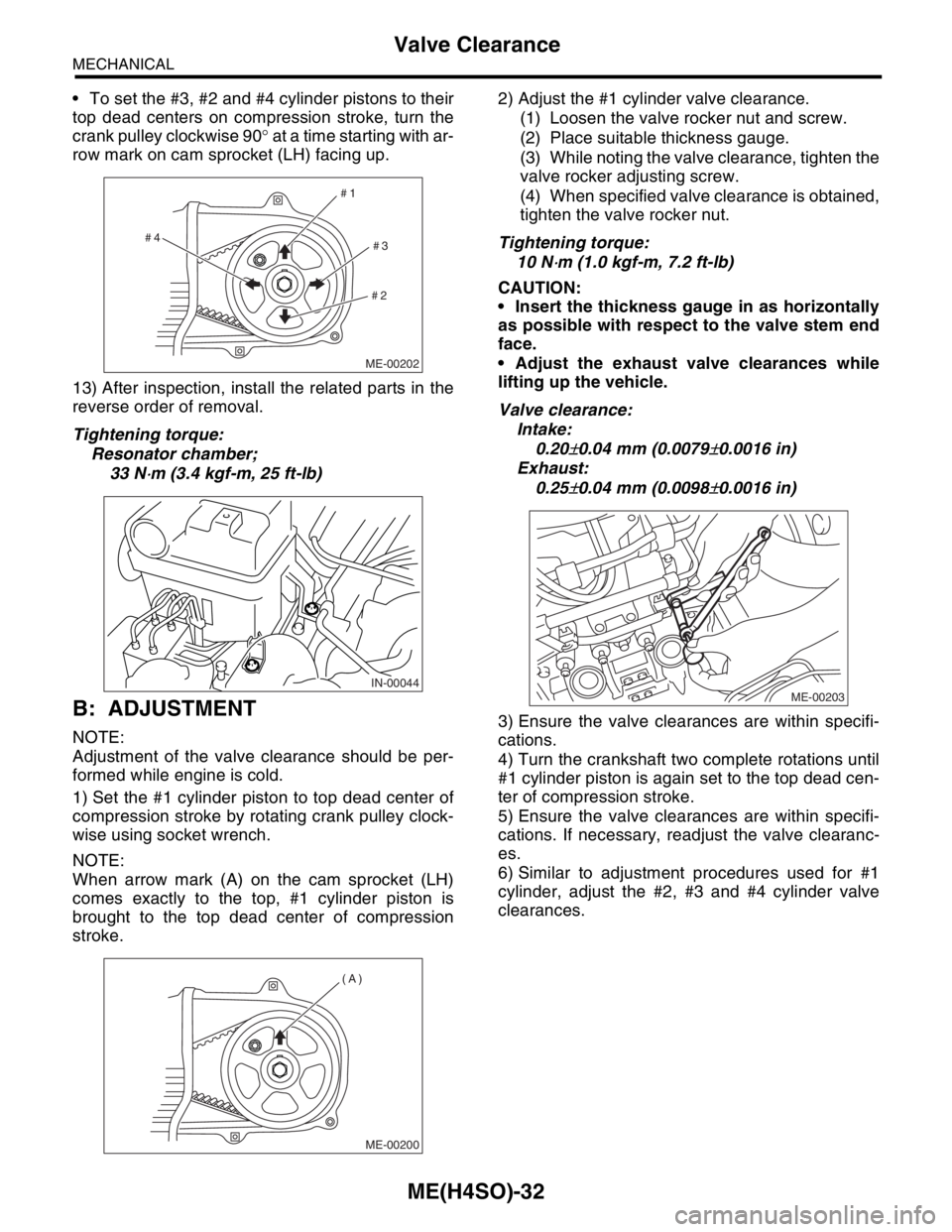

To set the #3, #2 and #4 cylinder pistons to their

top dead centers on compression stroke, turn the

crank pulley clockwise 90° at a time starting with ar-

row mark on cam sprocket (LH) facing up.

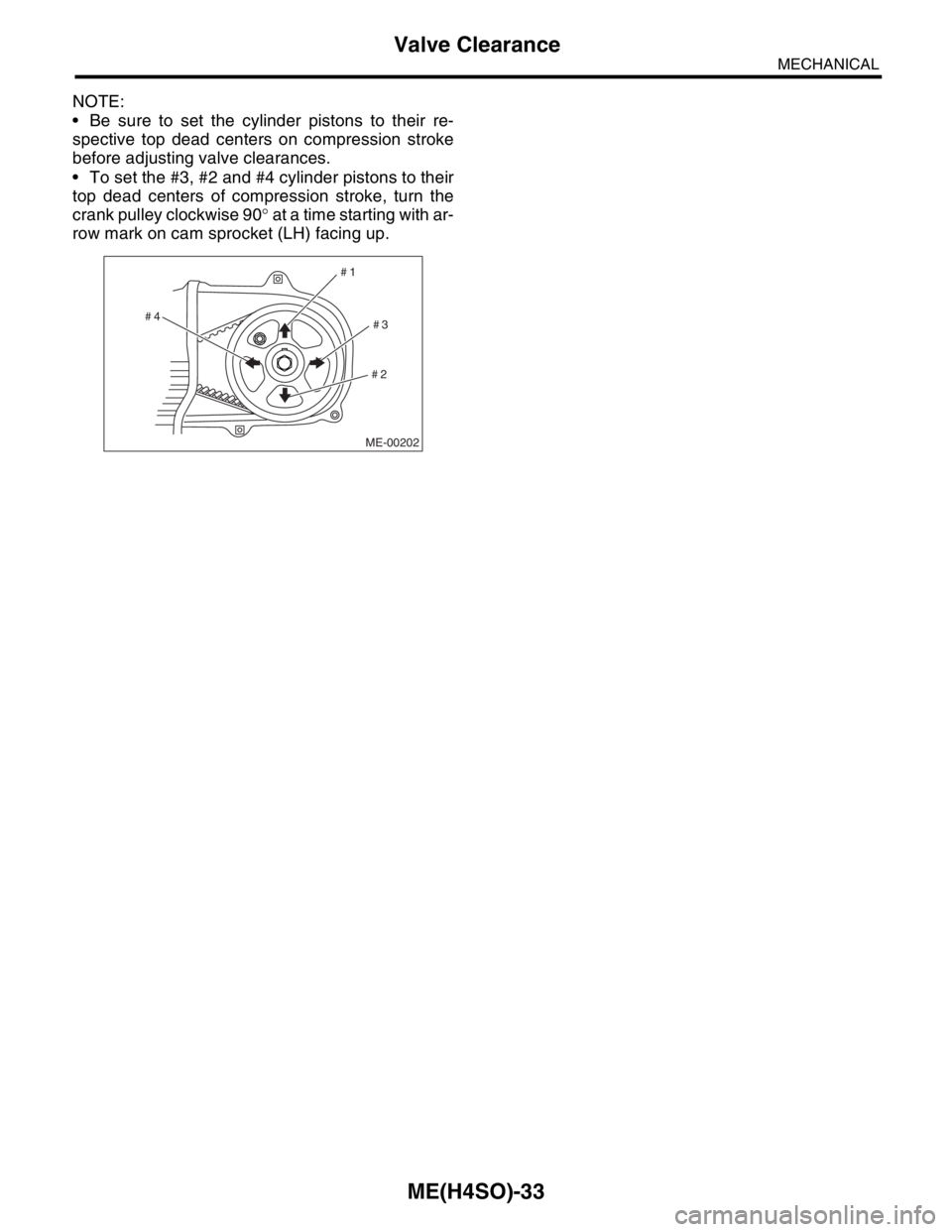

13) After inspection, install the related parts in the

reverse order of removal.

Tightening torque:

Resonator chamber;

33 N

⋅m (3.4 kgf-m, 25 ft-lb)

B: ADJUSTMENT

NOTE:

Adjustment of the valve clearance should be per-

formed while engine is cold.

1) Set the #1 cylinder piston to top dead center of

compression stroke by rotating crank pulley clock-

wise using socket wrench.

NOTE:

When arrow mark (A) on the cam sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of compression

stroke.2) Adjust the #1 cylinder valve clearance.

(1) Loosen the valve rocker nut and screw.

(2) Place suitable thickness gauge.

(3) While noting the valve clearance, tighten the

valve rocker adjusting screw.

(4) When specified valve clearance is obtained,

tighten the valve rocker nut.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

CAUTION:

Insert the thickness gauge in as horizontally

as possible with respect to the valve stem end

face.

Adjust the exhaust valve clearances while

lifting up the vehicle.

Valve clearance:

Intake:

0.20

±0.04 mm (0.0079±0.0016 in)

Exhaust:

0.25

±0.04 mm (0.0098±0.0016 in)

3) Ensure the valve clearances are within specifi-

cations.

4) Turn the crankshaft two complete rotations until

#1 cylinder piston is again set to the top dead cen-

ter of compression stroke.

5) Ensure the valve clearances are within specifi-

cations. If necessary, readjust the valve clearanc-

es.

6) Similar to adjustment procedures used for #1

cylinder, adjust the #2, #3 and #4 cylinder valve

clearances.

ME-00202

#1

#2#3 #4

IN-00044

ME-00200

(A)

ME-00203

Page 902 of 2870

ME(H4SO)-33

MECHANICAL

Valve Clearance

NOTE:

Be sure to set the cylinder pistons to their re-

spective top dead centers on compression stroke

before adjusting valve clearances.

To set the #3, #2 and #4 cylinder pistons to their

top dead centers of compression stroke, turn the

crank pulley clockwise 90° at a time starting with ar-

row mark on cam sprocket (LH) facing up.

ME-00202

#1

#2#3 #4

Page 938 of 2870

ME(H4SO)-67

MECHANICAL

Cylinder Head

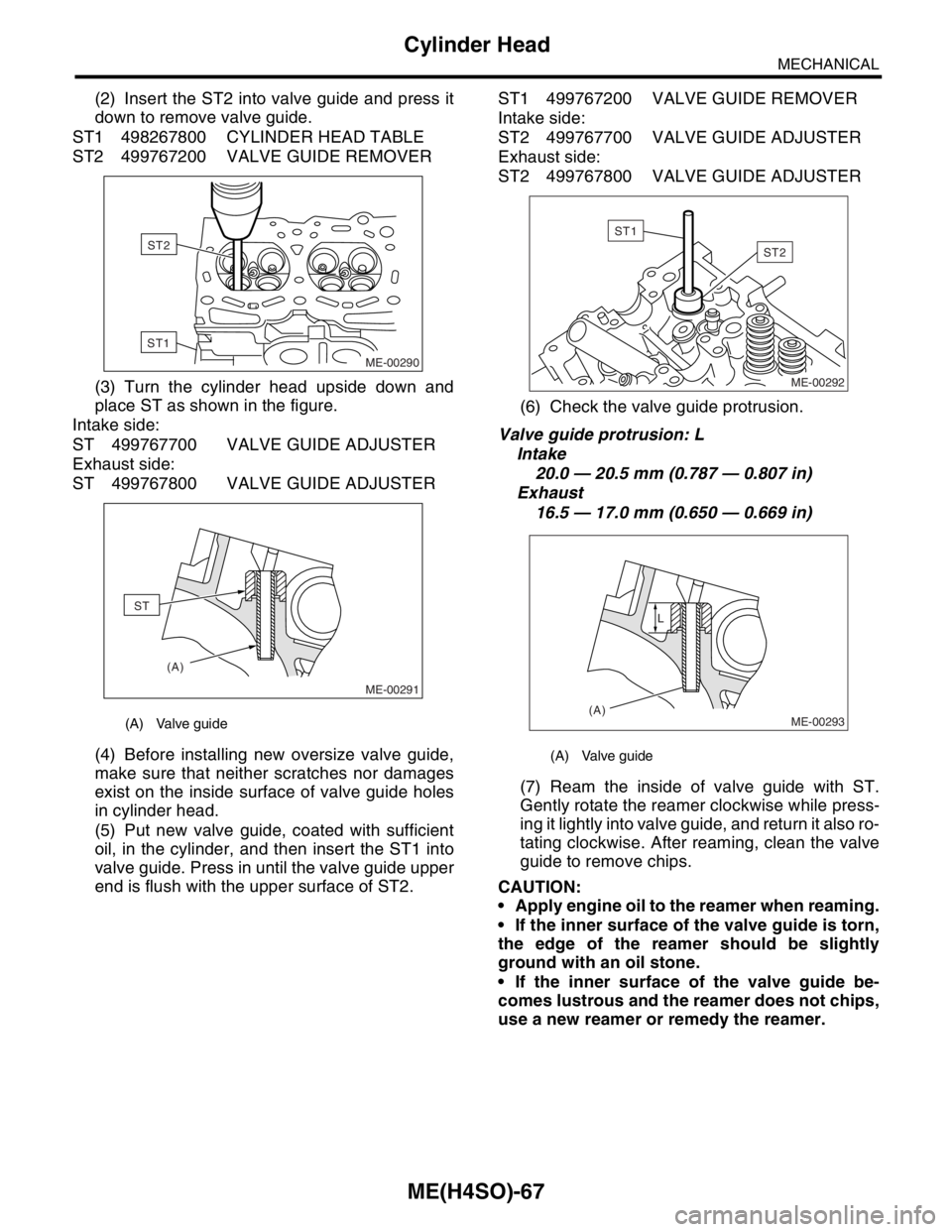

(2) Insert the ST2 into valve guide and press it

down to remove valve guide.

ST1 498267800 CYLINDER HEAD TABLE

ST2 499767200 VALVE GUIDE REMOVER

(3) Turn the cylinder head upside down and

place ST as shown in the figure.

Intake side:

ST 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST 499767800 VALVE GUIDE ADJUSTER

(4) Before installing new oversize valve guide,

make sure that neither scratches nor damages

exist on the inside surface of valve guide holes

in cylinder head.

(5) Put new valve guide, coated with sufficient

oil, in the cylinder, and then insert the ST1 into

valve guide. Press in until the valve guide upper

end is flush with the upper surface of ST2.ST1 499767200 VALVE GUIDE REMOVER

Intake side:

ST2 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST2 499767800 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion: L

Intake

20.0 — 20.5 mm (0.787 — 0.807 in)

Exhaust

16.5 — 17.0 mm (0.650 — 0.669 in)

(7) Ream the inside of valve guide with ST.

Gently rotate the reamer clockwise while press-

ing it lightly into valve guide, and return it also ro-

tating clockwise. After reaming, clean the valve

guide to remove chips.

CAUTION:

Apply engine oil to the reamer when reaming.

If the inner surface of the valve guide is torn,

the edge of the reamer should be slightly

ground with an oil stone.

If the inner surface of the valve guide be-

comes lustrous and the reamer does not chips,

use a new reamer or remedy the reamer.

(A) Valve guide

ME-00290

ST2

ST1

(A)

ME-00291

ST

(A) Valve guide

ST2

ME-00292

ST1

ME-00293(A)L

Page 1038 of 2870

LU(H4SO)-10

LUBRICATION

Engine Oil

3. Engine Oil

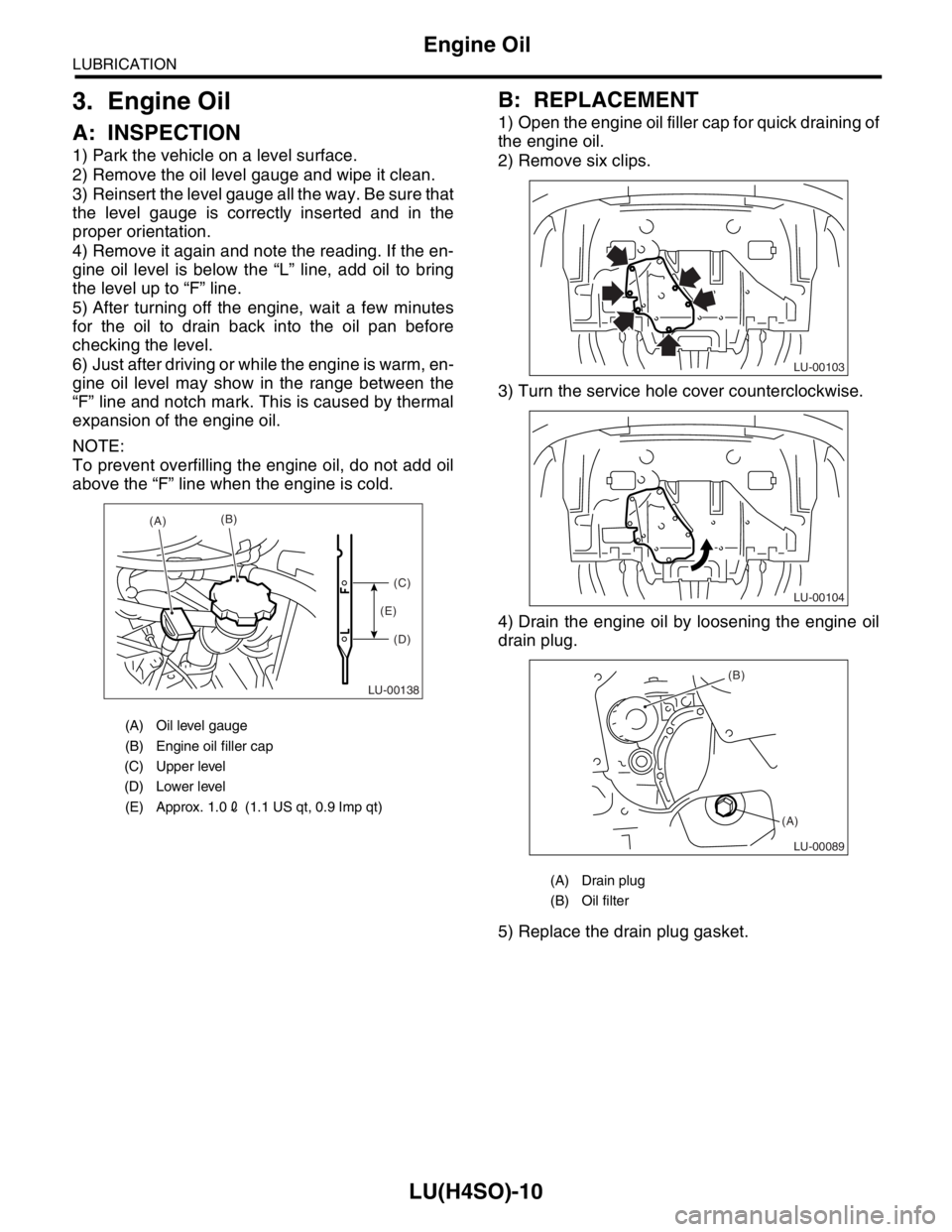

A: INSPECTION

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper orientation.

4) Remove it again and note the reading. If the en-

gine oil level is below the “L” line, add oil to bring

the level up to “F” line.

5) After turning off the engine, wait a few minutes

for the oil to drain back into the oil pan before

checking the level.

6) Just after driving or while the engine is warm, en-

gine oil level may show in the range between the

“F” line and notch mark. This is caused by thermal

expansion of the engine oil.

NOTE:

To prevent overfilling the engine oil, do not add oil

above the “F” line when the engine is cold.

B: REPLACEMENT

1) Open the engine oil filler cap for quick draining of

the engine oil.

2) Remove six clips.

3) Turn the service hole cover counterclockwise.

4) Drain the engine oil by loosening the engine oil

drain plug.

5) Replace the drain plug gasket.

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

(E) Approx. 1.02 (1.1 US qt, 0.9 Imp qt)

LU-00138

(A)(B)

(C)

(D) (E)

(A) Drain plug

(B) Oil filter

LU-00103

LU-00104

LU-00089

(B)

(A)

Page 1051 of 2870

LU(H4SO)-23

LUBRICATION

Engine Oil Filter

8. Engine Oil Filter

A: REMOVAL

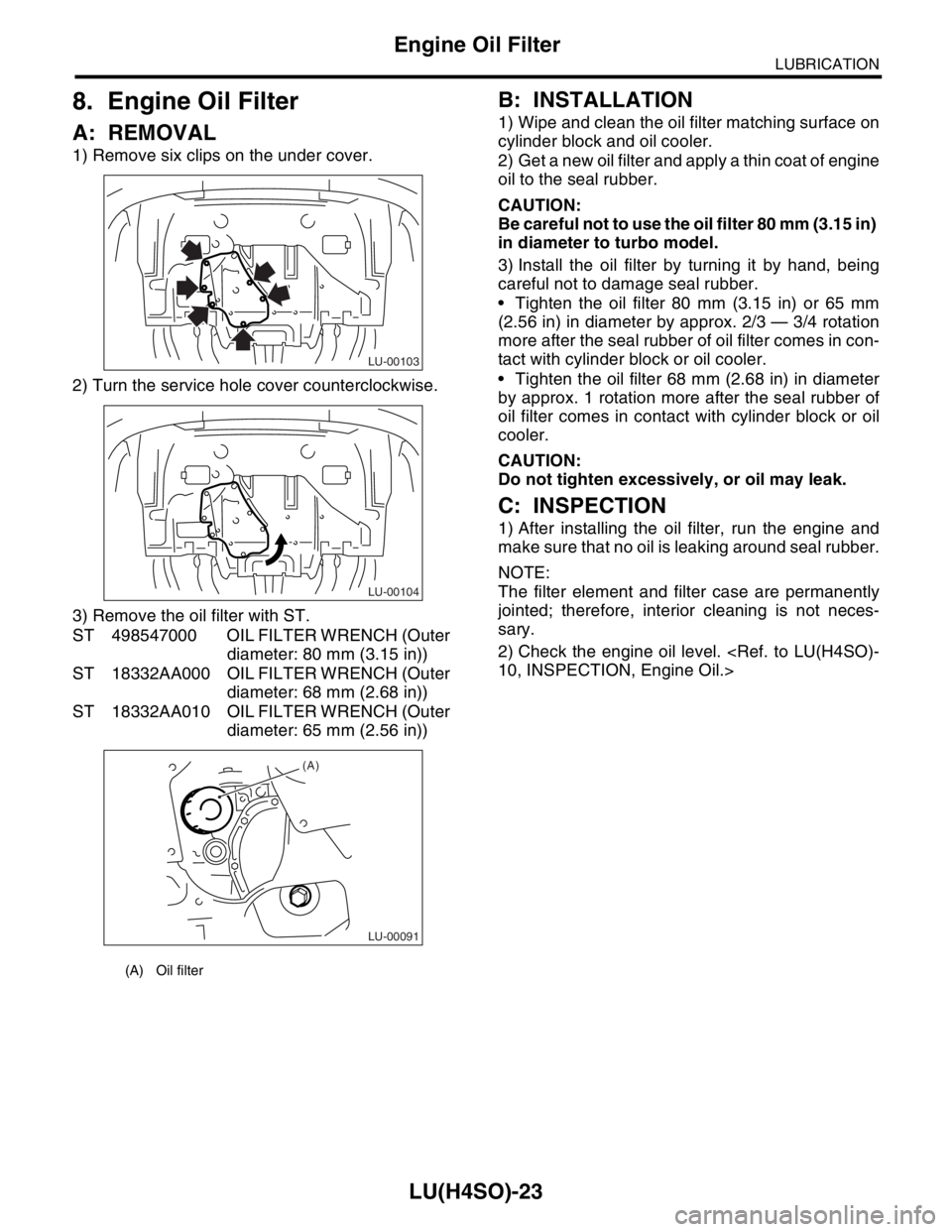

1) Remove six clips on the under cover.

2) Turn the service hole cover counterclockwise.

3) Remove the oil filter with ST.

ST 498547000 OIL FILTER WRENCH (Outer

diameter: 80 mm (3.15 in))

ST 18332AA000 OIL FILTER WRENCH (Outer

diameter: 68 mm (2.68 in))

ST 18332AA010 OIL FILTER WRENCH (Outer

diameter: 65 mm (2.56 in))

B: INSTALLATION

1) Wipe and clean the oil filter matching surface on

cylinder block and oil cooler.

2) Get a new oil filter and apply a thin coat of engine

oil to the seal rubber.

CAUTION:

Be careful not to use the oil filter 80 mm (3.15 in)

in diameter to turbo model.

3) Install the oil filter by turning it by hand, being

careful not to damage seal rubber.

Tighten the oil filter 80 mm (3.15 in) or 65 mm

(2.56 in) in diameter by approx. 2/3 — 3/4 rotation

more after the seal rubber of oil filter comes in con-

tact with cylinder block or oil cooler.

Tighten the oil filter 68 mm (2.68 in) in diameter

by approx. 1 rotation more after the seal rubber of

oil filter comes in contact with cylinder block or oil

cooler.

CAUTION:

Do not tighten excessively, or oil may leak.

C: INSPECTION

1) After installing the oil filter, run the engine and

make sure that no oil is leaking around seal rubber.

NOTE:

The filter element and filter case are permanently

jointed; therefore, interior cleaning is not neces-

sary.

2) Check the engine oil level.

(A) Oil filter

LU-00103

LU-00104

LU-00091

(A)

Page 1077 of 2870

SC(H4SO)-2

STARTING/CHARGING SYSTEM

General Description

1. General Description

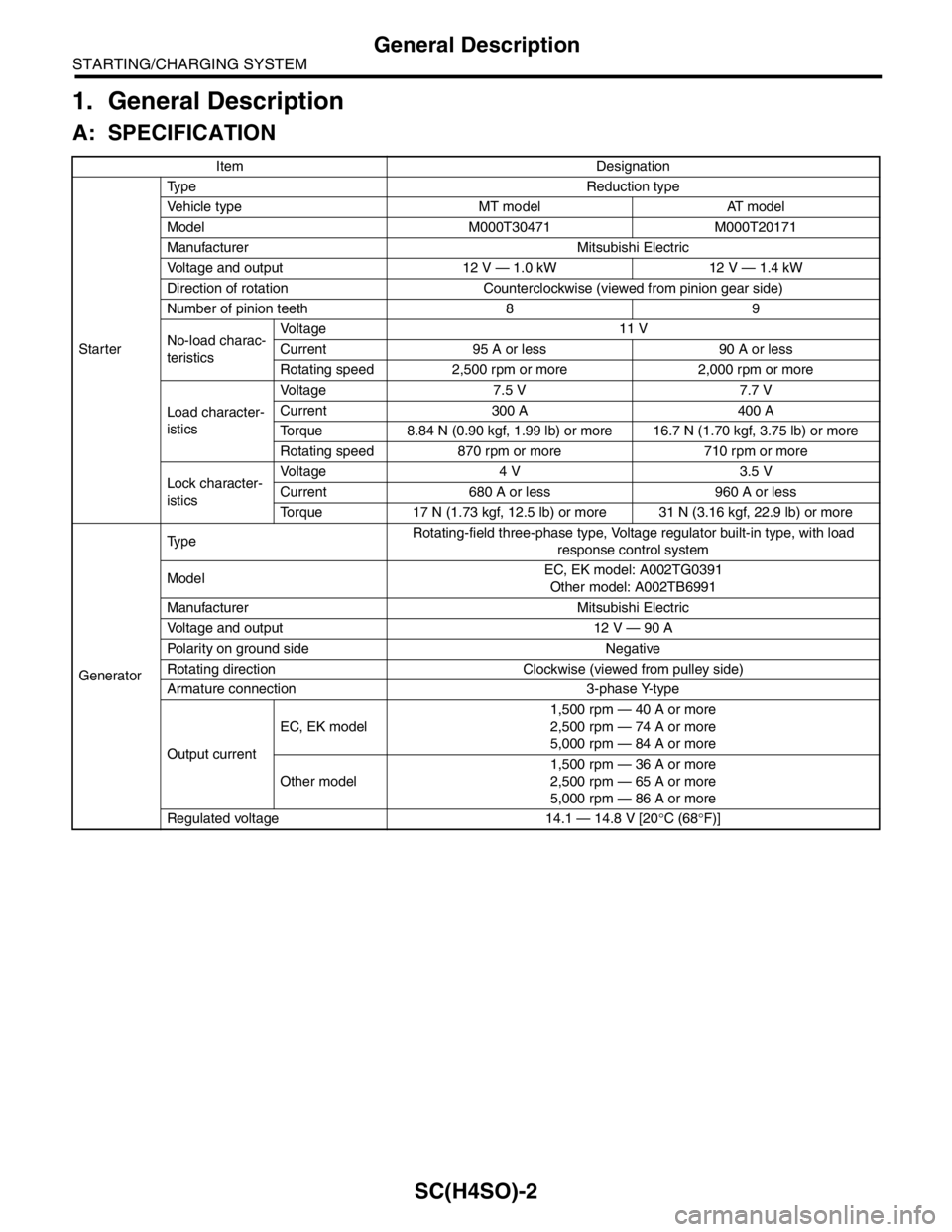

A: SPECIFICATION

Item Designation

StarterType Reduction type

Vehicle type MT model AT model

Model M000T30471 M000T20171

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 1.0 kW 12 V — 1.4 kW

Direction of rotation Counterclockwise (viewed from pinion gear side)

Number of pinion teeth 8 9

No-load charac-

teristicsVo l t a g e 1 1 V

Current 95 A or less 90 A or less

Rotating speed 2,500 rpm or more 2,000 rpm or more

Load character-

isticsVoltage 7.5 V 7.7 V

Current 300 A 400 A

Torque 8.84 N (0.90 kgf, 1.99 lb) or more 16.7 N (1.70 kgf, 3.75 lb) or more

Rotating speed 870 rpm or more 710 rpm or more

Lock character-

isticsVo l t a g e 4 V 3 . 5 V

Current 680 A or less 960 A or less

Torque 17 N (1.73 kgf, 12.5 lb) or more 31 N (3.16 kgf, 22.9 lb) or more

GeneratorTy p eRotating-field three-phase type, Voltage regulator built-in type, with load

response control system

ModelEC, EK model: A002TG0391

Other model: A002TB6991

Manufacturer Mitsubishi Electric

Voltage and output 12 V — 90 A

Polarity on ground side Negative

Rotating direction Clockwise (viewed from pulley side)

Armature connection 3-phase Y-type

Output currentEC, EK model1,500 rpm — 40 A or more

2,500 rpm — 74 A or more

5,000 rpm — 84 A or more

Other model1,500 rpm — 36 A or more

2,500 rpm — 65 A or more

5,000 rpm — 86 A or more

Regulated voltage 14.1 — 14.8 V [20°C (68°F)]

Page 1087 of 2870

SC(H4SO)-12

STARTING/CHARGING SYSTEM

Starter

2. YOKE

Make sure the pole is set in position.

3. OVERRUNNING CLUTCH

Inspect the teeth of pinion for wear and damage.

Replace if it is damaged. Rotate the pinion in direc-

tion of rotation (counterclockwise). It should rotate

smoothly. But in opposite direction, it should be

locked.

CAUTION:

Do not clean the overrunning clutch with oil to

prevent grease from flowing out.

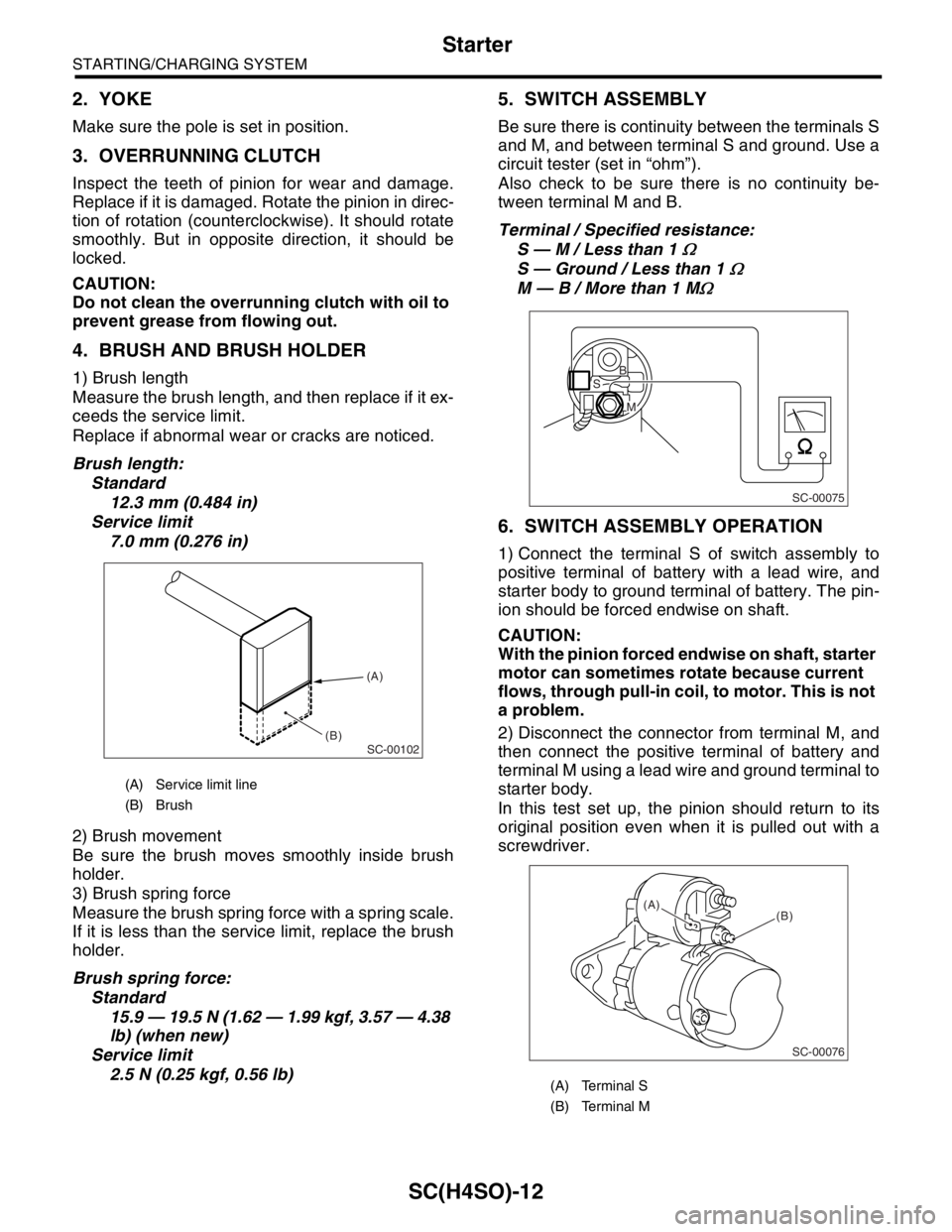

4. BRUSH AND BRUSH HOLDER

1) Brush length

Measure the brush length, and then replace if it ex-

ceeds the service limit.

Replace if abnormal wear or cracks are noticed.

Brush length:

Standard

12.3 mm (0.484 in)

Service limit

7.0 mm (0.276 in)

2) Brush movement

Be sure the brush moves smoothly inside brush

holder.

3) Brush spring force

Measure the brush spring force with a spring scale.

If it is less than the service limit, replace the brush

holder.

Brush spring force:

Standard

15.9 — 19.5 N (1.62 — 1.99 kgf, 3.57 — 4.38

lb) (when new)

Service limit

2.5 N (0.25 kgf, 0.56 lb)

5. SWITCH ASSEMBLY

Be sure there is continuity between the terminals S

and M, and between terminal S and ground. Use a

circuit tester (set in “ohm”).

Also check to be sure there is no continuity be-

tween terminal M and B.

Terminal / Specified resistance:

S — M / Less than 1

Ω

S — Ground / Less than 1 Ω

M — B / More than 1 MΩ

6. SWITCH ASSEMBLY OPERATION

1) Connect the terminal S of switch assembly to

positive terminal of battery with a lead wire, and

starter body to ground terminal of battery. The pin-

ion should be forced endwise on shaft.

CAUTION:

With the pinion forced endwise on shaft, starter

motor can sometimes rotate because current

flows, through pull-in coil, to motor. This is not

a problem.

2) Disconnect the connector from terminal M, and

then connect the positive terminal of battery and

terminal M using a lead wire and ground terminal to

starter body.

In this test set up, the pinion should return to its

original position even when it is pulled out with a

screwdriver.

(A) Service limit line

(B) Brush

SC-00102

(A)

(B)

(A) Terminal S

(B) Terminal M

SC-00075

B

M

S

SC-00076

(B) (A)

Page 1494 of 2870

ME(H4DOTC)-38

MECHANICAL

Valve Clearance

(5) Move the washer tank upward.

(6) Disconnect the ignition coil connector.

(7) Remove the ignition coil.

(8) Place a suitable container under the vehicle.

(9) Disconnect the PCV hose from rocker cover

(LH).

(10)Remove the bolts, and then remove the

rocker cover (LH).

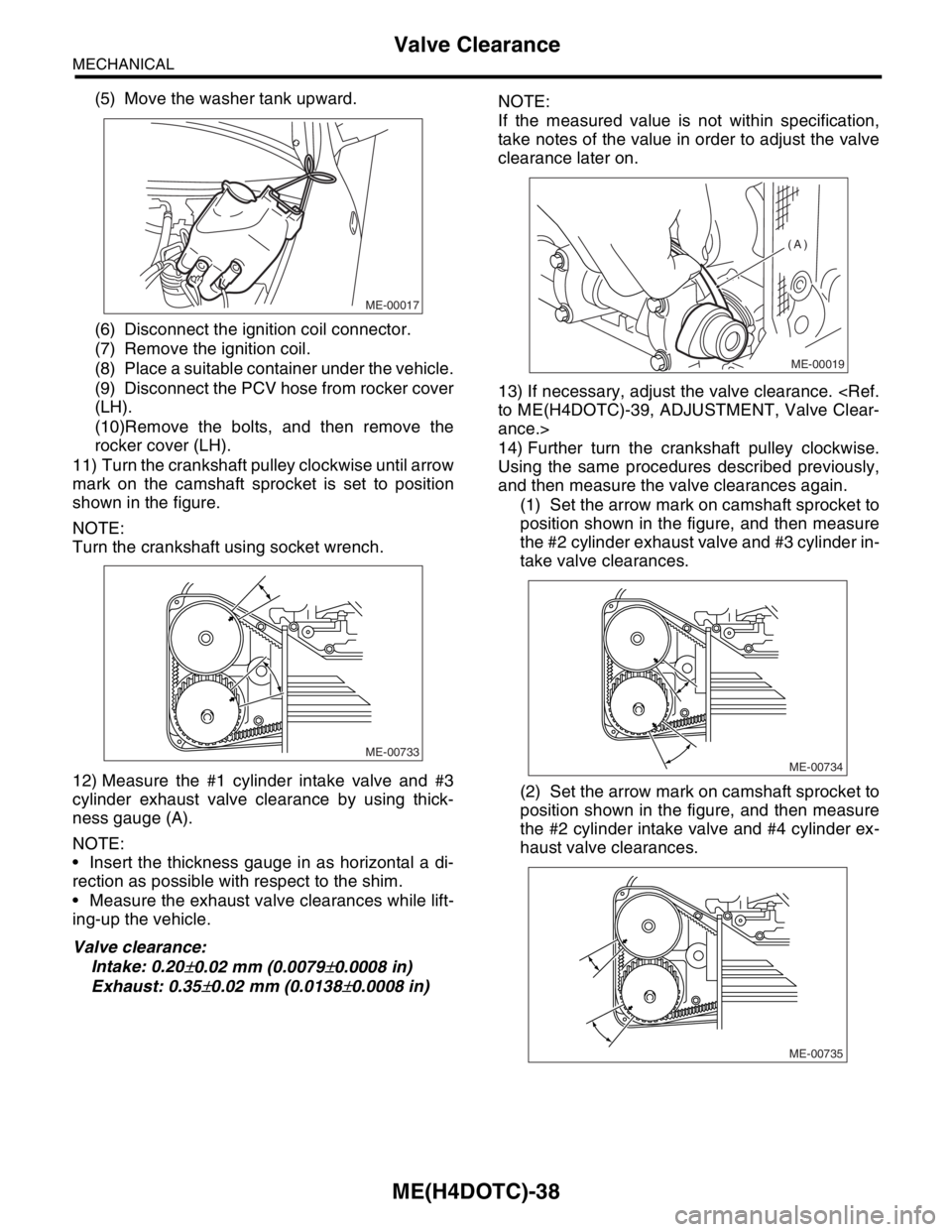

11) Turn the crankshaft pulley clockwise until arrow

mark on the camshaft sprocket is set to position

shown in the figure.

NOTE:

Turn the crankshaft using socket wrench.

12) Measure the #1 cylinder intake valve and #3

cylinder exhaust valve clearance by using thick-

ness gauge (A).

NOTE:

Insert the thickness gauge in as horizontal a di-

rection as possible with respect to the shim.

Measure the exhaust valve clearances while lift-

ing-up the vehicle.

Valve clearance:

Intake: 0.20

±0.02 mm (0.0079±0.0008 in)

Exhaust: 0.35

±0.02 mm (0.0138±0.0008 in)NOTE:

If the measured value is not within specification,

take notes of the value in order to adjust the valve

clearance later on.

13) If necessary, adjust the valve clearance.

ance.>

14) Further turn the crankshaft pulley clockwise.

Using the same procedures described previously,

and then measure the valve clearances again.

(1) Set the arrow mark on camshaft sprocket to

position shown in the figure, and then measure

the #2 cylinder exhaust valve and #3 cylinder in-

take valve clearances.

(2) Set the arrow mark on camshaft sprocket to

position shown in the figure, and then measure

the #2 cylinder intake valve and #4 cylinder ex-

haust valve clearances.

ME-00017

ME-00733

ME-00019

(A)

ME-00734

ME-00735

Page 1519 of 2870

ME(H4DOTC)-61

MECHANICAL

Timing Belt Assembly

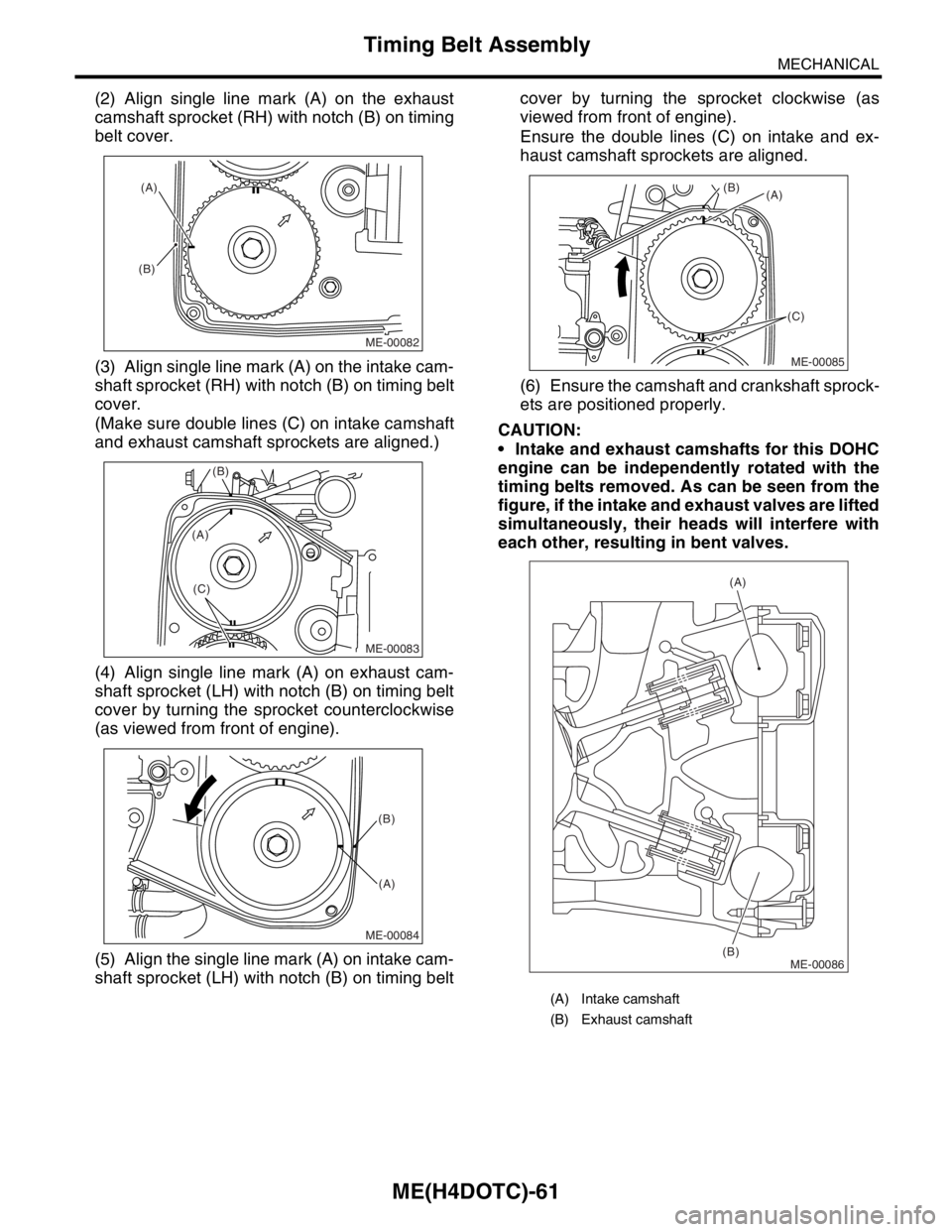

(2) Align single line mark (A) on the exhaust

camshaft sprocket (RH) with notch (B) on timing

belt cover.

(3) Align single line mark (A) on the intake cam-

shaft sprocket (RH) with notch (B) on timing belt

cover.

(Make sure double lines (C) on intake camshaft

and exhaust camshaft sprockets are aligned.)

(4) Align single line mark (A) on exhaust cam-

shaft sprocket (LH) with notch (B) on timing belt

cover by turning the sprocket counterclockwise

(as viewed from front of engine).

(5) Align the single line mark (A) on intake cam-

shaft sprocket (LH) with notch (B) on timing beltcover by turning the sprocket clockwise (as

viewed from front of engine).

Ensure the double lines (C) on intake and ex-

haust camshaft sprockets are aligned.

(6) Ensure the camshaft and crankshaft sprock-

ets are positioned properly.

CAUTION:

Intake and exhaust camshafts for this DOHC

engine can be independently rotated with the

timing belts removed. As can be seen from the

figure, if the intake and exhaust valves are lifted

simultaneously, their heads will interfere with

each other, resulting in bent valves.

ME-00082

(A)

(B)

ME-00083

(B)

(C)

(A)

ME-00084

(B)

(A)

(A) Intake camshaft

(B) Exhaust camshaft

ME-00085

(A) (B)

(C)

ME-00086

(A)

(B)

Page 1527 of 2870

ME(H4DOTC)-69

MECHANICAL

Camshaft

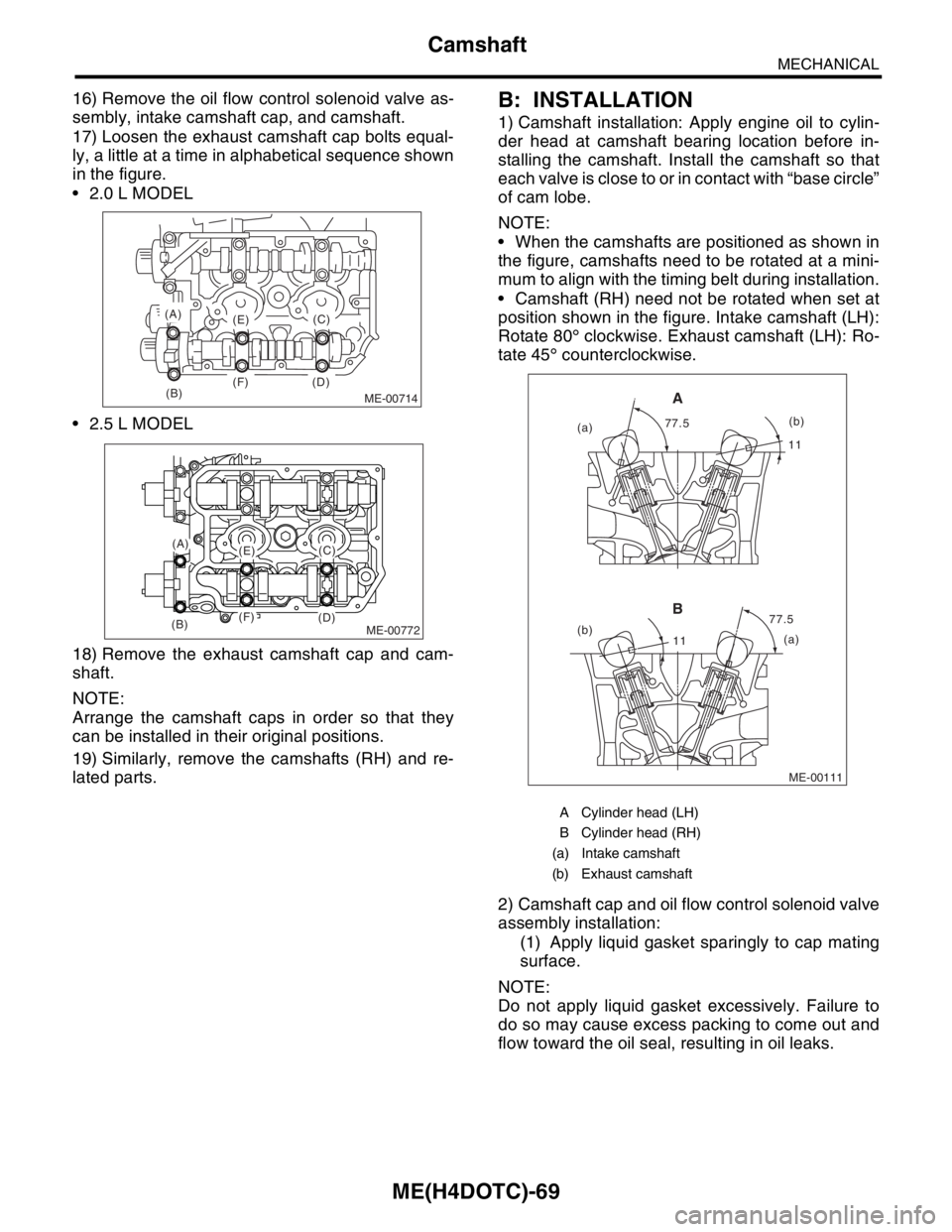

16) Remove the oil flow control solenoid valve as-

sembly, intake camshaft cap, and camshaft.

17) Loosen the exhaust camshaft cap bolts equal-

ly, a little at a time in alphabetical sequence shown

in the figure.

2.0 L MODEL

2.5 L MODEL

18) Remove the exhaust camshaft cap and cam-

shaft.

NOTE:

Arrange the camshaft caps in order so that they

can be installed in their original positions.

19) Similarly, remove the camshafts (RH) and re-

lated parts.B: INSTALLATION

1) Camshaft installation: Apply engine oil to cylin-

der head at camshaft bearing location before in-

stalling the camshaft. Install the camshaft so that

each valve is close to or in contact with “base circle”

of cam lobe.

NOTE:

When the camshafts are positioned as shown in

the figure, camshafts need to be rotated at a mini-

mum to align with the timing belt during installation.

Camshaft (RH) need not be rotated when set at

position shown in the figure. Intake camshaft (LH):

Rotate 80° clockwise. Exhaust camshaft (LH): Ro-

tate 45° counterclockwise.

2) Camshaft cap and oil flow control solenoid valve

assembly installation:

(1) Apply liquid gasket sparingly to cap mating

surface.

NOTE:

Do not apply liquid gasket excessively. Failure to

do so may cause excess packing to come out and

flow toward the oil seal, resulting in oil leaks.

ME-00714(B)

(A)

(E)

(F) (D)(C)

ME-00772

(A)(E)

(F)(B)(D)

(C)

A Cylinder head (LH)

B Cylinder head (RH)

(a) Intake camshaft

(b) Exhaust camshaft

ME-00111

1111

77.5 77.5

(a)

(b)

(a)(b)

A

B