clock SUBARU FORESTER 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1537 of 2870

ME(H4DOTC)-79

MECHANICAL

Cylinder Head Assembly

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measuring

the outside diameter of valve stem and the inside

diameter of valve guide with outside and inside mi-

crometers respectively.

Clearance between the valve guide and valve

stem:

Standard

Intake

0.030 — 0.057 mm (0.0012 — 0.0022 in)

Exhaust

0.040 — 0.067 mm (0.0016 — 0.0026 in)

Limit

0.15 mm (0.0059 in)

2) If the clearance between valve guide and stem

exceeds the limit, replace the valve guide or valve

itself whichever shows greater amount of wear.

See the following procedure for valve guide re-

placement.

Valve guide inner diameter:

6.000 — 6.012 mm (0.2362 — 0.2367 in)

Valve stem outer diameters:

Intake

5.955 — 5.970 mm (0.2344 — 0.2350 in)

Exhaust

5.945 — 5.960 mm (0.2341 — 0.2346 in)

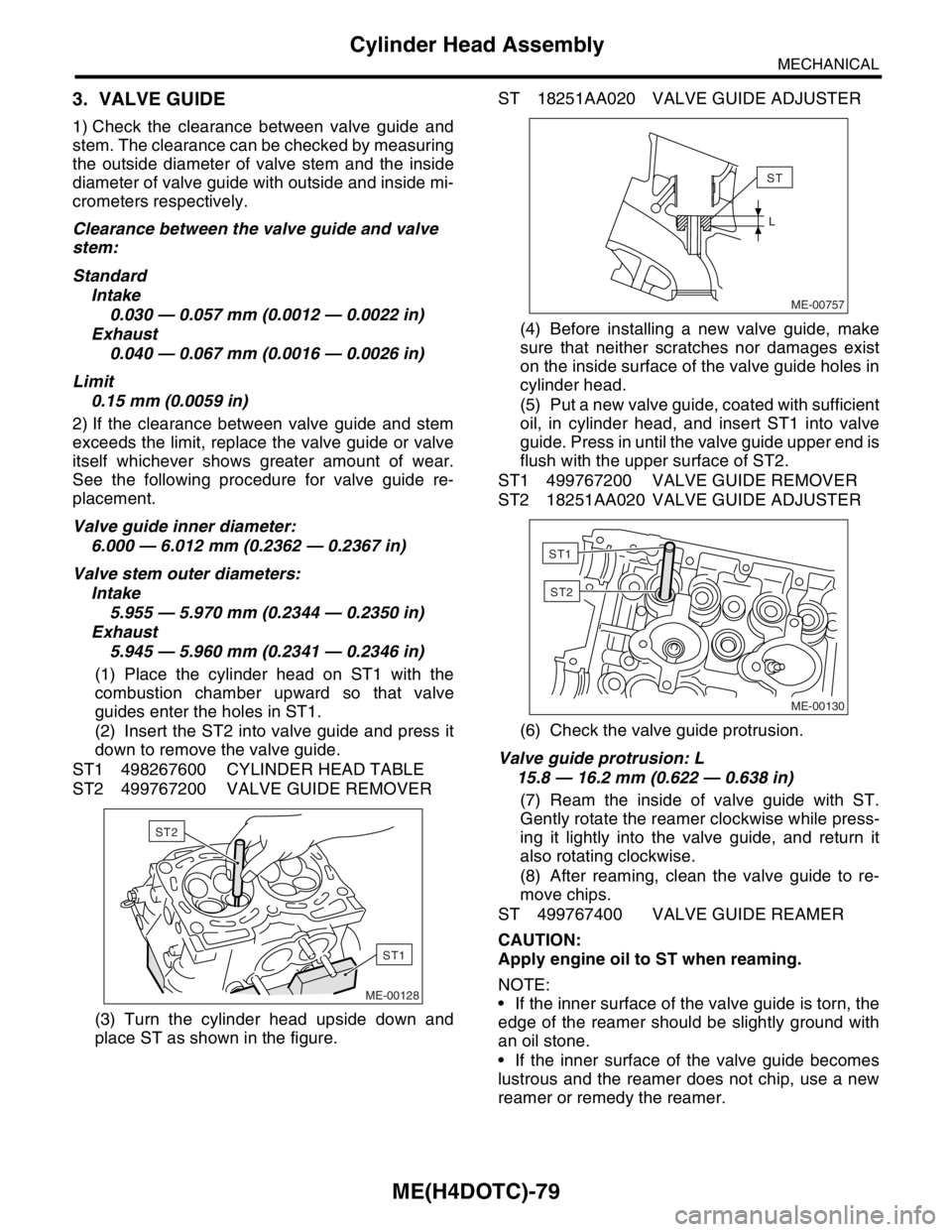

(1) Place the cylinder head on ST1 with the

combustion chamber upward so that valve

guides enter the holes in ST1.

(2) Insert the ST2 into valve guide and press it

down to remove the valve guide.

ST1 498267600 CYLINDER HEAD TABLE

ST2 499767200 VALVE GUIDE REMOVER

(3) Turn the cylinder head upside down and

place ST as shown in the figure.ST 18251AA020 VALVE GUIDE ADJUSTER

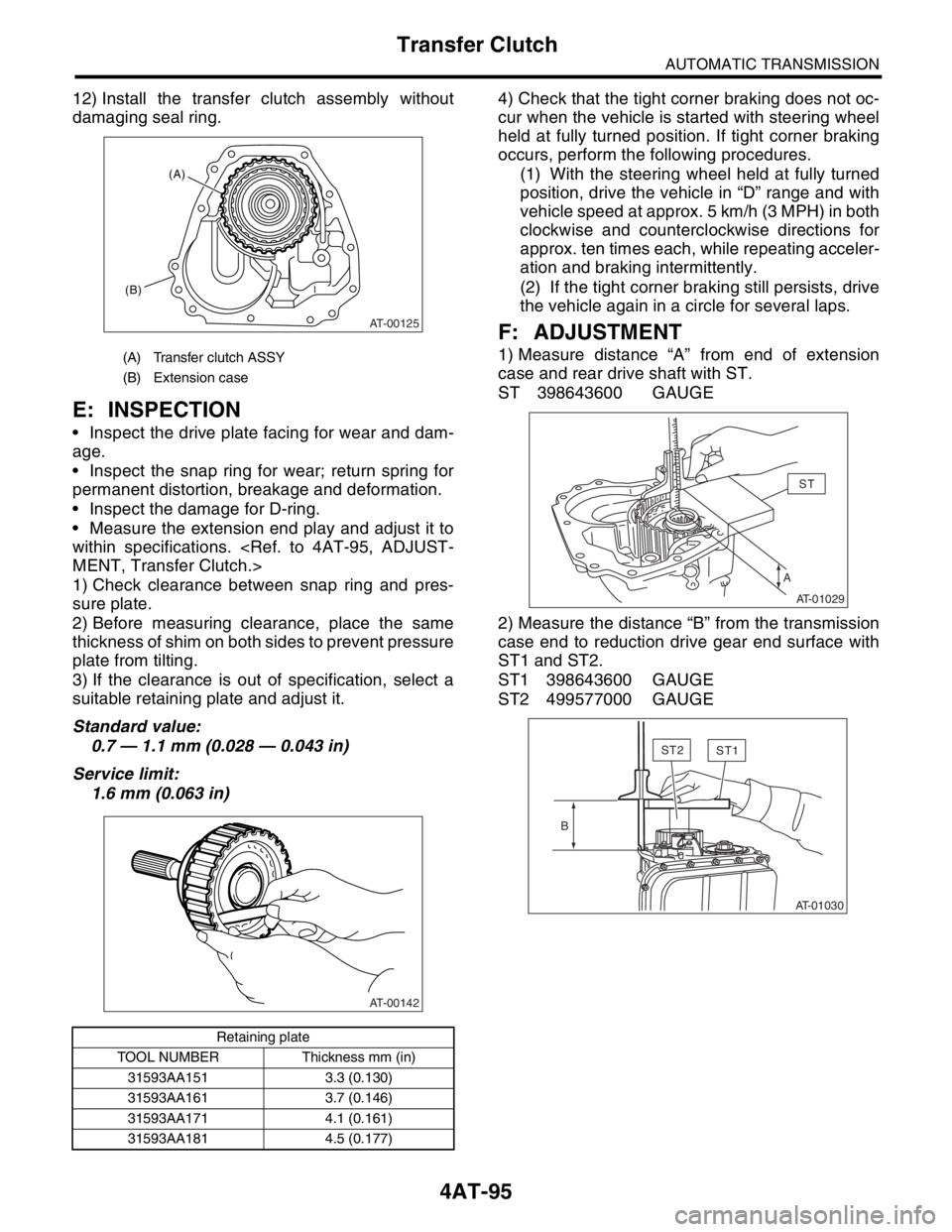

(4) Before installing a new valve guide, make

sure that neither scratches nor damages exist

on the inside surface of the valve guide holes in

cylinder head.

(5) Put a new valve guide, coated with sufficient

oil, in cylinder head, and insert ST1 into valve

guide. Press in until the valve guide upper end is

flush with the upper surface of ST2.

ST1 499767200 VALVE GUIDE REMOVER

ST2 18251AA020 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion: L

15.8 — 16.2 mm (0.622 — 0.638 in)

(7) Ream the inside of valve guide with ST.

Gently rotate the reamer clockwise while press-

ing it lightly into the valve guide, and return it

also rotating clockwise.

(8) After reaming, clean the valve guide to re-

move chips.

ST 499767400 VALVE GUIDE REAMER

CAUTION:

Apply engine oil to ST when reaming.

NOTE:

If the inner surface of the valve guide is torn, the

edge of the reamer should be slightly ground with

an oil stone.

If the inner surface of the valve guide becomes

lustrous and the reamer does not chip, use a new

reamer or remedy the reamer.

ME-00128

ST1

ST2ME-00757

ST

L

ME-00130

ST1

ST2

Page 2408 of 2870

4AT-95

AUTOMATIC TRANSMISSION

Transfer Clutch

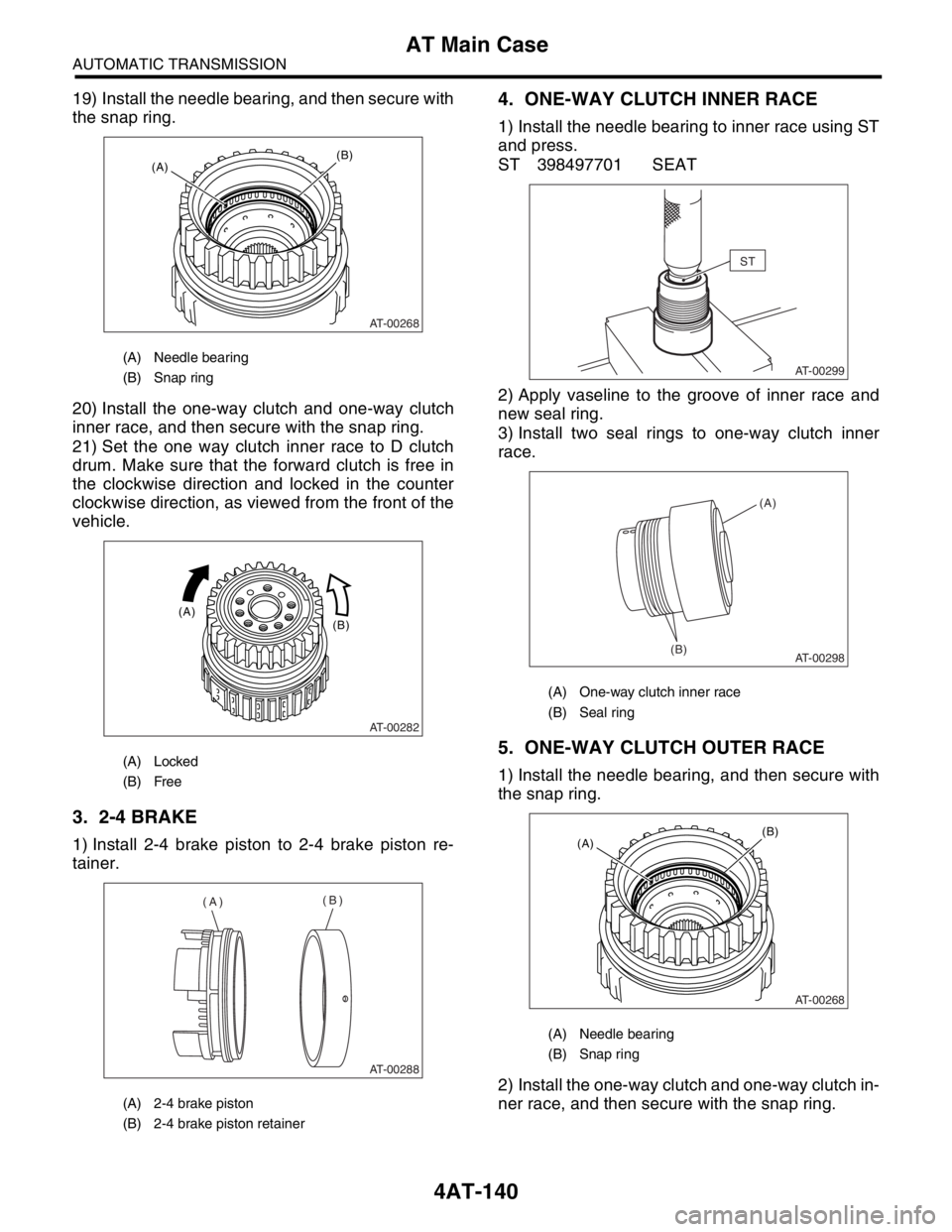

12) Install the transfer clutch assembly without

damaging seal ring.

E: INSPECTION

Inspect the drive plate facing for wear and dam-

age.

Inspect the snap ring for wear; return spring for

permanent distortion, breakage and deformation.

Inspect the damage for D-ring.

Measure the extension end play and adjust it to

within specifications.

1) Check clearance between snap ring and pres-

sure plate.

2) Before measuring clearance, place the same

thickness of shim on both sides to prevent pressure

plate from tilting.

3) If the clearance is out of specification, select a

suitable retaining plate and adjust it.

Standard value:

0.7 — 1.1 mm (0.028 — 0.043 in)

Service limit:

1.6 mm (0.063 in)4) Check that the tight corner braking does not oc-

cur when the vehicle is started with steering wheel

held at fully turned position. If tight corner braking

occurs, perform the following procedures.

(1) With the steering wheel held at fully turned

position, drive the vehicle in “D” range and with

vehicle speed at approx. 5 km/h (3 MPH) in both

clockwise and counterclockwise directions for

approx. ten times each, while repeating acceler-

ation and braking intermittently.

(2) If the tight corner braking still persists, drive

the vehicle again in a circle for several laps.

F: ADJUSTMENT

1) Measure distance “A” from end of extension

case and rear drive shaft with ST.

ST 398643600 GAUGE

2) Measure the distance “B” from the transmission

case end to reduction drive gear end surface with

ST1 and ST2.

ST1 398643600 GAUGE

ST2 499577000 GAUGE(A) Transfer clutch ASSY

(B) Extension case

Retaining plate

TOOL NUMBER Thickness mm (in)

31593AA151 3.3 (0.130)

31593AA161 3.7 (0.146)

31593AA171 4.1 (0.161)

31593AA181 4.5 (0.177)

AT-00125

(A)

(B)

AT-00142

AST

AT-01029

ST2ST1

B

AT-01030

Page 2454 of 2870

4AT-140

AUTOMATIC TRANSMISSION

AT Main Case

19) Install the needle bearing, and then secure with

the snap ring.

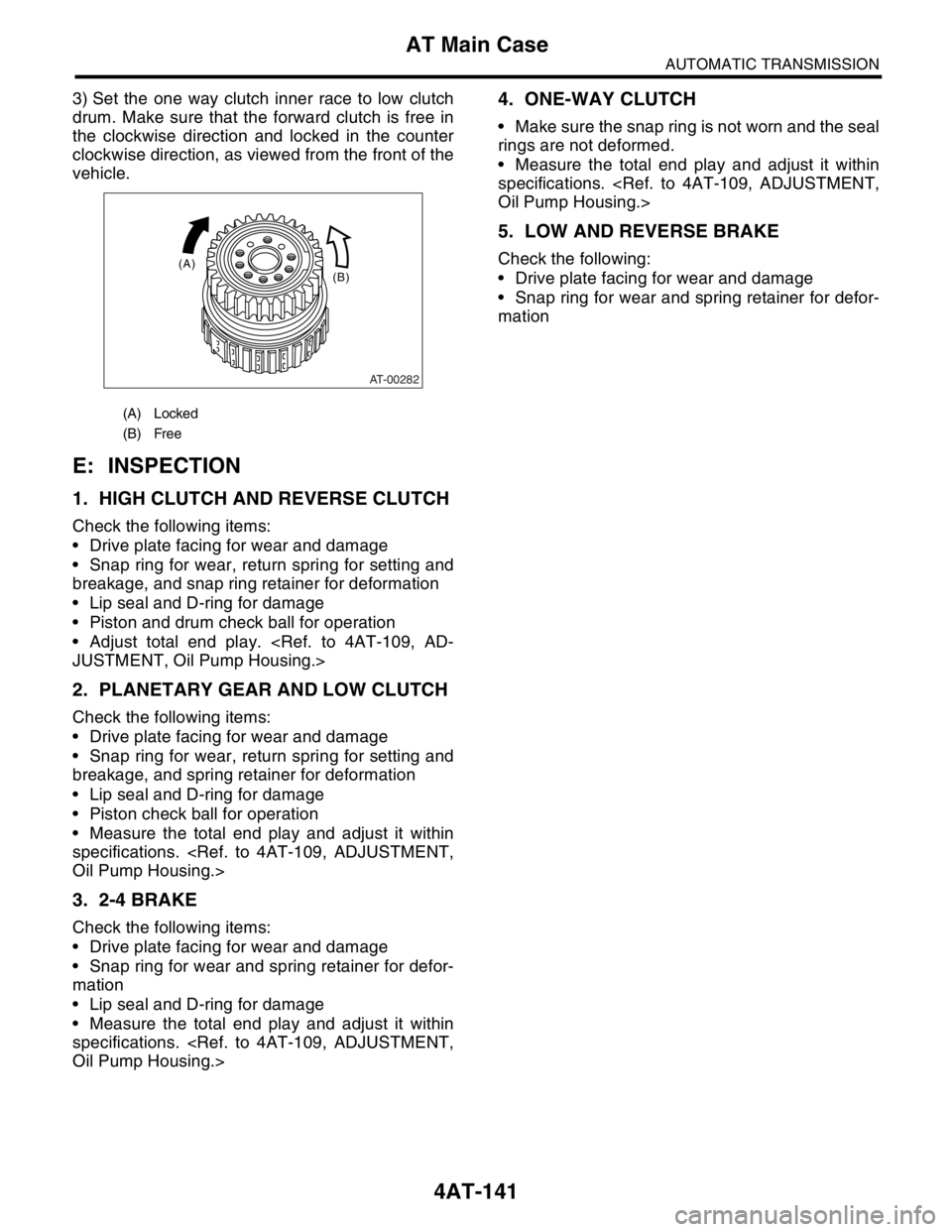

20) Install the one-way clutch and one-way clutch

inner race, and then secure with the snap ring.

21) Set the one way clutch inner race to D clutch

drum. Make sure that the forward clutch is free in

the clockwise direction and locked in the counter

clockwise direction, as viewed from the front of the

vehicle.

3. 2-4 BRAKE

1) Install 2-4 brake piston to 2-4 brake piston re-

tainer.

4. ONE-WAY CLUTCH INNER RACE

1) Install the needle bearing to inner race using ST

and press.

ST 398497701 SEAT

2) Apply vaseline to the groove of inner race and

new seal ring.

3) Install two seal rings to one-way clutch inner

race.

5. ONE-WAY CLUTCH OUTER RACE

1) Install the needle bearing, and then secure with

the snap ring.

2) Install the one-way clutch and one-way clutch in-

ner race, and then secure with the snap ring.

(A) Needle bearing

(B) Snap ring

(A) Locked

(B) Free

(A) 2-4 brake piston

(B) 2-4 brake piston retainer

AT-00268

(B)(A)

AT-00282

(B) (A)

AT-00288

(A)(B)

(A) One-way clutch inner race

(B) Seal ring

(A) Needle bearing

(B) Snap ring

ST

AT-00299

AT-00298(B)(A)

AT-00268

(B)(A)

Page 2455 of 2870

4AT-141

AUTOMATIC TRANSMISSION

AT Main Case

3) Set the one way clutch inner race to low clutch

drum. Make sure that the forward clutch is free in

the clockwise direction and locked in the counter

clockwise direction, as viewed from the front of the

vehicle.

E: INSPECTION

1. HIGH CLUTCH AND REVERSE CLUTCH

Check the following items:

Drive plate facing for wear and damage

Snap ring for wear, return spring for setting and

breakage, and snap ring retainer for deformation

Lip seal and D-ring for damage

Piston and drum check ball for operation

Adjust total end play.

2. PLANETARY GEAR AND LOW CLUTCH

Check the following items:

Drive plate facing for wear and damage

Snap ring for wear, return spring for setting and

breakage, and spring retainer for deformation

Lip seal and D-ring for damage

Piston check ball for operation

Measure the total end play and adjust it within

specifications.

3. 2-4 BRAKE

Check the following items:

Drive plate facing for wear and damage

Snap ring for wear and spring retainer for defor-

mation

Lip seal and D-ring for damage

Measure the total end play and adjust it within

specifications.

4. ONE-WAY CLUTCH

Make sure the snap ring is not worn and the seal

rings are not deformed.

Measure the total end play and adjust it within

specifications.

5. LOW AND REVERSE BRAKE

Check the following:

Drive plate facing for wear and damage

Snap ring for wear and spring retainer for defor-

mation

(A) Locked

(B) Free

AT-00282

(B) (A)

Page 2813 of 2870

5MT-100

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

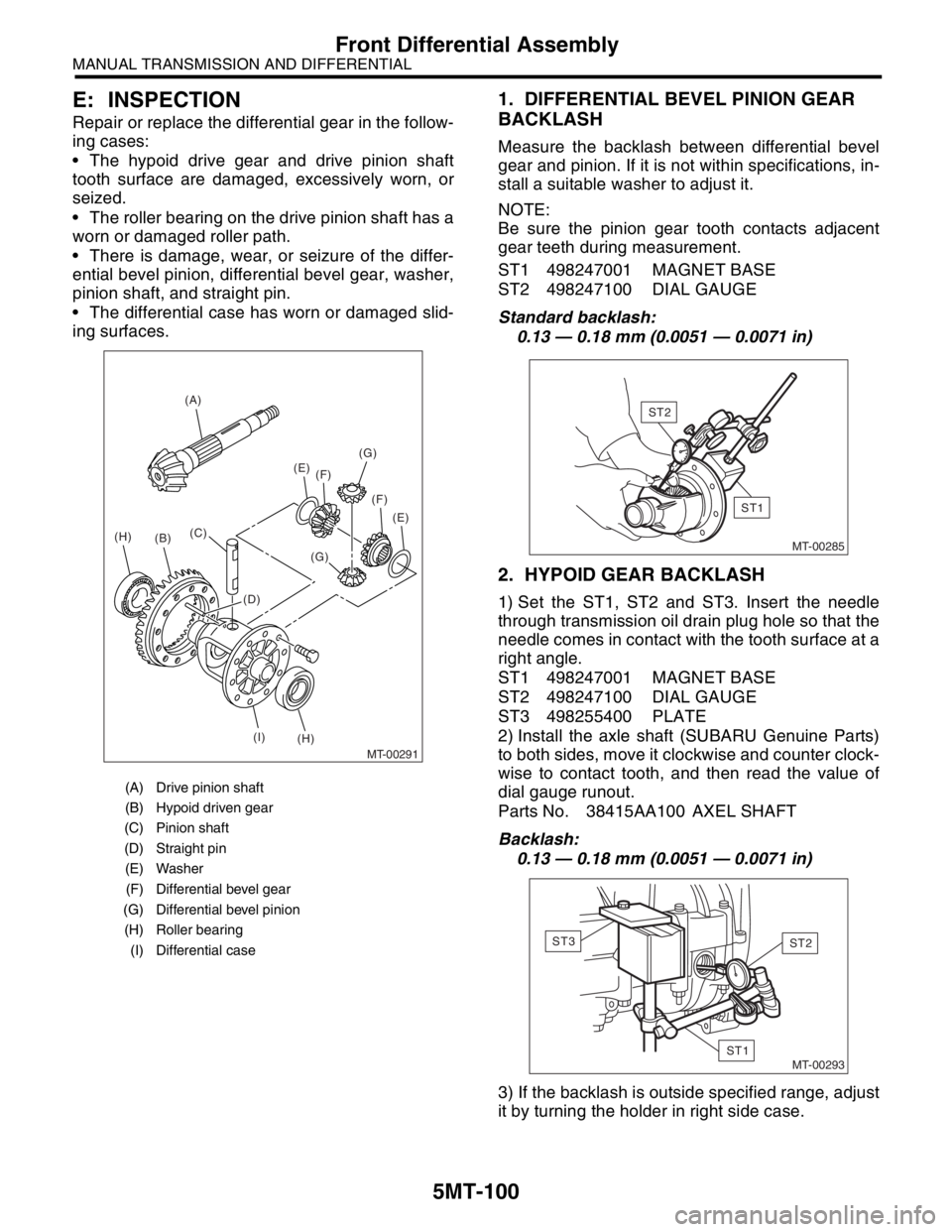

E: INSPECTION

Repair or replace the differential gear in the follow-

ing cases:

The hypoid drive gear and drive pinion shaft

tooth surface are damaged, excessively worn, or

seized.

The roller bearing on the drive pinion shaft has a

worn or damaged roller path.

There is damage, wear, or seizure of the differ-

ential bevel pinion, differential bevel gear, washer,

pinion shaft, and straight pin.

The differential case has worn or damaged slid-

ing surfaces.

1. DIFFERENTIAL BEVEL PINION GEAR

BACKLASH

Measure the backlash between differential bevel

gear and pinion. If it is not within specifications, in-

stall a suitable washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

1) Set the ST1, ST2 and ST3. Insert the needle

through transmission oil drain plug hole so that the

needle comes in contact with the tooth surface at a

right angle.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

ST3 498255400 PLATE

2) Install the axle shaft (SUBARU Genuine Parts)

to both sides, move it clockwise and counter clock-

wise to contact tooth, and then read the value of

dial gauge runout.

Parts No. 38415AA100 AXEL SHAFT

Backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

3) If the backlash is outside specified range, adjust

it by turning the holder in right side case.

(A) Drive pinion shaft

(B) Hypoid driven gear

(C) Pinion shaft

(D) Straight pin

(E) Washer

(F) Differential bevel gear

(G) Differential bevel pinion

(H) Roller bearing

(I) Differential case

MT-00291

(A)

(B)(C)

(E)

(E)

(F)

(F)

(G)

(G)

(D)

(H) (I)

(H)MT-00285

ST1

ST2

MT-00293ST1

ST2ST3

Page 2864 of 2870

CL-38

CLUTCH SYSTEM

Clutch Pedal

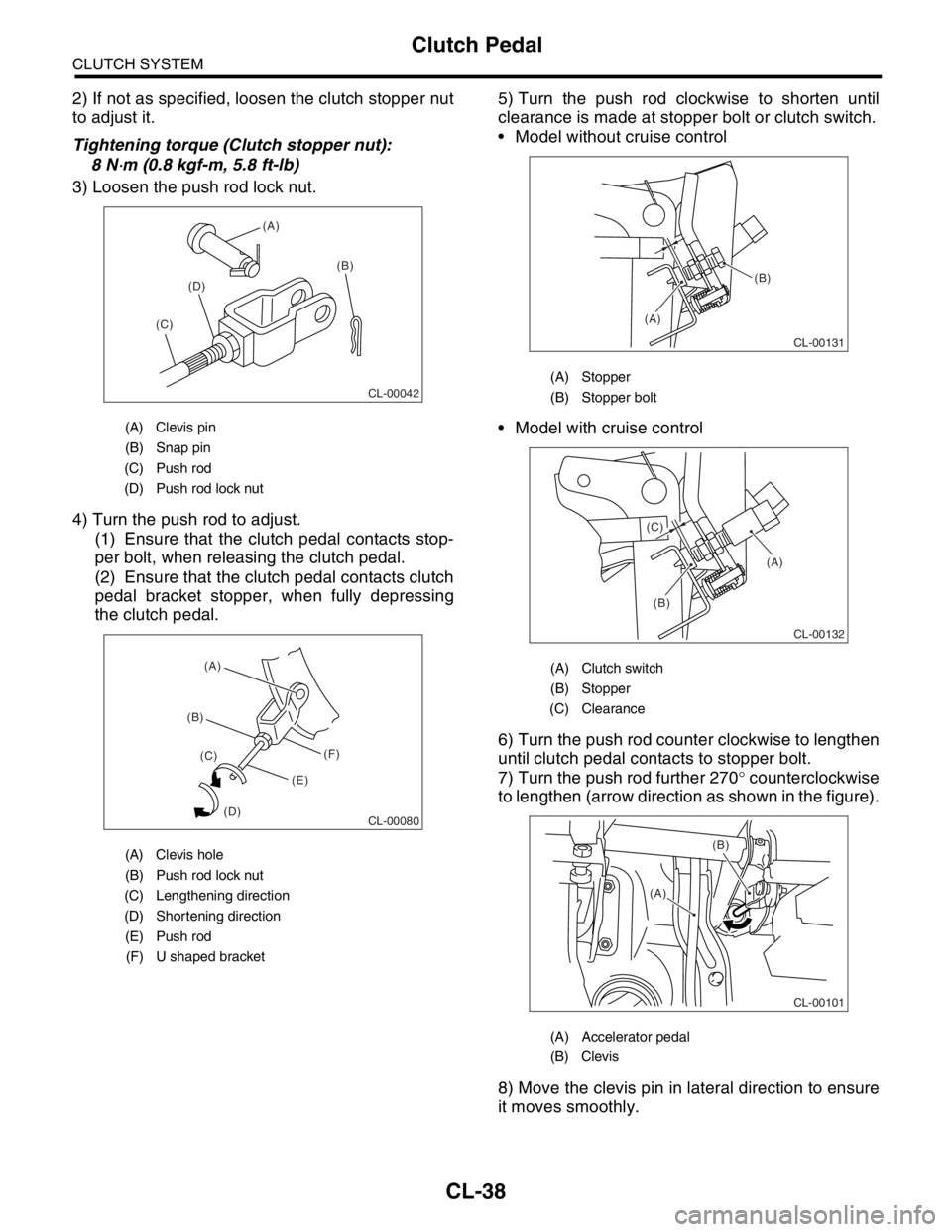

2) If not as specified, loosen the clutch stopper nut

to adjust it.

Tightening torque (Clutch stopper nut):

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

3) Loosen the push rod lock nut.

4) Turn the push rod to adjust.

(1) Ensure that the clutch pedal contacts stop-

per bolt, when releasing the clutch pedal.

(2) Ensure that the clutch pedal contacts clutch

pedal bracket stopper, when fully depressing

the clutch pedal.5) Turn the push rod clockwise to shorten until

clearance is made at stopper bolt or clutch switch.

Model without cruise control

Model with cruise control

6) Turn the push rod counter clockwise to lengthen

until clutch pedal contacts to stopper bolt.

7) Turn the push rod further 270° counterclockwise

to lengthen (arrow direction as shown in the figure).

8) Move the clevis pin in lateral direction to ensure

it moves smoothly.

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

(A) Clevis hole

(B) Push rod lock nut

(C) Lengthening direction

(D) Shortening direction

(E) Push rod

(F) U shaped bracket

CL-00042

(A)

(B)

(C)(D)

CL-00080

(B)(A)

(C)

(D)(E)(F)

(A) Stopper

(B) Stopper bolt

(A) Clutch switch

(B) Stopper

(C) Clearance

(A) Accelerator pedal

(B) Clevis

(A)

(B)

CL-00131

(A)

(B) (C)

CL-00132

CL-00101

(B)

(A)

Page 2866 of 2870

CL-40

CLUTCH SYSTEM

Clutch Pedal

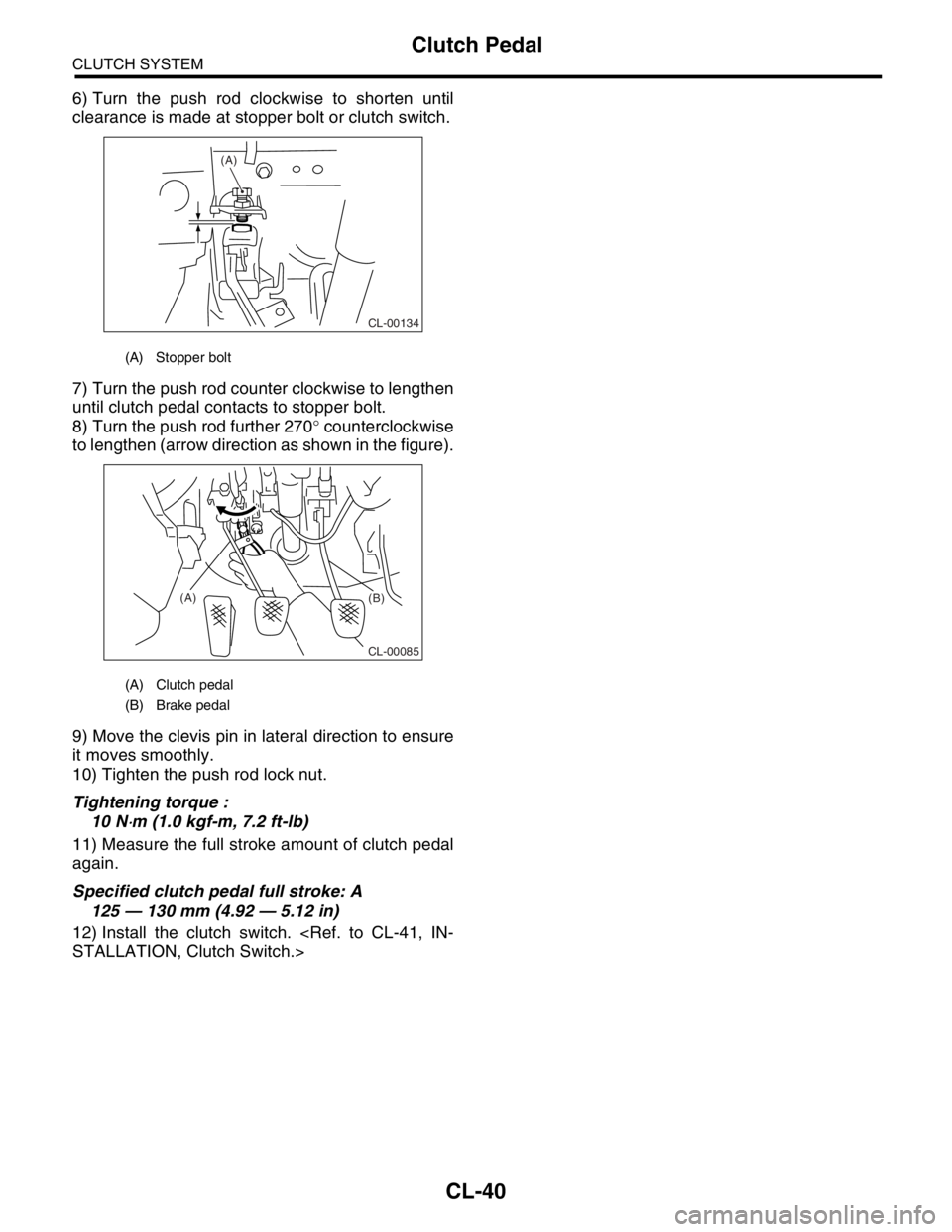

6) Turn the push rod clockwise to shorten until

clearance is made at stopper bolt or clutch switch.

7) Turn the push rod counter clockwise to lengthen

until clutch pedal contacts to stopper bolt.

8) Turn the push rod further 270° counterclockwise

to lengthen (arrow direction as shown in the figure).

9) Move the clevis pin in lateral direction to ensure

it moves smoothly.

10) Tighten the push rod lock nut.

Tightening torque :

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

11) Measure the full stroke amount of clutch pedal

again.

Specified clutch pedal full stroke: A

125 — 130 mm (4.92 — 5.12 in)

12) Install the clutch switch.

(A) Stopper bolt

(A) Clutch pedal

(B) Brake pedal

CL-00134

(A)

CL-00085

(A)

(B)