weight SUBARU FORESTER 2004 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1503 of 2870

ME(H4DOTC)-45

MECHANICAL

Engine Assembly

26) Support the transmission with a garage jack.

NOTE:

Before moving the engine away from transmission,

check to be sure no work has been overlooked. Do-

ing this is very important in order to facilitate re-in-

stallation and because transmission lowers under

its own weight.

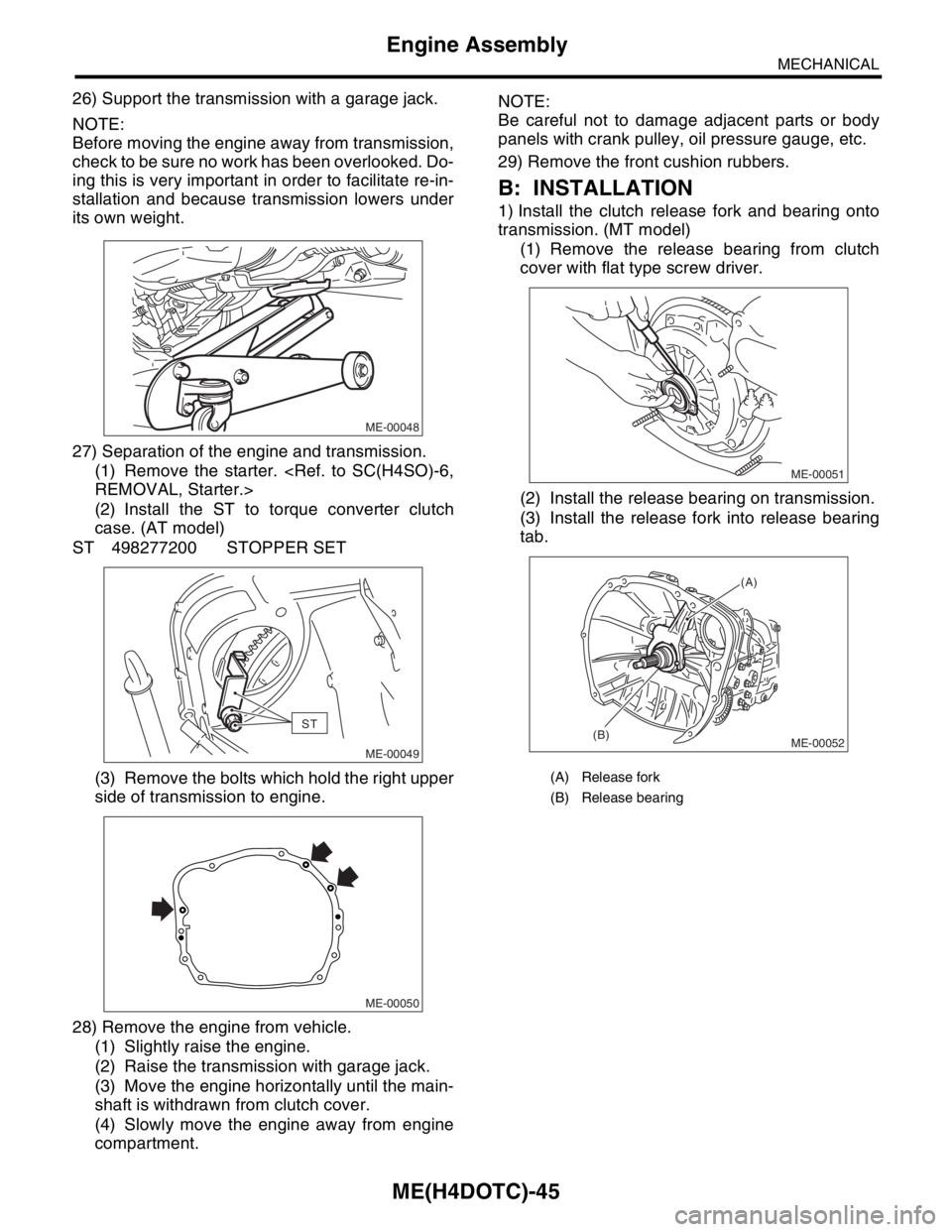

27) Separation of the engine and transmission.

(1) Remove the starter.

(2) Install the ST to torque converter clutch

case. (AT model)

ST 498277200 STOPPER SET

(3) Remove the bolts which hold the right upper

side of transmission to engine.

28) Remove the engine from vehicle.

(1) Slightly raise the engine.

(2) Raise the transmission with garage jack.

(3) Move the engine horizontally until the main-

shaft is withdrawn from clutch cover.

(4) Slowly move the engine away from engine

compartment.NOTE:

Be careful not to damage adjacent parts or body

panels with crank pulley, oil pressure gauge, etc.

29) Remove the front cushion rubbers.

B: INSTALLATION

1) Install the clutch release fork and bearing onto

transmission. (MT model)

(1) Remove the release bearing from clutch

cover with flat type screw driver.

(2) Install the release bearing on transmission.

(3) Install the release fork into release bearing

tab.

ME-00048

ST

ME-00049

ME-00050

(A) Release fork

(B) Release bearing

ME-00051

ME-00052

(A)

(B)

Page 2297 of 2870

![SUBARU FORESTER 2004 Service User Guide CS-12

CONTROL SYSTEM

Select Lever

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [SUNLIGHT 2 (Part No.

003602010) or equivalent] to each part. <Ref. to

CS-3, AT SELECT LEVER, COMPONEN SUBARU FORESTER 2004 Service User Guide CS-12

CONTROL SYSTEM

Select Lever

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [SUNLIGHT 2 (Part No.

003602010) or equivalent] to each part. <Ref. to

CS-3, AT SELECT LEVER, COMPONEN](/img/17/57426/w960_57426-2296.png)

CS-12

CONTROL SYSTEM

Select Lever

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [SUNLIGHT 2 (Part No.

003602010) or equivalent] to each part.

al Description.>

CAUTION:

Apply grease [SUNCALL] around the axle of lock

plate (Turbo model). Apply grease to only indi-

cated portion.

3) Assemble is in the reverse order of disassembly.

NOTE:

Refer to “COMPOTNENT” for tightening torque.

Tighten the lock plate bolt uniformly. After installa-

tion, put the base plate upside down, and then push

the lock plate up. Make sure the lock plate falls by its

weight when releasing it. If not, retighten the bolt.

4) After completion of fitting, transfer the select le-

ver to range “P” — “1”, then check the indicator and

select lever are matched, the pointer and position

mark are matched and the operating force.

E: INSPECTION

1) Inspect the removed parts by comparing with

new ones for deformation, damage and wear. Cor-

rect or replace if defective.

2) Confirm the following parts for operating condi-

tion before assembly. Moving condition of the se-

lect lever assembly, it should move smoothly.

CS-00355

CS-00356

Page 2440 of 2870

4AT-126

AUTOMATIC TRANSMISSION

AT Main Case

B: INSTALLATION

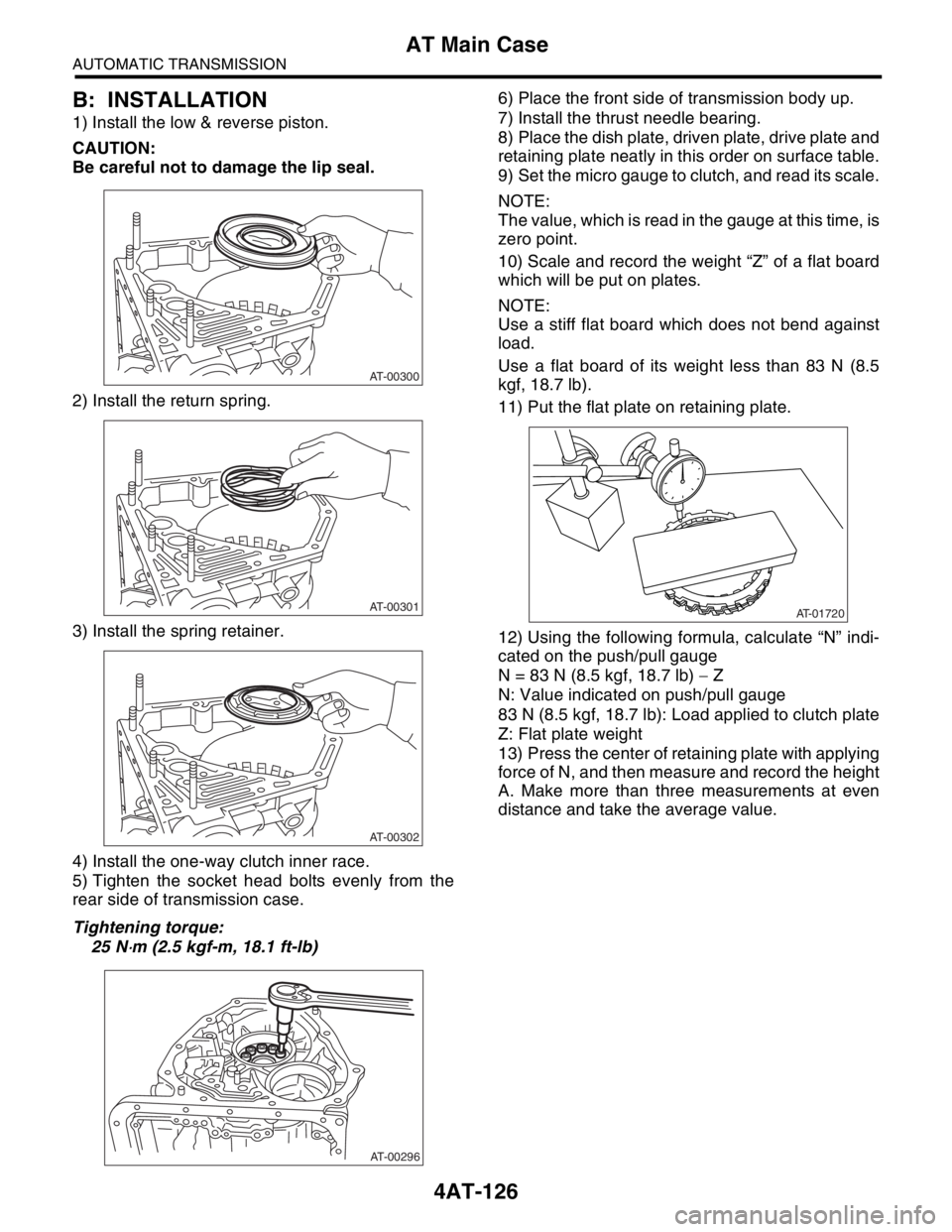

1) Install the low & reverse piston.

CAUTION:

Be careful not to damage the lip seal.

2) Install the return spring.

3) Install the spring retainer.

4) Install the one-way clutch inner race.

5) Tighten the socket head bolts evenly from the

rear side of transmission case.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)6) Place the front side of transmission body up.

7) Install the thrust needle bearing.

8) Place the dish plate, driven plate, drive plate and

retaining plate neatly in this order on surface table.

9) Set the micro gauge to clutch, and read its scale.

NOTE:

The value, which is read in the gauge at this time, is

zero point.

10) Scale and record the weight “Z” of a flat board

which will be put on plates.

NOTE:

Use a stiff flat board which does not bend against

load.

Use a flat board of its weight less than 83 N (8.5

kgf, 18.7 lb).

11) Put the flat plate on retaining plate.

12) Using the following formula, calculate “N” indi-

cated on the push/pull gauge

N = 83 N (8.5 kgf, 18.7 lb) − Z

N: Value indicated on push/pull gauge

83 N (8.5 kgf, 18.7 lb): Load applied to clutch plate

Z: Flat plate weight

13) Press the center of retaining plate with applying

force of N, and then measure and record the height

A. Make more than three measurements at even

distance and take the average value.

AT-00300

AT-00301

AT-00302

AT-00296

AT-01720

Page 2730 of 2870

5MT-18

MANUAL TRANSMISSION AND DIFFERENTIAL

General Description

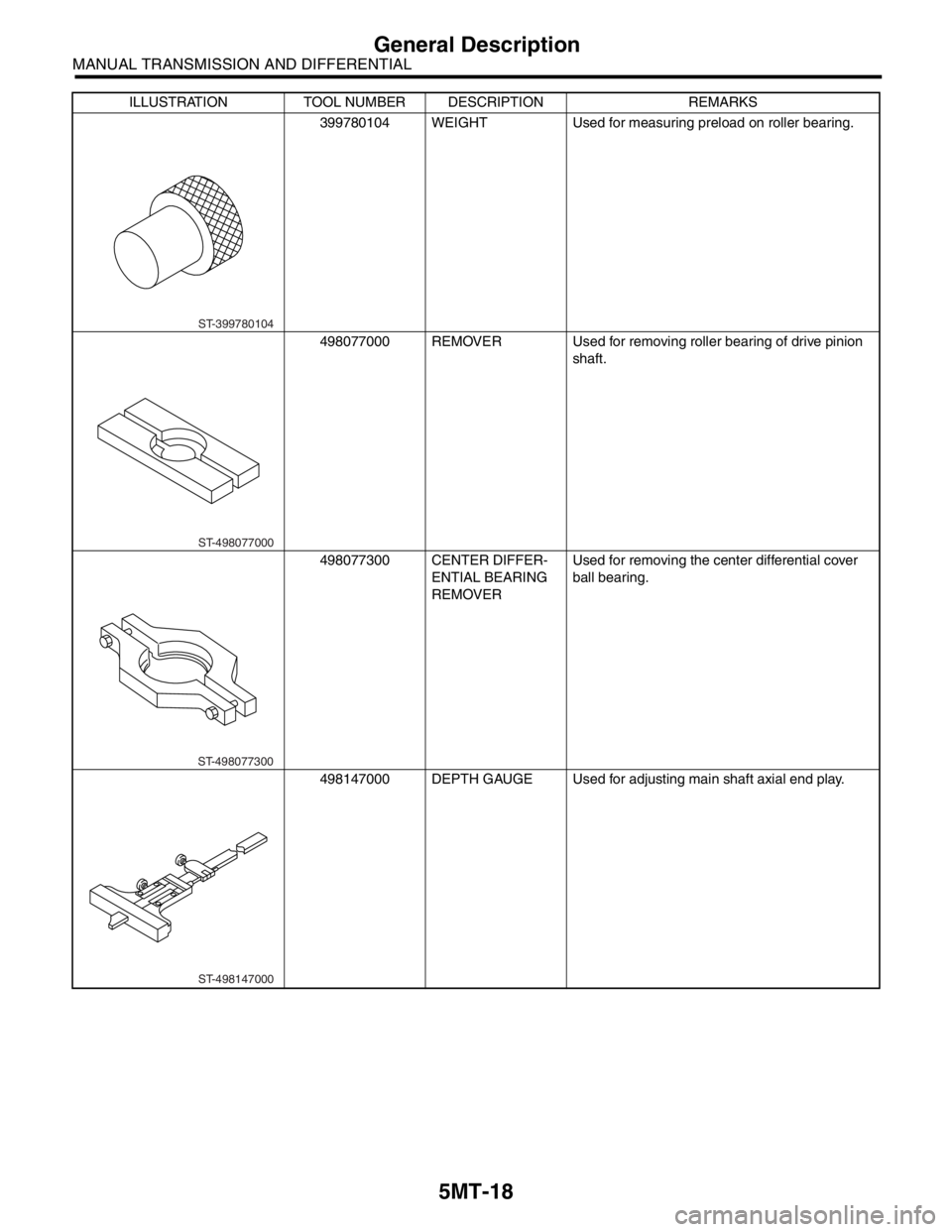

399780104 WEIGHT Used for measuring preload on roller bearing.

498077000 REMOVER Used for removing roller bearing of drive pinion

shaft.

498077300 CENTER DIFFER-

ENTIAL BEARING

REMOVERUsed for removing the center differential cover

ball bearing.

498147000 DEPTH GAUGE Used for adjusting main shaft axial end play. ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST-399780104

ST-498077000

ST-498077300

ST-498147000

Page 2778 of 2870

5MT-65

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

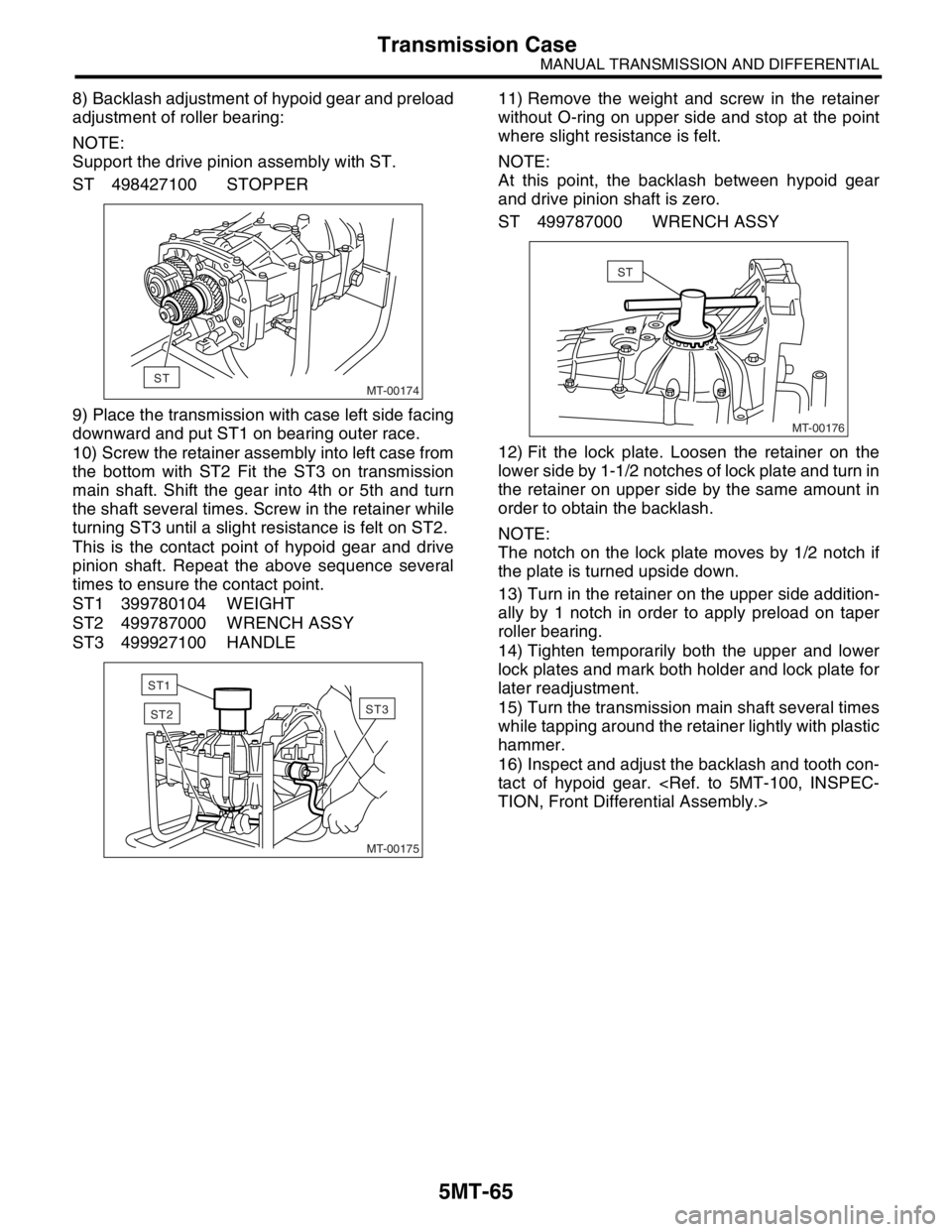

8) Backlash adjustment of hypoid gear and preload

adjustment of roller bearing:

NOTE:

Support the drive pinion assembly with ST.

ST 498427100 STOPPER

9) Place the transmission with case left side facing

downward and put ST1 on bearing outer race.

10) Screw the retainer assembly into left case from

the bottom with ST2 Fit the ST3 on transmission

main shaft. Shift the gear into 4th or 5th and turn

the shaft several times. Screw in the retainer while

turning ST3 until a slight resistance is felt on ST2.

This is the contact point of hypoid gear and drive

pinion shaft. Repeat the above sequence several

times to ensure the contact point.

ST1 399780104 WEIGHT

ST2 499787000 WRENCH ASSY

ST3 499927100 HANDLE11) Remove the weight and screw in the retainer

without O-ring on upper side and stop at the point

where slight resistance is felt.

NOTE:

At this point, the backlash between hypoid gear

and drive pinion shaft is zero.

ST 499787000 WRENCH ASSY

12) Fit the lock plate. Loosen the retainer on the

lower side by 1-1/2 notches of lock plate and turn in

the retainer on upper side by the same amount in

order to obtain the backlash.

NOTE:

The notch on the lock plate moves by 1/2 notch if

the plate is turned upside down.

13) Turn in the retainer on the upper side addition-

ally by 1 notch in order to apply preload on taper

roller bearing.

14) Tighten temporarily both the upper and lower

lock plates and mark both holder and lock plate for

later readjustment.

15) Turn the transmission main shaft several times

while tapping around the retainer lightly with plastic

hammer.

16) Inspect and adjust the backlash and tooth con-

tact of hypoid gear.

MT-00174ST

MT-00175

ST3ST2

ST1

MT-00176

ST

Page 2780 of 2870

5MT-67

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Case

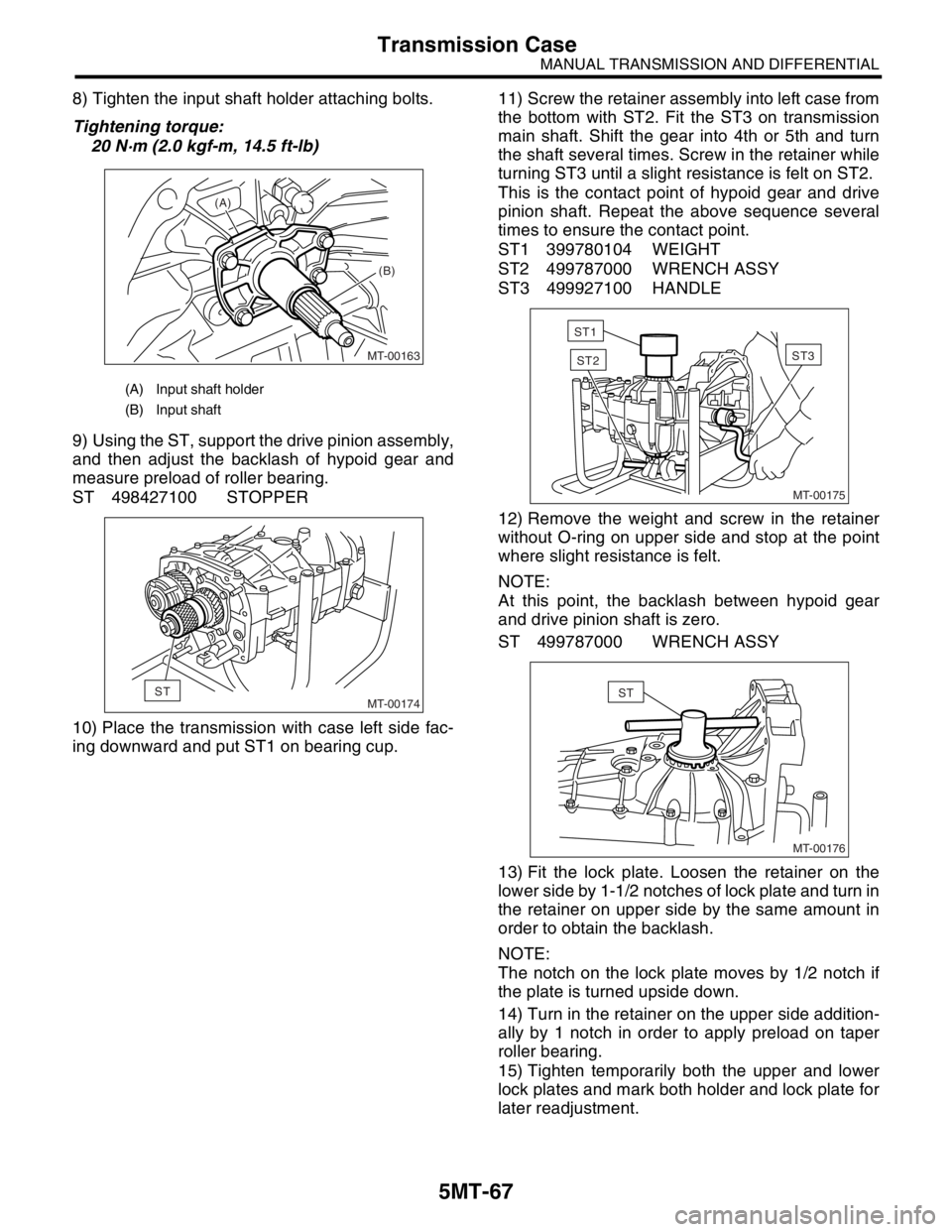

8) Tighten the input shaft holder attaching bolts.

Tightening torque:

20 N·m (2.0 kgf-m, 14.5 ft-lb)

9) Using the ST, support the drive pinion assembly,

and then adjust the backlash of hypoid gear and

measure preload of roller bearing.

ST 498427100 STOPPER

10) Place the transmission with case left side fac-

ing downward and put ST1 on bearing cup.11) Screw the retainer assembly into left case from

the bottom with ST2. Fit the ST3 on transmission

main shaft. Shift the gear into 4th or 5th and turn

the shaft several times. Screw in the retainer while

turning ST3 until a slight resistance is felt on ST2.

This is the contact point of hypoid gear and drive

pinion shaft. Repeat the above sequence several

times to ensure the contact point.

ST1 399780104 WEIGHT

ST2 499787000 WRENCH ASSY

ST3 499927100 HANDLE

12) Remove the weight and screw in the retainer

without O-ring on upper side and stop at the point

where slight resistance is felt.

NOTE:

At this point, the backlash between hypoid gear

and drive pinion shaft is zero.

ST 499787000 WRENCH ASSY

13) Fit the lock plate. Loosen the retainer on the

lower side by 1-1/2 notches of lock plate and turn in

the retainer on upper side by the same amount in

order to obtain the backlash.

NOTE:

The notch on the lock plate moves by 1/2 notch if

the plate is turned upside down.

14) Turn in the retainer on the upper side addition-

ally by 1 notch in order to apply preload on taper

roller bearing.

15) Tighten temporarily both the upper and lower

lock plates and mark both holder and lock plate for

later readjustment.

(A) Input shaft holder

(B) Input shaft

MT-00163

(A)

(B)

MT-00174ST

MT-00175

ST3ST2

ST1

MT-00176

ST