air filter SUBARU FORESTER 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2139 of 2870

EN(H4DOTC 2.5)-115

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

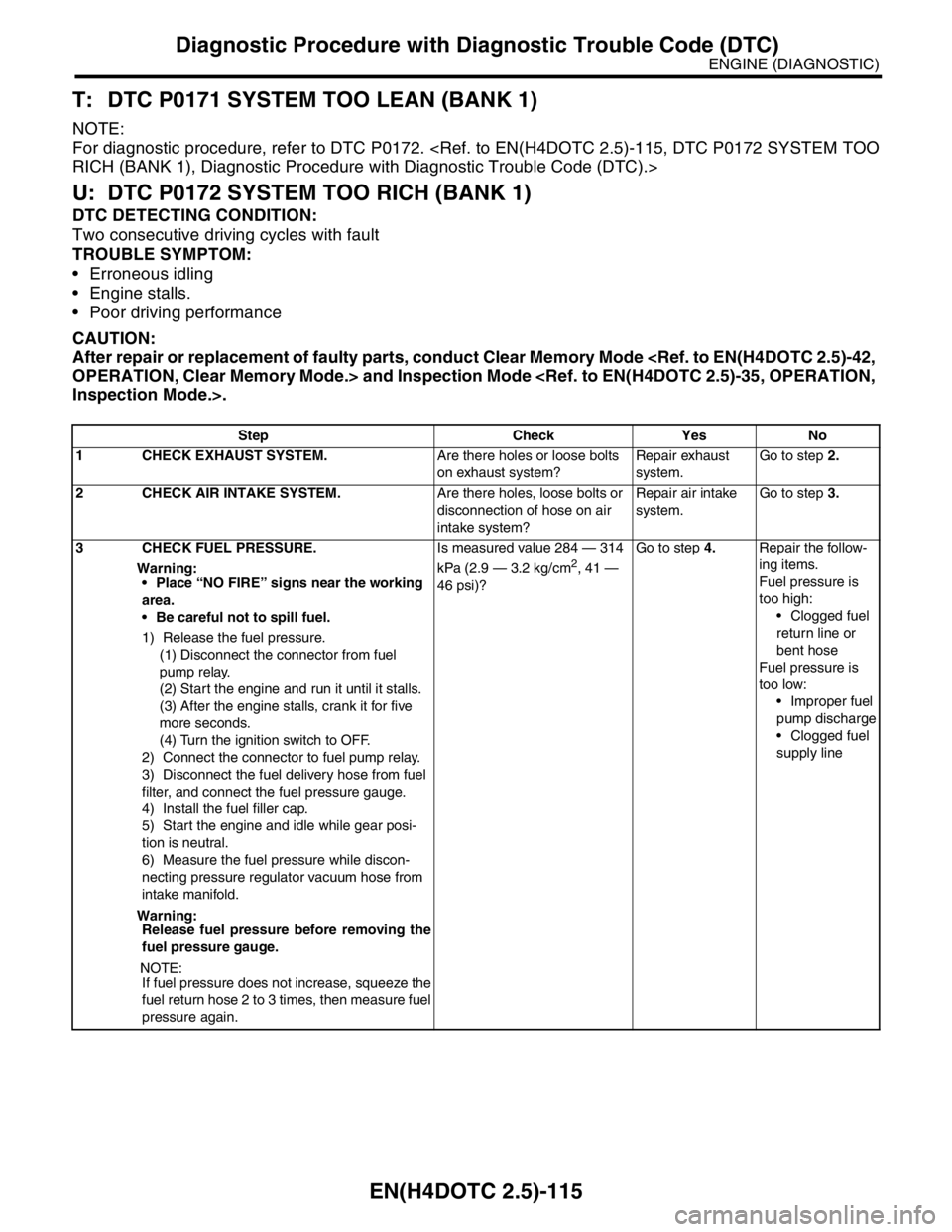

T: DTC P0171 SYSTEM TOO LEAN (BANK 1)

NOTE:

For diagnostic procedure, refer to DTC P0172.

U: DTC P0172 SYSTEM TOO RICH (BANK 1)

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Erroneous idling

Engine stalls.

Poor driving performance

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

Step Check Yes No

1 CHECK EXHAUST SYSTEM.Are there holes or loose bolts

on exhaust system?Repair exhaust

system.Go to step 2.

2 CHECK AIR INTAKE SYSTEM.Are there holes, loose bolts or

disconnection of hose on air

intake system?Repair air intake

system.Go to step 3.

3 CHECK FUEL PRESSURE.

Warning:

Place “NO FIRE” signs near the working

area.

Be careful not to spill fuel.

1) Release the fuel pressure.

(1) Disconnect the connector from fuel

pump relay.

(2) Start the engine and run it until it stalls.

(3) After the engine stalls, crank it for five

more seconds.

(4) Turn the ignition switch to OFF.

2) Connect the connector to fuel pump relay.

3) Disconnect the fuel delivery hose from fuel

filter, and connect the fuel pressure gauge.

4) Install the fuel filler cap.

5) Start the engine and idle while gear posi-

tion is neutral.

6) Measure the fuel pressure while discon-

necting pressure regulator vacuum hose from

intake manifold.

Warning:

Release fuel pressure before removing the

fuel pressure gauge.

N

OTE:

If fuel pressure does not increase, squeeze the

fuel return hose 2 to 3 times, then measure fuel

pressure again.Is measured value 284 — 314

kPa (2.9 — 3.2 kg/cm

2, 41 —

46 psi)?Go to step 4.Repair the follow-

ing items.

Fuel pressure is

too high:

Clogged fuel

return line or

bent hose

Fuel pressure is

too low:

Improper fuel

pump discharge

Clogged fuel

supply line

Page 2283 of 2870

EN(H4DOTC 2.5)-259

ENGINE (DIAGNOSTIC)

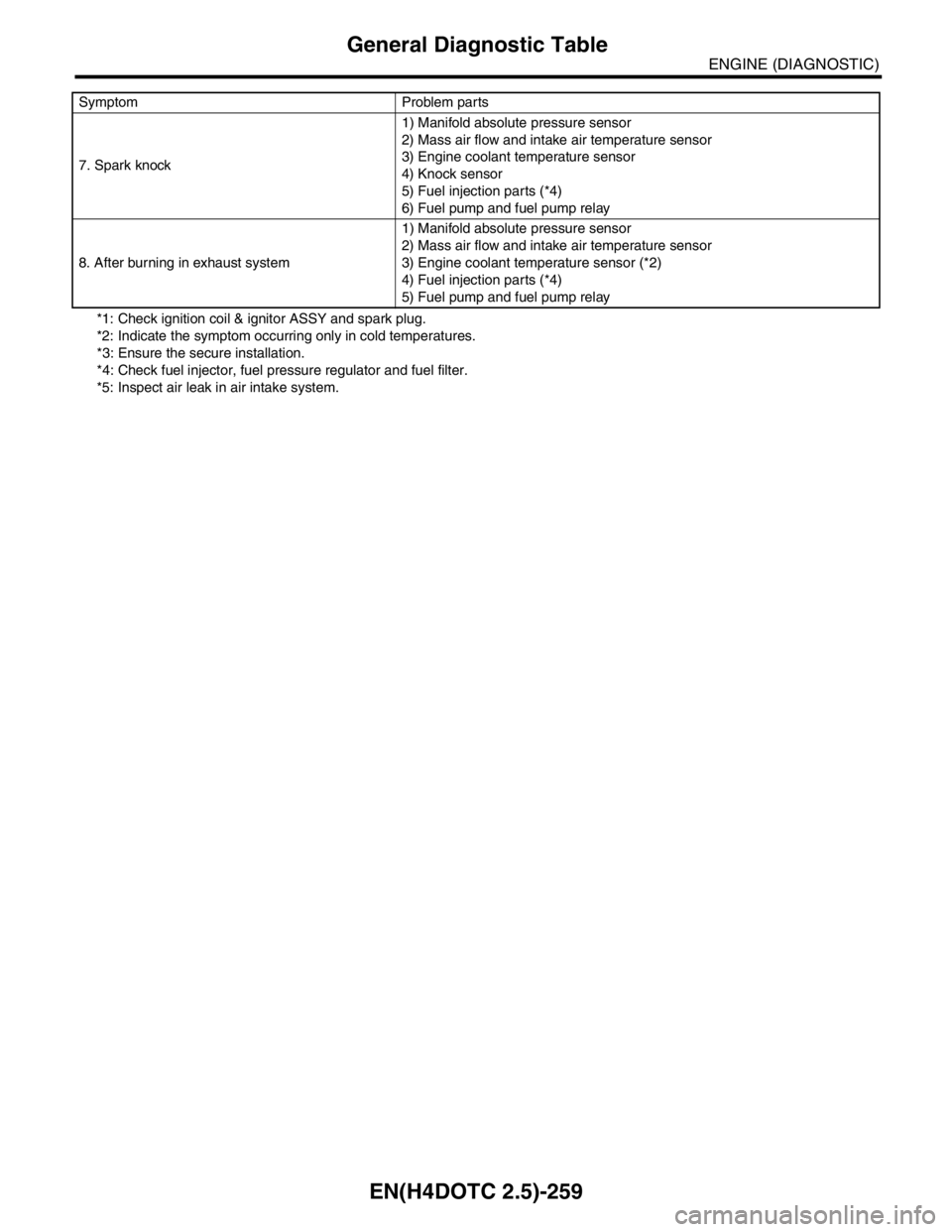

General Diagnostic Table

*1: Check ignition coil & ignitor ASSY and spark plug.

*2: Indicate the symptom occurring only in cold temperatures.

*3: Ensure the secure installation.

*4: Check fuel injector, fuel pressure regulator and fuel filter.

*5: Inspect air leak in air intake system. 7. Spark knock1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor

4) Knock sensor

5) Fuel injection parts (*4)

6) Fuel pump and fuel pump relay

8. After burning in exhaust system1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay Symptom Problem parts

Page 2313 of 2870

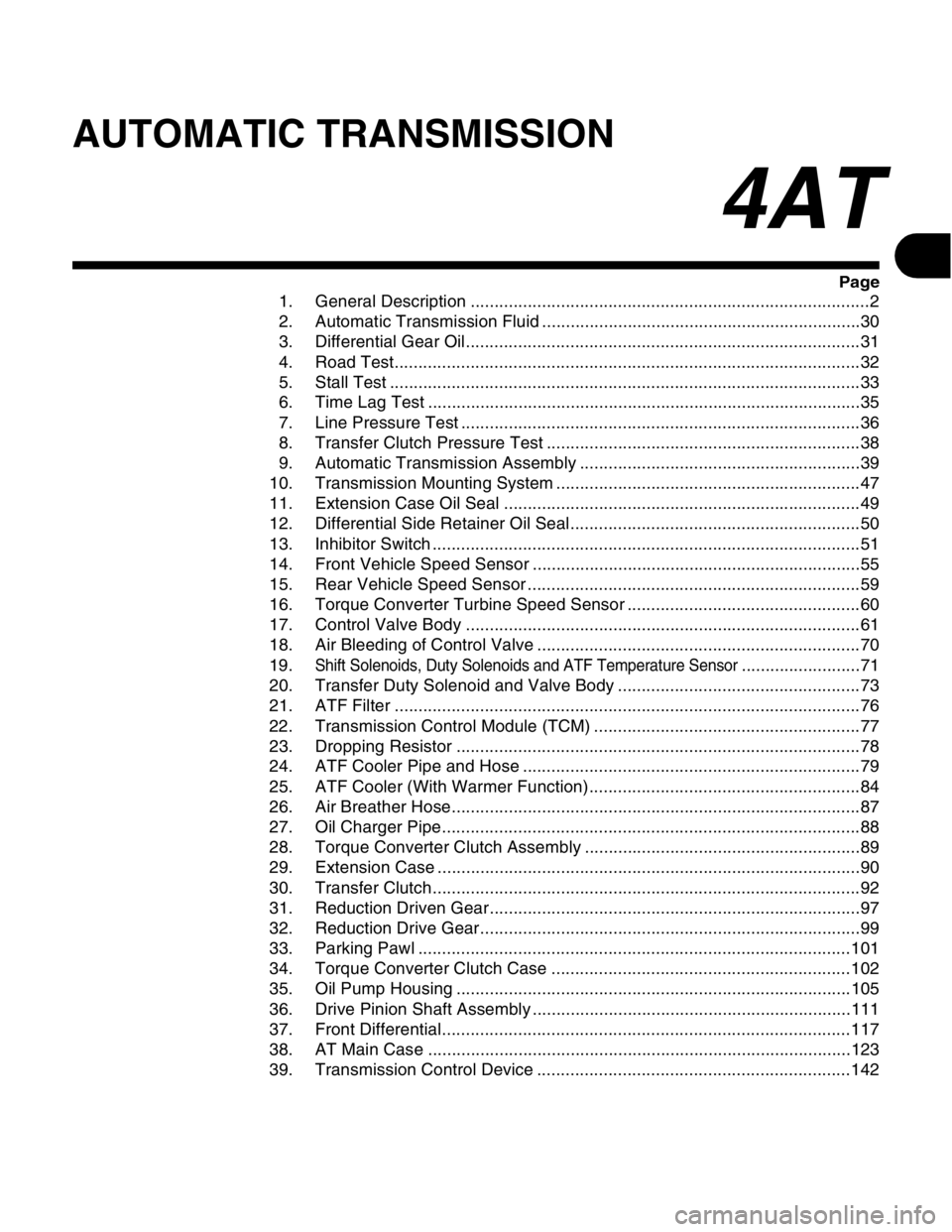

AUTOMATIC TRANSMISSION

4AT

Page

1. General Description ....................................................................................2

2. Automatic Transmission Fluid ...................................................................30

3. Differential Gear Oil...................................................................................31

4. Road Test..................................................................................................32

5. Stall Test ...................................................................................................33

6. Time Lag Test ...........................................................................................35

7. Line Pressure Test ....................................................................................36

8. Transfer Clutch Pressure Test ..................................................................38

9. Automatic Transmission Assembly ...........................................................39

10. Transmission Mounting System ................................................................47

11. Extension Case Oil Seal ...........................................................................49

12. Differential Side Retainer Oil Seal.............................................................50

13. Inhibitor Switch ..........................................................................................51

14. Front Vehicle Speed Sensor .....................................................................55

15. Rear Vehicle Speed Sensor ......................................................................59

16. Torque Converter Turbine Speed Sensor .................................................60

17. Control Valve Body ...................................................................................61

18. Air Bleeding of Control Valve ....................................................................70

19.

Shift Solenoids, Duty Solenoids and ATF Temperature Sensor.........................71

20. Transfer Duty Solenoid and Valve Body ...................................................73

21. ATF Filter ..................................................................................................76

22. Transmission Control Module (TCM) ........................................................77

23. Dropping Resistor .....................................................................................78

24. ATF Cooler Pipe and Hose .......................................................................79

25. ATF Cooler (With Warmer Function).........................................................84

26. Air Breather Hose......................................................................................87

27. Oil Charger Pipe........................................................................................88

28. Torque Converter Clutch Assembly ..........................................................89

29. Extension Case .........................................................................................90

30. Transfer Clutch..........................................................................................92

31. Reduction Driven Gear..............................................................................97

32. Reduction Drive Gear................................................................................99

33. Parking Pawl ...........................................................................................101

34. Torque Converter Clutch Case ...............................................................102

35. Oil Pump Housing ...................................................................................105

36. Drive Pinion Shaft Assembly ...................................................................111

37. Front Differential......................................................................................117

38. AT Main Case .........................................................................................123

39. Transmission Control Device ..................................................................142

Page 2320 of 2870

4AT-8

AUTOMATIC TRANSMISSION

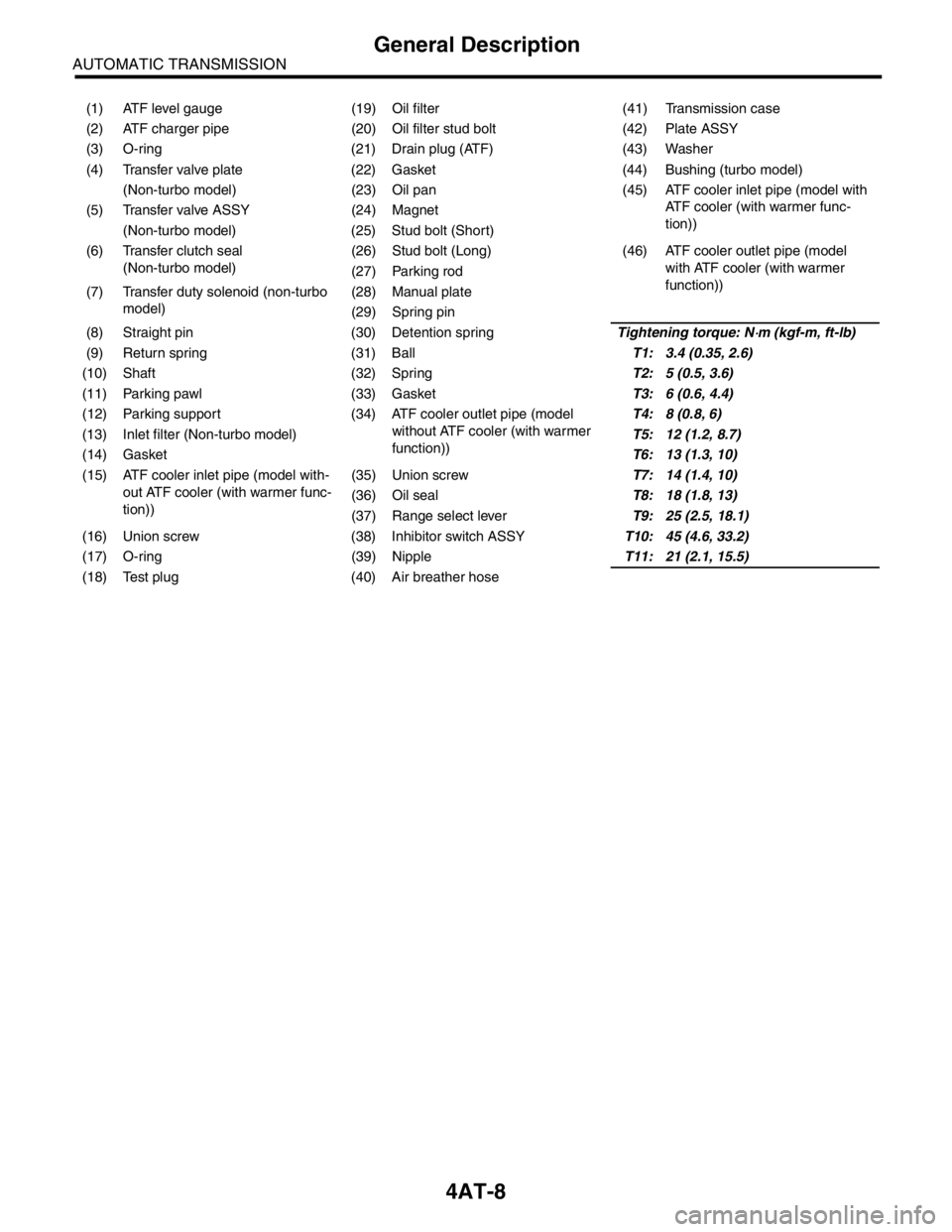

General Description

(1) ATF level gauge (19) Oil filter (41) Transmission case

(2) ATF charger pipe (20) Oil filter stud bolt (42) Plate ASSY

(3) O-ring (21) Drain plug (ATF) (43) Washer

(4) Transfer valve plate (22) Gasket (44) Bushing (turbo model)

(Non-turbo model) (23) Oil pan (45) ATF cooler inlet pipe (model with

ATF cooler (with warmer func-

tion)) (5) Transfer valve ASSY (24) Magnet

(Non-turbo model) (25) Stud bolt (Short)

(6) Transfer clutch seal

(Non-turbo model)(26) Stud bolt (Long) (46) ATF cooler outlet pipe (model

with ATF cooler (with warmer

function)) (27) Parking rod

(7) Transfer duty solenoid (non-turbo

model)(28) Manual plate

(29) Spring pin

(8) Straight pin (30) Detention springTightening torque: N

⋅m (kgf-m, ft-lb)

(9) Return spring (31) BallT1: 3.4 (0.35, 2.6)

(10) Shaft (32) SpringT2: 5 (0.5, 3.6)

(11) Parking pawl (33) GasketT3: 6 (0.6, 4.4)

(12) Parking support (34) ATF cooler outlet pipe (model

without ATF cooler (with warmer

function))T4: 8 (0.8, 6)

(13) Inlet filter (Non-turbo model)T5: 12 (1.2, 8.7)

(14) GasketT6: 13 (1.3, 10)

(15) ATF cooler inlet pipe (model with-

out ATF cooler (with warmer func-

tion))(35) Union screwT7: 14 (1.4, 10)

(36) Oil sealT8: 18 (1.8, 13)

(37) Range select leverT9: 25 (2.5, 18.1)

(16) Union screw (38) Inhibitor switch ASSYT10: 45 (4.6, 33.2)

(17) O-ring (39) NippleT11: 21 (2.1, 15.5)

(18) Test plug (40) Air breather hose

Page 2379 of 2870

4AT-66

AUTOMATIC TRANSMISSION

Control Valve Body

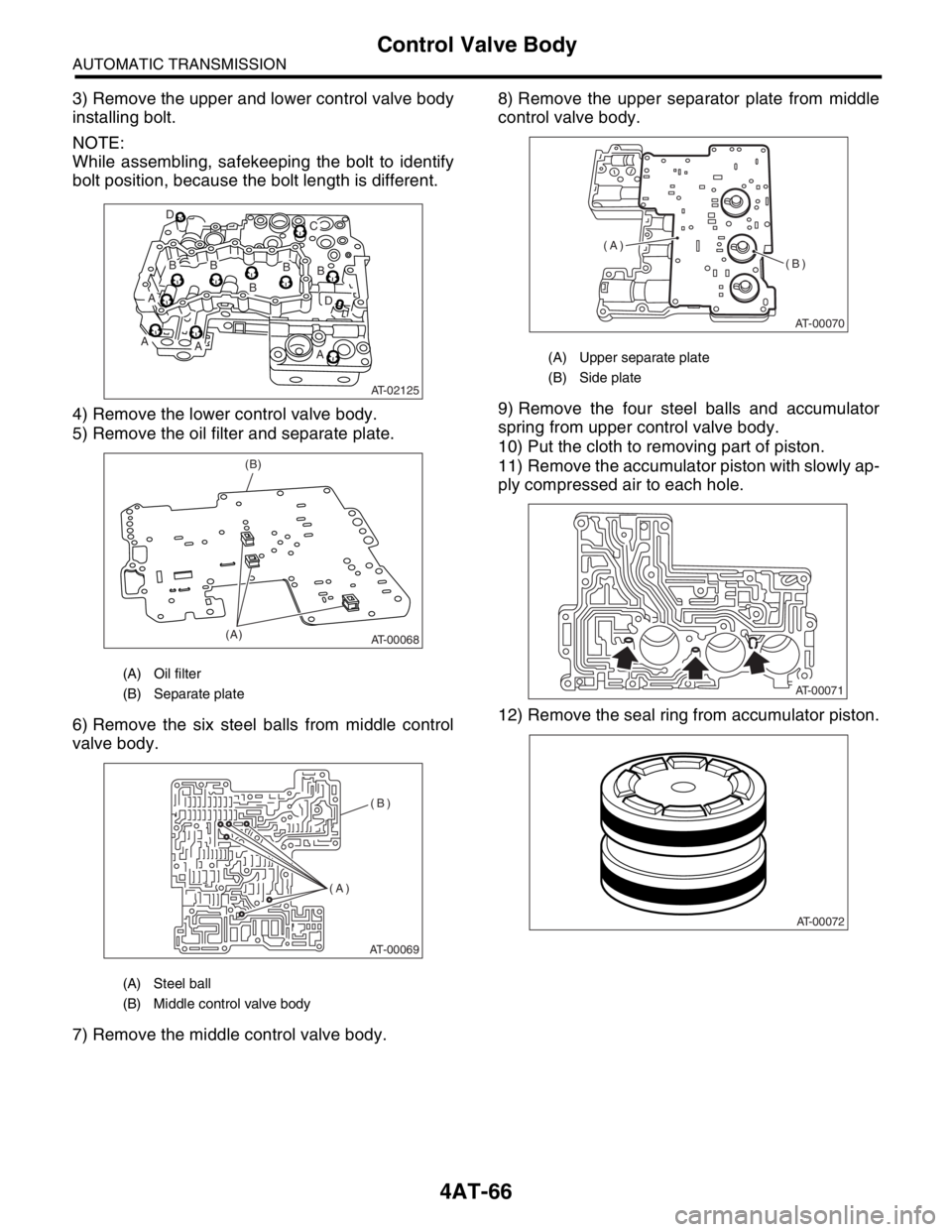

3) Remove the upper and lower control valve body

installing bolt.

NOTE:

While assembling, safekeeping the bolt to identify

bolt position, because the bolt length is different.

4) Remove the lower control valve body.

5) Remove the oil filter and separate plate.

6) Remove the six steel balls from middle control

valve body.

7) Remove the middle control valve body.8) Remove the upper separator plate from middle

control valve body.

9) Remove the four steel balls and accumulator

spring from upper control valve body.

10) Put the cloth to removing part of piston.

11) Remove the accumulator piston with slowly ap-

ply compressed air to each hole.

12) Remove the seal ring from accumulator piston.

(A) Oil filter

(B) Separate plate

(A) Steel ball

(B) Middle control valve body

AT-02125

B

B

BB D

C

B

D

AA

AA

AT-00068(A)(B)

AT-00069

(A)(B)

(A) Upper separate plate

(B) Side plate

AT-00070

(A)

(B)

AT-00071

AT-00072