tow SUBARU FORESTER 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1979 of 2870

FU(H4DOTC 2.5)-49

FUEL INJECTION (FUEL SYSTEM)

Fuel Filler Pipe

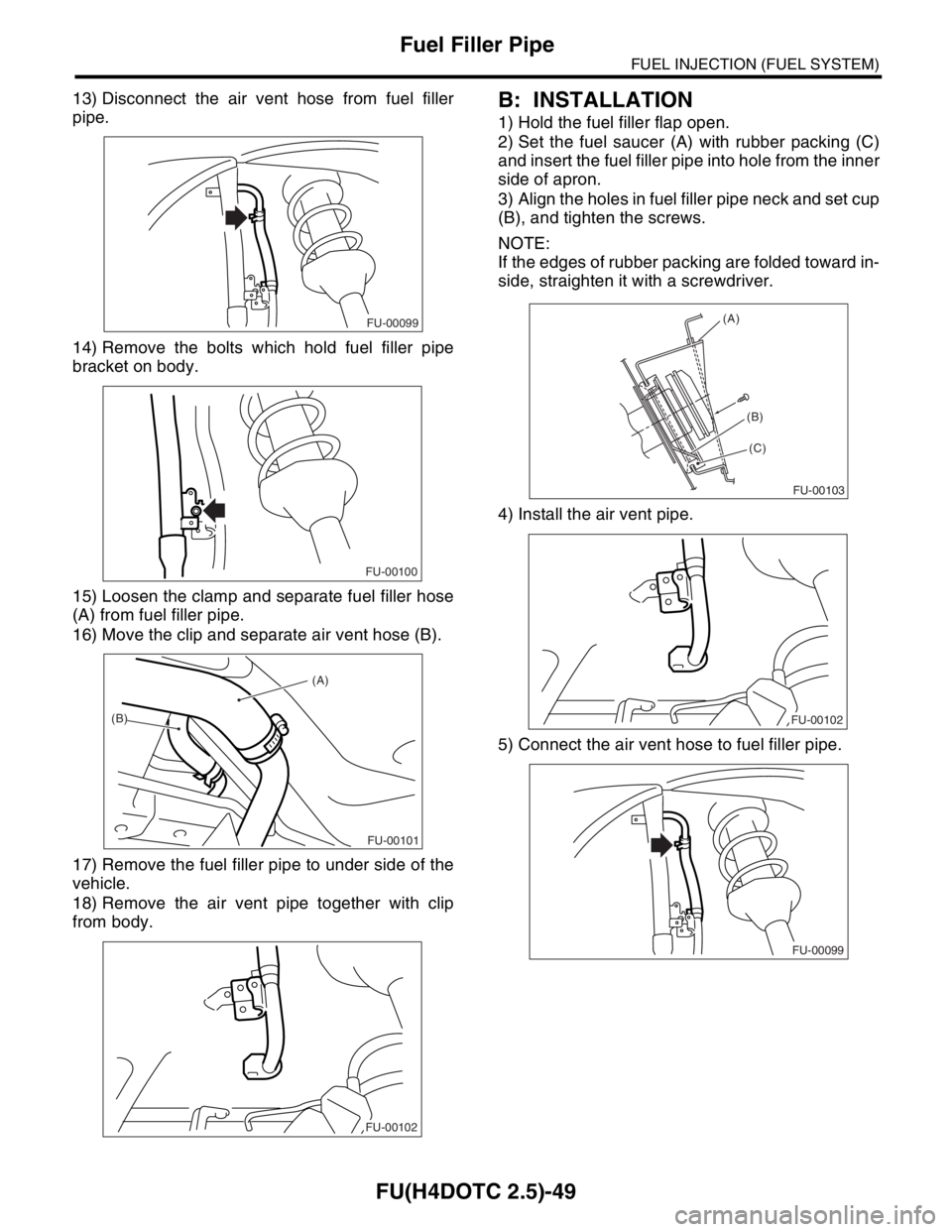

13) Disconnect the air vent hose from fuel filler

pipe.

14) Remove the bolts which hold fuel filler pipe

bracket on body.

15) Loosen the clamp and separate fuel filler hose

(A) from fuel filler pipe.

16) Move the clip and separate air vent hose (B).

17) Remove the fuel filler pipe to under side of the

vehicle.

18) Remove the air vent pipe together with clip

from body.B: INSTALLATION

1) Hold the fuel filler flap open.

2) Set the fuel saucer (A) with rubber packing (C)

and insert the fuel filler pipe into hole from the inner

side of apron.

3) Align the holes in fuel filler pipe neck and set cup

(B), and tighten the screws.

NOTE:

If the edges of rubber packing are folded toward in-

side, straighten it with a screwdriver.

4) Install the air vent pipe.

5) Connect the air vent hose to fuel filler pipe.

FU-00099

FU-00100

(A)

(B)

FU-00101

FU-00102

FU-00103

(A)

(C)

(B)

FU-00102

FU-00099

Page 2061 of 2870

EN(H4DOTC 2.5)-37

ENGINE (DIAGNOSTIC)

Inspection Mode

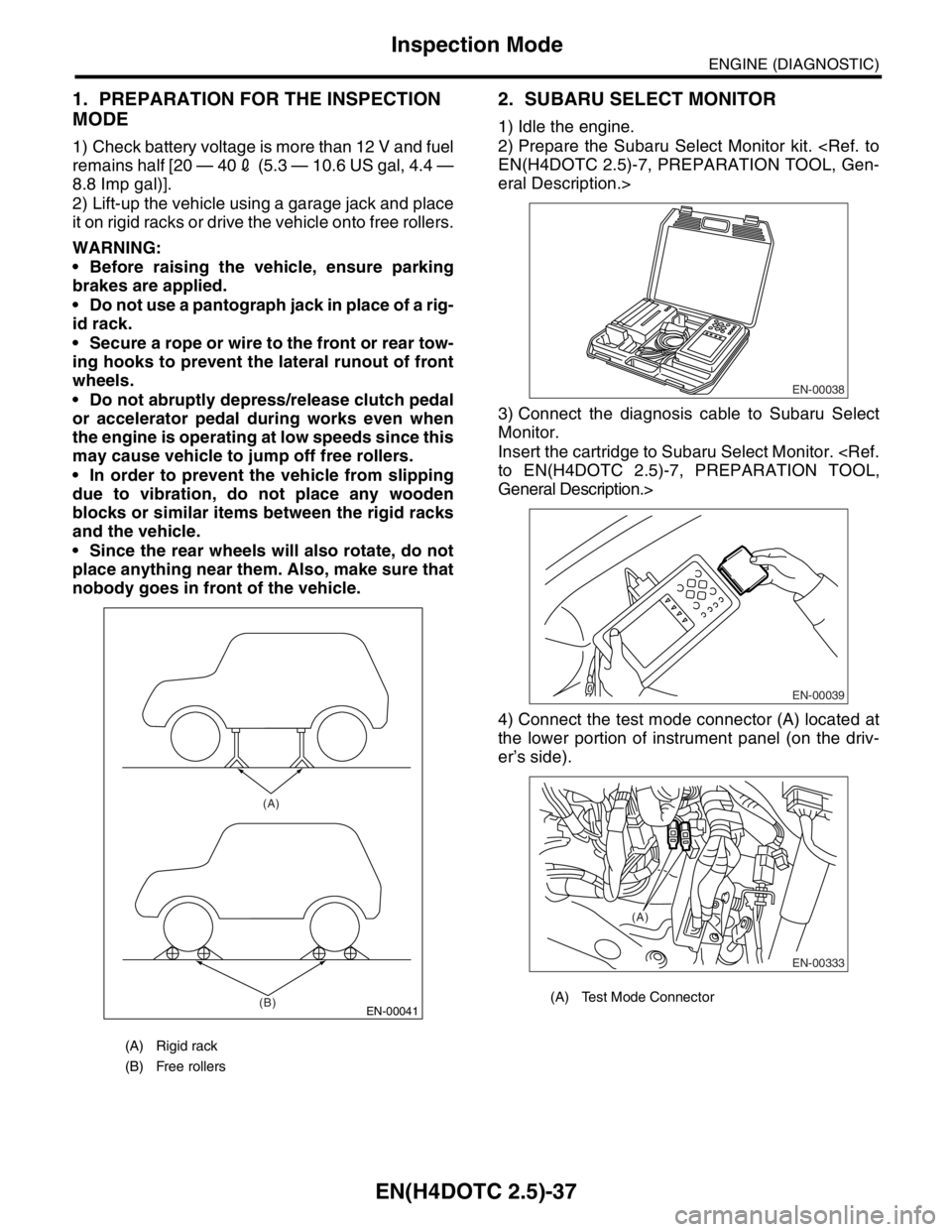

1. PREPARATION FOR THE INSPECTION

MODE

1) Check battery voltage is more than 12 V and fuel

remains half [20 — 402 (5.3 — 10.6 US gal, 4.4 —

8.8 Imp gal)].

2) Lift-up the vehicle using a garage jack and place

it on rigid racks or drive the vehicle onto free rollers.

WARNING:

Before raising the vehicle, ensure parking

brakes are applied.

Do not use a pantograph jack in place of a rig-

id rack.

Secure a rope or wire to the front or rear tow-

ing hooks to prevent the lateral runout of front

wheels.

Do not abruptly depress/release clutch pedal

or accelerator pedal during works even when

the engine is operating at low speeds since this

may cause vehicle to jump off free rollers.

In order to prevent the vehicle from slipping

due to vibration, do not place any wooden

blocks or similar items between the rigid racks

and the vehicle.

Since the rear wheels will also rotate, do not

place anything near them. Also, make sure that

nobody goes in front of the vehicle.

2. SUBARU SELECT MONITOR

1) Idle the engine.

2) Prepare the Subaru Select Monitor kit.

eral Description.>

3) Connect the diagnosis cable to Subaru Select

Monitor.

Insert the cartridge to Subaru Select Monitor.

General Description.>

4) Connect the test mode connector (A) located at

the lower portion of instrument panel (on the driv-

er’s side).

(A) Rigid rack

(B) Free rollers

EN-00041

(A)

(B)

(A) Test Mode Connector

EN-00038

EN-00039

EN-00333

(A)

Page 2428 of 2870

4AT-114

AUTOMATIC TRANSMISSION

Drive Pinion Shaft Assembly

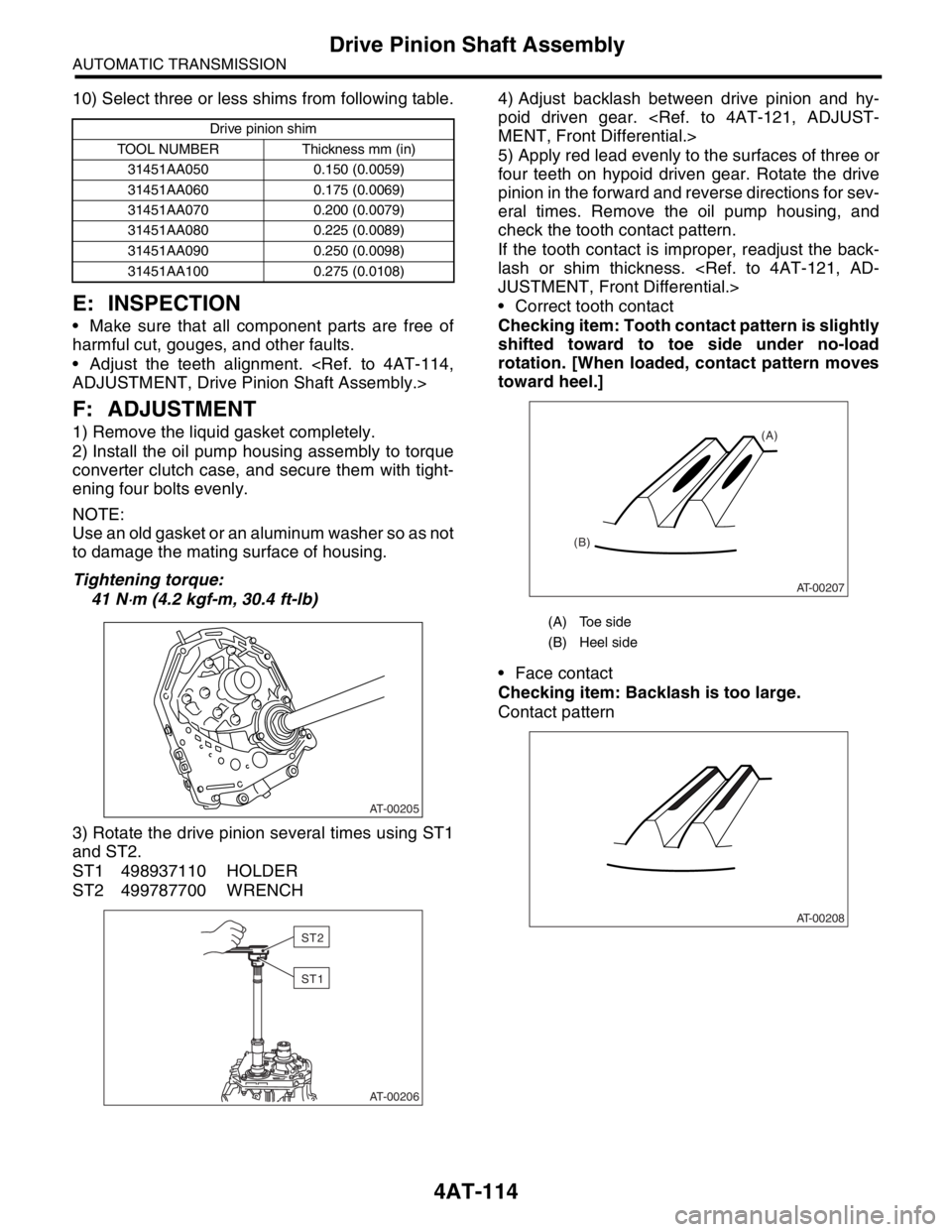

10) Select three or less shims from following table.

E: INSPECTION

Make sure that all component parts are free of

harmful cut, gouges, and other faults.

Adjust the teeth alignment.

F: ADJUSTMENT

1) Remove the liquid gasket completely.

2) Install the oil pump housing assembly to torque

converter clutch case, and secure them with tight-

ening four bolts evenly.

NOTE:

Use an old gasket or an aluminum washer so as not

to damage the mating surface of housing.

Tightening torque:

41 N

⋅m (4.2 kgf-m, 30.4 ft-lb)

3) Rotate the drive pinion several times using ST1

and ST2.

ST1 498937110 HOLDER

ST2 499787700 WRENCH4) Adjust backlash between drive pinion and hy-

poid driven gear.

5) Apply red lead evenly to the surfaces of three or

four teeth on hypoid driven gear. Rotate the drive

pinion in the forward and reverse directions for sev-

eral times. Remove the oil pump housing, and

check the tooth contact pattern.

If the tooth contact is improper, readjust the back-

lash or shim thickness.

Correct tooth contact

Checking item: Tooth contact pattern is slightly

shifted toward to toe side under no-load

rotation. [When loaded, contact pattern moves

toward heel.]

Face contact

Checking item: Backlash is too large.

Contact pattern

Drive pinion shim

TOOL NUMBER Thickness mm (in)

31451AA050 0.150 (0.0059)

31451AA060 0.175 (0.0069)

31451AA070 0.200 (0.0079)

31451AA080 0.225 (0.0089)

31451AA090 0.250 (0.0098)

31451AA100 0.275 (0.0108)

AT-00205

AT-00206

ST2

ST1

(A) Toe side

(B) Heel side

AT-00207

(A)

(B)

AT-00208

Page 2747 of 2870

5MT-35

MANUAL TRANSMISSION AND DIFFERENTIAL

Manual Transmission Assembly

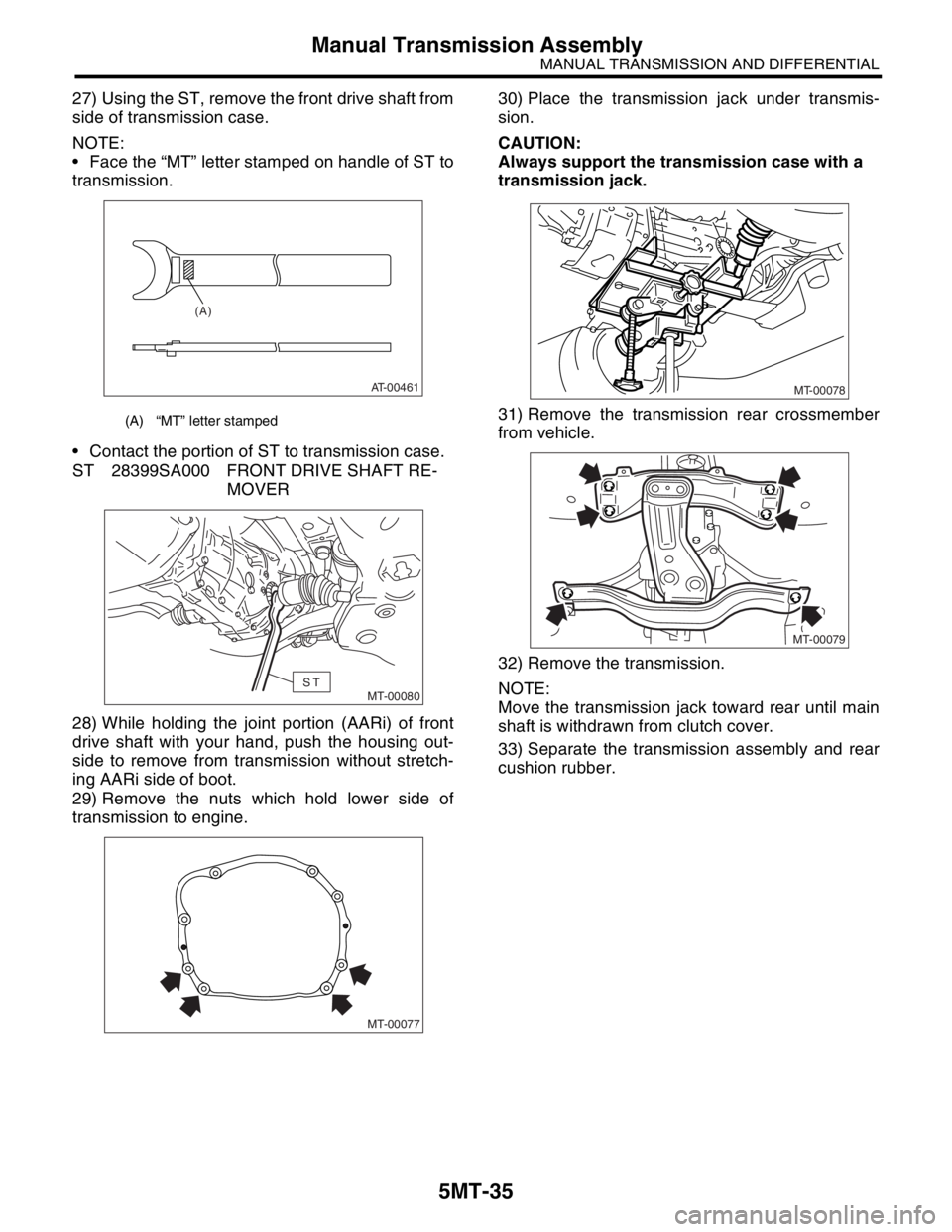

27) Using the ST, remove the front drive shaft from

side of transmission case.

NOTE:

Face the “MT” letter stamped on handle of ST to

transmission.

Contact the portion of ST to transmission case.

ST 28399SA000 FRONT DRIVE SHAFT RE-

MOVER

28) While holding the joint portion (AARi) of front

drive shaft with your hand, push the housing out-

side to remove from transmission without stretch-

ing AARi side of boot.

29) Remove the nuts which hold lower side of

transmission to engine.30) Place the transmission jack under transmis-

sion.

CAUTION:

Always support the transmission case with a

transmission jack.

31) Remove the transmission rear crossmember

from vehicle.

32) Remove the transmission.

NOTE:

Move the transmission jack toward rear until main

shaft is withdrawn from clutch cover.

33) Separate the transmission assembly and rear

cushion rubber.

(A) “MT” letter stamped

AT-00461

(A)

MT-00080ST

MT-00077

MT-00078

MT-00079

Page 2774 of 2870

5MT-61

MANUAL TRANSMISSION AND DIFFERENTIAL

Reverse Check Sleeve

E: INSPECTION

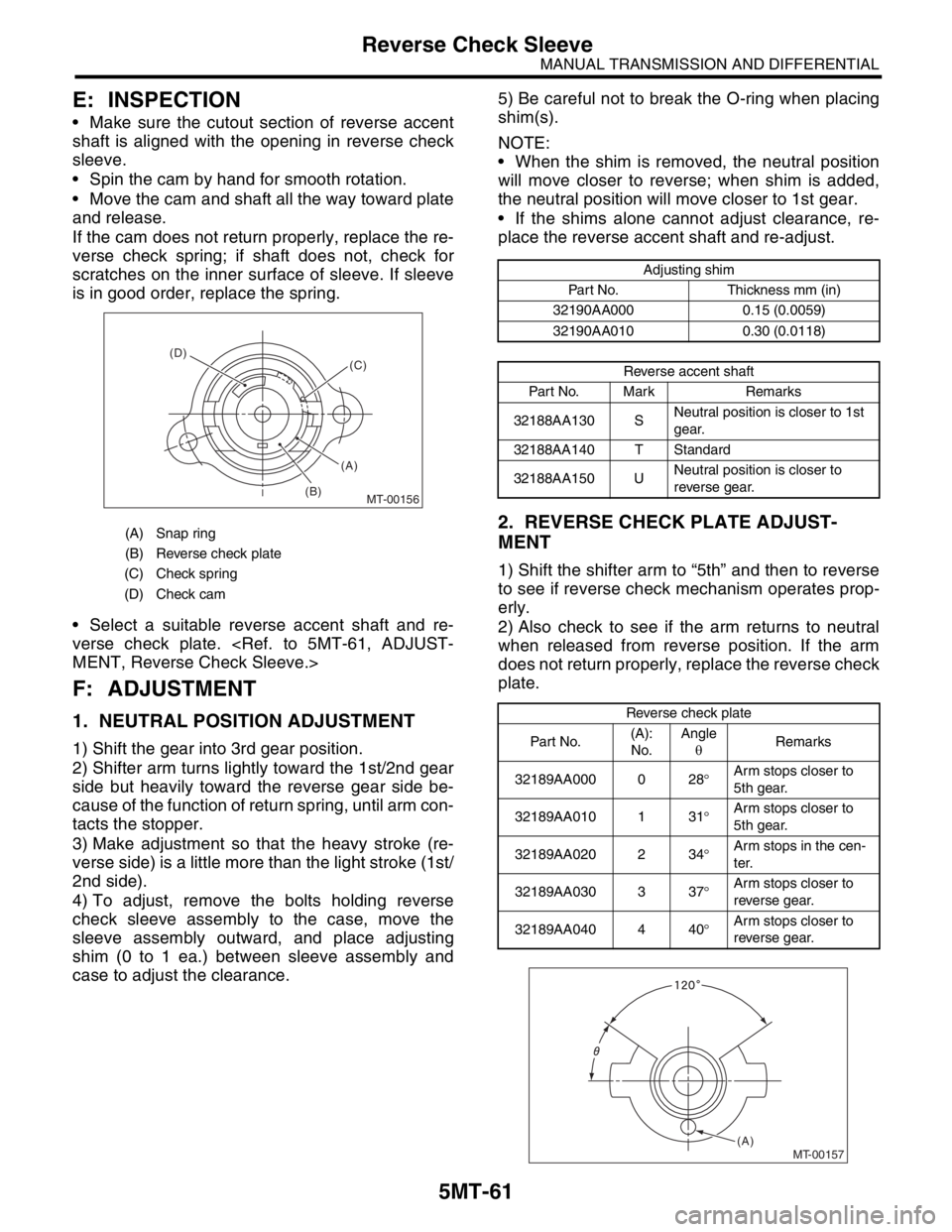

Make sure the cutout section of reverse accent

shaft is aligned with the opening in reverse check

sleeve.

Spin the cam by hand for smooth rotation.

Move the cam and shaft all the way toward plate

and release.

If the cam does not return properly, replace the re-

verse check spring; if shaft does not, check for

scratches on the inner surface of sleeve. If sleeve

is in good order, replace the spring.

Select a suitable reverse accent shaft and re-

verse check plate.

F: ADJUSTMENT

1. NEUTRAL POSITION ADJUSTMENT

1) Shift the gear into 3rd gear position.

2) Shifter arm turns lightly toward the 1st/2nd gear

side but heavily toward the reverse gear side be-

cause of the function of return spring, until arm con-

tacts the stopper.

3) Make adjustment so that the heavy stroke (re-

verse side) is a little more than the light stroke (1st/

2nd side).

4) To adjust, remove the bolts holding reverse

check sleeve assembly to the case, move the

sleeve assembly outward, and place adjusting

shim (0 to 1 ea.) between sleeve assembly and

case to adjust the clearance.5) Be careful not to break the O-ring when placing

shim(s).

NOTE:

When the shim is removed, the neutral position

will move closer to reverse; when shim is added,

the neutral position will move closer to 1st gear.

If the shims alone cannot adjust clearance, re-

place the reverse accent shaft and re-adjust.

2. REVERSE CHECK PLATE ADJUST-

MENT

1) Shift the shifter arm to “5th” and then to reverse

to see if reverse check mechanism operates prop-

erly.

2) Also check to see if the arm returns to neutral

when released from reverse position. If the arm

does not return properly, replace the reverse check

plate.

(A) Snap ring

(B) Reverse check plate

(C) Check spring

(D) Check cam

MT-00156

(A) (D)

(B)(C)

Adjusting shim

Part No. Thickness mm (in)

32190AA000 0.15 (0.0059)

32190AA010 0.30 (0.0118)

Reverse accent shaft

Part No. Mark Remarks

32188AA130 SNeutral position is closer to 1st

gear.

32188AA140 T Standard

32188AA150 UNeutral position is closer to

reverse gear.

Reverse check plate

Par t No.(A):

No.Angle

θRemarks

32189AA000 0 28°Arm stops closer to

5th gear.

32189AA010 1 31°Arm stops closer to

5th gear.

32189AA020 2 34°Arm stops in the cen-

ter.

32189AA030 3 37°Arm stops closer to

reverse gear.

32189AA040 4 40°Arm stops closer to

reverse gear.

MT-00157(A)

Page 2794 of 2870

5MT-81

MANUAL TRANSMISSION AND DIFFERENTIAL

Main Shaft Assembly For Dual-Range

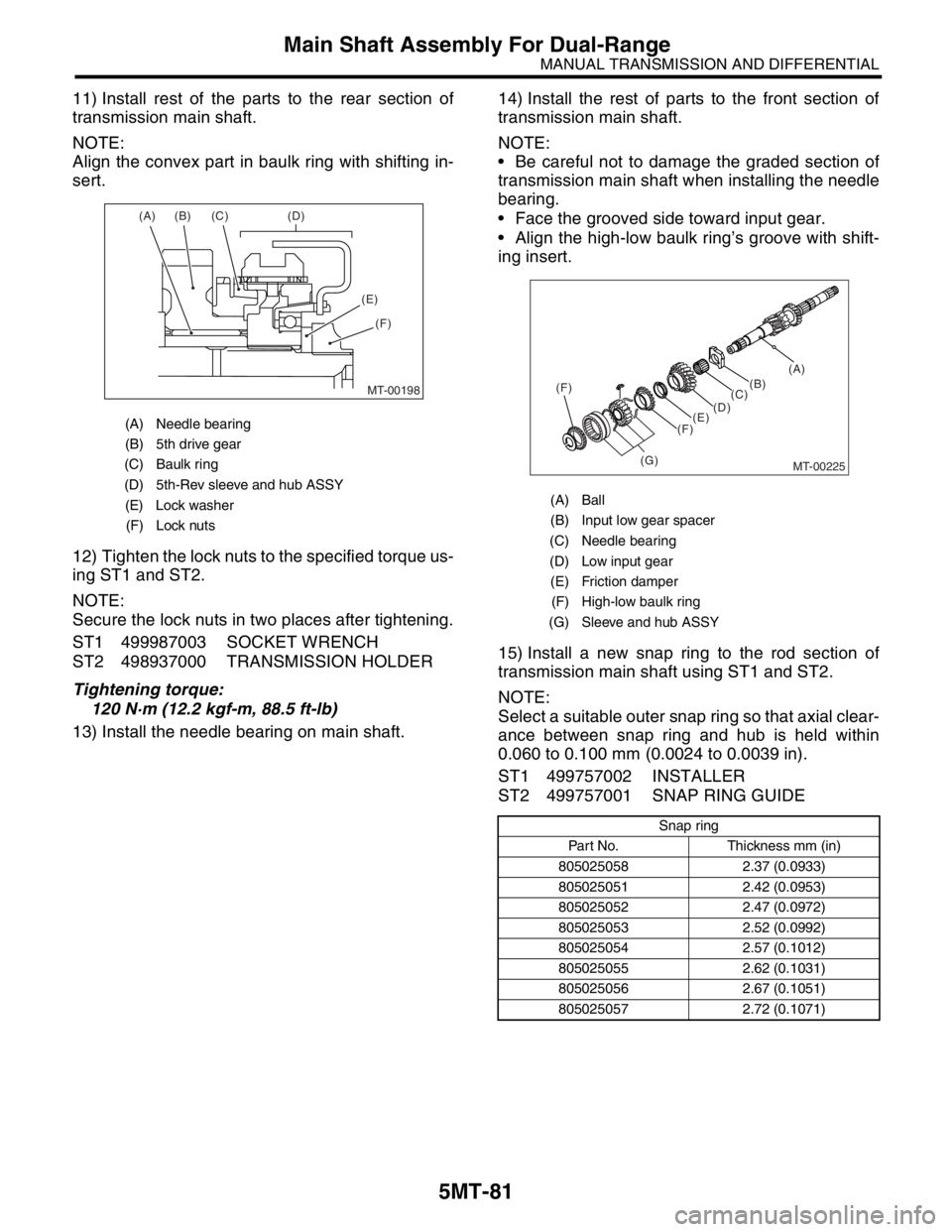

11) Install rest of the parts to the rear section of

transmission main shaft.

NOTE:

Align the convex part in baulk ring with shifting in-

sert.

12) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

NOTE:

Secure the lock nuts in two places after tightening.

ST1 499987003 SOCKET WRENCH

ST2 498937000 TRANSMISSION HOLDER

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

13) Install the needle bearing on main shaft.14) Install the rest of parts to the front section of

transmission main shaft.

NOTE:

Be careful not to damage the graded section of

transmission main shaft when installing the needle

bearing.

Face the grooved side toward input gear.

Align the high-low baulk ring’s groove with shift-

ing insert.

15) Install a new snap ring to the rod section of

transmission main shaft using ST1 and ST2.

NOTE:

Select a suitable outer snap ring so that axial clear-

ance between snap ring and hub is held within

0.060 to 0.100 mm (0.0024 to 0.0039 in).

ST1 499757002 INSTALLER

ST2 499757001 SNAP RING GUIDE

(A) Needle bearing

(B) 5th drive gear

(C) Baulk ring

(D) 5th-Rev sleeve and hub ASSY

(E) Lock washer

(F) Lock nuts

MT-00198

(A) (B) (C) (D)

(E)

(F)

(A) Ball

(B) Input low gear spacer

(C) Needle bearing

(D) Low input gear

(E) Friction damper

(F) High-low baulk ring

(G) Sleeve and hub ASSY

Snap ring

Part No. Thickness mm (in)

805025058 2.37 (0.0933)

805025051 2.42 (0.0953)

805025052 2.47 (0.0972)

805025053 2.52 (0.0992)

805025054 2.57 (0.1012)

805025055 2.62 (0.1031)

805025056 2.67 (0.1051)

805025057 2.72 (0.1071)

MT-00225

(F)

(G)(C)(B)(A)

(D)

(E)

(F)

Page 2810 of 2870

5MT-97

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

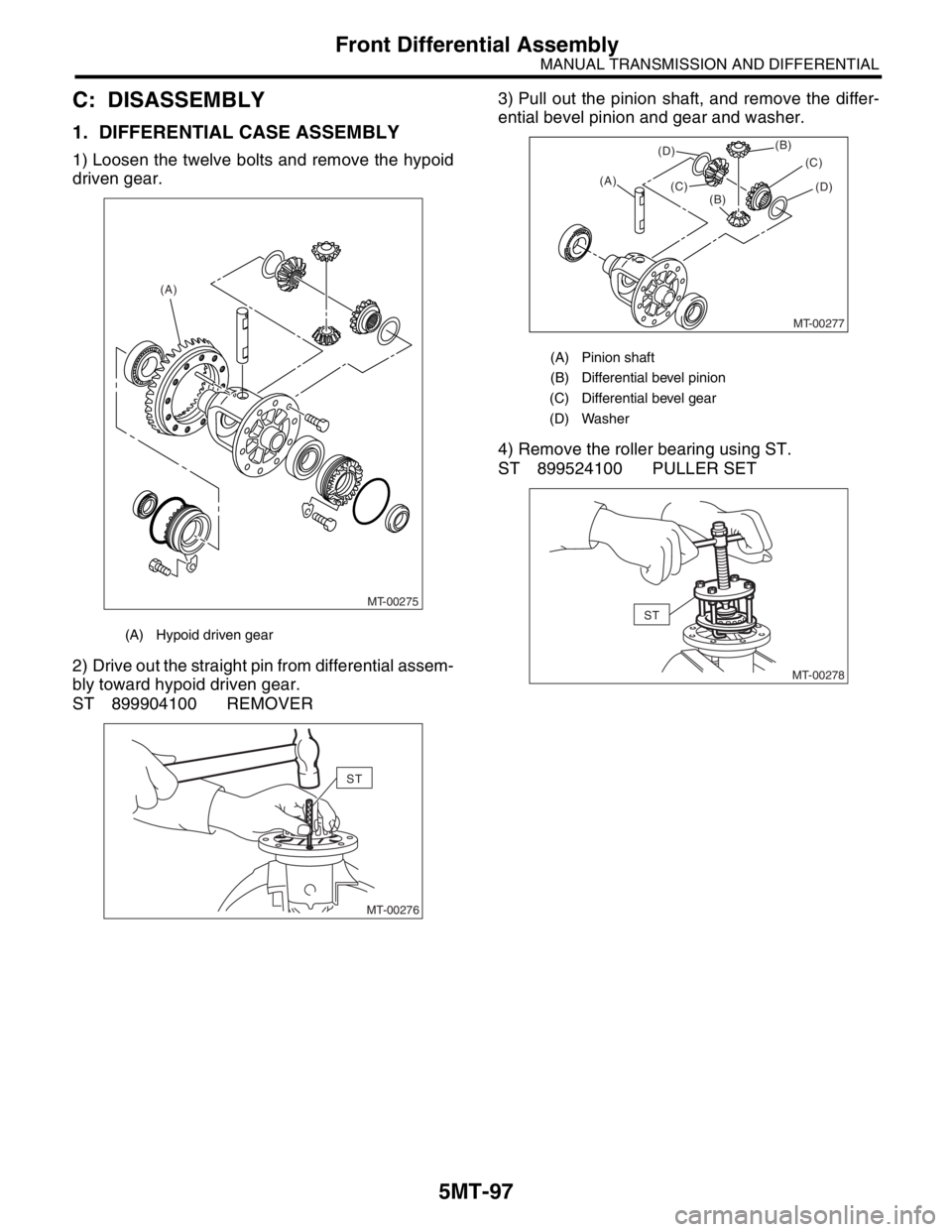

C: DISASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

1) Loosen the twelve bolts and remove the hypoid

driven gear.

2) Drive out the straight pin from differential assem-

bly toward hypoid driven gear.

ST 899904100 REMOVER3) Pull out the pinion shaft, and remove the differ-

ential bevel pinion and gear and washer.

4) Remove the roller bearing using ST.

ST 899524100 PULLER SET

(A) Hypoid driven gear

(A)

MT-00275

MT-00276

ST

(A) Pinion shaft

(B) Differential bevel pinion

(C) Differential bevel gear

(D) Washer

MT-00277

(A)

(D)

(D)

(C)

(C)

(B)

(B)

MT-00278

ST

Page 2811 of 2870

5MT-98

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

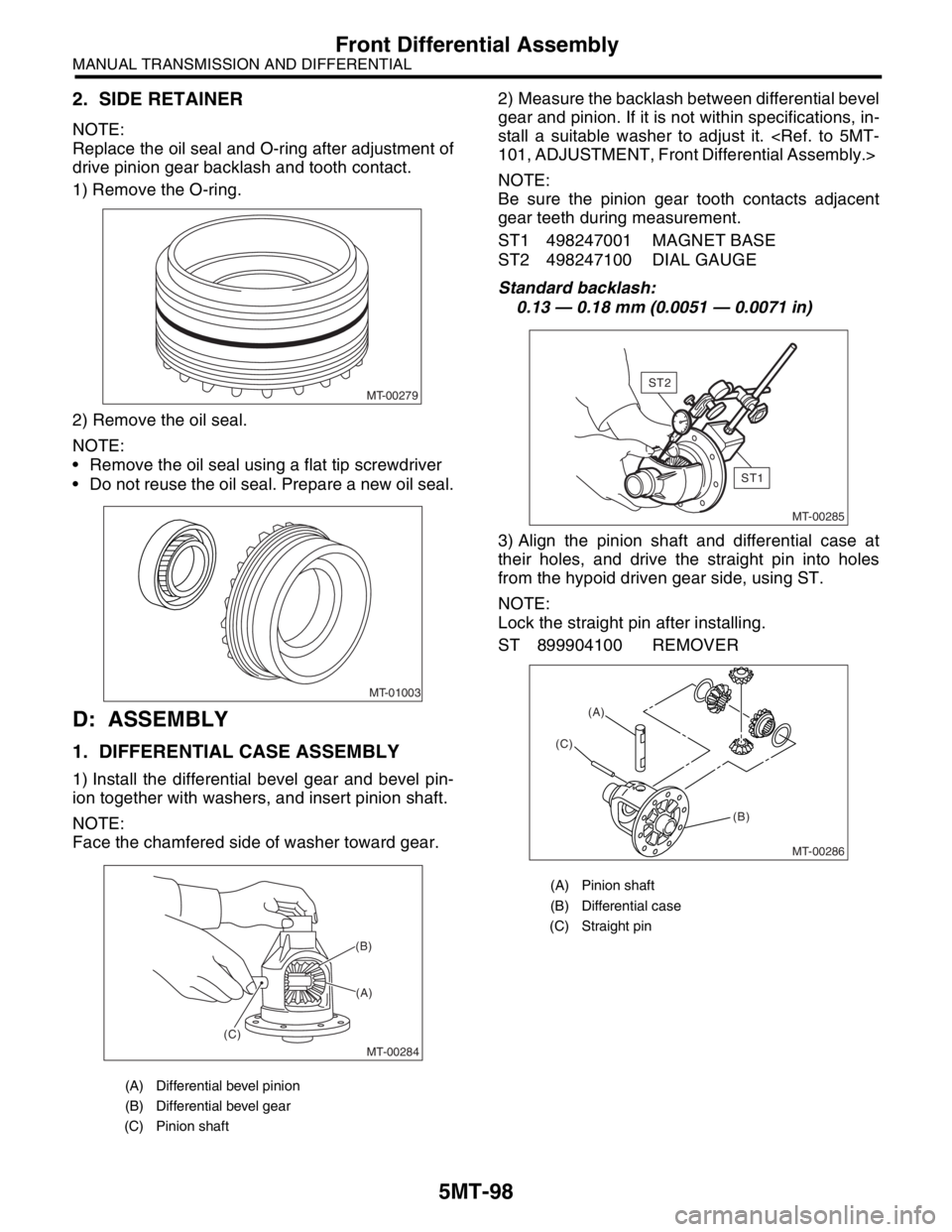

2. SIDE RETAINER

NOTE:

Replace the oil seal and O-ring after adjustment of

drive pinion gear backlash and tooth contact.

1) Remove the O-ring.

2) Remove the oil seal.

NOTE:

Remove the oil seal using a flat tip screwdriver

Do not reuse the oil seal. Prepare a new oil seal.

D: ASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

1) Install the differential bevel gear and bevel pin-

ion together with washers, and insert pinion shaft.

NOTE:

Face the chamfered side of washer toward gear.2) Measure the backlash between differential bevel

gear and pinion. If it is not within specifications, in-

stall a suitable washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

3) Align the pinion shaft and differential case at

their holes, and drive the straight pin into holes

from the hypoid driven gear side, using ST.

NOTE:

Lock the straight pin after installing.

ST 899904100 REMOVER

(A) Differential bevel pinion

(B) Differential bevel gear

(C) Pinion shaft

MT-00279

MT-01003

MT-00284

(A) (B)

(C)

(A) Pinion shaft

(B) Differential case

(C) Straight pin

MT-00285

ST1

ST2

MT-00286

(A)

(C)

(B)

Page 2814 of 2870

5MT-101

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

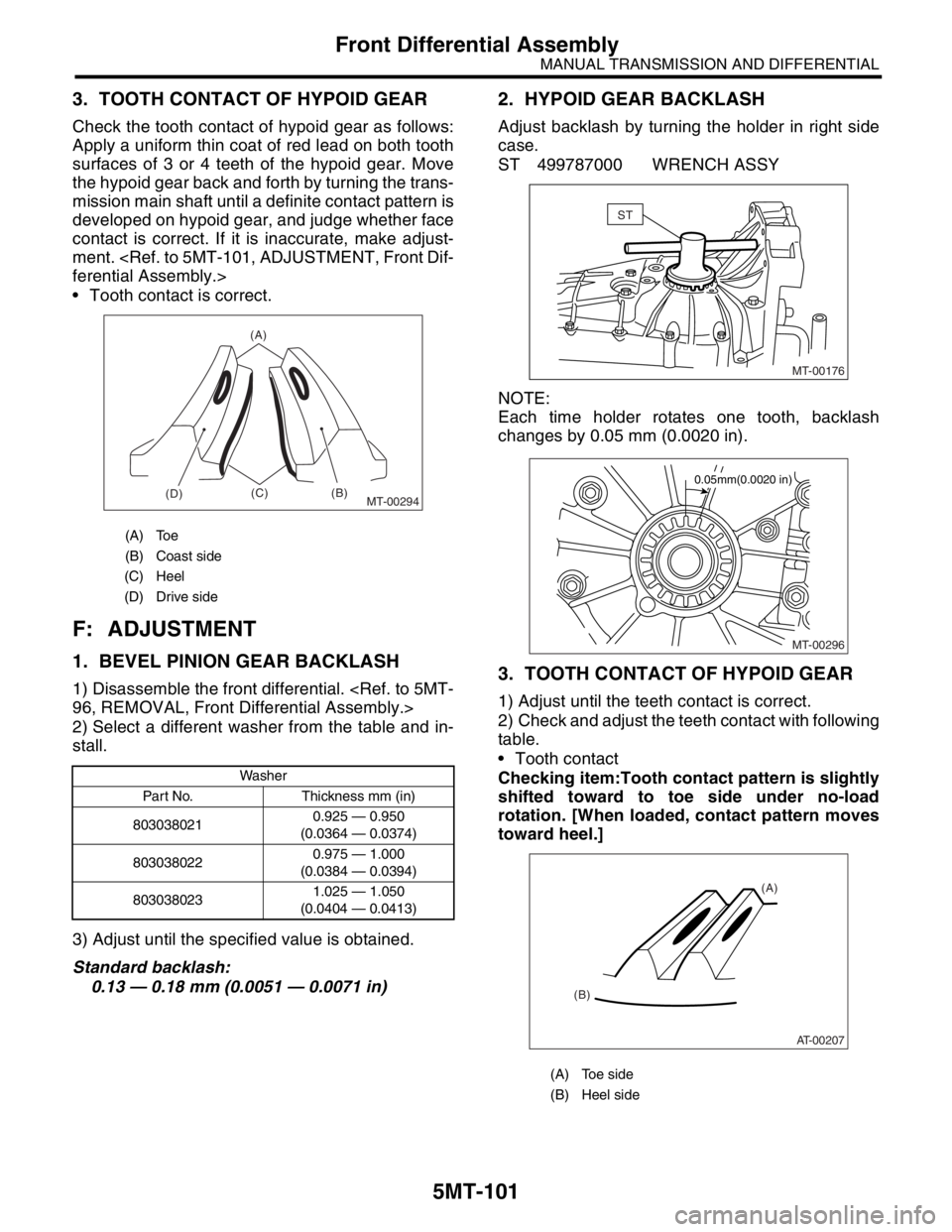

3. TOOTH CONTACT OF HYPOID GEAR

Check the tooth contact of hypoid gear as follows:

Apply a uniform thin coat of red lead on both tooth

surfaces of 3 or 4 teeth of the hypoid gear. Move

the hypoid gear back and forth by turning the trans-

mission main shaft until a definite contact pattern is

developed on hypoid gear, and judge whether face

contact is correct. If it is inaccurate, make adjust-

ment.

Tooth contact is correct.

F: ADJUSTMENT

1. BEVEL PINION GEAR BACKLASH

1) Disassemble the front differential.

2) Select a different washer from the table and in-

stall.

3) Adjust until the specified value is obtained.

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

Adjust backlash by turning the holder in right side

case.

ST 499787000 WRENCH ASSY

NOTE:

Each time holder rotates one tooth, backlash

changes by 0.05 mm (0.0020 in).

3. TOOTH CONTACT OF HYPOID GEAR

1) Adjust until the teeth contact is correct.

2) Check and adjust the teeth contact with following

table.

Tooth contact

Checking item:Tooth contact pattern is slightly

shifted toward to toe side under no-load

rotation. [When loaded, contact pattern moves

toward heel.]

(A) Toe

(B) Coast side

(C) Heel

(D) Drive side

Washer

Part No. Thickness mm (in)

8030380210.925 — 0.950

(0.0364 — 0.0374)

8030380220.975 — 1.000

(0.0384 — 0.0394)

803038023 1.025 — 1.050

(0.0404 — 0.0413)

MT-00294

(A)

(B) (C)

(D)

(A) Toe side

(B) Heel side

MT-00176

ST

MT-00296

0.05mm(0.0020 in)

AT-00207

(A)

(B)

Page 2818 of 2870

5MT-105

MANUAL TRANSMISSION AND DIFFERENTIAL

Reverse Idler Gear

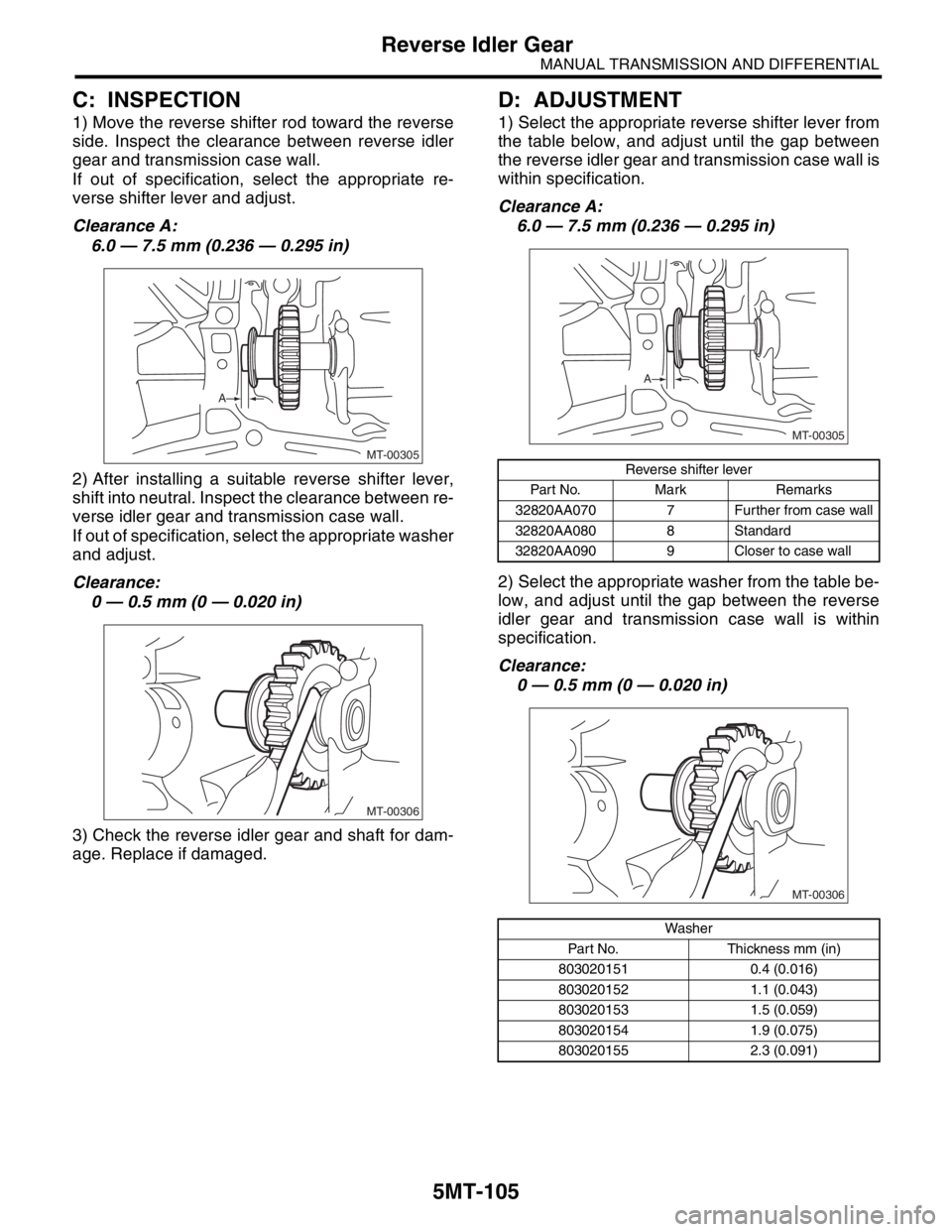

C: INSPECTION

1) Move the reverse shifter rod toward the reverse

side. Inspect the clearance between reverse idler

gear and transmission case wall.

If out of specification, select the appropriate re-

verse shifter lever and adjust.

Clearance A:

6.0 — 7.5 mm (0.236 — 0.295 in)

2) After installing a suitable reverse shifter lever,

shift into neutral. Inspect the clearance between re-

verse idler gear and transmission case wall.

If out of specification, select the appropriate washer

and adjust.

Clearance:

0 — 0.5 mm (0 — 0.020 in)

3) Check the reverse idler gear and shaft for dam-

age. Replace if damaged.

D: ADJUSTMENT

1) Select the appropriate reverse shifter lever from

the table below, and adjust until the gap between

the reverse idler gear and transmission case wall is

within specification.

Clearance A:

6.0 — 7.5 mm (0.236 — 0.295 in)

2) Select the appropriate washer from the table be-

low, and adjust until the gap between the reverse

idler gear and transmission case wall is within

specification.

Clearance:

0 — 0.5 mm (0 — 0.020 in)

MT-00305

A

MT-00306

Reverse shifter lever

Part No. Mark Remarks

32820AA070 7 Further from case wall

32820AA080 8 Standard

32820AA090 9 Closer to case wall

Washer

Part No. Thickness mm (in)

803020151 0.4 (0.016)

803020152 1.1 (0.043)

803020153 1.5 (0.059)

803020154 1.9 (0.075)

803020155 2.3 (0.091)

MT-00305

A

MT-00306