sensor SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2622 of 2870

4AT(H4DOTC)-46

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

C: DTC P0713 TRANSMISSION FLUID TEMPERATURE SENSOR CIRCUIT HIGH

INPUT

DTC DETECTING CONDITION:

Input signal circuit of TCM to ATF temperature sensor is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock.

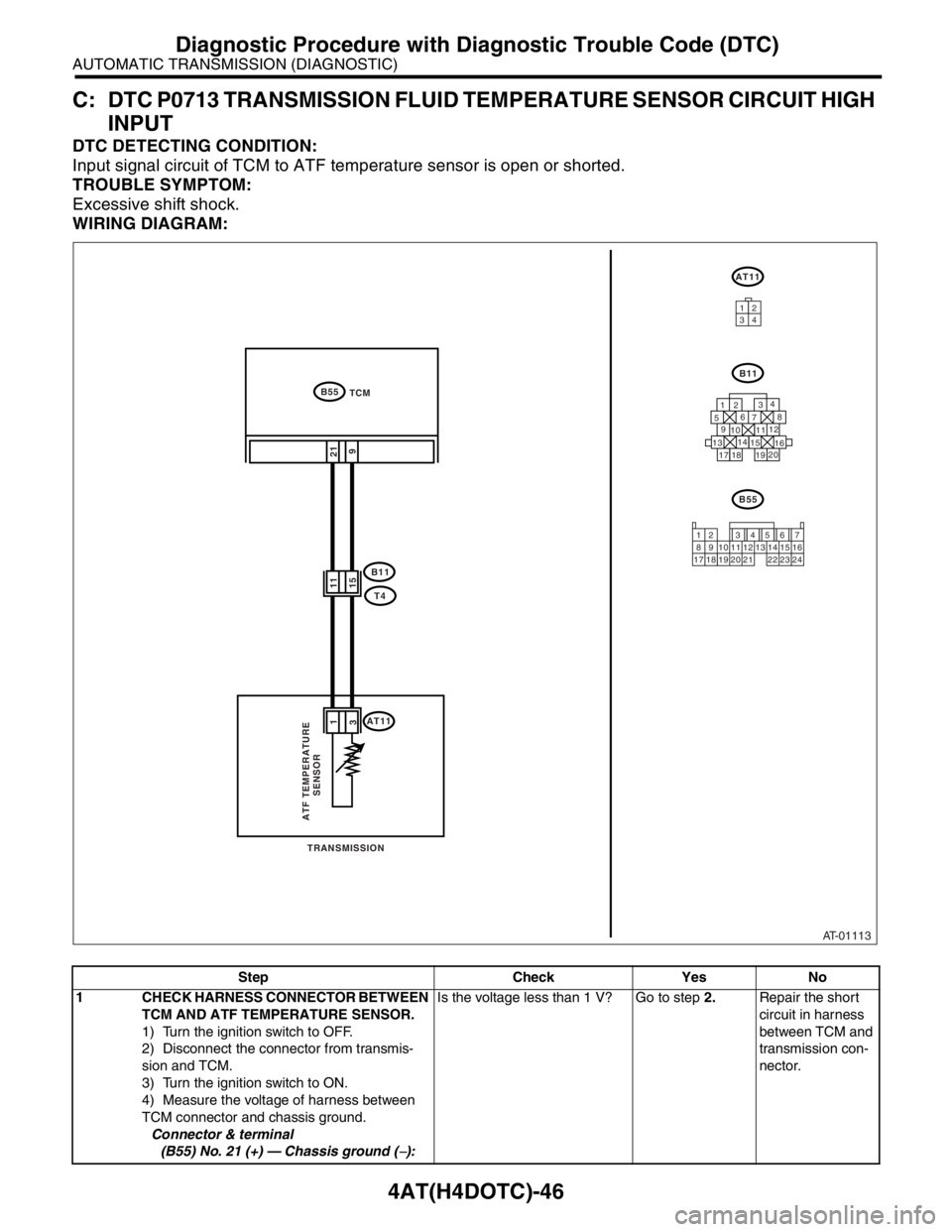

WIRING DIAGRAM:

Step Check Yes No

1 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ATF TEMPERATURE SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion and TCM.

3) Turn the ignition switch to ON.

4) Measure the voltage of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 21 (+) — Chassis ground (

−):Is the voltage less than 1 V? Go to step 2.Repair the short

circuit in harness

between TCM and

transmission con-

nector.

AT-01113

B11

B55

AT11

1

234

56

78

9

1314

15

20

19 1716 10 1112

1821

9

15 11 1

3

B55

B11

AT11

T4 TCM

3412

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

ATF TEMPERATURE

SENSOR

TRANSMISSION

Page 2623 of 2870

4AT(H4DOTC)-47

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ATF TEMPERATURE SENSOR.

Measure the voltage of harness between TCM

connector and chassis ground.

Connector & terminal

(B55) No. 9 (+) — Chassis ground (

−):Is the voltage less than 1 V? Go to step 3.Repair the short

circuit in harness

between TCM and

transmission con-

nector.

3 CHECK ATF TEMPERATURE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect the connectors to transmission

and TCM.

3) Turn the ignition switch to ON and start

engine.

4) Warm-up the transmission until ATF tem-

perature reaches to 80°C (176°F).

N

OTE:

If ambient temperature is below 0°C (32°F),

drive the vehicle until ATF reaches its operating

temperature.

5) Disconnect the connector from transmis-

sion.

6) Measure the resistance between transmis-

sion connector terminals.

Connector & terminal

(T4) No. 11 — No. 15:Is the resistance 500 — 600

Ω?Go to step 4.Replace ATF tem-

perature sensor.

Body.>

4 CHECK ATF TEMPERATURE SENSOR.

Measure the resistance between transmission

connector terminals.

Connector & terminal

(T4) No. 11 — No. 15:Does the resistance value

increase when ATF tempera-

ture decreases? Go to step 5.Replace ATF tem-

perature sensor.

Body.>

5 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 7.Go to step 6.

6 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connector to transmission.

2) Warm-up the transmission until ATF tem-

perature is about 80°C (176°F).

N

OTE:

If ambient temperature is below 0°C (32°F),

drive the vehicle until ATF reaches its operating

temperature.

3) Measure the voltage between TCM con-

nector terminal.

Connector & terminal

(B55) No. 9 (+) — No. 21 (

−):Is the voltage 1.5 — 1.9 V? Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. Tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or contact

in ATF temperature

sensor and trans-

mission connector.Go to step 8.

7 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connector to transmission.

2) Turn the ignition switch to ON (engine

OFF).

3) Read the data of ATF temperature using

the Subaru Select Monitor.

Select Monitor.>Does the ATF temperature

gradually decrease?Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. Tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or contact

in ATF temperature

sensor and trans-

mission connector.Go to step 8. Step Check Yes No

Page 2624 of 2870

4AT(H4DOTC)-48

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

8 CHECK POOR CONTACT.Is there poor contact in ATF

temperature sensor circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2625 of 2870

4AT(H4DOTC)-49

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

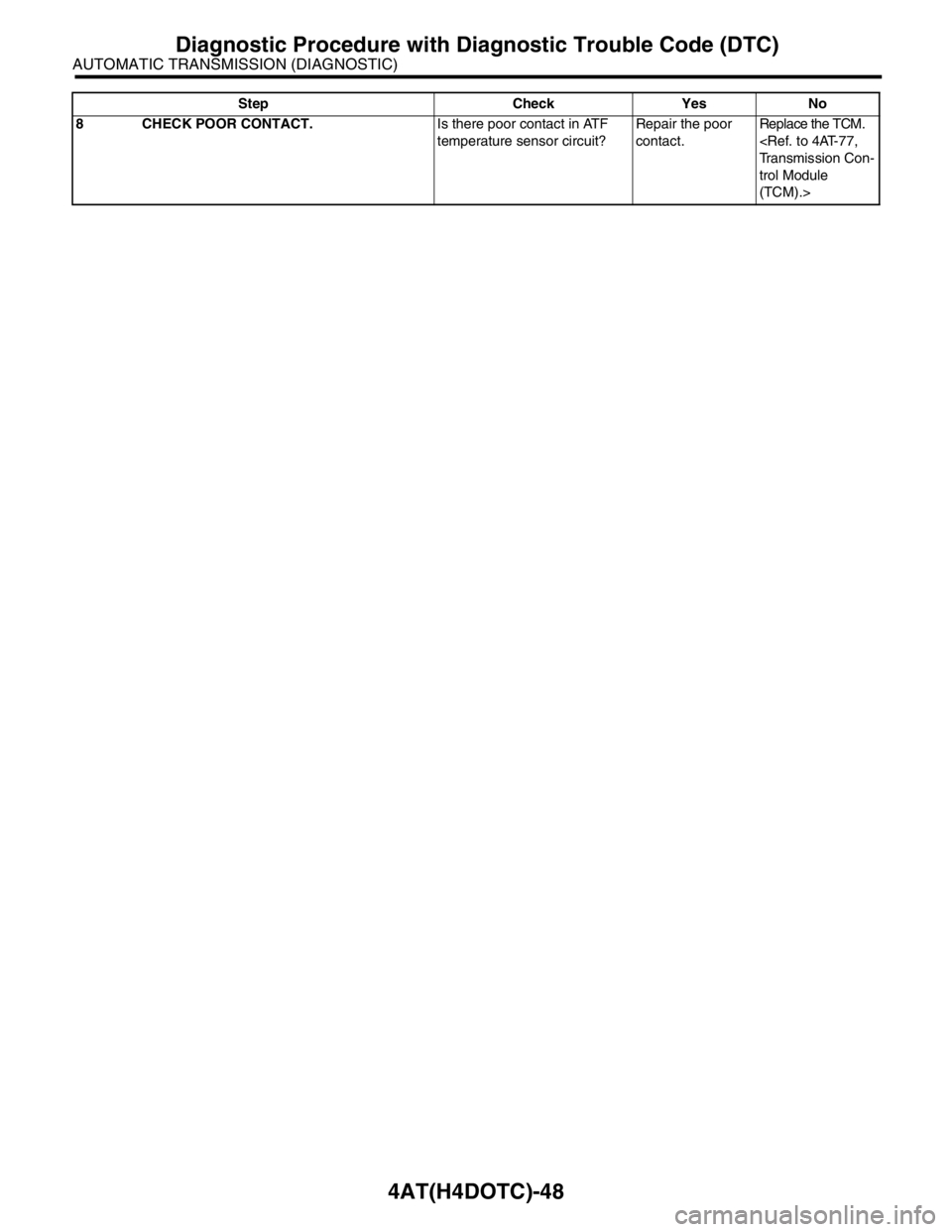

D: DTC P0715 INPUT/TURBINE SPEED SENSOR CIRCUIT

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmission.

3) Measure the resistance between transmis-

sion connector receptacle’s terminals.

Connector & terminal

(T4) No. 5 — No. 10:Is the resistance 450 — 650

Ω?Go to step 2.Replace the torque

converter turbine

speed sensor.

Turbine Speed

Sensor.>

AT-01843

5

10B11

T4

TCMB55

7

16

B11

1

234

56

78

9

1314

15

20

19 1716 10 1112

18

B55

TORQUE

CONVERTER

TURBINE SPEED

SENSOR

B299SHIELD

JOINT

CONNECTOR

612

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

B299

12345678

Page 2627 of 2870

4AT(H4DOTC)-51

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

10 CHECK INPUT SIGNAL FOR TCM USING

OSCILLOSCOPE.

1) Connect the connectors to TCM and trans-

mission.

2) Set the oscilloscope to TCM connector ter-

minals.

Connector & terminal

Positive probe; (B55) No. 7:

Earth lead; (B55) No. 16:

3) Start the engine and move select lever to

“P” or “N” range.Is the voltage more than AC 1

V?Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in TCM and

transmission.Go to step 11.

11 CHECK POOR CONTACT.Is there poor contact in torque

converter turbine speed sensor

circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2630 of 2870

4AT(H4DOTC)-54

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

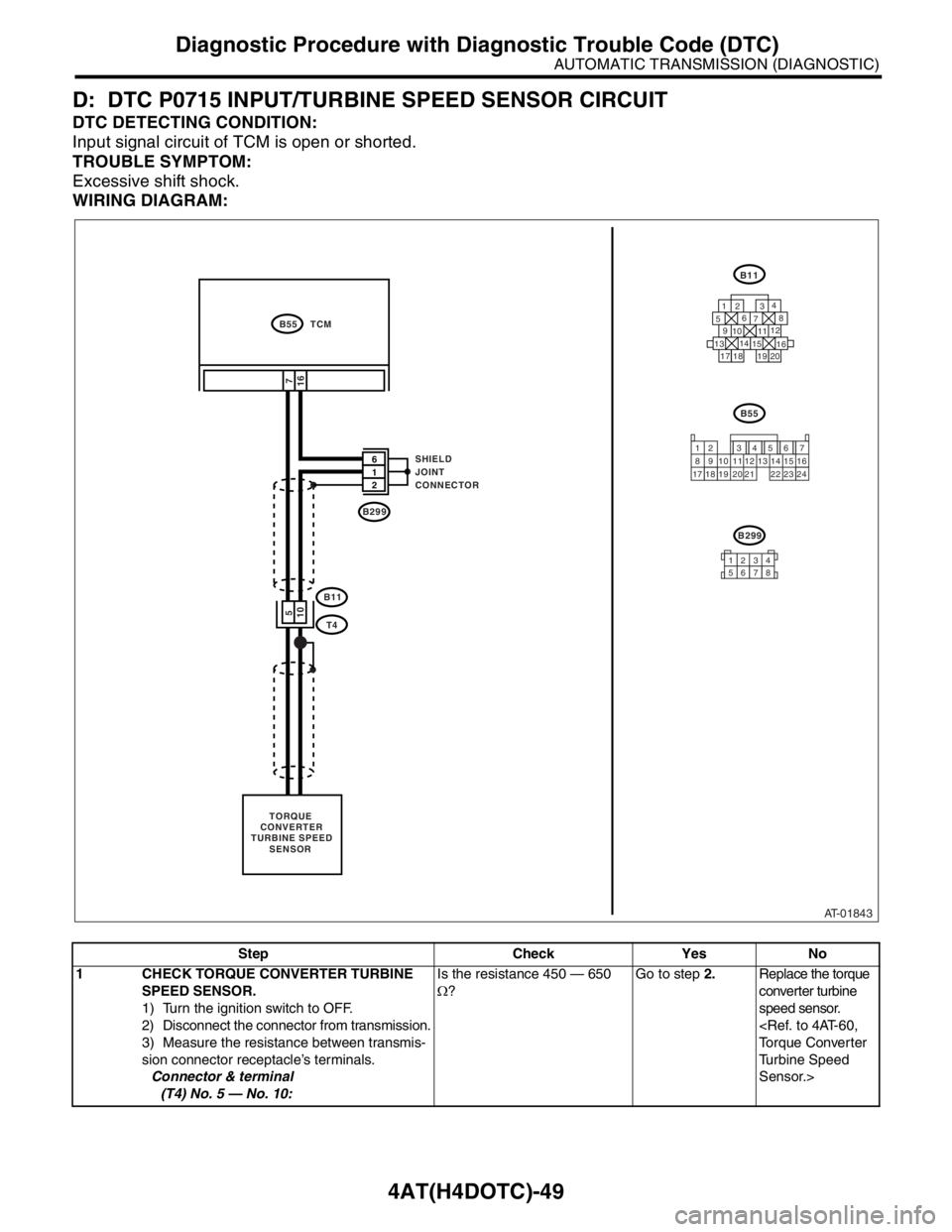

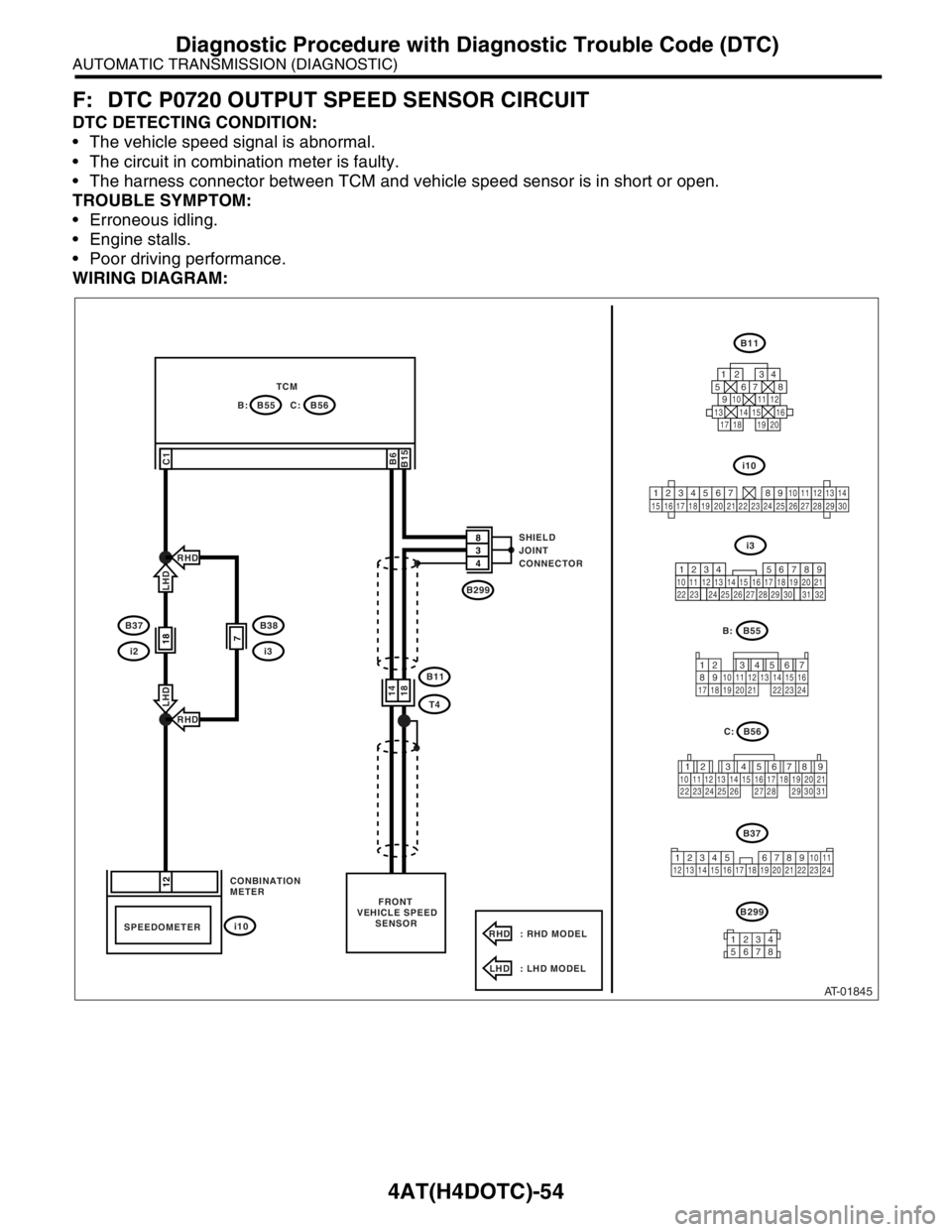

F: DTC P0720 OUTPUT SPEED SENSOR CIRCUIT

DTC DETECTING CONDITION:

The vehicle speed signal is abnormal.

The circuit in combination meter is faulty.

The harness connector between TCM and vehicle speed sensor is in short or open.

TROUBLE SYMPTOM:

Erroneous idling.

Engine stalls.

Poor driving performance.

WIRING DIAGRAM:

AT-01845

18 14

B11

B299

T4

B6

B15C1

B11

12 34

5678

9

13 14 15

20 19 1716 10 11 1218

i10

B37

i2

B38

i3

TCM

B55 B:

B56 C:

18

12

1234567813 14 15 16 17 18 1911 101225 26 27 28 29 30 31

921203223 2224

i3

B56

12 78 956 34

10 11 12 19 20 21

29 30 31 13 14 15 16 17

27 2818

22 23 24 25 26

C:

FRONT

VEHICLE SPEED

SENSOR CONBINATION

METER

SPEEDOMETER

: RHD MODEL SHIELD

JOINT

CONNECTOR

LHD

RHD

RHD

: LHD MODEL

LHD RHD

7

834

LHD

i10

123456789101112131415161718192021222324252627282930

B:B55

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

B37

34 12 89

10 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

B299

12345678

Page 2631 of 2870

4AT(H4DOTC)-55

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM and

transmission.

3) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B55) No. 6 — (B11) No. 14:Is the resistance less than 1

Ω?Go to step 2.Repair the open

circuit in harness

between TCM and

transmission con-

nector.

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM and transmission connector.

Connector & terminal

(B55) No. 15 — (B11) No. 18:Is the resistance less than 1

Ω?Go to step 3.Repair the open

circuit in harness

between TCM and

transmission con-

nector, and poor

contact in cou-

pling connector.

3 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM and transmission connector.

Connector & terminal

(B55) No. 6 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 4.Repair the short

circuit in harness

between TCM and

transmission con-

nector.

4 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM and transmission connector.

Connector & terminal

(B55) No. 15 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair the short

circuit in harness

between TCM and

transmission con-

nector, and poor

contact in cou-

pling connector.

5 CHECK FRONT VEHICLE SPEED SENSOR.

Measure the resistance between transmission

connector receptacle’s terminals.

Connector & terminal

(T4) No. 14 — No. 18:Is the resistance 450 — 650

Ω?Go to step 6.Replace the front

vehicle speed sen-

sor.

Speed Sensor.>

6 PREPARE OSCILLOSCOPE.Do you have an oscilloscope? Go to step 9.Go to step 7.

7 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 10.Go to step 8.

8 CHECK INPUT SIGNAL FOR TCM.

1) Connect all connectors.

2) Lift-up the vehicle and place rigid racks.

N

OTE:

Raise all wheels off floor.

3) Start the engine and set vehicle in 20 km/h

(12 MPH) condition.

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control diag-

nosis is finished, perform the ABS memory clear-

ance procedure of on-board diagnostics system.

4) Measure the voltage between TCM con-

nector terminals.

Connector & terminal

(B55) No. 6 (+) — No. 15 (

−):Is the voltage more than AC 1

V?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

or harness may be

the cause. Repair

the harness or

connector in the

front vehicle speed

sensor circuit.Go to step 11.

Page 2632 of 2870

4AT(H4DOTC)-56

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

9 CHECK FRONT VEHICLE SPEED SENSOR

USING OSCILLOSCOPE.

1) Connect all connectors.

2) Lift-up the vehicle and place rigid racks.

N

OTE:

Raise all wheels off ground.

3) Set the oscilloscope to TCM connector ter-

minals.

Connector & terminal

Positive probe; (B55) No. 6:

Earth lead; (B55) No. 15:

4) Start the engine, and drive the wheels

slowly.

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunctions. When AT control di-

agnosis is finished, perform the ABS memory

clearance procedure of on-board diagnostic sys-

tem.

5) Measure the signal voltage indicated on

oscilloscope.Is the voltage more than AC 4

V?Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact or

harness may be the

cause. Repair the

harness or connec-

tor in front vehicle

speed sensor cir-

cuit.Go to step 11.

10 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all connectors.

2) Connect the Subaru Select Monitor to data

link connector.

3) Lift-up the vehicle and place rigid racks.

N

OTE:

Raise all wheels off floor.

4) Turn the ignition switch to ON and turn Sub-

aru Select Monitor switch to ON.

5) Start the engine.

6) Read the data of vehicle speed using Sub-

aru Select Monitor.

Compare the speedometer with Subaru

Select Monitor indications.

Vehicle speed is indicated in “km/h” or

“MPH”.

7) Slowly increase the vehicle speed to 60 km/

h (37 MPH).

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control diag-

nosis is finished, perform the ABS memory clear-

ance procedure of on-board diagnostics system.

tion increase as Subaru Select

Monitor data increases?Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor connec-

tor or harness may

be the cause.

Repair the harness

or connector in

front vehicle speed

sensor circuit.Go to step 11.

11 CHECK POOR CONTACT.Is there poor contact in front

vehicle speed sensor circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2638 of 2870

4AT(H4DOTC)-62

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

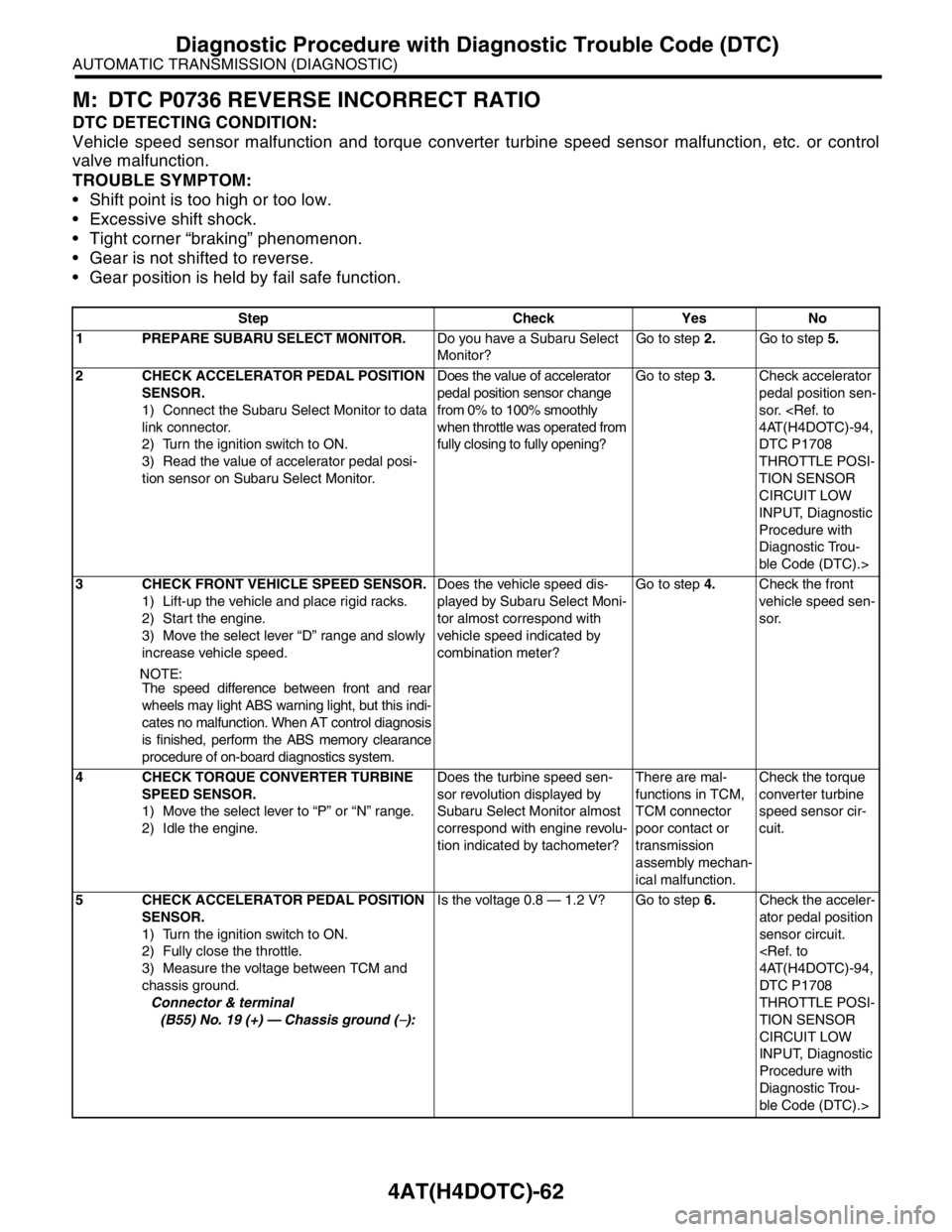

M: DTC P0736 REVERSE INCORRECT RATIO

DTC DETECTING CONDITION:

Vehicle speed sensor malfunction and torque converter turbine speed sensor malfunction, etc. or control

valve malfunction.

TROUBLE SYMPTOM:

Shift point is too high or too low.

Excessive shift shock.

Tight corner “braking” phenomenon.

Gear is not shifted to reverse.

Gear position is held by fail safe function.

Step Check Yes No

1 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 2.Go to step 5.

2 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch to ON.

3) Read the value of accelerator pedal posi-

tion sensor on Subaru Select Monitor.Does the value of accelerator

pedal position sensor change

from 0% to 100% smoothly

when throttle was operated from

fully closing to fully opening?Go to step 3.Check accelerator

pedal position sen-

sor.

DTC P1708

THROTTLE POSI-

TION SENSOR

CIRCUIT LOW

INPUT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

3 CHECK FRONT VEHICLE SPEED SENSOR.

1) Lift-up the vehicle and place rigid racks.

2) Start the engine.

3) Move the select lever “D” range and slowly

increase vehicle speed.

NOTE:

The speed difference between front and rear

wheels may light ABS warning light, but this indi-

cates no malfunction. When AT control diagnosis

is finished, perform the ABS memory clearance

procedure of on-board diagnostics system.Does the vehicle speed dis-

played by Subaru Select Moni-

tor almost correspond with

vehicle speed indicated by

combination meter?Go to step 4.Check the front

vehicle speed sen-

sor.

4 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Move the select lever to “P” or “N” range.

2) Idle the engine.Does the turbine speed sen-

sor revolution displayed by

Subaru Select Monitor almost

correspond with engine revolu-

tion indicated by tachometer?There are mal-

functions in TCM,

TCM connector

poor contact or

transmission

assembly mechan-

ical malfunction.Check the torque

converter turbine

speed sensor cir-

cuit.

5 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Turn the ignition switch to ON.

2) Fully close the throttle.

3) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage 0.8 — 1.2 V? Go to step 6.Check the acceler-

ator pedal position

sensor circuit.

DTC P1708

THROTTLE POSI-

TION SENSOR

CIRCUIT LOW

INPUT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

Page 2639 of 2870

4AT(H4DOTC)-63

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

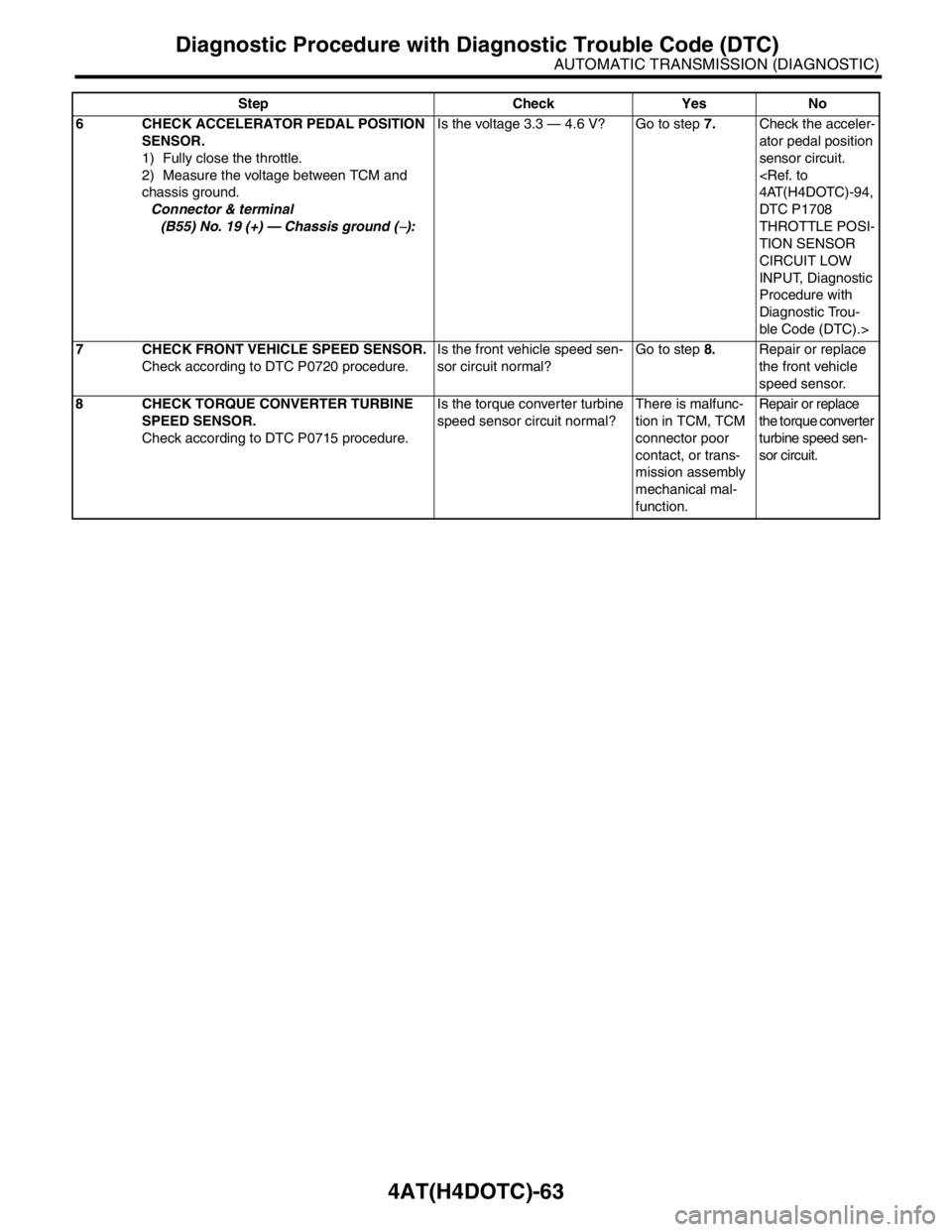

6 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Fully close the throttle.

2) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage 3.3 — 4.6 V? Go to step 7.Check the acceler-

ator pedal position

sensor circuit.

DTC P1708

THROTTLE POSI-

TION SENSOR

CIRCUIT LOW

INPUT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

7 CHECK FRONT VEHICLE SPEED SENSOR.

Check according to DTC P0720 procedure.Is the front vehicle speed sen-

sor circuit normal?Go to step 8.Repair or replace

the front vehicle

speed sensor.

8 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

Check according to DTC P0715 procedure.Is the torque converter turbine

speed sensor circuit normal?There is malfunc-

tion in TCM, TCM

connector poor

contact, or trans-

mission assembly

mechanical mal-

function.Repair or replace

the torque converter

turbine speed sen-

sor circuit. Step Check Yes No