sensor SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2640 of 2870

4AT(H4DOTC)-64

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

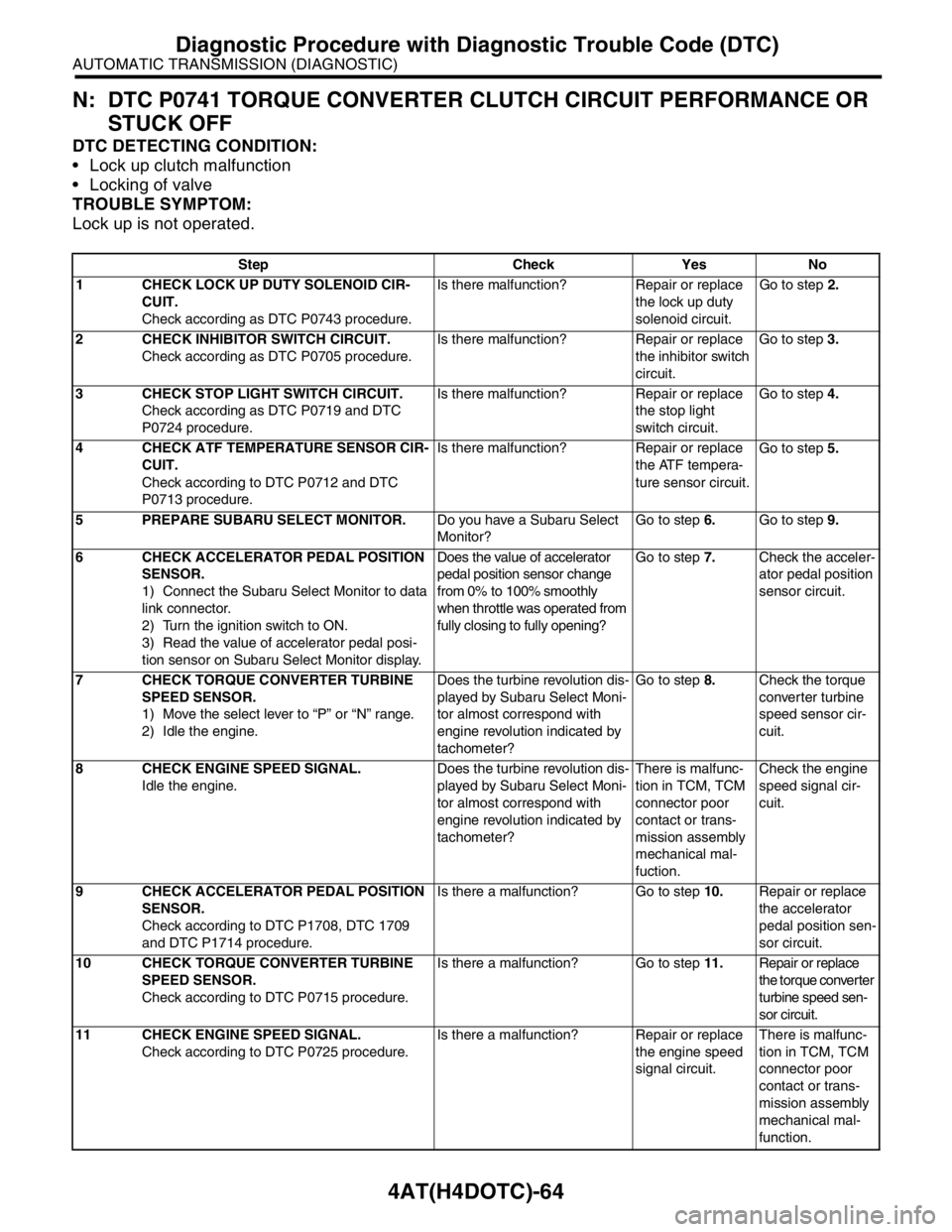

N: DTC P0741 TORQUE CONVERTER CLUTCH CIRCUIT PERFORMANCE OR

STUCK OFF

DTC DETECTING CONDITION:

Lock up clutch malfunction

Locking of valve

TROUBLE SYMPTOM:

Lock up is not operated.

Step Check Yes No

1 CHECK LOCK UP DUTY SOLENOID CIR-

CUIT.

Check according as DTC P0743 procedure.Is there malfunction? Repair or replace

the lock up duty

solenoid circuit.Go to step 2.

2 CHECK INHIBITOR SWITCH CIRCUIT.

Check according as DTC P0705 procedure.Is there malfunction? Repair or replace

the inhibitor switch

circuit.Go to step 3.

3 CHECK STOP LIGHT SWITCH CIRCUIT.

Check according as DTC P0719 and DTC

P0724 procedure.Is there malfunction? Repair or replace

the stop light

switch circuit.Go to step 4.

4 CHECK ATF TEMPERATURE SENSOR CIR-

CUIT.

Check according to DTC P0712 and DTC

P0713 procedure.Is there malfunction? Repair or replace

the ATF tempera-

ture sensor circuit.Go to step 5.

5 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 6.Go to step 9.

6 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch to ON.

3) Read the value of accelerator pedal posi-

tion sensor on Subaru Select Monitor display.Does the value of accelerator

pedal position sensor change

from 0% to 100% smoothly

when throttle was operated from

fully closing to fully opening?Go to step 7.Check the acceler-

ator pedal position

sensor circuit.

7 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Move the select lever to “P” or “N” range.

2) Idle the engine.Does the turbine revolution dis-

played by Subaru Select Moni-

tor almost correspond with

engine revolution indicated by

tachometer?Go to step 8.Check the torque

converter turbine

speed sensor cir-

cuit.

8 CHECK ENGINE SPEED SIGNAL.

Idle the engine.Does the turbine revolution dis-

played by Subaru Select Moni-

tor almost correspond with

engine revolution indicated by

tachometer?There is malfunc-

tion in TCM, TCM

connector poor

contact or trans-

mission assembly

mechanical mal-

fuction.Check the engine

speed signal cir-

cuit.

9 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Check according to DTC P1708, DTC 1709

and DTC P1714 procedure.Is there a malfunction? Go to step 10.Repair or replace

the accelerator

pedal position sen-

sor circuit.

10 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

Check according to DTC P0715 procedure.Is there a malfunction? Go to step 11.Repair or replace

the torque converter

turbine speed sen-

sor circuit.

11 CHECK ENGINE SPEED SIGNAL.

Check according to DTC P0725 procedure.Is there a malfunction? Repair or replace

the engine speed

signal circuit. There is malfunc-

tion in TCM, TCM

connector poor

contact or trans-

mission assembly

mechanical mal-

function.

Page 2664 of 2870

4AT(H4DOTC)-88

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

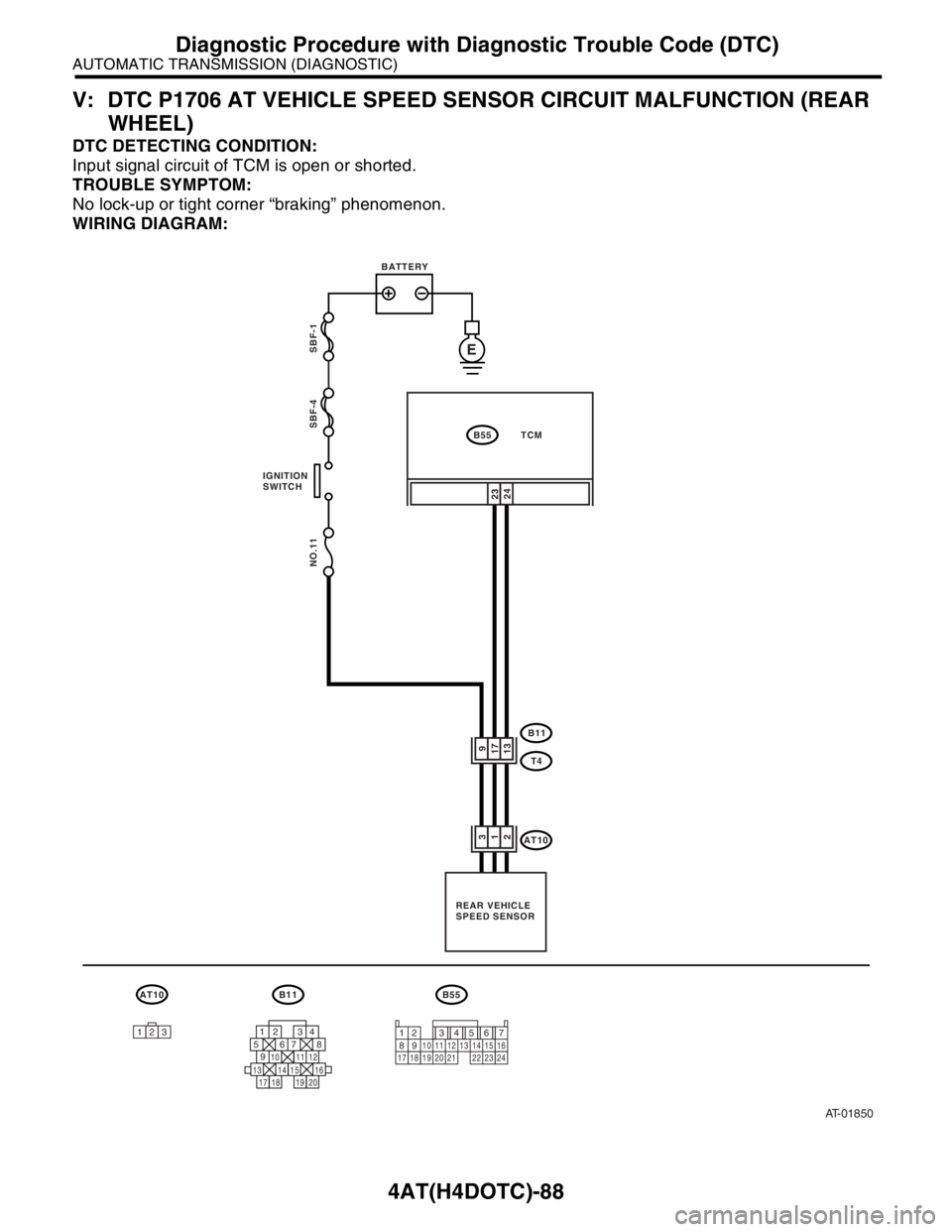

V: DTC P1706 AT VEHICLE SPEED SENSOR CIRCUIT MALFUNCTION (REAR

WHEEL)

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

No lock-up or tight corner “braking” phenomenon.

WIRING DIAGRAM:

AT-01850

2324

B11

AT10

T491713

312

B55 TCM BATTERY

IGNITION

SWITCH

REAR VEHICLE

SPEED SENSOR

ESBF-1

SBF-4 NO.11

123

AT10B11

12 34

5678

9

13 14 15

20 19 1716 10 11 1218

B55

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

Page 2665 of 2870

4AT(H4DOTC)-89

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

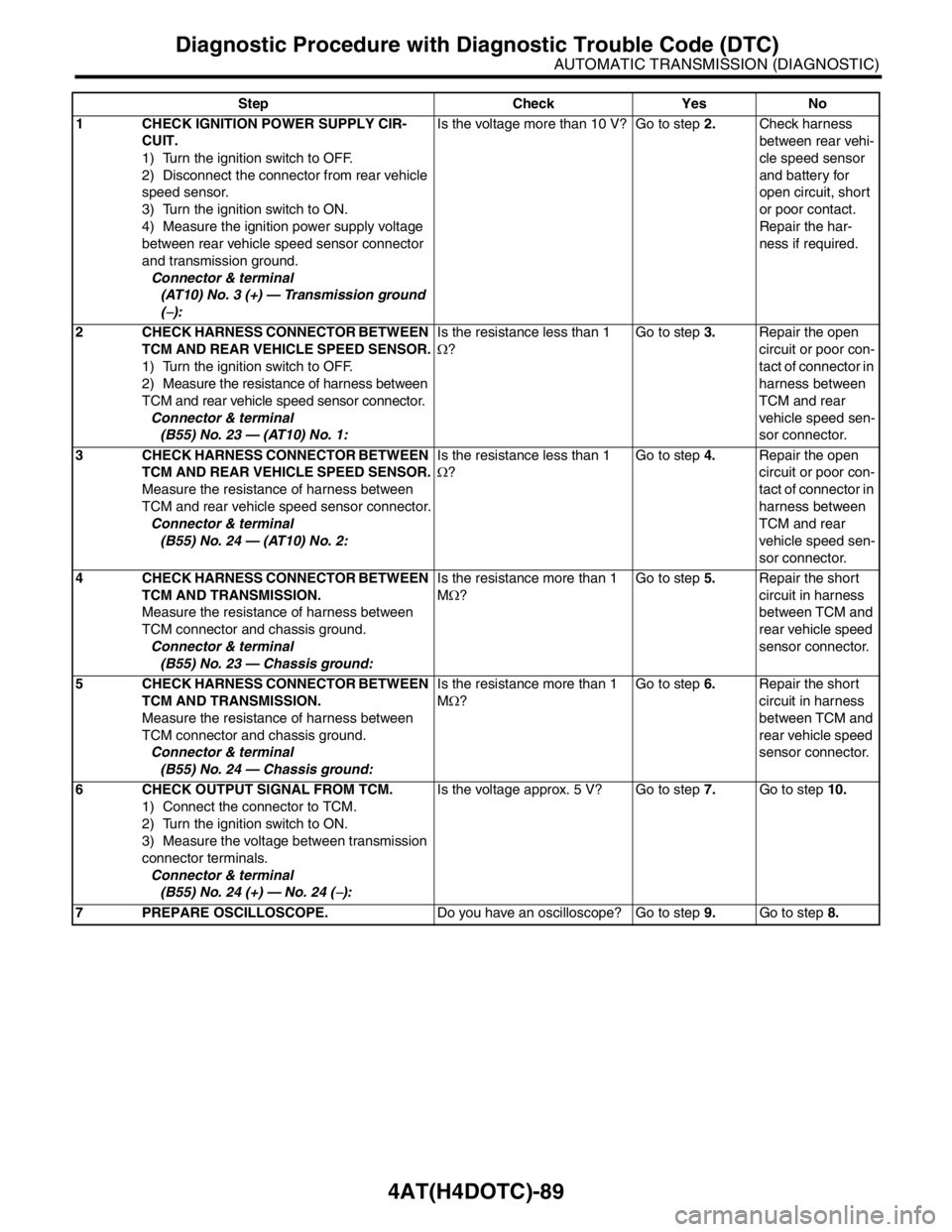

Step Check Yes No

1 CHECK IGNITION POWER SUPPLY CIR-

CUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear vehicle

speed sensor.

3) Turn the ignition switch to ON.

4) Measure the ignition power supply voltage

between rear vehicle speed sensor connector

and transmission ground.

Connector & terminal

(AT10) No. 3 (+) — Transmission ground

(

−):Is the voltage more than 10 V? Go to step 2.Check harness

between rear vehi-

cle speed sensor

and battery for

open circuit, short

or poor contact.

Repair the har-

ness if required.

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND REAR VEHICLE SPEED SENSOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness between

TCM and rear vehicle speed sensor connector.

Connector & terminal

(B55) No. 23 — (AT10) No. 1:Is the resistance less than 1

Ω?Go to step 3.Repair the open

circuit or poor con-

tact of connector in

harness between

TCM and rear

vehicle speed sen-

sor connector.

3 CHECK HARNESS CONNECTOR BETWEEN

TCM AND REAR VEHICLE SPEED SENSOR.

Measure the resistance of harness between

TCM and rear vehicle speed sensor connector.

Connector & terminal

(B55) No. 24 — (AT10) No. 2:Is the resistance less than 1

Ω?Go to step 4.Repair the open

circuit or poor con-

tact of connector in

harness between

TCM and rear

vehicle speed sen-

sor connector.

4 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 23 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair the short

circuit in harness

between TCM and

rear vehicle speed

sensor connector.

5 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 24 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 6.Repair the short

circuit in harness

between TCM and

rear vehicle speed

sensor connector.

6 CHECK OUTPUT SIGNAL FROM TCM.

1) Connect the connector to TCM.

2) Turn the ignition switch to ON.

3) Measure the voltage between transmission

connector terminals.

Connector & terminal

(B55) No. 24 (+) — No. 24 (

−):Is the voltage approx. 5 V? Go to step 7.Go to step 10.

7 PREPARE OSCILLOSCOPE.Do you have an oscilloscope? Go to step 9.Go to step 8.

Page 2666 of 2870

4AT(H4DOTC)-90

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

8 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM and trans-

mission.

2) Lift-up the vehicle and place rigid racks.

N

OTE:

Raise all wheels off ground.

3) Start the engine and set vehicle in 20 km/h

(12 MPH) condition.

N

OTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control diag-

nosis is finished, perform the ABS memory

clearance procedure of on-board diagnostics

system.

4) Measure the AC voltage between TCM

connector terminals.

Connector & terminal

(B55) No. 24 (+) — No. 23 (

−):Is the voltage more than AC 2

V?Go to step 10.Replace the rear

vehicle speed sen-

sor.

9 CHECK INPUT SIGNAL FOR TCM USING

OSCILLOSCOPE.

1) Connect the connectors to TCM and trans-

mission.

2) Lift-up the vehicle and place rigid racks.

NOTE:

Raise all wheels off ground.

3) Set the oscilloscope to TCM connector ter-

minals.

Connector & terminal

Positive probe; (B55) No. 24:

Earth lead; (B55) No. 23:

4) Start the engine and set vehicle in 20 km/h

(12 MPH) condition.

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control diag-

nosis is finished, perform the ABS memory

clearance procedure of on-board diagnostics

system.

5) Measure the signal voltage indicated on

oscilloscope.Is the voltage more than AC 2

V?Go to step 10.Replace the rear

vehicle speed sen-

sor.

10 CHECK POOR CONTACT.Is there poor contact in rear

vehicle speed sensor circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2670 of 2870

4AT(H4DOTC)-94

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

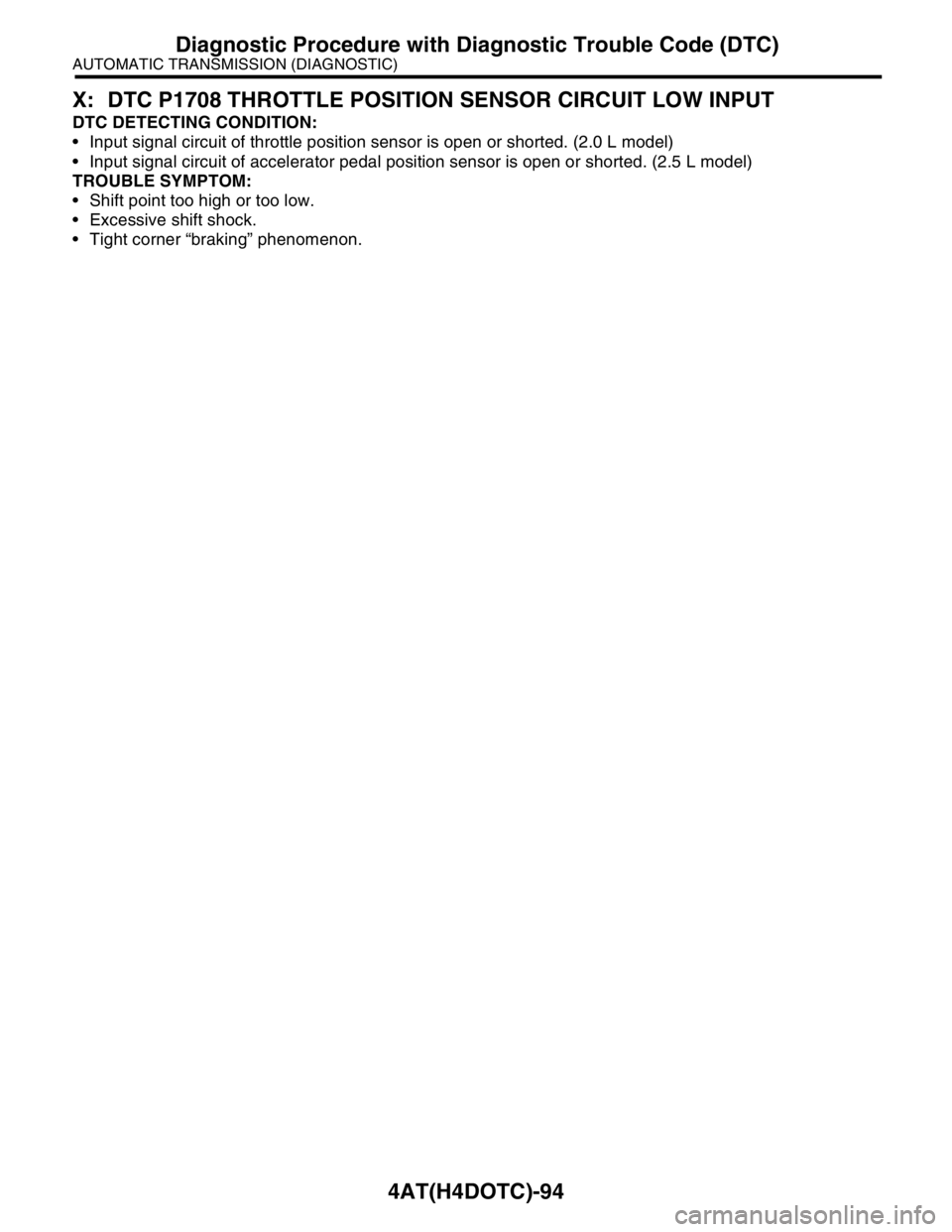

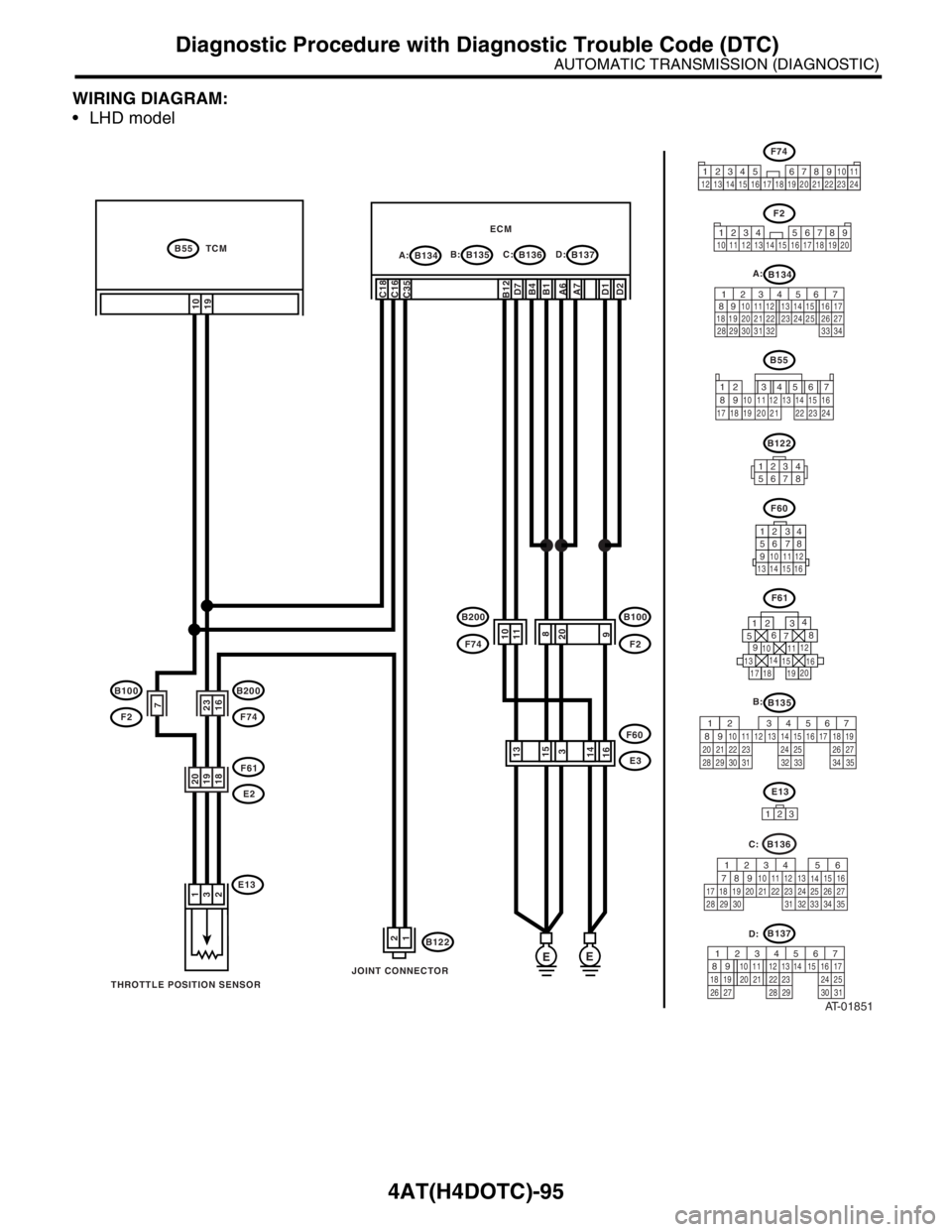

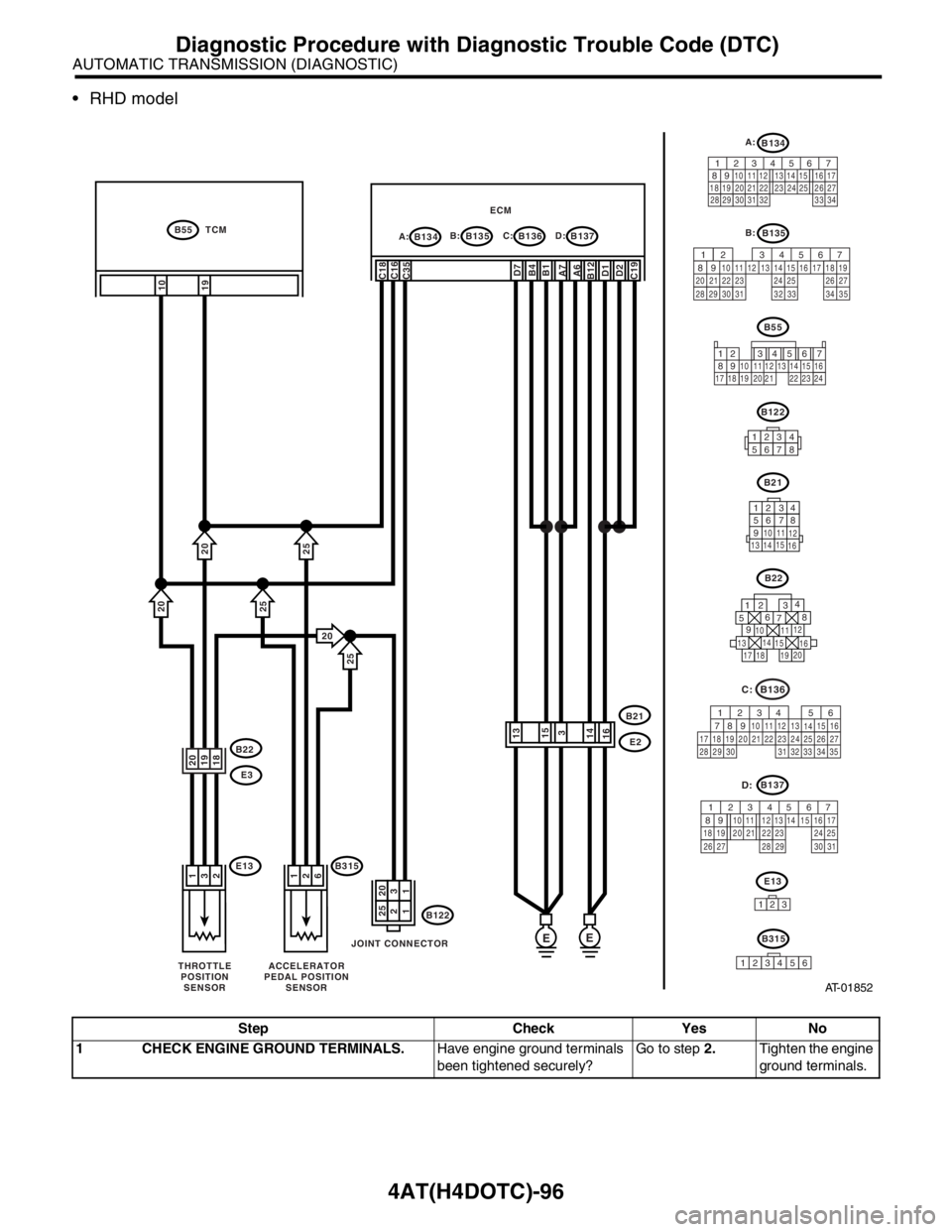

X: DTC P1708 THROTTLE POSITION SENSOR CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

Input signal circuit of throttle position sensor is open or shorted. (2.0 L model)

Input signal circuit of accelerator pedal position sensor is open or shorted. (2.5 L model)

TROUBLE SYMPTOM:

Shift point too high or too low.

Excessive shift shock.

Tight corner “braking” phenomenon.

Page 2671 of 2870

4AT(H4DOTC)-95

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

WIRING DIAGRAM:

LHD model

AT-01851

E13

B122

F60

B134B55 TCM

A:B135 B:ECMB136 C:B137 D:

E3

B100

F2

B200

F74

F61

E2

B200

F74

B100

F2F60

13 14 15 16

12 34

56 78

9

10 11 12

13161415

3

111098

20

1

3

210

19

C18

C16

C35D2D1 D7

B4B12A7 A6B1

EE

12

20

19

18

7

23

16

F61

1

234

56

78

9

1314

15

20

19 1716 10 111218

JOINT CONNECTOR

THROTTLE POSITION SENSOR

F74

34 12 89

10 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

F2

1234 56789

10 11 12 13 14 15 16 17 18 19 20

B134 A:

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

B55

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

B122

12345678

B136

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

C:

B137

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

D:

123

E13

B135 B:

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

Page 2672 of 2870

4AT(H4DOTC)-96

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

RHD model

Step Check Yes No

1 CHECK ENGINE GROUND TERMINALS.Have engine ground terminals

been tightened securely?Go to step 2.Tighten the engine

ground terminals.

AT-01852

B55

12 7

8956 34

10 11 12

19 20 2113 14 15 16

17 18 22 23 24

E13

B122

B21

B134B55 TCM

A:B135 B:B137 D: ECMB136 C:

E2B22

E3

B21

13 1415

16

12 34

56 78

9

10

11

12

13161415

3

1

3

210

19

C18

C16

C35D2D1D7

B12B4C19A6 A7B1

EE

1225

1320

20

19

18

B22

1

234

56

78

9

1314

15

20

19 1716 10 111218

JOINT CONNECTOR

THROTTLE

POSITION

SENSOR

B3151

2

6

ACCELERATOR

PEDAL POSITION

SENSOR

123

E13

20

20

20

25

25

25

B315

1

23456

B136

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

C:

B137

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

D:

B122

12345678

B135 B:

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B134 A:

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

Page 2673 of 2870

4AT(H4DOTC)-97

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

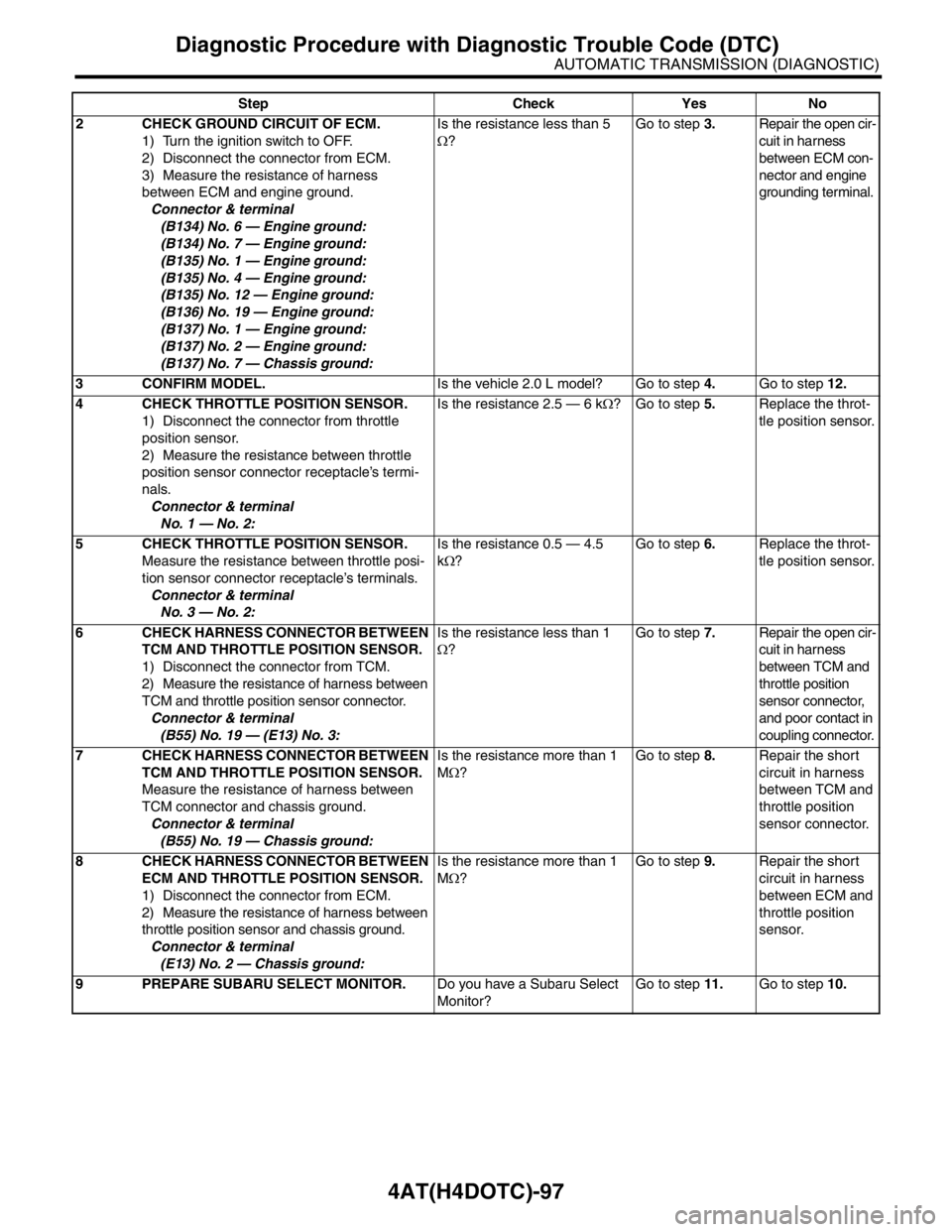

2 CHECK GROUND CIRCUIT OF ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness

between ECM and engine ground.

Connector & terminal

(B134) No. 6 — Engine ground:

(B134) No. 7 — Engine ground:

(B135) No. 1 — Engine ground:

(B135) No. 4 — Engine ground:

(B135) No. 12 — Engine ground:

(B136) No. 19 — Engine ground:

(B137) No. 1 — Engine ground:

(B137) No. 2 — Engine ground:

(B137) No. 7 — Chassis ground:Is the resistance less than 5

Ω?Go to step 3.Repair the open cir-

cuit in harness

between ECM con-

nector and engine

grounding terminal.

3 CONFIRM MODEL.Is the vehicle 2.0 L model? Go to step 4.Go to step 12.

4 CHECK THROTTLE POSITION SENSOR.

1) Disconnect the connector from throttle

position sensor.

2) Measure the resistance between throttle

position sensor connector receptacle’s termi-

nals.

Connector & terminal

No. 1 — No. 2:Is the resistance 2.5 — 6 kΩ? Go to step 5.Replace the throt-

tle position sensor.

5 CHECK THROTTLE POSITION SENSOR.

Measure the resistance between throttle posi-

tion sensor connector receptacle’s terminals.

Connector & terminal

No. 3 — No. 2:Is the resistance 0.5 — 4.5

kΩ?Go to step 6.Replace the throt-

tle position sensor.

6 CHECK HARNESS CONNECTOR BETWEEN

TCM AND THROTTLE POSITION SENSOR.

1) Disconnect the connector from TCM.

2) Measure the resistance of harness between

TCM and throttle position sensor connector.

Connector & terminal

(B55) No. 19 — (E13) No. 3:Is the resistance less than 1

Ω?Go to step 7.Repair the open cir-

cuit in harness

between TCM and

throttle position

sensor connector,

and poor contact in

coupling connector.

7 CHECK HARNESS CONNECTOR BETWEEN

TCM AND THROTTLE POSITION SENSOR.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 19 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 8.Repair the short

circuit in harness

between TCM and

throttle position

sensor connector.

8 CHECK HARNESS CONNECTOR BETWEEN

ECM AND THROTTLE POSITION SENSOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness between

throttle position sensor and chassis ground.

Connector & terminal

(E13) No. 2 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 9.Repair the short

circuit in harness

between ECM and

throttle position

sensor.

9 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 11.Go to step 10. Step Check Yes No

Page 2674 of 2870

4AT(H4DOTC)-98

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

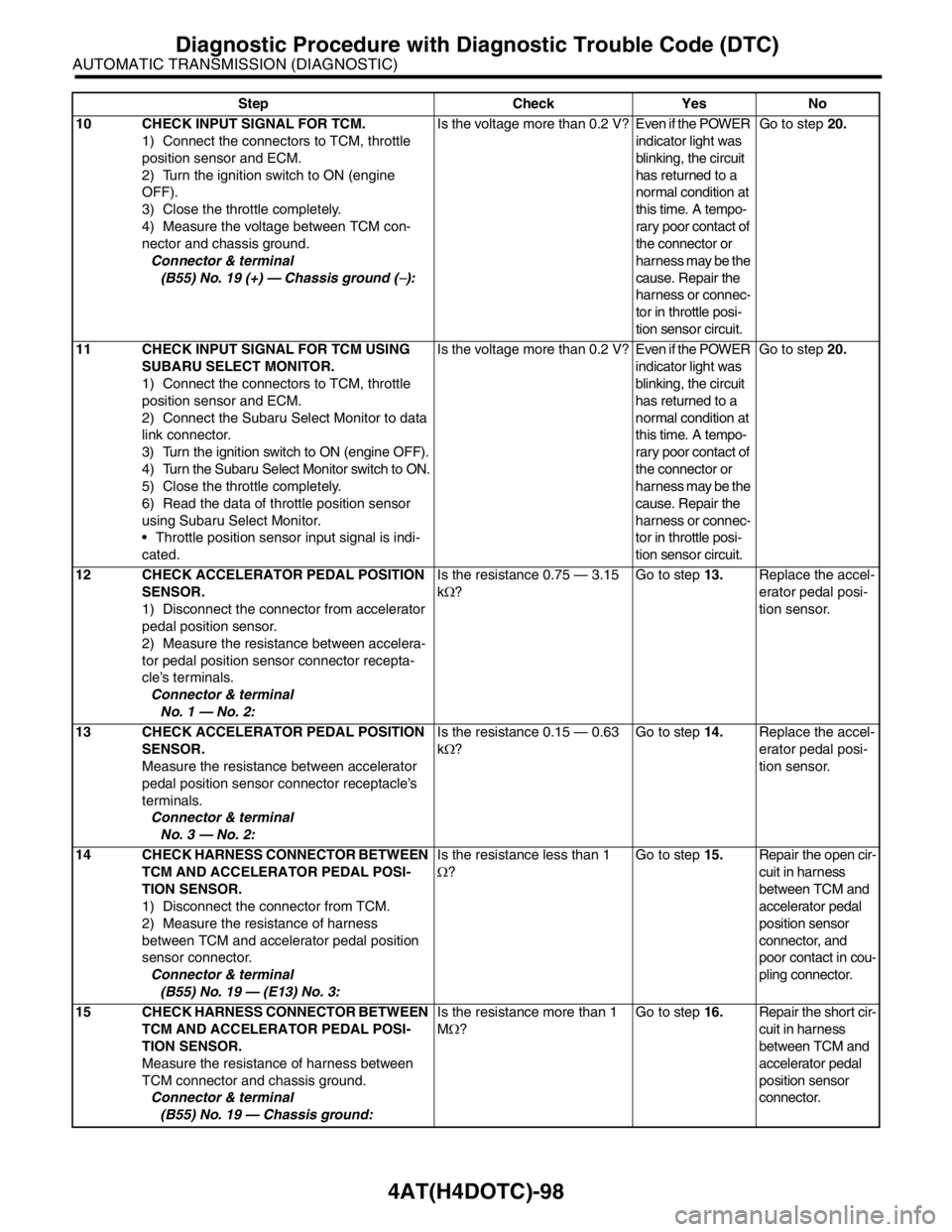

10 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM, throttle

position sensor and ECM.

2) Turn the ignition switch to ON (engine

OFF).

3) Close the throttle completely.

4) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage more than 0.2 V? Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in throttle posi-

tion sensor circuit.Go to step 20.

11 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM, throttle

position sensor and ECM.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON (engine OFF).

4) Turn the Subaru Select Monitor switch to ON.

5) Close the throttle completely.

6) Read the data of throttle position sensor

using Subaru Select Monitor.

Throttle position sensor input signal is indi-

cated.Is the voltage more than 0.2 V? Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in throttle posi-

tion sensor circuit.Go to step 20.

12 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

1) Disconnect the connector from accelerator

pedal position sensor.

2) Measure the resistance between accelera-

tor pedal position sensor connector recepta-

cle’s terminals.

Connector & terminal

No. 1 — No. 2:Is the resistance 0.75 — 3.15

kΩ?Go to step 13.Replace the accel-

erator pedal posi-

tion sensor.

13 CHECK ACCELERATOR PEDAL POSITION

SENSOR.

Measure the resistance between accelerator

pedal position sensor connector receptacle’s

terminals.

Connector & terminal

No. 3 — No. 2:Is the resistance 0.15 — 0.63

kΩ?Go to step 14.Replace the accel-

erator pedal posi-

tion sensor.

14 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ACCELERATOR PEDAL POSI-

TION SENSOR.

1) Disconnect the connector from TCM.

2) Measure the resistance of harness

between TCM and accelerator pedal position

sensor connector.

Connector & terminal

(B55) No. 19 — (E13) No. 3:Is the resistance less than 1

Ω?Go to step 15.Repair the open cir-

cuit in harness

between TCM and

accelerator pedal

position sensor

connector, and

poor contact in cou-

pling connector.

15 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ACCELERATOR PEDAL POSI-

TION SENSOR.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 19 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 16.Repair the short cir-

cuit in harness

between TCM and

accelerator pedal

position sensor

connector. Step Check Yes No

Page 2675 of 2870

4AT(H4DOTC)-99

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

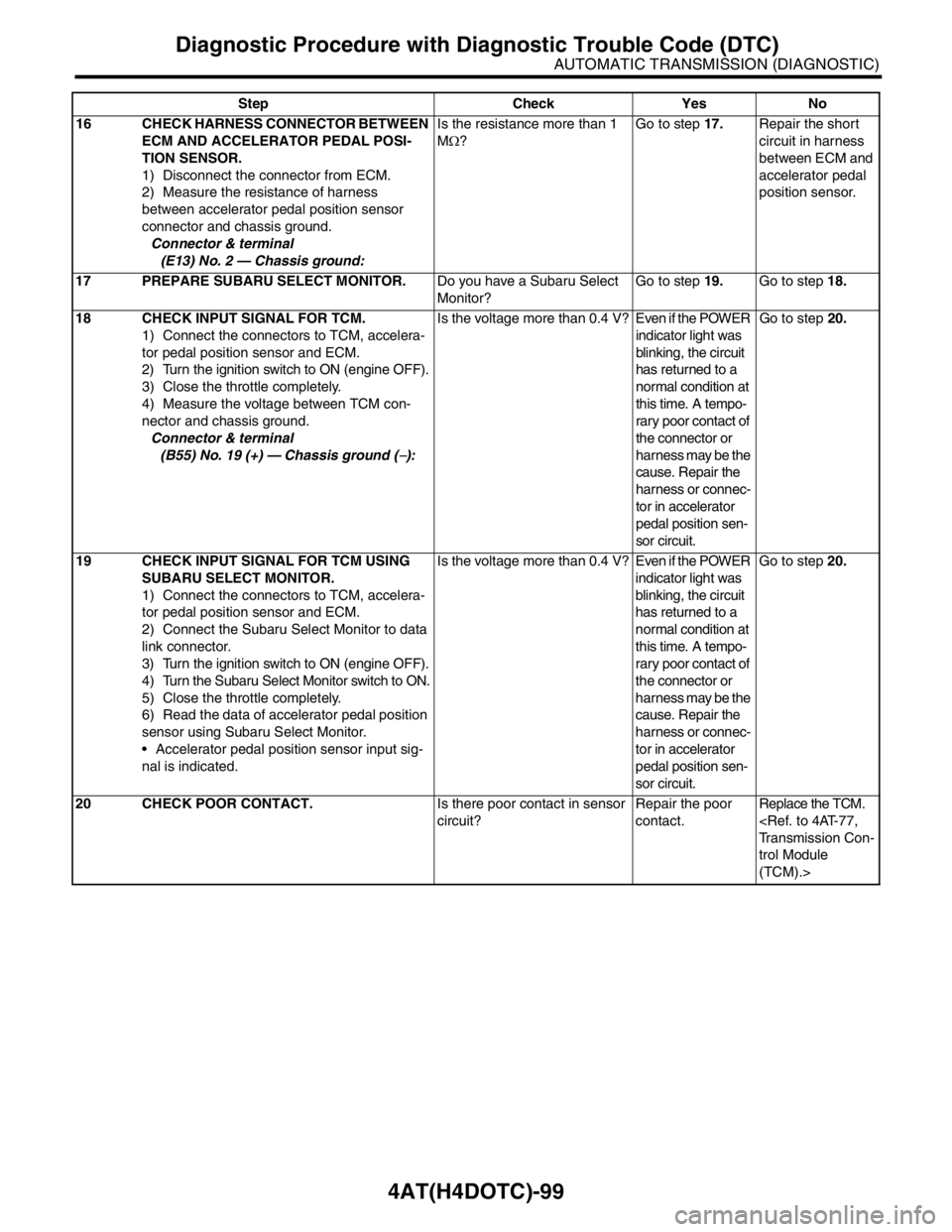

16 CHECK HARNESS CONNECTOR BETWEEN

ECM AND ACCELERATOR PEDAL POSI-

TION SENSOR.

1) Disconnect the connector from ECM.

2) Measure the resistance of harness

between accelerator pedal position sensor

connector and chassis ground.

Connector & terminal

(E13) No. 2 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 17.Repair the short

circuit in harness

between ECM and

accelerator pedal

position sensor.

17 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 19.Go to step 18.

18 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM, accelera-

tor pedal position sensor and ECM.

2) Turn the ignition switch to ON (engine OFF).

3) Close the throttle completely.

4) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (

−):Is the voltage more than 0.4 V? Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in accelerator

pedal position sen-

sor circuit.Go to step 20.

19 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM, accelera-

tor pedal position sensor and ECM.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON (engine OFF).

4) Turn the Subaru Select Monitor switch to ON.

5) Close the throttle completely.

6) Read the data of accelerator pedal position

sensor using Subaru Select Monitor.

Accelerator pedal position sensor input sig-

nal is indicated.Is the voltage more than 0.4 V? Even if the POWER

indicator light was

blinking, the circuit

has returned to a

normal condition at

this time. A tempo-

rary poor contact of

the connector or

harness may be the

cause. Repair the

harness or connec-

tor in accelerator

pedal position sen-

sor circuit.Go to step 20.

20 CHECK POOR CONTACT.Is there poor contact in sensor

circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No