key battery SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 427 of 2870

SL-7

SECURITY AND LOCK

General Description

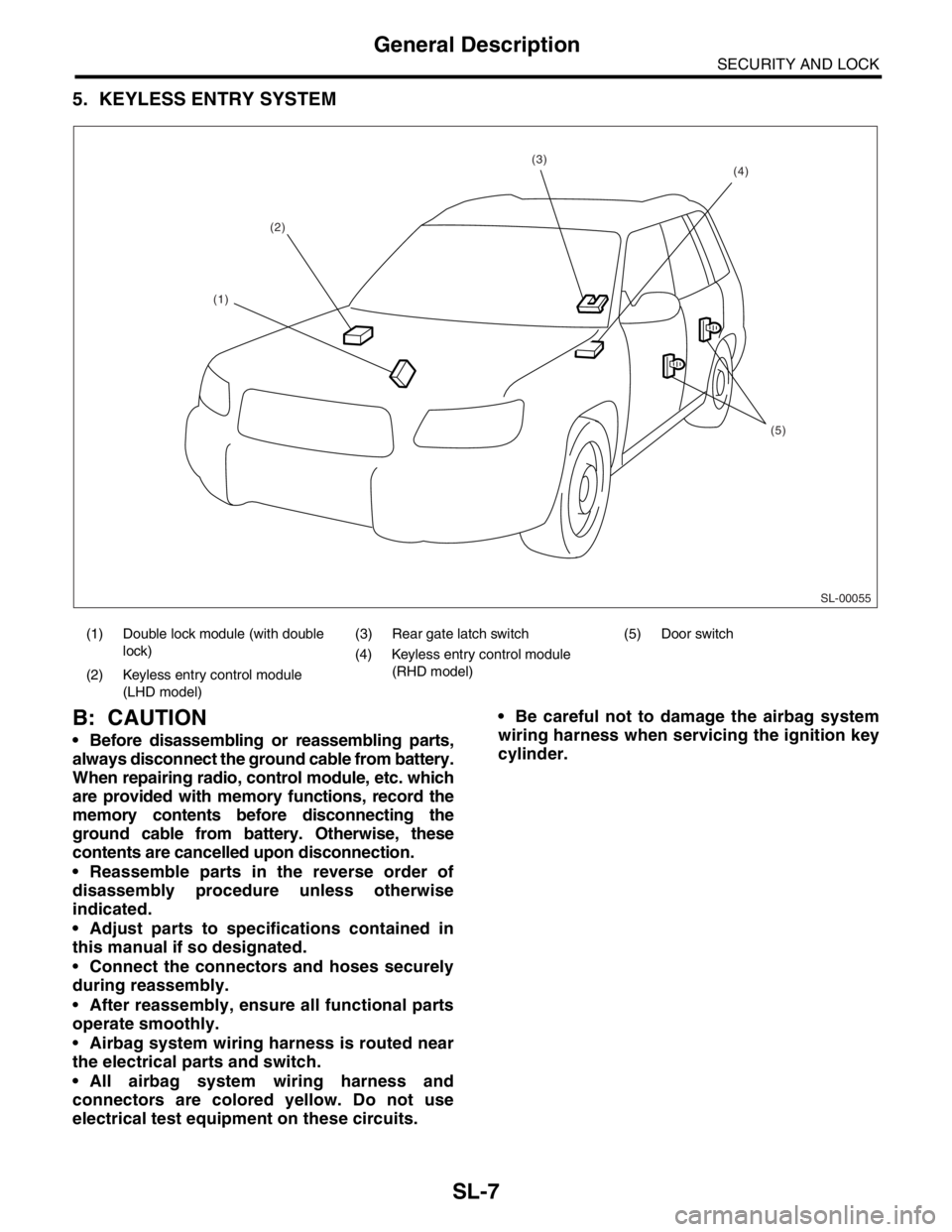

5. KEYLESS ENTRY SYSTEM

B: CAUTION

Before disassembling or reassembling parts,

always disconnect the ground cable from battery.

When repairing radio, control module, etc. which

are provided with memory functions, record the

memory contents before disconnecting the

ground cable from battery. Otherwise, these

contents are cancelled upon disconnection.

Reassemble parts in the reverse order of

disassembly procedure unless otherwise

indicated.

Adjust parts to specifications contained in

this manual if so designated.

Connect the connectors and hoses securely

during reassembly.

After reassembly, ensure all functional parts

operate smoothly.

Airbag system wiring harness is routed near

the electrical parts and switch.

All airbag system wiring harness and

connectors are colored yellow. Do not use

electrical test equipment on these circuits. Be careful not to damage the airbag system

wiring harness when servicing the ignition key

cylinder.

(1) Double lock module (with double

lock)(3) Rear gate latch switch (5) Door switch

(4) Keyless entry control module

(RHD model)

(2) Keyless entry control module

(LHD model)

SL-00055

(2)

(5)

(4)(3)

(1)

Page 434 of 2870

SL-14

SECURITY AND LOCK

Keyless Entry System

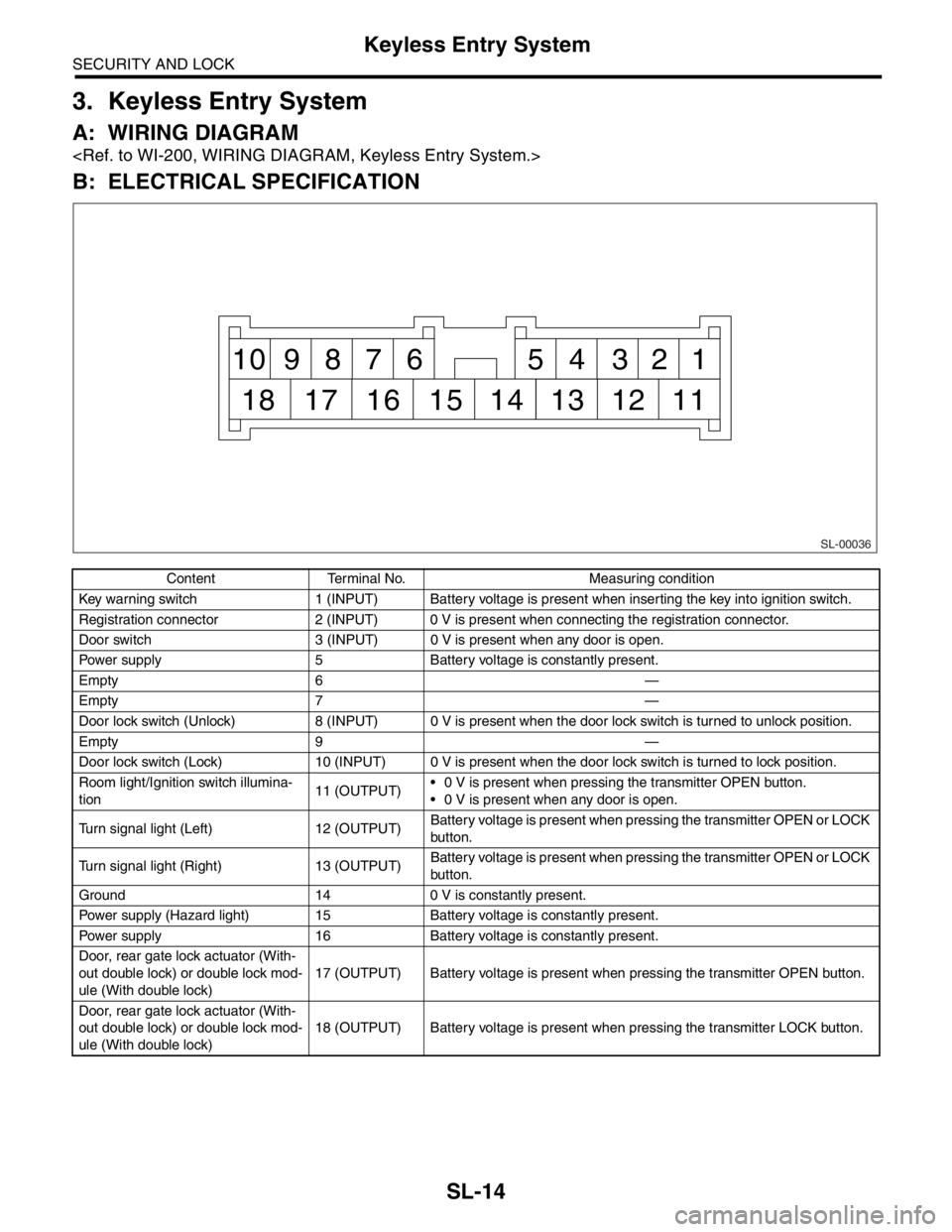

3. Keyless Entry System

A: WIRING DIAGRAM

B: ELECTRICAL SPECIFICATION

Content Terminal No. Measuring condition

Key warning switch 1 (INPUT) Battery voltage is present when inserting the key into ignition switch.

Registration connector 2 (INPUT) 0 V is present when connecting the registration connector.

Door switch 3 (INPUT) 0 V is present when any door is open.

Power supply 5 Battery voltage is constantly present.

Empty 6 —

Empty 7 —

Door lock switch (Unlock) 8 (INPUT) 0 V is present when the door lock switch is turned to unlock position.

Empty 9 —

Door lock switch (Lock) 10 (INPUT) 0 V is present when the door lock switch is turned to lock position.

Room light/Ignition switch illumina-

tion11 (OUTPUT) 0 V is present when pressing the transmitter OPEN button.

0 V is present when any door is open.

Turn signal light (Left) 12 (OUTPUT)Battery voltage is present when pressing the transmitter OPEN or LOCK

button.

Turn signal light (Right) 13 (OUTPUT)Battery voltage is present when pressing the transmitter OPEN or LOCK

button.

Ground 14 0 V is constantly present.

Power supply (Hazard light) 15 Battery voltage is constantly present.

Power supply 16 Battery voltage is constantly present.

Door, rear gate lock actuator (With-

out double lock) or double lock mod-

ule (With double lock)17 (OUTPUT) Battery voltage is present when pressing the transmitter OPEN button.

Door, rear gate lock actuator (With-

out double lock) or double lock mod-

ule (With double lock)18 (OUTPUT) Battery voltage is present when pressing the transmitter LOCK button.

SL-00036

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18

Page 435 of 2870

SL-15

SECURITY AND LOCK

Keyless Entry System

C: INSPECTION

1. SYMPTOM CHART

Symptom Repair order Reference

None of the functions of keyless entry

system operate.1. Check the transmitter battery.

less Entry System.>

2. Check the fuse.

tem.>

3. Check the keyless entry control module power

supply and ground circuit.

INSPECTION, Keyless Entry Sys-

tem.>

4. Replace the keyless entry control module.

The transmitter cannot be registered. 1. Check the transmitter battery.

less Entry System.>

2. Check the registration connector circuit.

INSPECTION, Keyless Entry Sys-

tem.>

3. Check the door lock switch and circuit.

Entry System.>

4. Replace the keyless entry control module.

The door lock or unlock does not

operate.

N

OTE:

If the door lock control system does

not operate when using the door lock

switch, check the door lock control

system.

less Entry System.>

2. Make sure the registration connector is not

connected.Make sure the registration connector

is not connected because keyless

entry system does not operate during

the registration connector connected.

3. Check the key warning switch.

Entry System.>

4. Check the door switch.

Entry System.>

5. Check output signal to double lock module.

(With double lock)

ULE, INSPECTION, Keyless Entry

System.>

6. Replace the keyless entry control module.

The hazard light does not operate. 1. Check the hazard light operation.

Keyless Entry System.>

2. Replace the keyless entry control module.

Page 436 of 2870

SL-16

SECURITY AND LOCK

Keyless Entry System

2. CHECK TRANSMITTER BATTERY

3. CHECK FUSE

The room light and ignition switch illu-

mination operation does not activate.1. Check the room light operation.

Keyless Entry System.>

2. Check the ignition switch illumination circuit.

INSPECTION, Keyless Entry Sys-

tem.>

3. Replace the keyless entry control module.

(without double lock)

4. Replace the double lock module. (with double

lock)

Step Check Yes No

1 CHECK TRANSMITTER BATTERY.

1) Remove the battery from transmitter.

2) Check the battery voltage.

NOTE:

If the transmitter battery voltage is 2.5 V or less,

the range of transmission becomes very short.Is the voltage more than 2.5 V? If further inspec-

tion is necessary,

refer to “SYMP-

TOM CHART”.

CHART, INSPEC-

TION, Keyless

Entry System.>Replace the trans-

mitter battery.

Step Check Yes No

1 CHECK FUSE.

Remove and visually check the fuse No. 2 (in

the main fuse box), No. 3 (in the fuse and relay

box) and SBF-6 (in the main fuse box)Is the fuse blown out? Replace the fuse

with a new one.Check the power

supply and ground

circuit.

POWER SUPPLY

AND GROUND

CIRCUIT,

INSPECTION,

Keyless Entry Sys-

tem.> Symptom Repair order Reference

Page 455 of 2870

SL-35

SECURITY AND LOCK

Ignition Key Lock

17.Ignition Key Lock

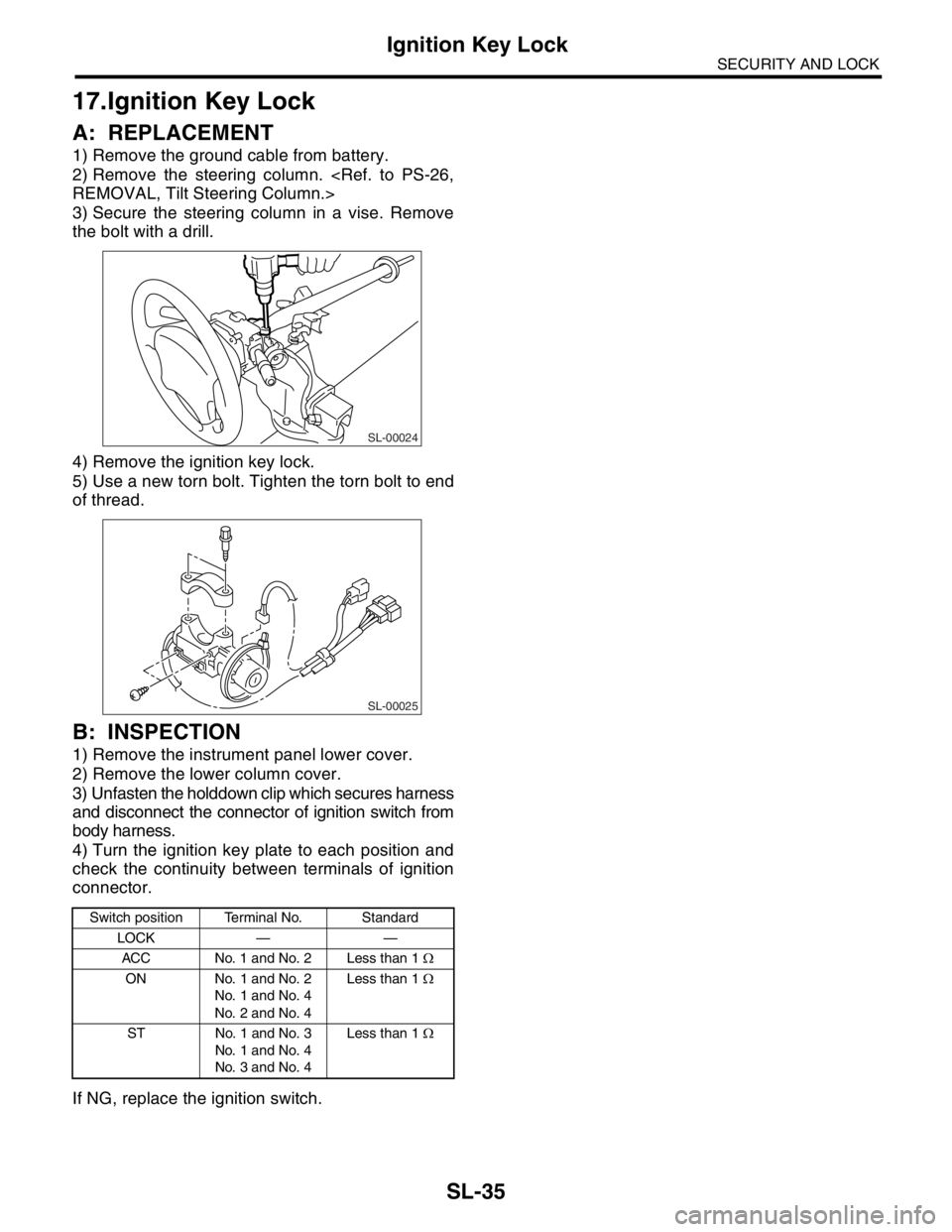

A: REPLACEMENT

1) Remove the ground cable from battery.

2) Remove the steering column.

3) Secure the steering column in a vise. Remove

the bolt with a drill.

4) Remove the ignition key lock.

5) Use a new torn bolt. Tighten the torn bolt to end

of thread.

B: INSPECTION

1) Remove the instrument panel lower cover.

2) Remove the lower column cover.

3) Unfasten the holddown clip which secures harness

and disconnect the connector of ignition switch from

body harness.

4) Turn the ignition key plate to each position and

check the continuity between terminals of ignition

connector.

If NG, replace the ignition switch.

Switch position Terminal No. Standard

LOCK — —

ACC No. 1 and No. 2 Less than 1 Ω

ON No. 1 and No. 2

No. 1 and No. 4

No. 2 and No. 4Less than 1 Ω

ST No. 1 and No. 3

No. 1 and No. 4

No. 3 and No. 4Less than 1 Ω

SL-00024

SL-00025

Page 459 of 2870

SL-39

SECURITY AND LOCK

Keyless Entry Control Module

21.Keyless Entry Control Mod-

ule

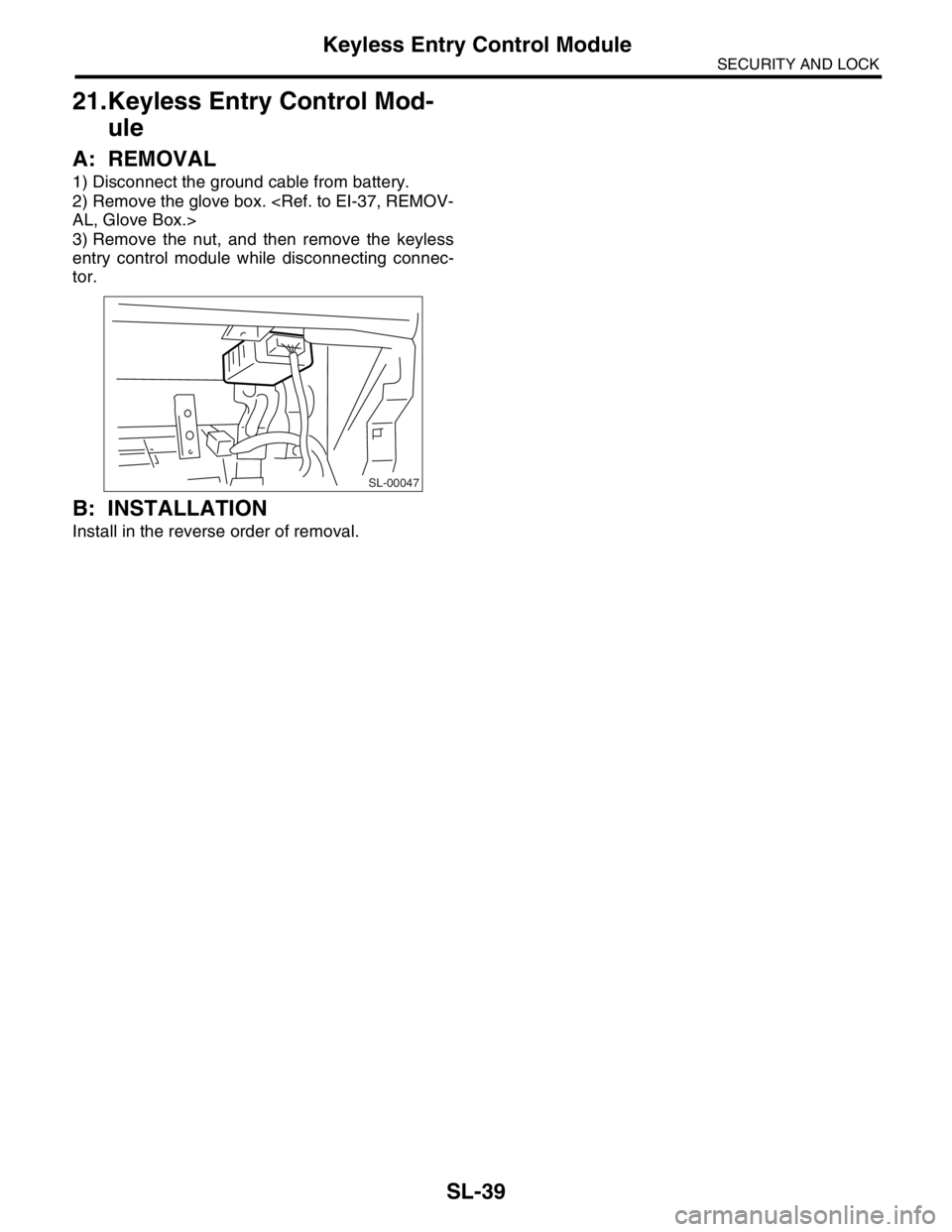

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the glove box.

3) Remove the nut, and then remove the keyless

entry control module while disconnecting connec-

tor.

B: INSTALLATION

Install in the reverse order of removal.

SL-00047

Page 461 of 2870

SL-41

SECURITY AND LOCK

Keyless Transmitter

23.Keyless Transmitter

A: REMOVAL

1. TRANSMITTER BATTERY

Remove the battery from transmitter.

NOTE:

To prevent static electricity damage to transmitter

printed circuit board, touch the steel area of building

with hand to discharge the static electricity carried

on body or clothes before disassembling transmitter.

B: INSTALLATION

1. TRANSMITTER BATTERY

Install in the reverse order of removal.

C: INSPECTION

1. TRANSMITTER BATTERY

Measure the voltage between battery (+) terminal

and (–) terminal.

NOTE:

Battery discharge occurs during measurement.

Complete the measurement within 5 seconds.

During battery voltage measurement, voltage

falls more than 1.8 volts in 3 seconds period.If NG, replace the battery. (Use CR1620 or equiva-

lent.)

D: REPLACEMENT

1. TRANSMITTER REGISTRATION

NOTE:

A maximum of three transmitters can be regis-

tered for each individual vehicle.

When replacing the transmitter (key), registration

to immobilizer system is also necessary.

1) Remove the side sill cover at driver’s side, then

connect the registration connectors at front pillar

lower section.

2) Unlock the door lock.

3) Press any button of the transmitter twice while

pressing driver’s door lock switch to unlock side to

be registered.

4) The door lock will automatically lock and unlock

in sequence. This indicates the completion of trans-

mitter registration for first transmitter.

5) If the registration of second and third transmitter

is now to be carried out, repeat the procedure 3)

and 4).

6) Disconnect the registration connectors after the

completion of all registration operations. After con-

firming the operation of door lock using newly reg-

istered transmitter(s), reinstall the side sill cover at

driver’s side.

(A) Resistance 300 Ω

Tester connection

Standard

(+) (–)

Battery (+) termi-

nalBattery (–) termi-

nal2.5 — 3.0 V

SL-00065

SL-00066

(A)

Page 654 of 2870

IM-12

IMMOBILIZER (DIAGNOSTIC)

Diagnostics Chart for Immobilizer Warning Light

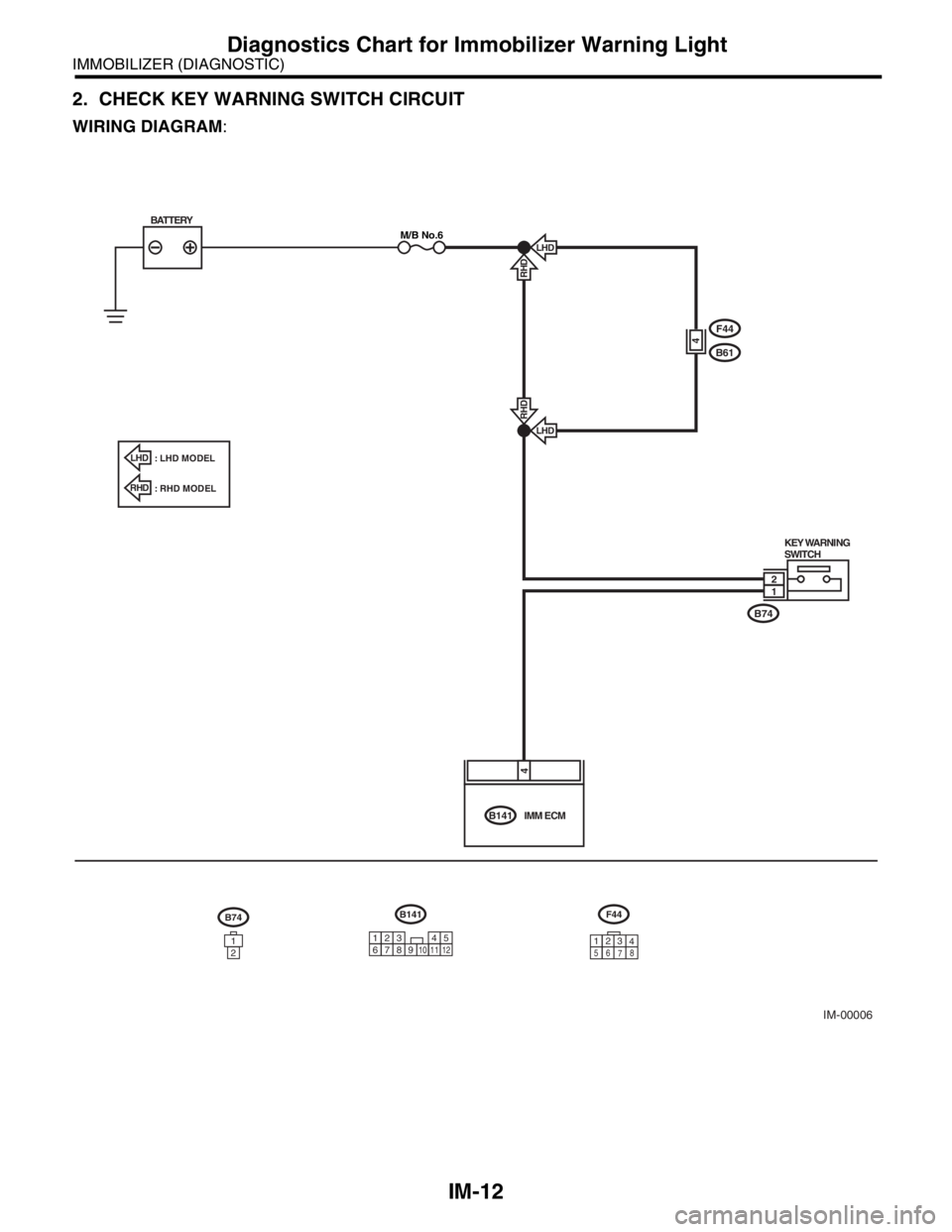

2. CHECK KEY WARNING SWITCH CIRCUIT

WIRING DIAGRAM:

IM-00006

B74

B61

F44

KEY WARNING

SWITCH

B141IMM ECM

LHD

RHDLHD

RHD

BATTERYM/B No.6

4

12

4

B74

1

2

B141

34 12

89

10 11125

67

F44

3

1

56

78

LHD: LHD MODEL

: RHD MODEL

RHD

2

4

Page 660 of 2870

IM-18

IMMOBILIZER (DIAGNOSTIC)

Diagnostics Procedure with Diagnostic Trouble Code (DTC)

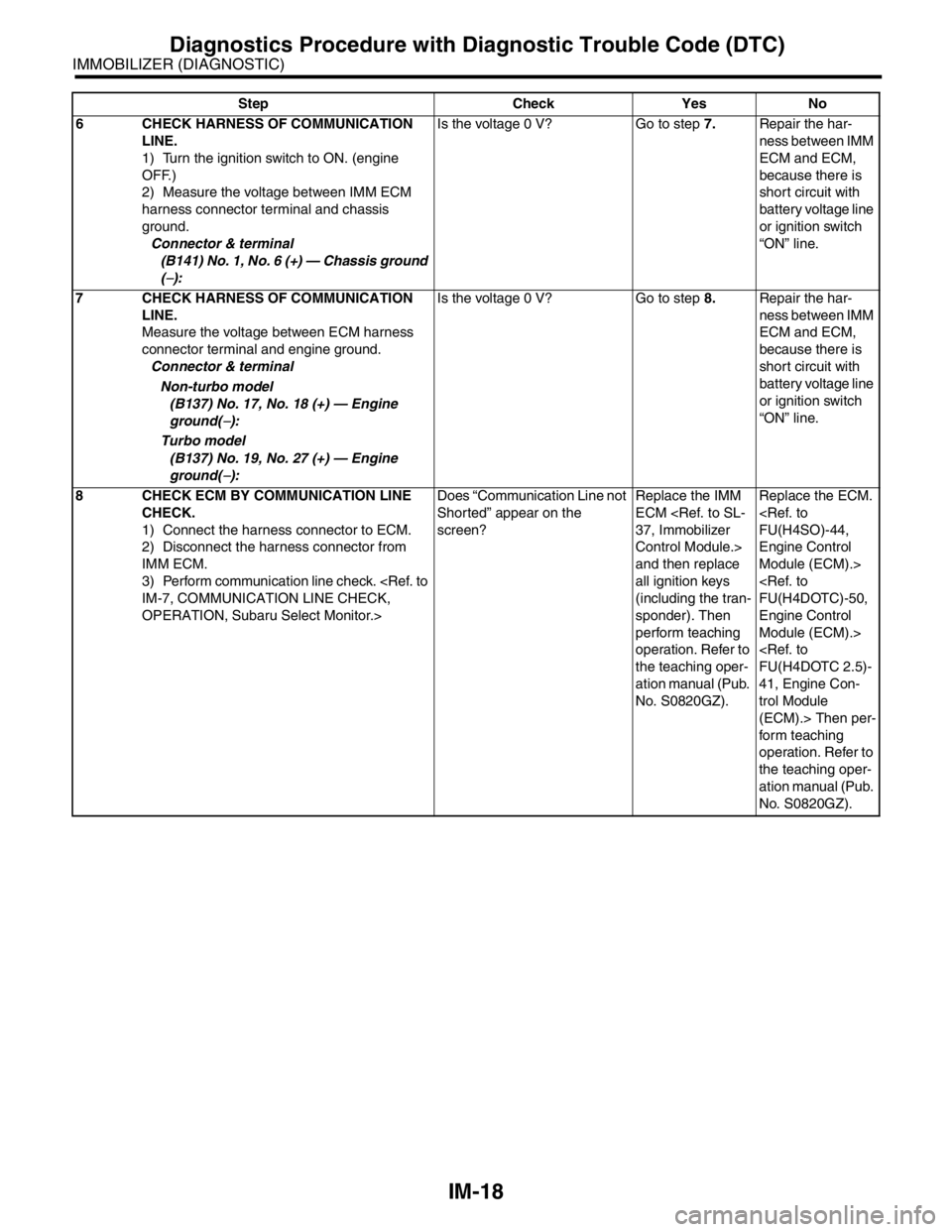

6 CHECK HARNESS OF COMMUNICATION

LINE.

1) Turn the ignition switch to ON. (engine

OFF.)

2) Measure the voltage between IMM ECM

harness connector terminal and chassis

ground.

Connector & terminal

(B141) No. 1, No. 6 (+) — Chassis ground

(

−):Is the voltage 0 V? Go to step 7.Repair the har-

ness between IMM

ECM and ECM,

because there is

short circuit with

battery voltage line

or ignition switch

“ON” line.

7 CHECK HARNESS OF COMMUNICATION

LINE.

Measure the voltage between ECM harness

connector terminal and engine ground.

Connector & terminal

Non-turbo model

(B137) No. 17, No. 18 (+) — Engine

ground(

−):

Turbo model

(B137) No. 19, No. 27 (+) — Engine

ground(

−):Is the voltage 0 V? Go to step 8.Repair the har-

ness between IMM

ECM and ECM,

because there is

short circuit with

battery voltage line

or ignition switch

“ON” line.

8 CHECK ECM BY COMMUNICATION LINE

CHECK.

1) Connect the harness connector to ECM.

2) Disconnect the harness connector from

IMM ECM.

3) Perform communication line check.

OPERATION, Subaru Select Monitor.>Does “Communication Line not

Shorted” appear on the

screen?Replace the IMM

ECM

Control Module.>

and then replace

all ignition keys

(including the tran-

sponder). Then

perform teaching

operation. Refer to

the teaching oper-

ation manual (Pub.

No. S0820GZ).Replace the ECM.

Engine Control

Module (ECM).>

Engine Control

Module (ECM).>

41, Engine Con-

trol Module

(ECM).> Then per-

form teaching

operation. Refer to

the teaching oper-

ation manual (Pub.

No. S0820GZ). Step Check Yes No

Page 726 of 2870

PI-3

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

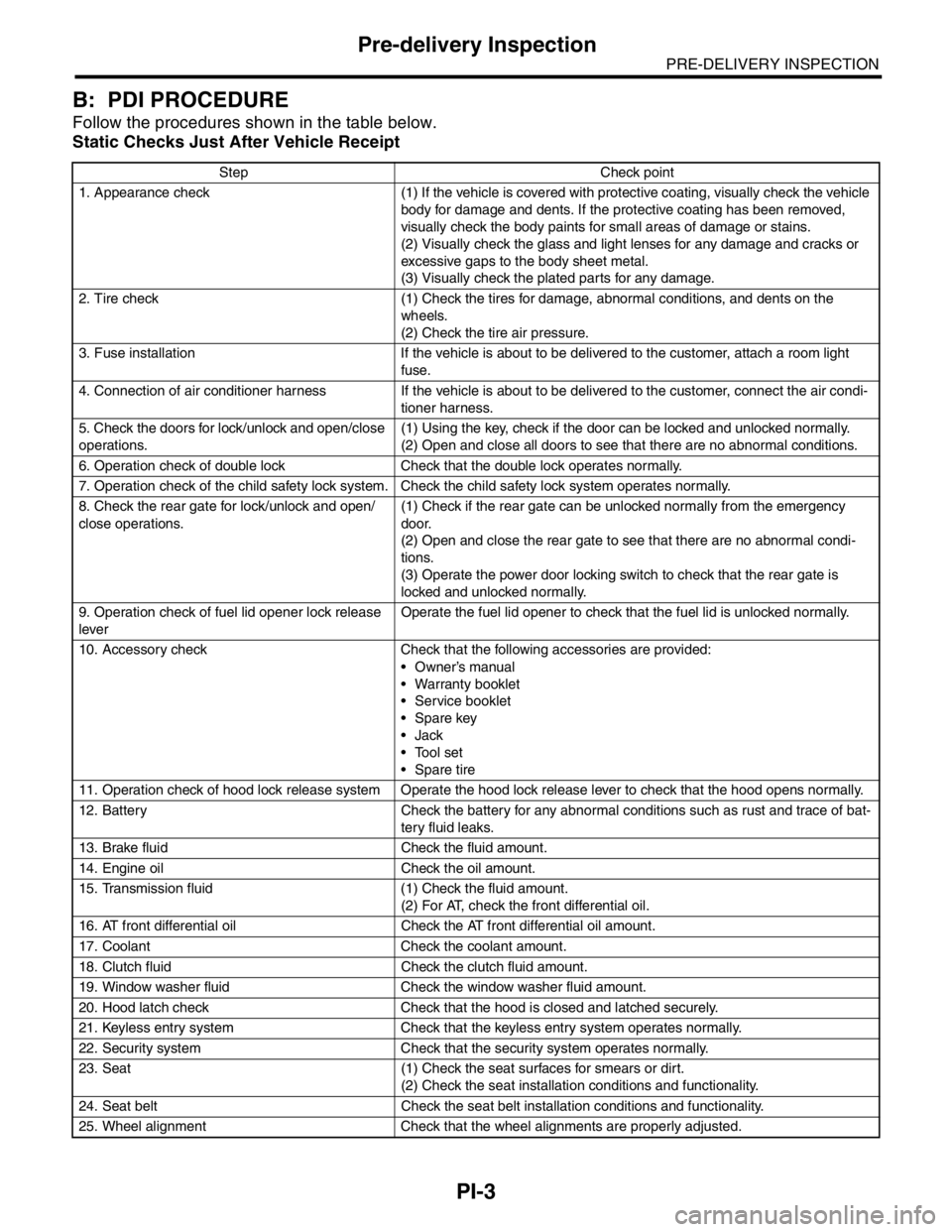

B: PDI PROCEDURE

Follow the procedures shown in the table below.

Static Checks Just After Vehicle Receipt

Step Check point

1. Appearance check (1) If the vehicle is covered with protective coating, visually check the vehicle

body for damage and dents. If the protective coating has been removed,

visually check the body paints for small areas of damage or stains.

(2) Visually check the glass and light lenses for any damage and cracks or

excessive gaps to the body sheet metal.

(3) Visually check the plated parts for any damage.

2. Tire check (1) Check the tires for damage, abnormal conditions, and dents on the

wheels.

(2) Check the tire air pressure.

3. Fuse installation If the vehicle is about to be delivered to the customer, attach a room light

fuse.

4. Connection of air conditioner harness If the vehicle is about to be delivered to the customer, connect the air condi-

tioner harness.

5. Check the doors for lock/unlock and open/close

operations.(1) Using the key, check if the door can be locked and unlocked normally.

(2) Open and close all doors to see that there are no abnormal conditions.

6. Operation check of double lock Check that the double lock operates normally.

7. Operation check of the child safety lock system. Check the child safety lock system operates normally.

8. Check the rear gate for lock/unlock and open/

close operations.(1) Check if the rear gate can be unlocked normally from the emergency

door.

(2) Open and close the rear gate to see that there are no abnormal condi-

tions.

(3) Operate the power door locking switch to check that the rear gate is

locked and unlocked normally.

9. Operation check of fuel lid opener lock release

leverOperate the fuel lid opener to check that the fuel lid is unlocked normally.

10. Accessory check Check that the following accessories are provided:

Owner’s manual

Warranty booklet

Service booklet

Spare key

Jack

Tool set

Spare tire

11. Operation check of hood lock release system Operate the hood lock release lever to check that the hood opens normally.

12. Battery Check the battery for any abnormal conditions such as rust and trace of bat-

tery fluid leaks.

13. Brake fluid Check the fluid amount.

14. Engine oil Check the oil amount.

15. Transmission fluid (1) Check the fluid amount.

(2) For AT, check the front differential oil.

16. AT front differential oil Check the AT front differential oil amount.

17. Coolant Check the coolant amount.

18. Clutch fluid Check the clutch fluid amount.

19. Window washer fluid Check the window washer fluid amount.

20. Hood latch check Check that the hood is closed and latched securely.

21. Keyless entry system Check that the keyless entry system operates normally.

22. Security system Check that the security system operates normally.

23. Seat (1) Check the seat surfaces for smears or dirt.

(2) Check the seat installation conditions and functionality.

24. Seat belt Check the seat belt installation conditions and functionality.

25. Wheel alignment Check that the wheel alignments are properly adjusted.