low oil pressure SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 3 of 2870

HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)

AC

Page

1. General Description ....................................................................................2

2. Refrigerant Pressure with Manifold Gauge Set .........................................25

3. Refrigerant Recovery Procedure...............................................................26

4. Refrigerant Charging Procedure ...............................................................27

5. Refrigerant Leak Check ............................................................................30

6. Compressor Oil .........................................................................................31

7. Blower Motor Unit Assembly .....................................................................32

8. Blower Resistor (Manual A/C Model) ........................................................33

9. Heater Core...............................................................................................34

10. Control Unit ...............................................................................................35

11. Compressor...............................................................................................36

12. Condenser.................................................................................................37

13. Condenser (Sub Fan)................................................................................38

14. Heater Cooling Unit ...................................................................................39

15. Evaporator.................................................................................................40

16. Hose and Tube..........................................................................................41

17. Relay and Fuse .........................................................................................42

18. Pressure Switch (Triple Pressure Switch) .................................................43

19. Ambient Sensor (Auto A/C Model) ............................................................44

20. Sunload Sensor (Auto A/C Model) ............................................................45

21. Air Vent Grille ............................................................................................46

22. Heater Duct ...............................................................................................47

23. Heater Vent Duct.......................................................................................48

24. Heater Cock Solenoid Valve .....................................................................49

25. General Diagnostics ..................................................................................50

Page 22 of 2870

AC-20

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

C: CAUTION

1. HFC-134a A/C SYSTEM

The cooling system components for the HFC-

134a system such as the refrigerant and compres-

sor oil are different from the old conventional HFC-

12 system components and they are incompatible

with each other.

Vehicles with the HFC-134a system can be iden-

tified by the label (A) attached to the vehicle.

Before maintenance, check which A/C system is in-

stalled in the vehicle.

2. COMPRESSOR OIL

HFC-134a compressor oil has no compatibility

with that for R12 system.

Use only the manufacturer-authorized compres-

sor oil for the HFC-134a system; only use

ZXL200PG.

Do not mix multiple compressor oils.

If HFC-12 compressor oil is used in a HFC-134a A/

C system, the compressor may become stuck due

to poor lubrication, or the refrigerant may leak due

to swelling of rubber parts.

On the other hand, if HFC-134a compressor oil is

used in a HFC-12 A/C system, the durability of the

A/C system will be lowered.

HFC-134a compressor oil is very hygroscopic.

When replacing or installing/removing A/C parts,

immediately isolate the oil from the atmosphere us-

ing a plug or tape. In order to avoid moisture, store

the oil in a container with its cap securely closed.

3. REFRIGERANT

The HFC-12 refrigerant cannot be used in the

HFC-134a A/C system. The HFC-134a refrigerant,

also, cannot be used in the HFC-12 A/C system.

If an incorrect or no refrigerant is used, poor lu-

brication will result and the compressor itself may

be damaged.

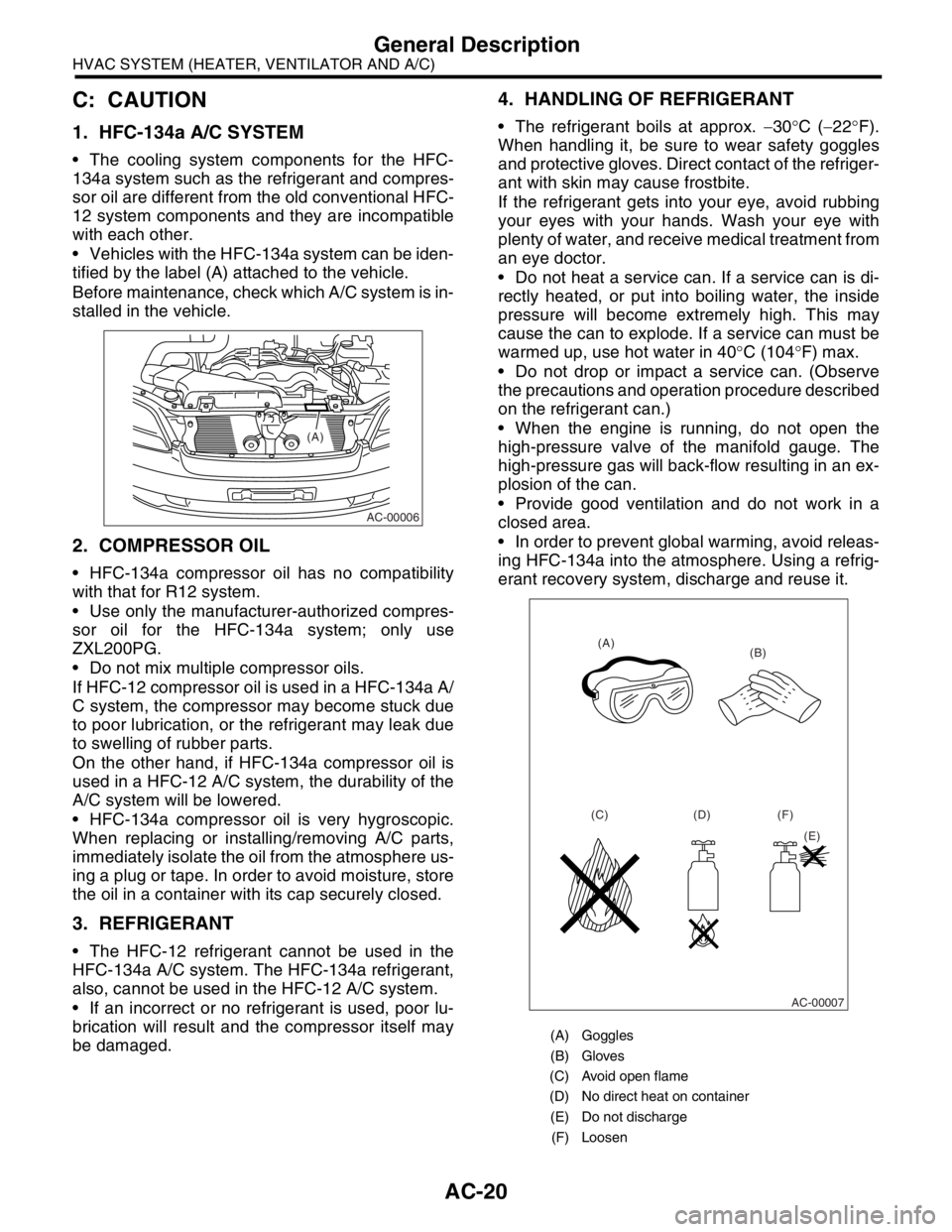

4. HANDLING OF REFRIGERANT

The refrigerant boils at approx. −30°C (−22°F).

When handling it, be sure to wear safety goggles

and protective gloves. Direct contact of the refriger-

ant with skin may cause frostbite.

If the refrigerant gets into your eye, avoid rubbing

your eyes with your hands. Wash your eye with

plenty of water, and receive medical treatment from

an eye doctor.

Do not heat a service can. If a service can is di-

rectly heated, or put into boiling water, the inside

pressure will become extremely high. This may

cause the can to explode. If a service can must be

warmed up, use hot water in 40°C (104°F) max.

Do not drop or impact a service can. (Observe

the precautions and operation procedure described

on the refrigerant can.)

When the engine is running, do not open the

high-pressure valve of the manifold gauge. The

high-pressure gas will back-flow resulting in an ex-

plosion of the can.

Provide good ventilation and do not work in a

closed area.

In order to prevent global warming, avoid releas-

ing HFC-134a into the atmosphere. Using a refrig-

erant recovery system, discharge and reuse it.

AC-00006

(A)

(A) Goggles

(B) Gloves

(C) Avoid open flame

(D) No direct heat on container

(E) Do not discharge

(F) Loosen

(A)

(B)

(C) (D)

(E) (F)

AC-00007

Page 28 of 2870

AC-26

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Recovery Procedure

3. Refrigerant Recovery Proce-

dure

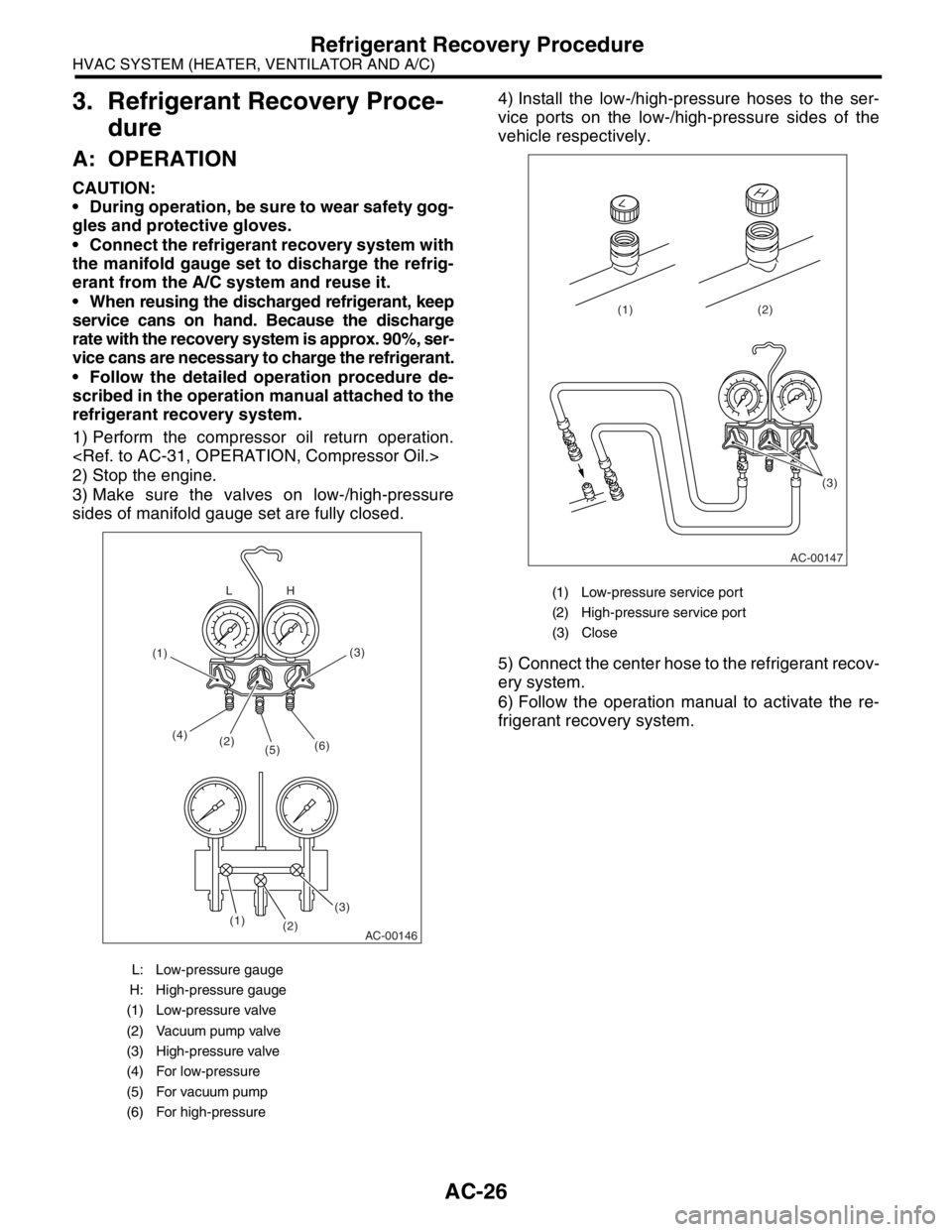

A: OPERATION

CAUTION:

During operation, be sure to wear safety gog-

gles and protective gloves.

Connect the refrigerant recovery system with

the manifold gauge set to discharge the refrig-

erant from the A/C system and reuse it.

When reusing the discharged refrigerant, keep

service cans on hand. Because the discharge

rate with the recovery system is approx. 90%, ser-

vice cans are necessary to charge the refrigerant.

Follow the detailed operation procedure de-

scribed in the operation manual attached to the

refrigerant recovery system.

1) Perform the compressor oil return operation.

2) Stop the engine.

3) Make sure the valves on low-/high-pressure

sides of manifold gauge set are fully closed.4) Install the low-/high-pressure hoses to the ser-

vice ports on the low-/high-pressure sides of the

vehicle respectively.

5) Connect the center hose to the refrigerant recov-

ery system.

6) Follow the operation manual to activate the re-

frigerant recovery system.

L: Low-pressure gauge

H: High-pressure gauge

(1) Low-pressure valve

(2) Vacuum pump valve

(3) High-pressure valve

(4) For low-pressure

(5) For vacuum pump

(6) For high-pressure

AC-00146

(2) (4)

(5)(6)

(3)(3)

(2) (1)H L

(1)

(1) Low-pressure service port

(2) High-pressure service port

(3) Close

AC-00147

(3) (2) (1)

Page 32 of 2870

AC-30

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Leak Check

5. Refrigerant Leak Check

A: INSPECTION

1) Operate the A/C system for approx. 10 minutes,

and confirm that the high-pressure side shows at

least 690 kPa (7.03 kg/cm

2, 100 psi). Then stop the

engine to start the leak test.

2) Starting from the connection between the high-

pressure pipe and evaporator, check the system for

leaks along the high-pressure side through the

compressor. The following items must be checked

thoroughly.

3) Check the joint and seam between the pressure

switch (triple pressure switch) and high-pressure

pipe.

4) Check the connections between the condenser

and pipes, and welded joints on the condenser.

The leak tester may detect the oil on the condenser

fins as a leak.

5) Check the joint between the compressor and

hoses.

6) Check the machined area of compressor and

other joints on the compressor.

7) Check the compressor shaft seal at the area

near the center of compressor clutch pulley.

Some shaft seals show a slight amount of leakage

about 28 g (1.0 oz) per year. This is not a problem.

8) Starting from the connection between the low-

pressure pipe and evaporator, check the system for

leakage along the low-pressure side through the

compressor. The following items must be checked

thoroughly.

Connection between two parts

Connection between the pipe and plate

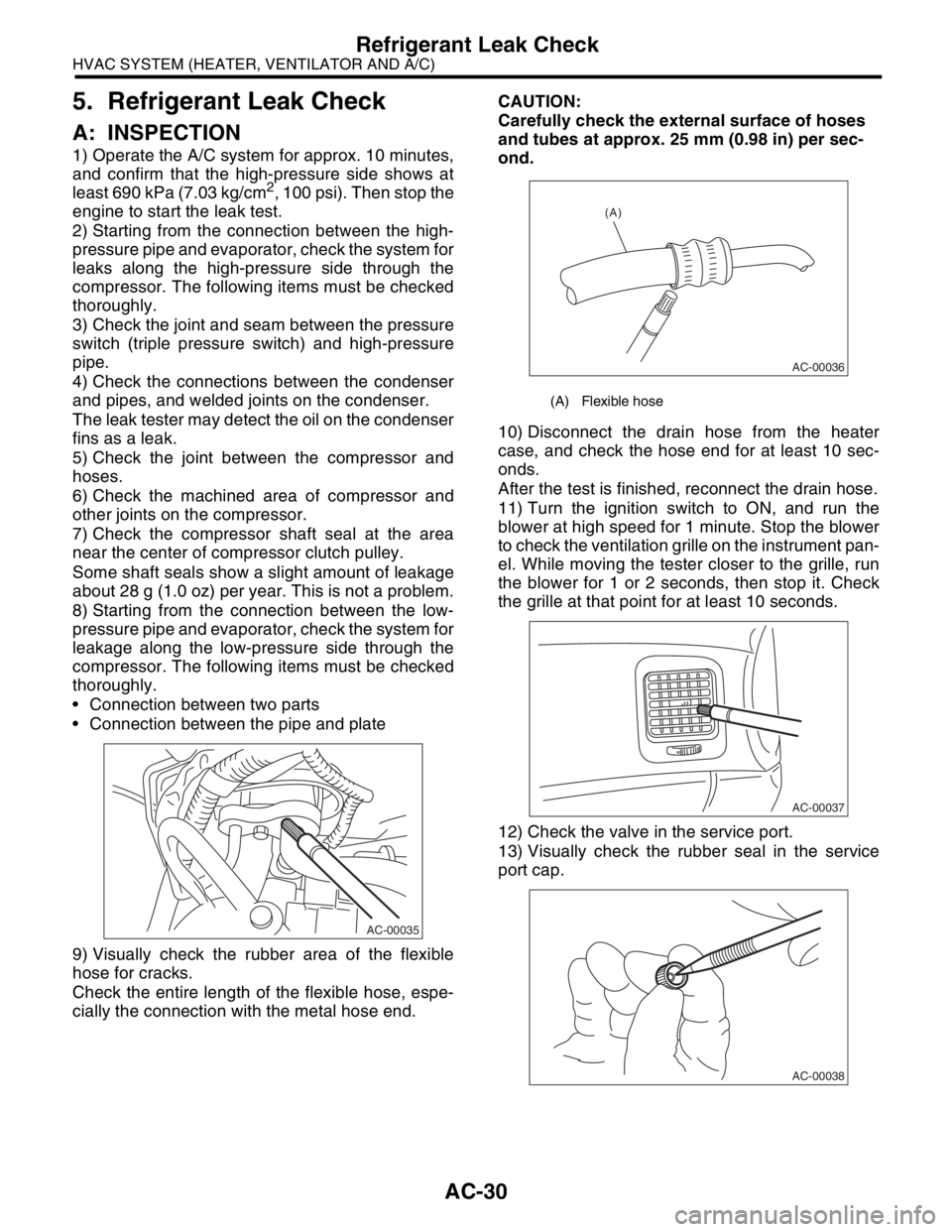

9) Visually check the rubber area of the flexible

hose for cracks.

Check the entire length of the flexible hose, espe-

cially the connection with the metal hose end.CAUTION:

Carefully check the external surface of hoses

and tubes at approx. 25 mm (0.98 in) per sec-

ond.

10) Disconnect the drain hose from the heater

case, and check the hose end for at least 10 sec-

onds.

After the test is finished, reconnect the drain hose.

11) Turn the ignition switch to ON, and run the

blower at high speed for 1 minute. Stop the blower

to check the ventilation grille on the instrument pan-

el. While moving the tester closer to the grille, run

the blower for 1 or 2 seconds, then stop it. Check

the grille at that point for at least 10 seconds.

12) Check the valve in the service port.

13) Visually check the rubber seal in the service

port cap.

AC-00035

(A) Flexible hose

AC-00036

(A)

AC-00037

AC-00038

Page 38 of 2870

AC-36

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Compressor

11.Compressor

A: INSPECTION

1. MAGNETIC CLUTCH CLEARANCE

1) Check the clearance of the entire circumference

around the drive plate and pulley.

Standard:

0.3 — 0.6 mm (0.0118 — 0.0236 in)

2. MAGNETIC CLUTCH OPERATION

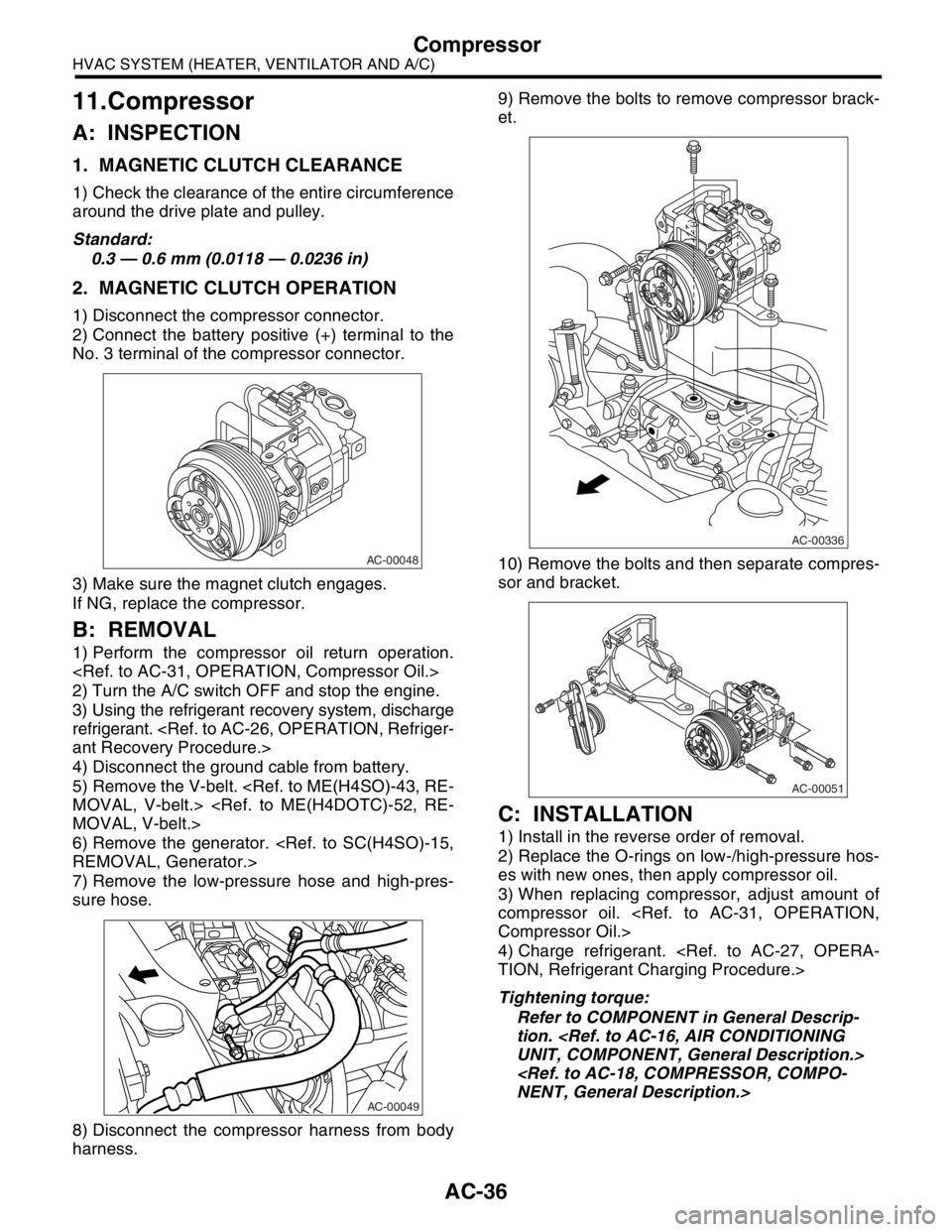

1) Disconnect the compressor connector.

2) Connect the battery positive (+) terminal to the

No. 3 terminal of the compressor connector.

3) Make sure the magnet clutch engages.

If NG, replace the compressor.

B: REMOVAL

1) Perform the compressor oil return operation.

2) Turn the A/C switch OFF and stop the engine.

3) Using the refrigerant recovery system, discharge

refrigerant.

4) Disconnect the ground cable from battery.

5) Remove the V-belt.

6) Remove the generator.

7) Remove the low-pressure hose and high-pres-

sure hose.

8) Disconnect the compressor harness from body

harness.9) Remove the bolts to remove compressor brack-

et.

10) Remove the bolts and then separate compres-

sor and bracket.

C: INSTALLATION

1) Install in the reverse order of removal.

2) Replace the O-rings on low-/high-pressure hos-

es with new ones, then apply compressor oil.

3) When replacing compressor, adjust amount of

compressor oil.

4) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

AC-00048

AC-00049

AC-00336

AC-00051

Page 39 of 2870

AC-37

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Condenser

12.Condenser

A: REMOVAL

1) Using the refrigerant recovery system, discharge

refrigerant.

2) Disconnect the ground cable from battery.

3) Disconnect the pressure hose and pipe from

condenser.

4) Remove the radiator bracket (A).

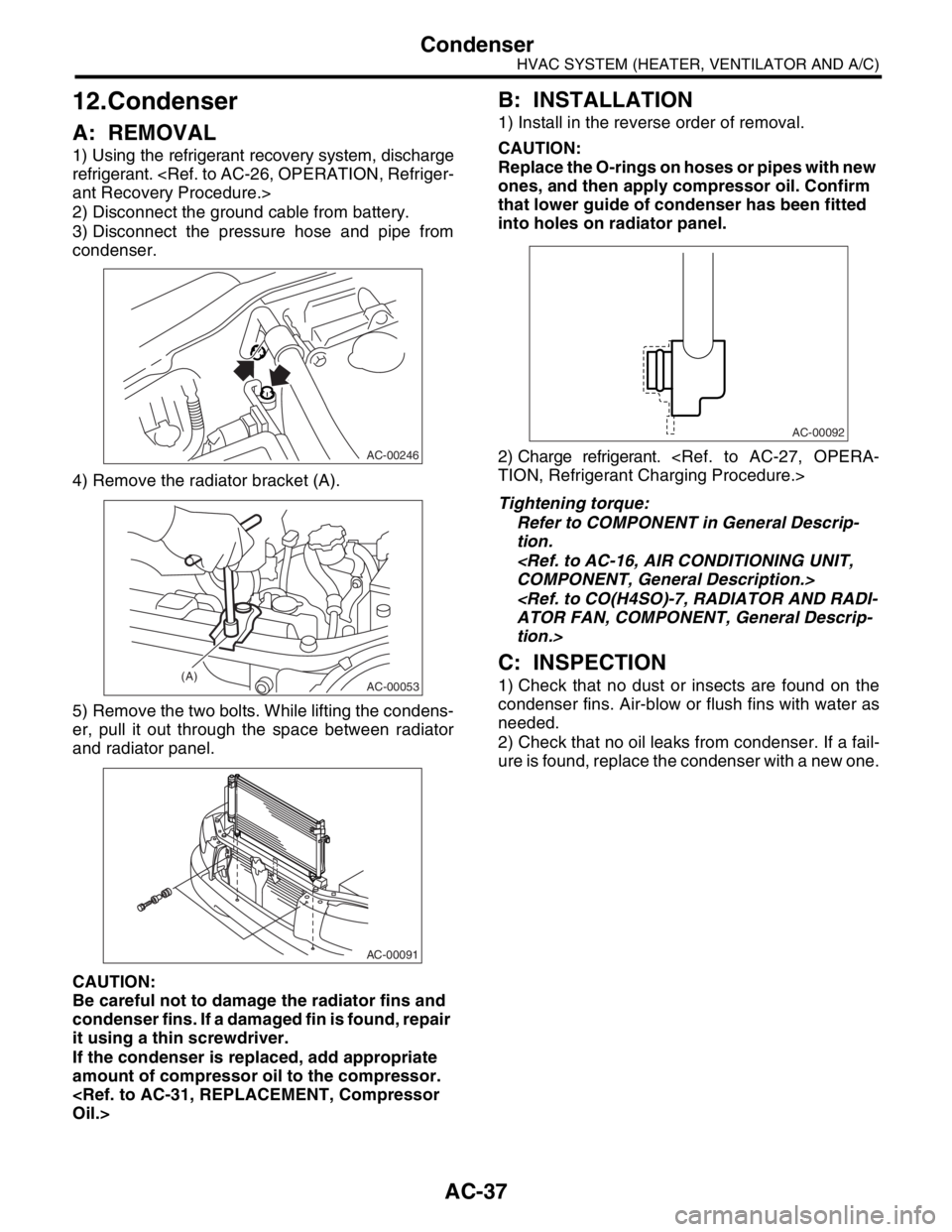

5) Remove the two bolts. While lifting the condens-

er, pull it out through the space between radiator

and radiator panel.

CAUTION:

Be careful not to damage the radiator fins and

condenser fins. If a damaged fin is found, repair

it using a thin screwdriver.

If the condenser is replaced, add appropriate

amount of compressor oil to the compressor.

B: INSTALLATION

1) Install in the reverse order of removal.

CAUTION:

Replace the O-rings on hoses or pipes with new

ones, and then apply compressor oil. Confirm

that lower guide of condenser has been fitted

into holes on radiator panel.

2) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

tion.>

C: INSPECTION

1) Check that no dust or insects are found on the

condenser fins. Air-blow or flush fins with water as

needed.

2) Check that no oil leaks from condenser. If a fail-

ure is found, replace the condenser with a new one.

AC-00246

AC-00053(A)

AC-00091

AC-00092

Page 43 of 2870

AC-41

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Hose and Tube

16.Hose and Tube

A: REMOVAL

CAUTION:

When disconnecting/connecting hoses, do not

apply excessive force to them. Confirm that no

torsion and excessive tension exists after install-

ing.

Seal the disconnected hose with a plug or vi-

nyl tape to prevent foreign matters from enter-

ing.

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge refrigerant.

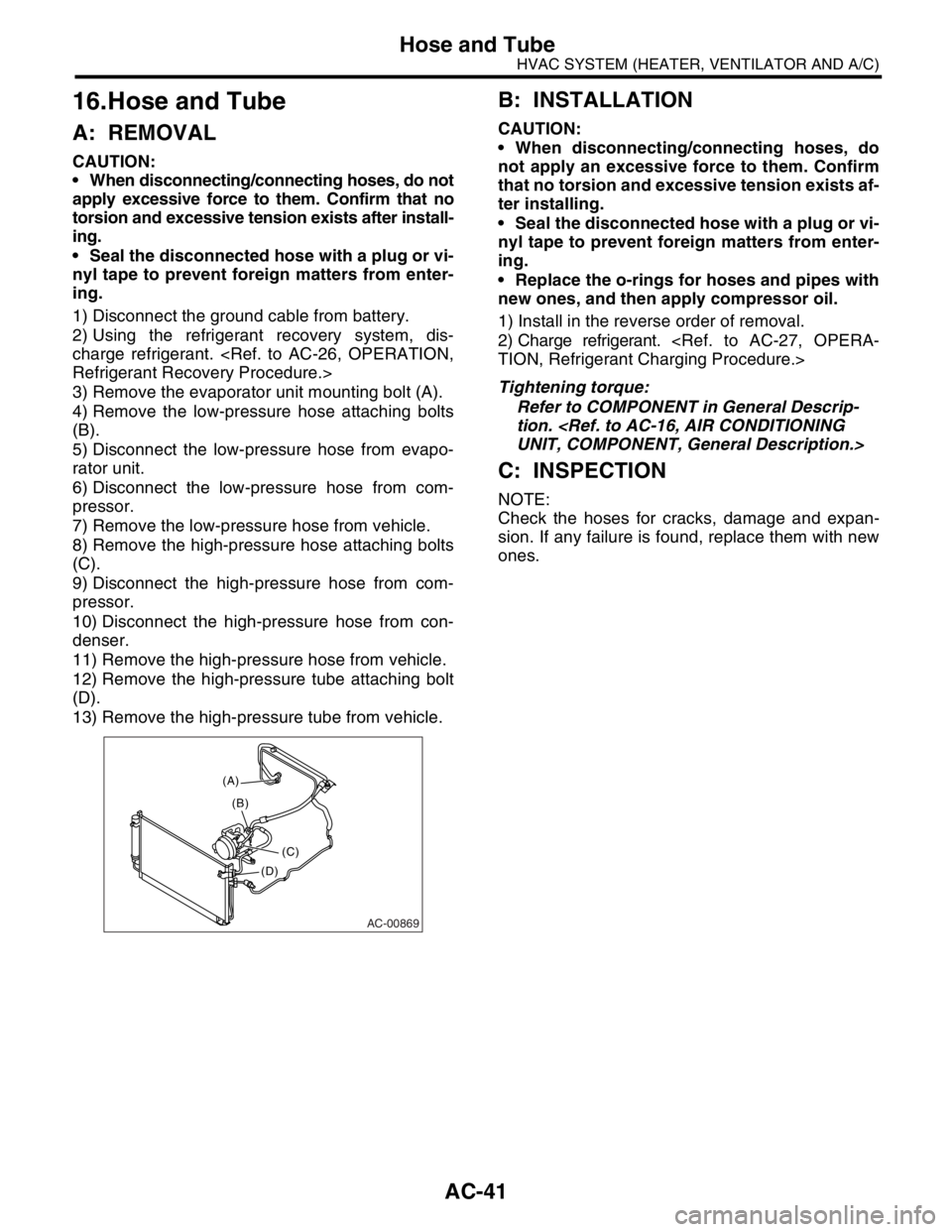

3) Remove the evaporator unit mounting bolt (A).

4) Remove the low-pressure hose attaching bolts

(B).

5) Disconnect the low-pressure hose from evapo-

rator unit.

6) Disconnect the low-pressure hose from com-

pressor.

7) Remove the low-pressure hose from vehicle.

8) Remove the high-pressure hose attaching bolts

(C).

9) Disconnect the high-pressure hose from com-

pressor.

10) Disconnect the high-pressure hose from con-

denser.

11) Remove the high-pressure hose from vehicle.

12) Remove the high-pressure tube attaching bolt

(D).

13) Remove the high-pressure tube from vehicle.

B: INSTALLATION

CAUTION:

When disconnecting/connecting hoses, do

not apply an excessive force to them. Confirm

that no torsion and excessive tension exists af-

ter installing.

Seal the disconnected hose with a plug or vi-

nyl tape to prevent foreign matters from enter-

ing.

Replace the o-rings for hoses and pipes with

new ones, and then apply compressor oil.

1) Install in the reverse order of removal.

2) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

C: INSPECTION

NOTE:

Check the hoses for cracks, damage and expan-

sion. If any failure is found, replace them with new

ones.

AC-00869

(A)

(C) (B)

(D)

Page 386 of 2870

IDI-2

INSTRUMENTATION/DRIVER INFO

General Description

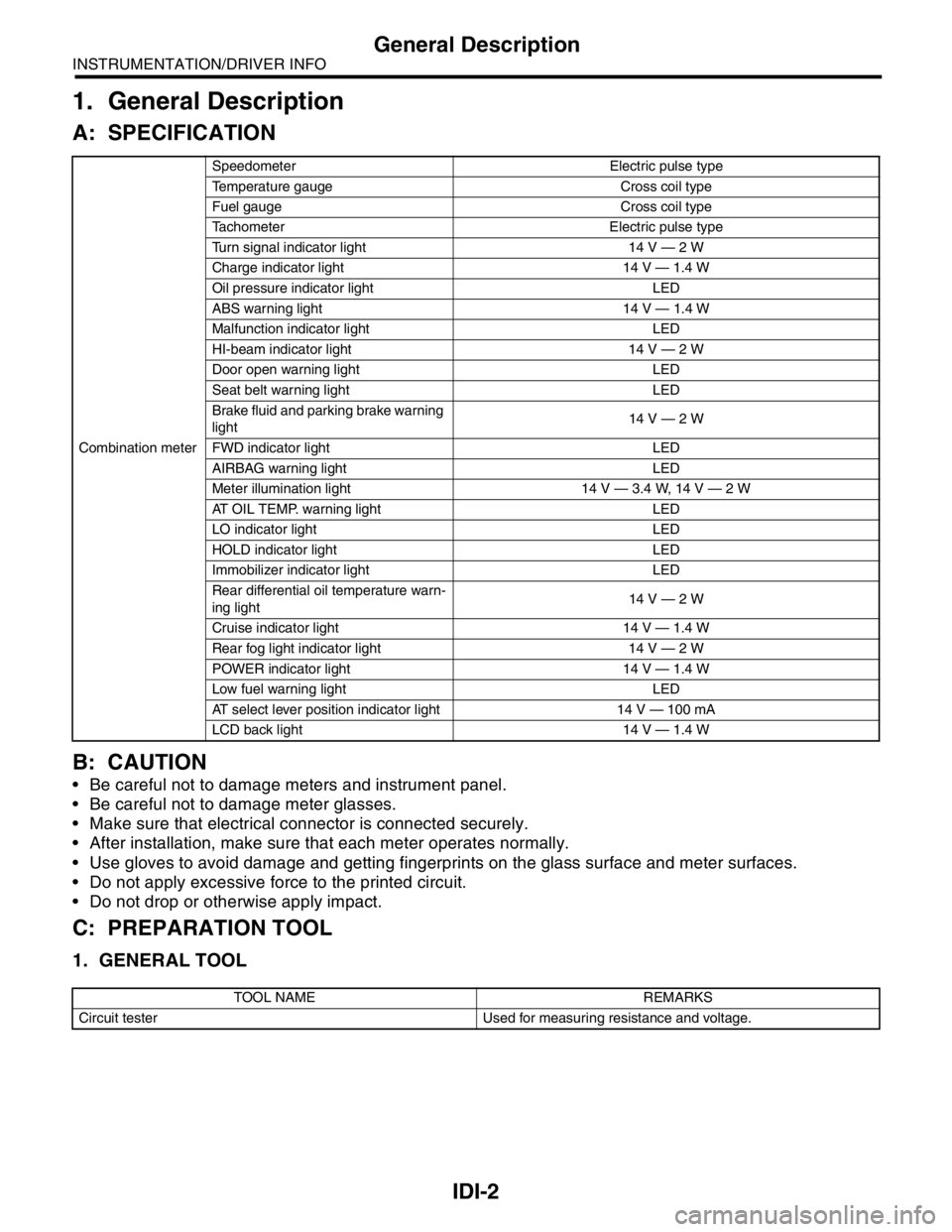

1. General Description

A: SPECIFICATION

B: CAUTION

Be careful not to damage meters and instrument panel.

Be careful not to damage meter glasses.

Make sure that electrical connector is connected securely.

After installation, make sure that each meter operates normally.

Use gloves to avoid damage and getting fingerprints on the glass surface and meter surfaces.

Do not apply excessive force to the printed circuit.

Do not drop or otherwise apply impact.

C: PREPARATION TOOL

1. GENERAL TOOL

Combination meterSpeedometer Electric pulse type

Temperature gauge Cross coil type

Fuel gauge Cross coil type

Tachometer Electric pulse type

Turn signal indicator light 14 V — 2 W

Charge indicator light 14 V — 1.4 W

Oil pressure indicator light LED

ABS warning light 14 V — 1.4 W

Malfunction indicator light LED

HI-beam indicator light 14 V — 2 W

Door open warning light LED

Seat belt warning light LED

Brake fluid and parking brake warning

light14 V — 2 W

FWD indicator light LED

AIRBAG warning light LED

Meter illumination light 14 V — 3.4 W, 14 V — 2 W

AT OIL TEMP. warning light LED

LO indicator light LED

HOLD indicator light LED

Immobilizer indicator light LED

Rear differential oil temperature warn-

ing light14 V — 2 W

Cruise indicator light 14 V — 1.4 W

Rear fog light indicator light 14 V — 2 W

POWER indicator light 14 V — 1.4 W

Low fuel warning light LED

AT select lever position indicator light 14 V — 100 mA

LCD back light 14 V — 1.4 W

TOOL NAME REMARKS

Circuit tester Used for measuring resistance and voltage.

Page 726 of 2870

PI-3

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

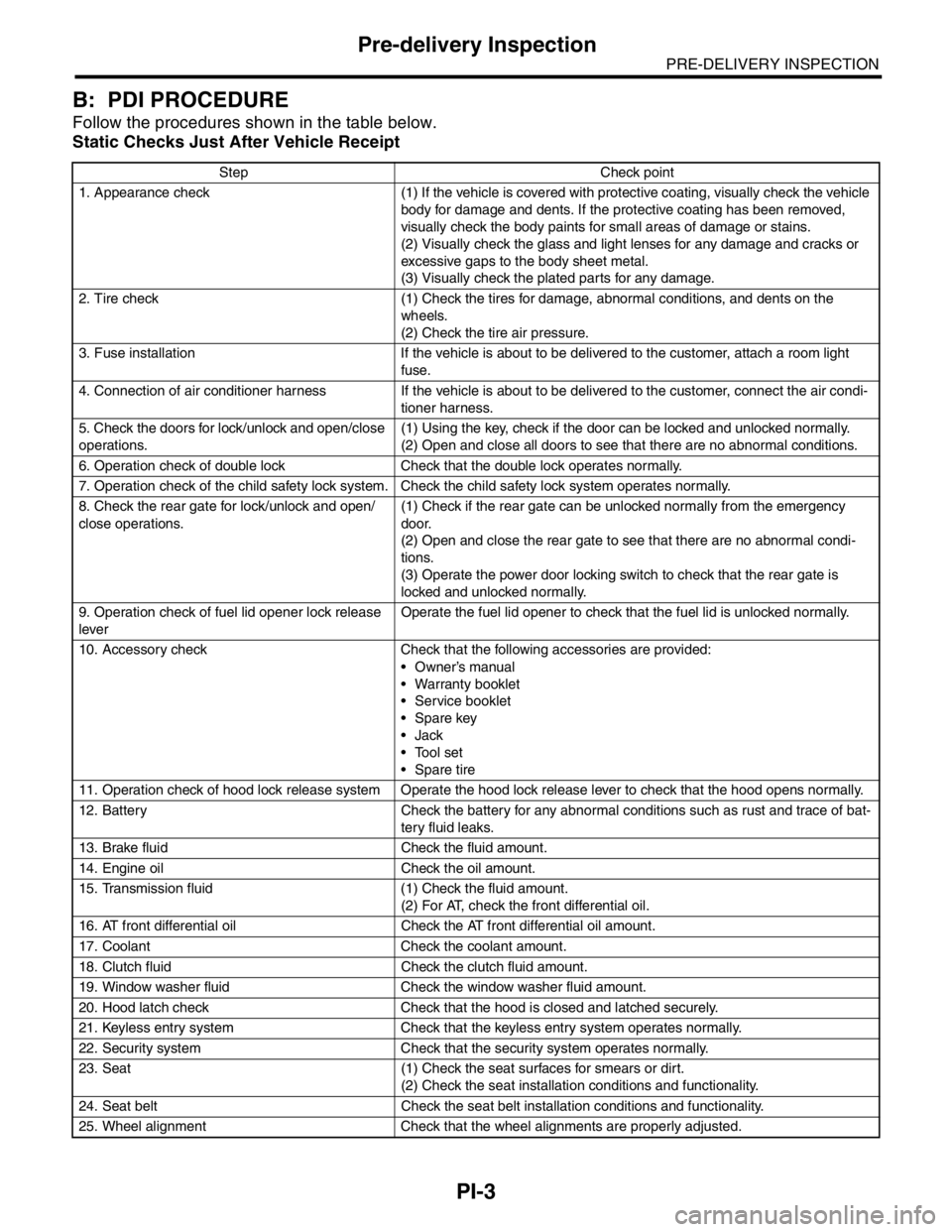

B: PDI PROCEDURE

Follow the procedures shown in the table below.

Static Checks Just After Vehicle Receipt

Step Check point

1. Appearance check (1) If the vehicle is covered with protective coating, visually check the vehicle

body for damage and dents. If the protective coating has been removed,

visually check the body paints for small areas of damage or stains.

(2) Visually check the glass and light lenses for any damage and cracks or

excessive gaps to the body sheet metal.

(3) Visually check the plated parts for any damage.

2. Tire check (1) Check the tires for damage, abnormal conditions, and dents on the

wheels.

(2) Check the tire air pressure.

3. Fuse installation If the vehicle is about to be delivered to the customer, attach a room light

fuse.

4. Connection of air conditioner harness If the vehicle is about to be delivered to the customer, connect the air condi-

tioner harness.

5. Check the doors for lock/unlock and open/close

operations.(1) Using the key, check if the door can be locked and unlocked normally.

(2) Open and close all doors to see that there are no abnormal conditions.

6. Operation check of double lock Check that the double lock operates normally.

7. Operation check of the child safety lock system. Check the child safety lock system operates normally.

8. Check the rear gate for lock/unlock and open/

close operations.(1) Check if the rear gate can be unlocked normally from the emergency

door.

(2) Open and close the rear gate to see that there are no abnormal condi-

tions.

(3) Operate the power door locking switch to check that the rear gate is

locked and unlocked normally.

9. Operation check of fuel lid opener lock release

leverOperate the fuel lid opener to check that the fuel lid is unlocked normally.

10. Accessory check Check that the following accessories are provided:

Owner’s manual

Warranty booklet

Service booklet

Spare key

Jack

Tool set

Spare tire

11. Operation check of hood lock release system Operate the hood lock release lever to check that the hood opens normally.

12. Battery Check the battery for any abnormal conditions such as rust and trace of bat-

tery fluid leaks.

13. Brake fluid Check the fluid amount.

14. Engine oil Check the oil amount.

15. Transmission fluid (1) Check the fluid amount.

(2) For AT, check the front differential oil.

16. AT front differential oil Check the AT front differential oil amount.

17. Coolant Check the coolant amount.

18. Clutch fluid Check the clutch fluid amount.

19. Window washer fluid Check the window washer fluid amount.

20. Hood latch check Check that the hood is closed and latched securely.

21. Keyless entry system Check that the keyless entry system operates normally.

22. Security system Check that the security system operates normally.

23. Seat (1) Check the seat surfaces for smears or dirt.

(2) Check the seat installation conditions and functionality.

24. Seat belt Check the seat belt installation conditions and functionality.

25. Wheel alignment Check that the wheel alignments are properly adjusted.

Page 735 of 2870

PI-12

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

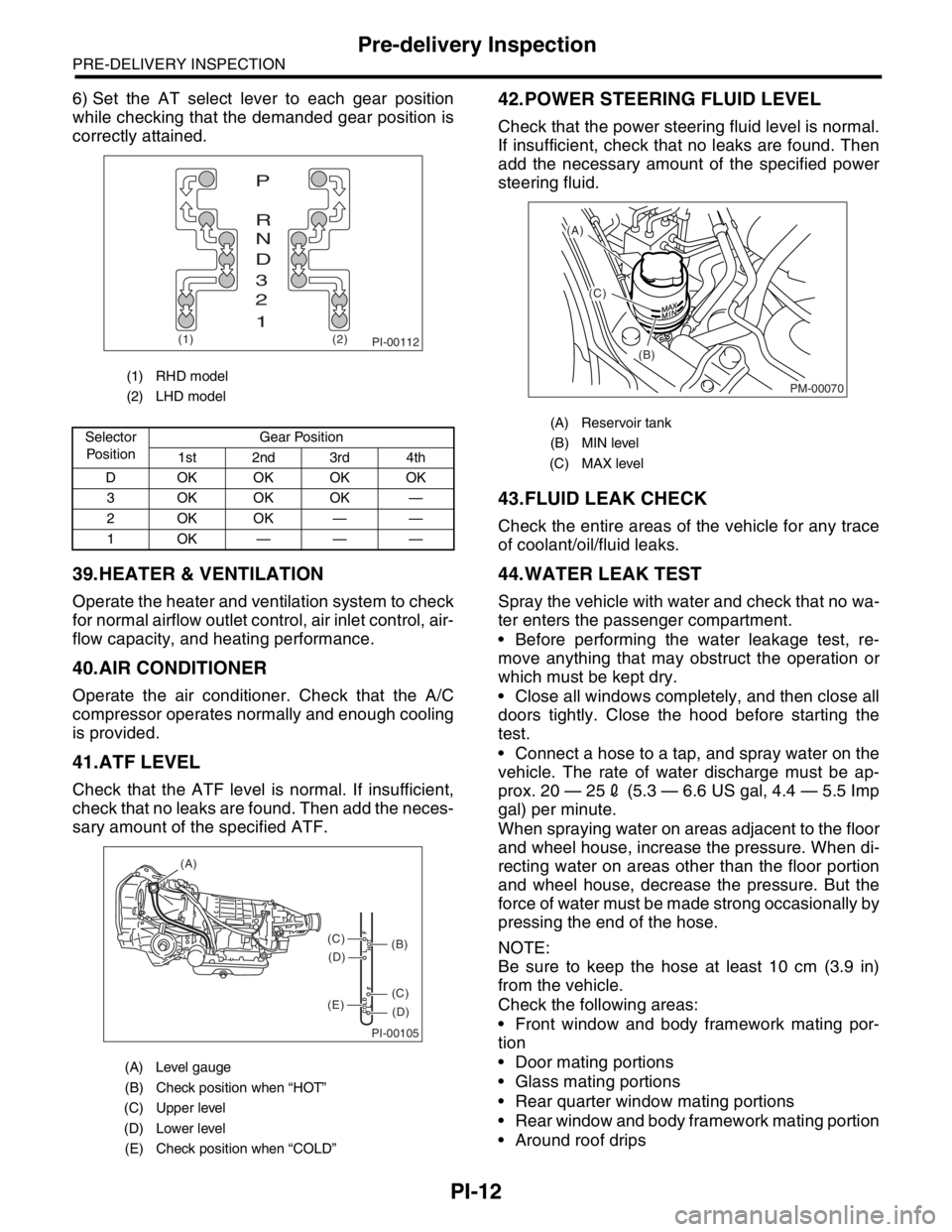

6) Set the AT select lever to each gear position

while checking that the demanded gear position is

correctly attained.

39.HEATER & VENTILATION

Operate the heater and ventilation system to check

for normal airflow outlet control, air inlet control, air-

flow capacity, and heating performance.

40.AIR CONDITIONER

Operate the air conditioner. Check that the A/C

compressor operates normally and enough cooling

is provided.

41.ATF LEVEL

Check that the ATF level is normal. If insufficient,

check that no leaks are found. Then add the neces-

sary amount of the specified ATF.

42.POWER STEERING FLUID LEVEL

Check that the power steering fluid level is normal.

If insufficient, check that no leaks are found. Then

add the necessary amount of the specified power

steering fluid.

43.FLUID LEAK CHECK

Check the entire areas of the vehicle for any trace

of coolant/oil/fluid leaks.

44.WATER LEAK TEST

Spray the vehicle with water and check that no wa-

ter enters the passenger compartment.

Before performing the water leakage test, re-

move anything that may obstruct the operation or

which must be kept dry.

Close all windows completely, and then close all

doors tightly. Close the hood before starting the

test.

Connect a hose to a tap, and spray water on the

vehicle. The rate of water discharge must be ap-

prox. 20 — 252 (5.3 — 6.6 US gal, 4.4 — 5.5 Imp

gal) per minute.

When spraying water on areas adjacent to the floor

and wheel house, increase the pressure. When di-

recting water on areas other than the floor portion

and wheel house, decrease the pressure. But the

force of water must be made strong occasionally by

pressing the end of the hose.

NOTE:

Be sure to keep the hose at least 10 cm (3.9 in)

from the vehicle.

Check the following areas:

Front window and body framework mating por-

tion

Door mating portions

Glass mating portions

Rear quarter window mating portions

Rear window and body framework mating portion

Around roof drips

(1) RHD model

(2) LHD model

Selector

Po si t io nGear Position

1st 2nd 3rd 4th

D OKOKOKOK

3 OKOKOK —

2OKOK——

1OK———

(A) Level gauge

(B) Check position when “HOT”

(C) Upper level

(D) Lower level

(E) Check position when “COLD”

PI-00112(1) (2)

P

R

N

D

3

2

1

PI-00105

COLD

LFHOT LF

(A)

(C)

(D)

(C)

(D)

(E)

(B)

(A) Reservoir tank

(B) MIN level

(C) MAX level

PM-00070

(A)

(C)

(B)