water pump SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 721 of 2870

RM-6

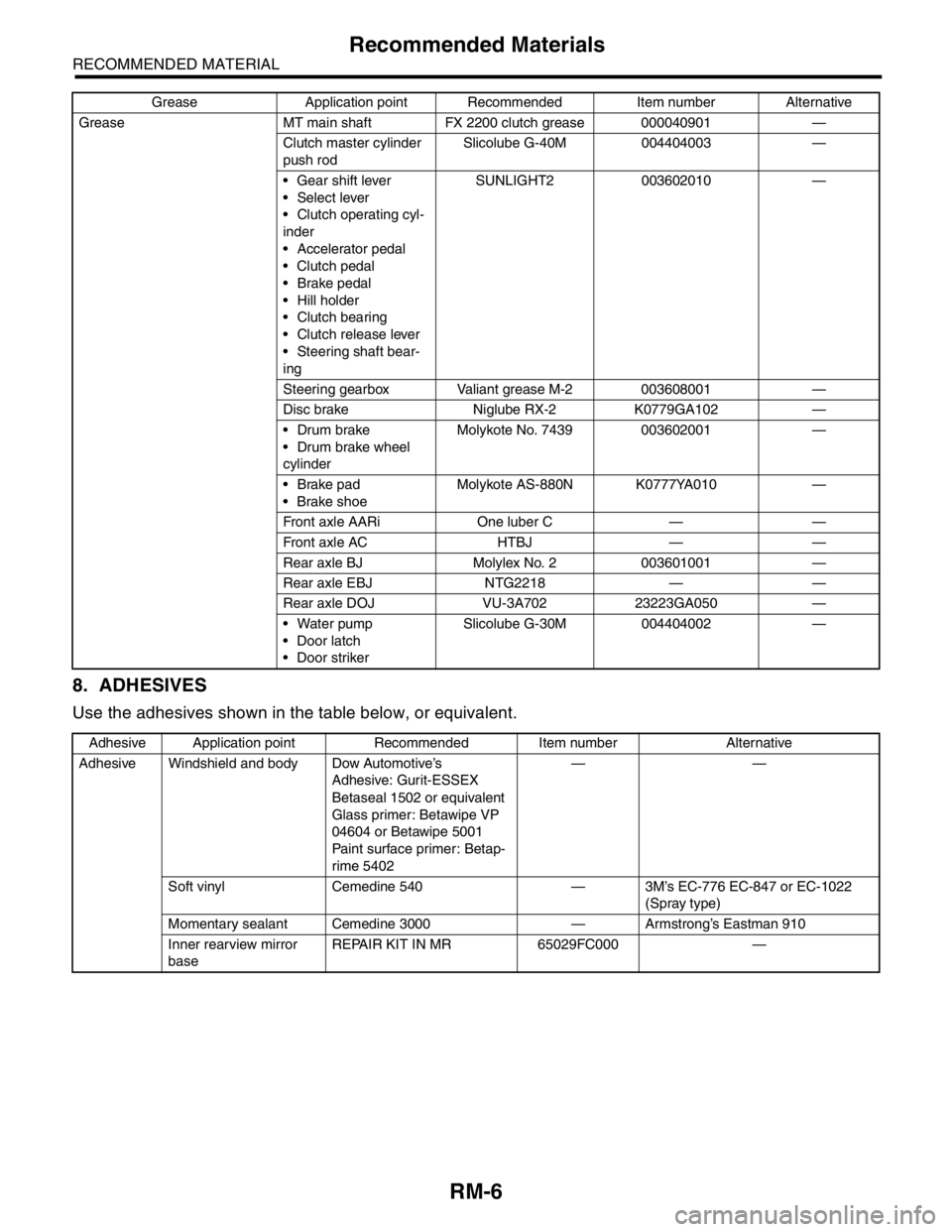

RECOMMENDED MATERIAL

Recommended Materials

8. ADHESIVES

Use the adhesives shown in the table below, or equivalent.

Grease MT main shaft FX 2200 clutch grease 000040901 —

Clutch master cylinder

push rodSlicolube G-40M 004404003 —

Gear shift lever

Select lever

Clutch operating cyl-

inder

Accelerator pedal

Clutch pedal

Brake pedal

Hill holder

Clutch bearing

Clutch release lever

Steering shaft bear-

ingSUNLIGHT2 003602010 —

Steering gearbox Valiant grease M-2 003608001 —

Disc brake Niglube RX-2 K0779GA102 —

Drum brake

Drum brake wheel

cylinderMolykote No. 7439 003602001 —

Brake pad

Brake shoeMolykote AS-880N K0777YA010 —

Front axle AARi One luber C — —

Front axle AC HTBJ — —

Rear axle BJ Molylex No. 2 003601001 —

Rear axle EBJ NTG2218 — —

Rear axle DOJ VU-3A702 23223GA050 —

Water pump

Door latch

Door strikerSlicolube G-30M 004404002 —

Adhesive Application point Recommended Item number Alternative

Adhesive Windshield and body Dow Automotive’s

Adhesive: Gurit-ESSEX

Betaseal 1502 or equivalent

Glass primer: Betawipe VP

04604 or Betawipe 5001

Paint surface primer: Betap-

rime 5402——

Soft vinyl Cemedine 540 — 3M’s EC-776 EC-847 or EC-1022

(Spray type)

Momentary sealant Cemedine 3000 — Armstrong’s Eastman 910

Inner rearview mirror

baseREPAIR KIT IN MR 65029FC000 — Grease Application point Recommended Item number Alternative

Page 748 of 2870

PM-11

PERIODIC MAINTENANCE SERVICE

V-belt

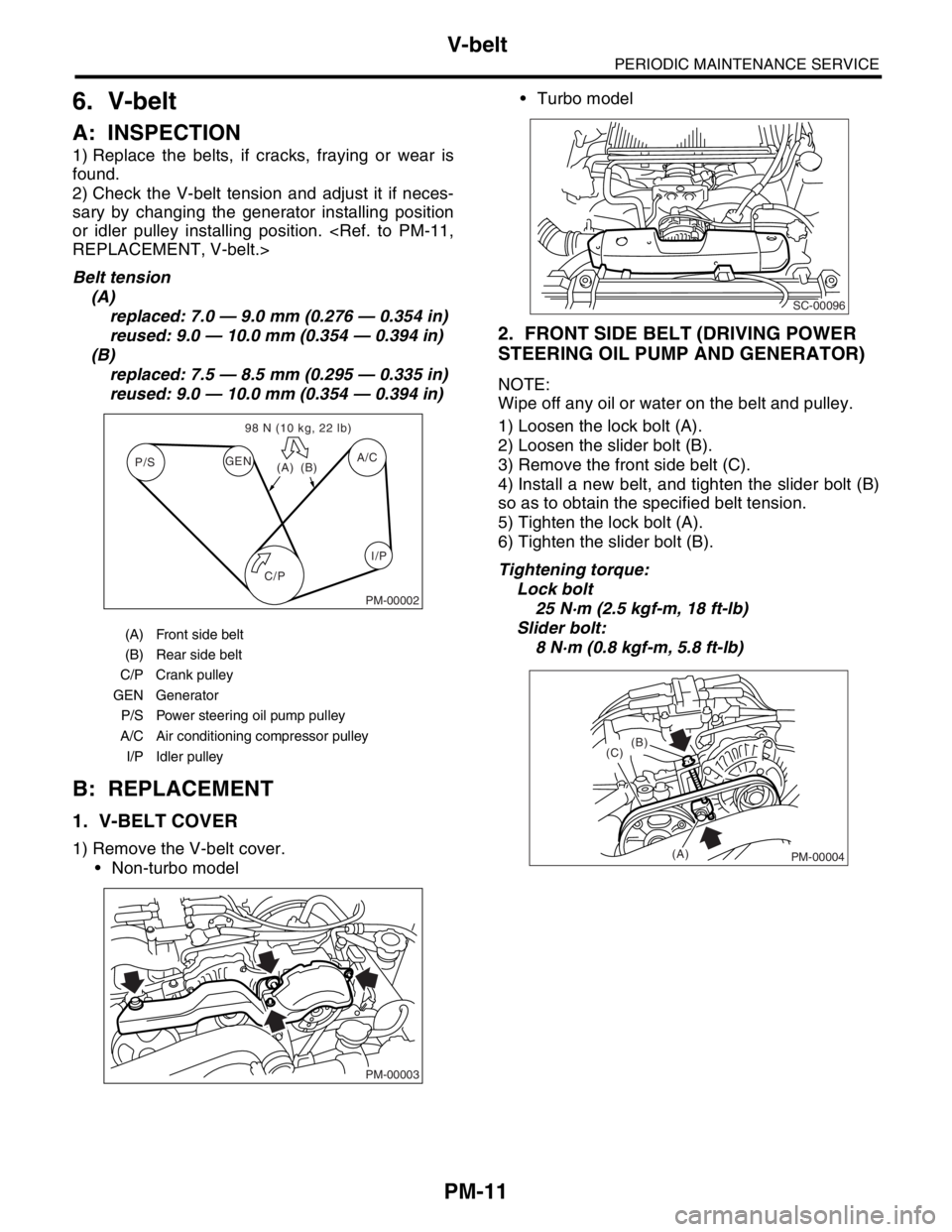

6. V-belt

A: INSPECTION

1) Replace the belts, if cracks, fraying or wear is

found.

2) Check the V-belt tension and adjust it if neces-

sary by changing the generator installing position

or idler pulley installing position.

Belt tension

(A)

replaced: 7.0 — 9.0 mm (0.276 — 0.354 in)

reused: 9.0 — 10.0 mm (0.354 — 0.394 in)

(B)

replaced: 7.5 — 8.5 mm (0.295 — 0.335 in)

reused: 9.0 — 10.0 mm (0.354 — 0.394 in)

B: REPLACEMENT

1. V-BELT COVER

1) Remove the V-belt cover.

Non-turbo model Turbo model

2. FRONT SIDE BELT (DRIVING POWER

STEERING OIL PUMP AND GENERATOR)

NOTE:

Wipe off any oil or water on the belt and pulley.

1) Loosen the lock bolt (A).

2) Loosen the slider bolt (B).

3) Remove the front side belt (C).

4) Install a new belt, and tighten the slider bolt (B)

so as to obtain the specified belt tension.

5) Tighten the lock bolt (A).

6) Tighten the slider bolt (B).

Tightening torque:

Lock bolt

25 N·m (2.5 kgf-m, 18 ft-lb)

Slider bolt:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

(A) Front side belt

(B) Rear side belt

C/P Crank pulley

GEN Generator

P/S Power steering oil pump pulley

A/C Air conditioning compressor pulley

I/P Idler pulley

C/P P/SA/C

GEN

(A)(B) 98 N (10 kg, 22 lb)

I/P

PM-00002

PM-00003

SC-00096

PM-00004

(B)

(C)

(A)

Page 752 of 2870

PM-15

PERIODIC MAINTENANCE SERVICE

Timing Belt

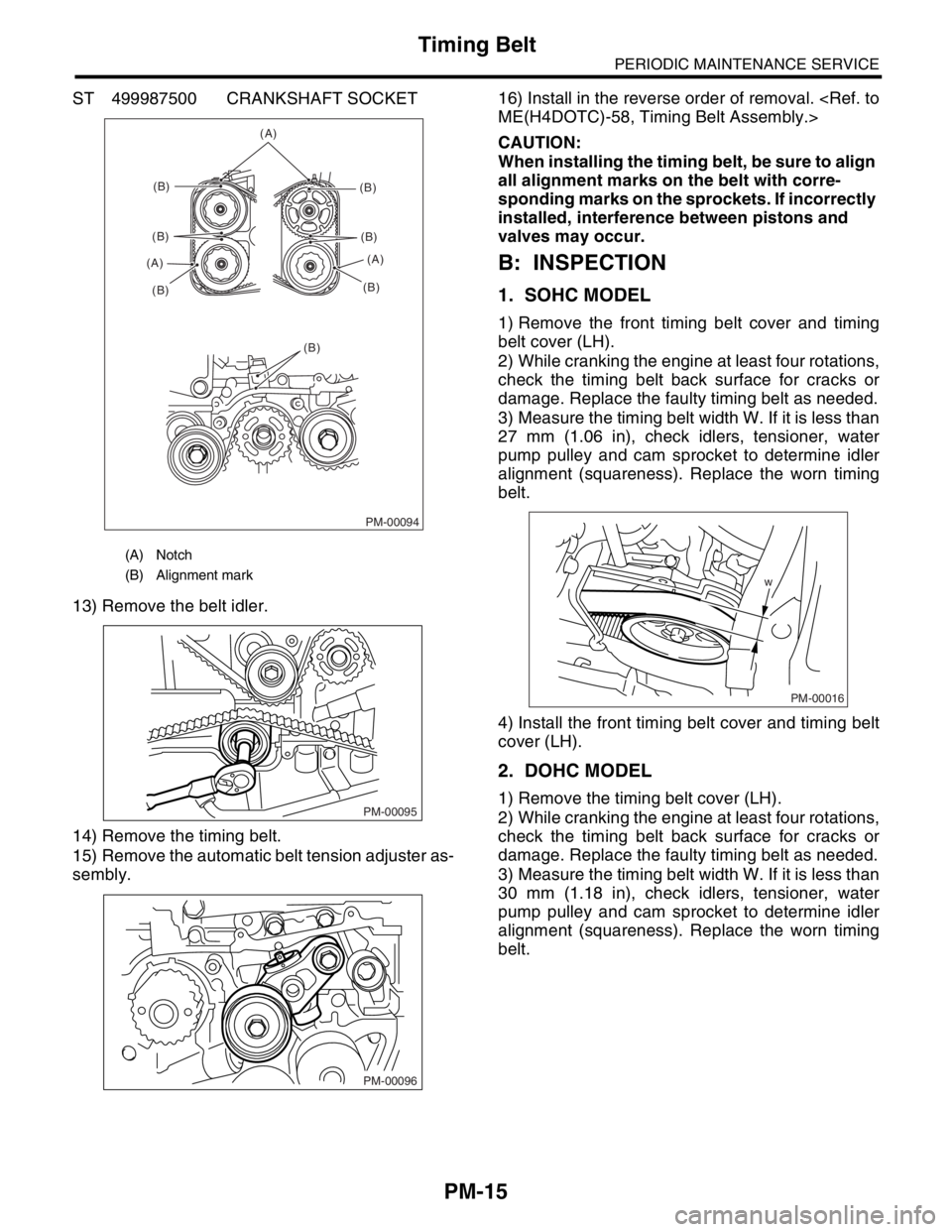

ST 499987500 CRANKSHAFT SOCKET

13) Remove the belt idler.

14) Remove the timing belt.

15) Remove the automatic belt tension adjuster as-

sembly.16) Install in the reverse order of removal.

CAUTION:

When installing the timing belt, be sure to align

all alignment marks on the belt with corre-

sponding marks on the sprockets. If incorrectly

installed, interference between pistons and

valves may occur.

B: INSPECTION

1. SOHC MODEL

1) Remove the front timing belt cover and timing

belt cover (LH).

2) While cranking the engine at least four rotations,

check the timing belt back surface for cracks or

damage. Replace the faulty timing belt as needed.

3) Measure the timing belt width W. If it is less than

27 mm (1.06 in), check idlers, tensioner, water

pump pulley and cam sprocket to determine idler

alignment (squareness). Replace the worn timing

belt.

4) Install the front timing belt cover and timing belt

cover (LH).

2. DOHC MODEL

1) Remove the timing belt cover (LH).

2) While cranking the engine at least four rotations,

check the timing belt back surface for cracks or

damage. Replace the faulty timing belt as needed.

3) Measure the timing belt width W. If it is less than

30 mm (1.18 in), check idlers, tensioner, water

pump pulley and cam sprocket to determine idler

alignment (squareness). Replace the worn timing

belt.

(A) Notch

(B) Alignment mark

PM-00094

(A)

(B)

(B)

(B) (A)(B)

(B)

(B)(A)

(B)

PM-00095

PM-00096

w

PM-00016

Page 757 of 2870

PM-20

PERIODIC MAINTENANCE SERVICE

Cooling System

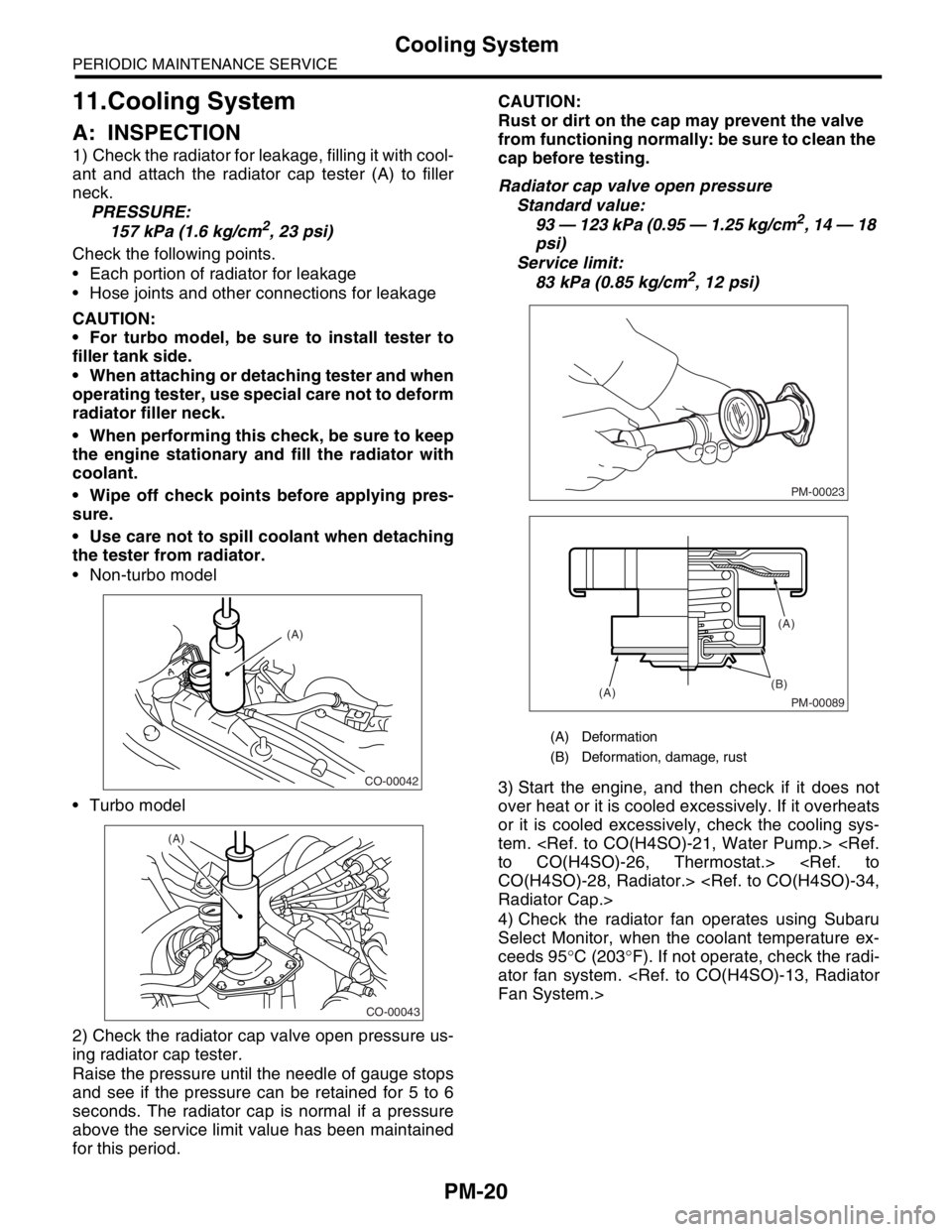

11.Cooling System

A: INSPECTION

1) Check the radiator for leakage, filling it with cool-

ant and attach the radiator cap tester (A) to filler

neck.

PRESSURE:

157 kPa (1.6 kg/cm

2, 23 psi)

Check the following points.

Each portion of radiator for leakage

Hose joints and other connections for leakage

CAUTION:

For turbo model, be sure to install tester to

filler tank side.

When attaching or detaching tester and when

operating tester, use special care not to deform

radiator filler neck.

When performing this check, be sure to keep

the engine stationary and fill the radiator with

coolant.

Wipe off check points before applying pres-

sure.

Use care not to spill coolant when detaching

the tester from radiator.

Non-turbo model

Turbo model

2) Check the radiator cap valve open pressure us-

ing radiator cap tester.

Raise the pressure until the needle of gauge stops

and see if the pressure can be retained for 5 to 6

seconds. The radiator cap is normal if a pressure

above the service limit value has been maintained

for this period.CAUTION:

Rust or dirt on the cap may prevent the valve

from functioning normally: be sure to clean the

cap before testing.

Radiator cap valve open pressure

Standard value:

93 — 123 kPa (0.95 — 1.25 kg/cm2, 14 — 18

psi)

Service limit:

83 kPa (0.85 kg/cm

2, 12 psi)

3) Start the engine, and then check if it does not

over heat or it is cooled excessively. If it overheats

or it is cooled excessively, check the cooling sys-

tem.

4) Check the radiator fan operates using Subaru

Select Monitor, when the coolant temperature ex-

ceeds 95°C (203°F). If not operate, check the radi-

ator fan system.

CO-00042

(A)

CO-00043

(A)

(A) Deformation

(B) Deformation, damage, rust

PM-00023

PM-00089

(B)

(A)(A)

Page 848 of 2870

FU(H4SO)-66

FUEL INJECTION (FUEL SYSTEM)

Fuel System Trouble in General

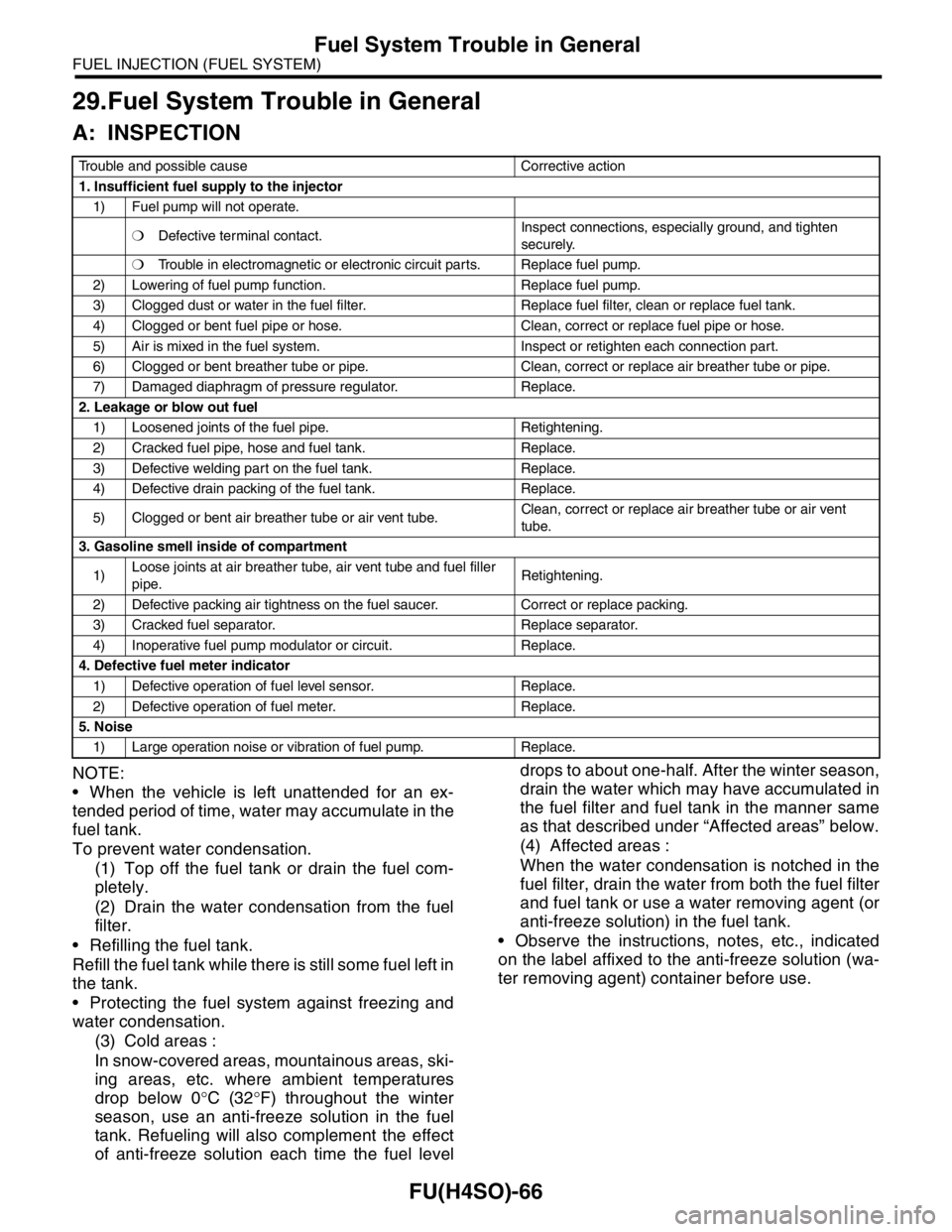

29.Fuel System Trouble in General

A: INSPECTION

NOTE:

When the vehicle is left unattended for an ex-

tended period of time, water may accumulate in the

fuel tank.

To prevent water condensation.

(1) Top off the fuel tank or drain the fuel com-

pletely.

(2) Drain the water condensation from the fuel

filter.

Refilling the fuel tank.

Refill the fuel tank while there is still some fuel left in

the tank.

Protecting the fuel system against freezing and

water condensation.

(3) Cold areas :

In snow-covered areas, mountainous areas, ski-

ing areas, etc. where ambient temperatures

drop below 0°C (32°F) throughout the winter

season, use an anti-freeze solution in the fuel

tank. Refueling will also complement the effect

of anti-freeze solution each time the fuel leveldrops to about one-half. After the winter season,

drain the water which may have accumulated in

the fuel filter and fuel tank in the manner same

as that described under “Affected areas” below.

(4) Affected areas :

When the water condensation is notched in the

fuel filter, drain the water from both the fuel filter

and fuel tank or use a water removing agent (or

anti-freeze solution) in the fuel tank.

Observe the instructions, notes, etc., indicated

on the label affixed to the anti-freeze solution (wa-

ter removing agent) container before use.

Trouble and possible cause Corrective action

1. Insufficient fuel supply to the injector

1) Fuel pump will not operate.

❍Defective terminal contact.Inspect connections, especially ground, and tighten

securely.

❍Trouble in electromagnetic or electronic circuit parts. Replace fuel pump.

2) Lowering of fuel pump function. Replace fuel pump.

3) Clogged dust or water in the fuel filter. Replace fuel filter, clean or replace fuel tank.

4) Clogged or bent fuel pipe or hose. Clean, correct or replace fuel pipe or hose.

5) Air is mixed in the fuel system. Inspect or retighten each connection part.

6) Clogged or bent breather tube or pipe. Clean, correct or replace air breather tube or pipe.

7) Damaged diaphragm of pressure regulator. Replace.

2. Leakage or blow out fuel

1) Loosened joints of the fuel pipe. Retightening.

2) Cracked fuel pipe, hose and fuel tank. Replace.

3) Defective welding part on the fuel tank. Replace.

4) Defective drain packing of the fuel tank. Replace.

5) Clogged or bent air breather tube or air vent tube.Clean, correct or replace air breather tube or air vent

tube.

3. Gasoline smell inside of compartment

1)Loose joints at air breather tube, air vent tube and fuel filler

pipe.Retightening.

2) Defective packing air tightness on the fuel saucer. Correct or replace packing.

3) Cracked fuel separator. Replace separator.

4) Inoperative fuel pump modulator or circuit. Replace.

4. Defective fuel meter indicator

1) Defective operation of fuel level sensor. Replace.

2) Defective operation of fuel meter. Replace.

5. Noise

1) Large operation noise or vibration of fuel pump. Replace.

Page 879 of 2870

ME(H4SO)-10

MECHANICAL

General Description

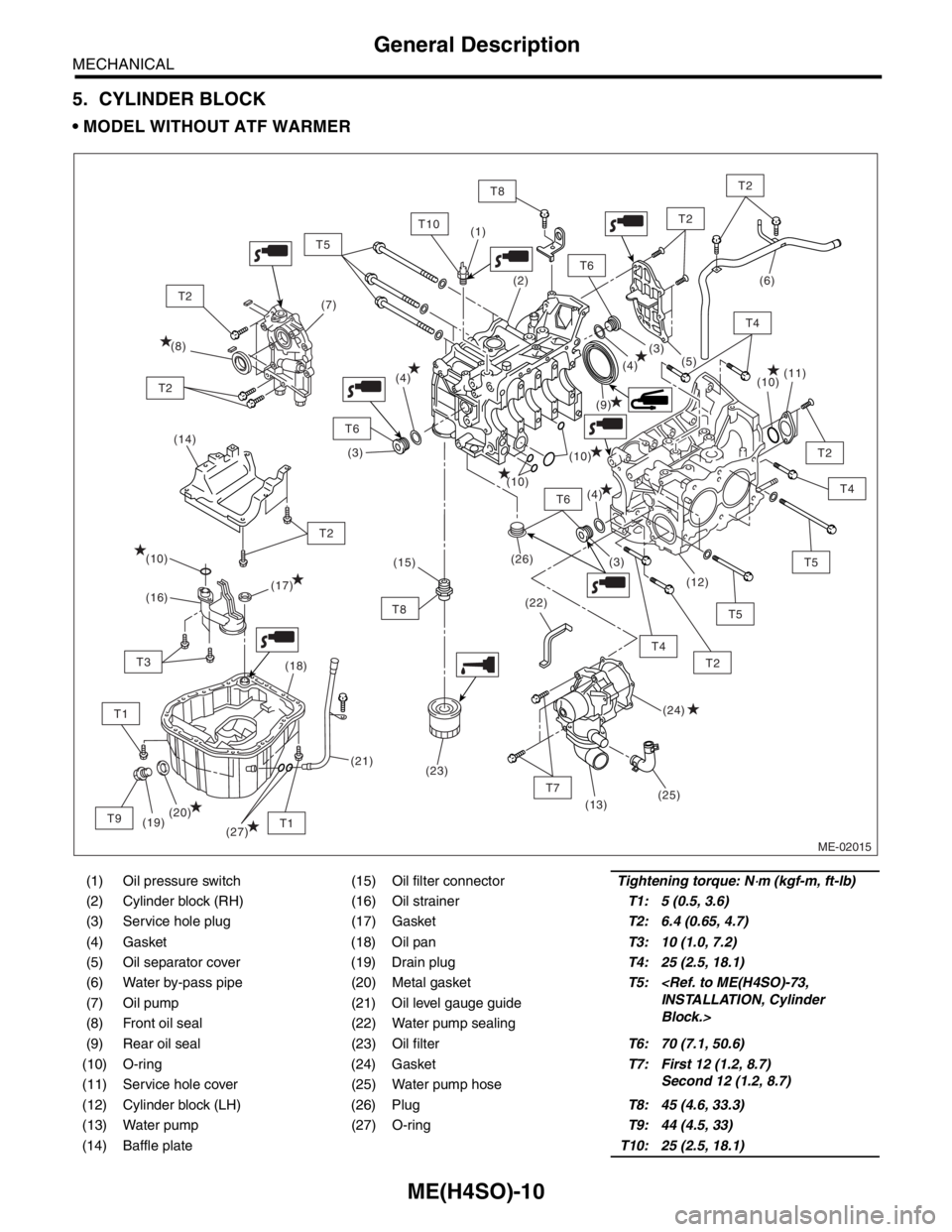

5. CYLINDER BLOCK

MODEL WITHOUT ATF WARMER

(1) Oil pressure switch (15) Oil filter connectorTightening torque: N⋅m (kgf-m, ft-lb)

(2) Cylinder block (RH) (16) Oil strainerT1: 5 (0.5, 3.6)

(3) Service hole plug (17) GasketT2: 6.4 (0.65, 4.7)

(4) Gasket (18) Oil panT3: 10 (1.0, 7.2)

(5) Oil separator cover (19) Drain plugT4: 25 (2.5, 18.1)

(6) Water by-pass pipe (20) Metal gasketT5:

Block.> (7) Oil pump (21) Oil level gauge guide

(8) Front oil seal (22) Water pump sealing

(9) Rear oil seal (23) Oil filterT6: 70 (7.1, 50.6)

(10) O-ring (24) GasketT7: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(11) Service hole cover (25) Water pump hose

(12) Cylinder block (LH) (26) PlugT8: 45 (4.6, 33.3)

(13) Water pump (27) O-ringT9: 44 (4.5, 33)

(14) Baffle plateT10: 25 (2.5, 18.1)

ME-02015

(14)

T6

T7

T2

T2

T4

T8

T4

T5

T2

T6

T6

T10

T1

T2

T8

T1

T3

T9

T2

T2

(9) (8)(7)(6)

(10)

(10)

(10)

(26)

(22)(11)

(12)

(13)

(19)(18)

(20)(17)

(16)

(24) (10)

(25)(5)

(4)

(4)

(4)(3)

(3)

(3) (2) (1)

(21)(15)

(23)

T5

T2

T5

T4

(27)

Page 880 of 2870

ME(H4SO)-11

MECHANICAL

General Description

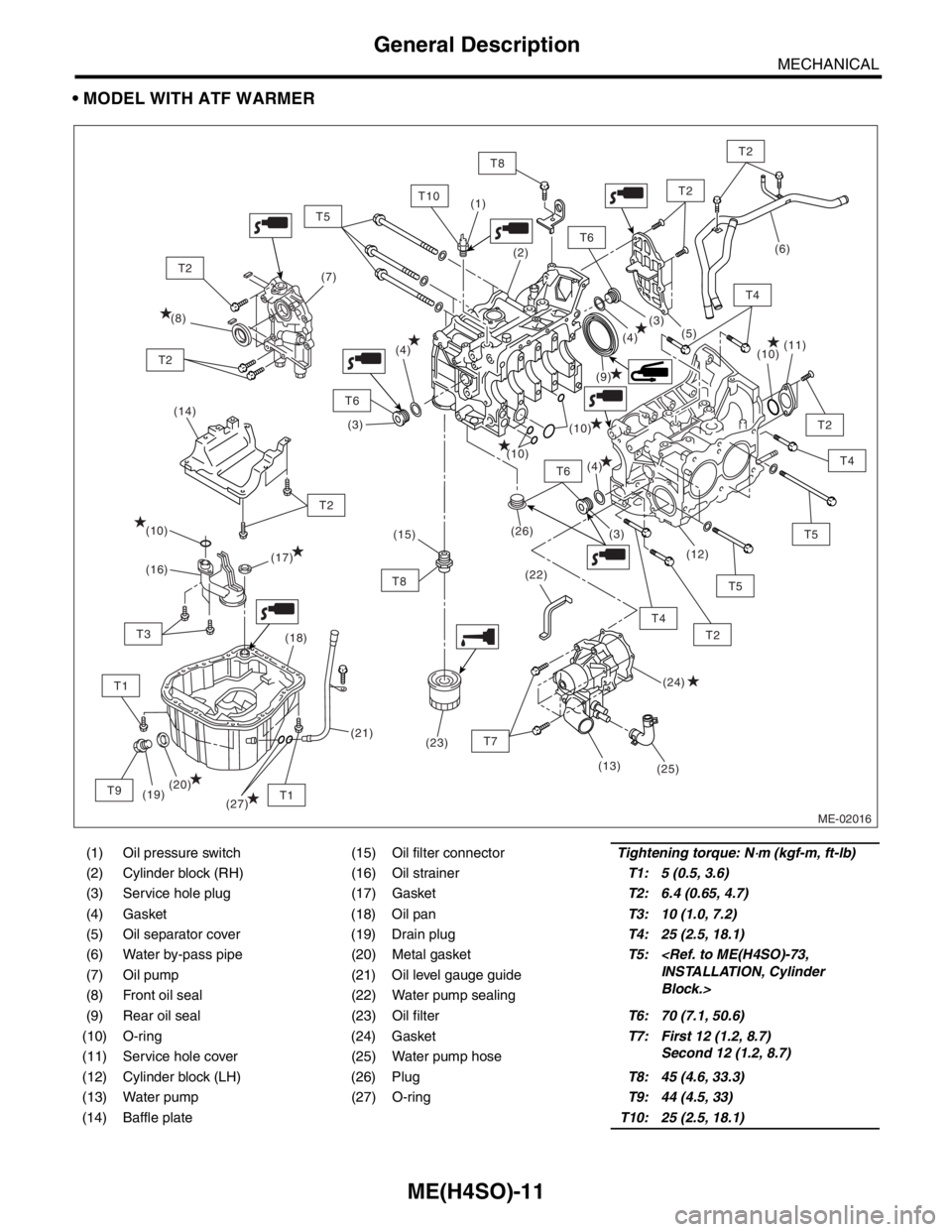

MODEL WITH ATF WARMER

(1) Oil pressure switch (15) Oil filter connectorTightening torque: N⋅m (kgf-m, ft-lb)

(2) Cylinder block (RH) (16) Oil strainerT1: 5 (0.5, 3.6)

(3) Service hole plug (17) GasketT2: 6.4 (0.65, 4.7)

(4) Gasket (18) Oil panT3: 10 (1.0, 7.2)

(5) Oil separator cover (19) Drain plugT4: 25 (2.5, 18.1)

(6) Water by-pass pipe (20) Metal gasketT5:

Block.> (7) Oil pump (21) Oil level gauge guide

(8) Front oil seal (22) Water pump sealing

(9) Rear oil seal (23) Oil filterT6: 70 (7.1, 50.6)

(10) O-ring (24) GasketT7: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(11) Service hole cover (25) Water pump hose

(12) Cylinder block (LH) (26) PlugT8: 45 (4.6, 33.3)

(13) Water pump (27) O-ringT9: 44 (4.5, 33)

(14) Baffle plateT10: 25 (2.5, 18.1)

ME-02016

(14)

T6

T2

T2

T4

T8

T5

T2

T6

T6

T10

T1

T2

T8

T1

T3

T9

T2

T2

(9) (8)(7)

(10)

(10)

(10)

(26)

(22)(11)

(12)

(19)(18)

(20)(17)

(16)

(24) (10)

(25)(5)

(4)

(4)

(4)(3)

(3)

(3) (2) (1)

(21)(15)

(23)

T5

T2

T5

T4

(27)

T7

(13)

(6)

T4

Page 941 of 2870

ME(H4SO)-70

MECHANICAL

Cylinder Block

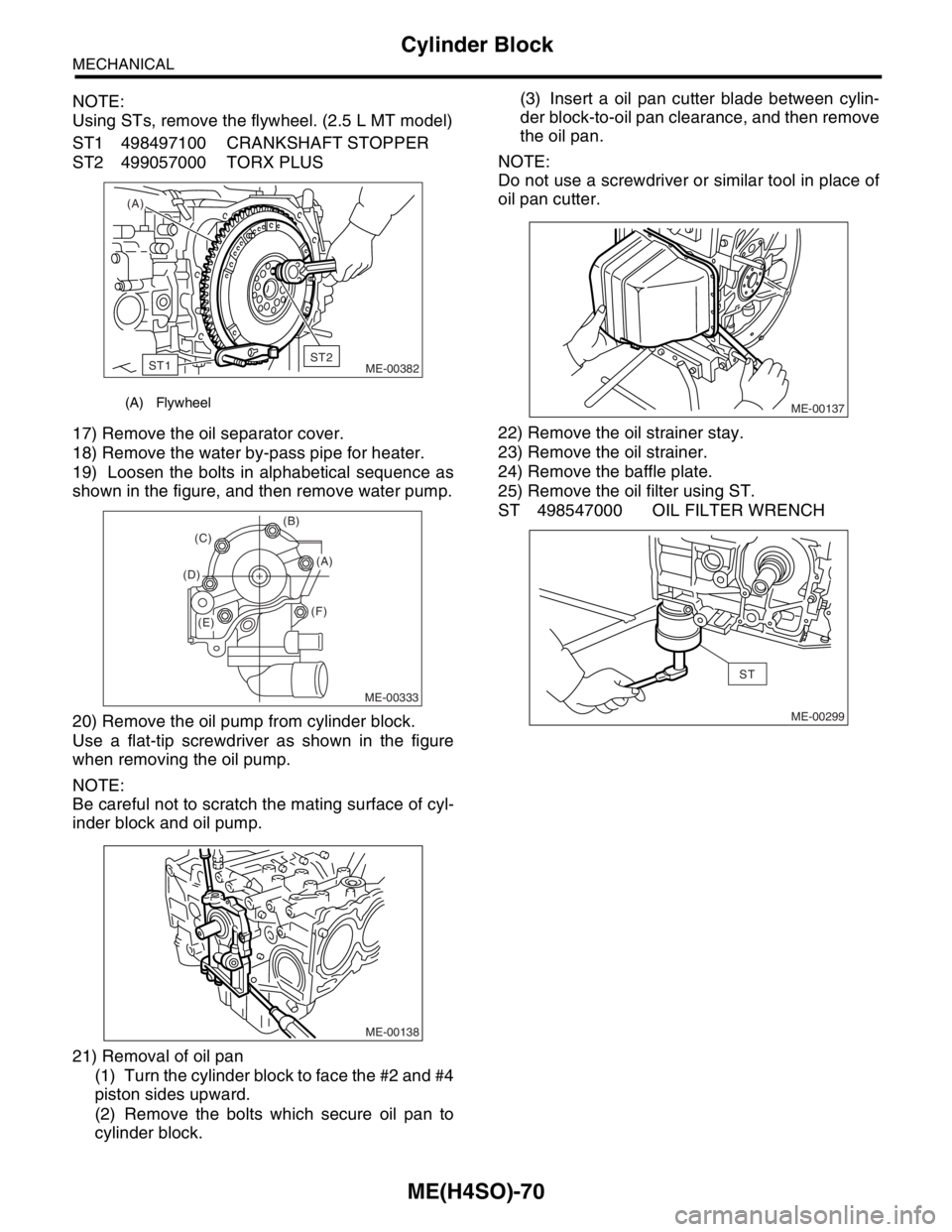

NOTE:

Using STs, remove the flywheel. (2.5 L MT model)

ST1 498497100 CRANKSHAFT STOPPER

ST2 499057000 TORX PLUS

17) Remove the oil separator cover.

18) Remove the water by-pass pipe for heater.

19) Loosen the bolts in alphabetical sequence as

shown in the figure, and then remove water pump.

20) Remove the oil pump from cylinder block.

Use a flat-tip screwdriver as shown in the figure

when removing the oil pump.

NOTE:

Be careful not to scratch the mating surface of cyl-

inder block and oil pump.

21) Removal of oil pan

(1) Turn the cylinder block to face the #2 and #4

piston sides upward.

(2) Remove the bolts which secure oil pan to

cylinder block.(3) Insert a oil pan cutter blade between cylin-

der block-to-oil pan clearance, and then remove

the oil pan.

NOTE:

Do not use a screwdriver or similar tool in place of

oil pan cutter.

22) Remove the oil strainer stay.

23) Remove the oil strainer.

24) Remove the baffle plate.

25) Remove the oil filter using ST.

ST 498547000 OIL FILTER WRENCH

(A) Flywheel

(A)

ME-00382

ST1ST2

ME-00333

(B)

(F) (D)(C)

(A)

(E)

ME-00138

ME-00137

ME-00299

ST

Page 951 of 2870

ME(H4SO)-80

MECHANICAL

Cylinder Block

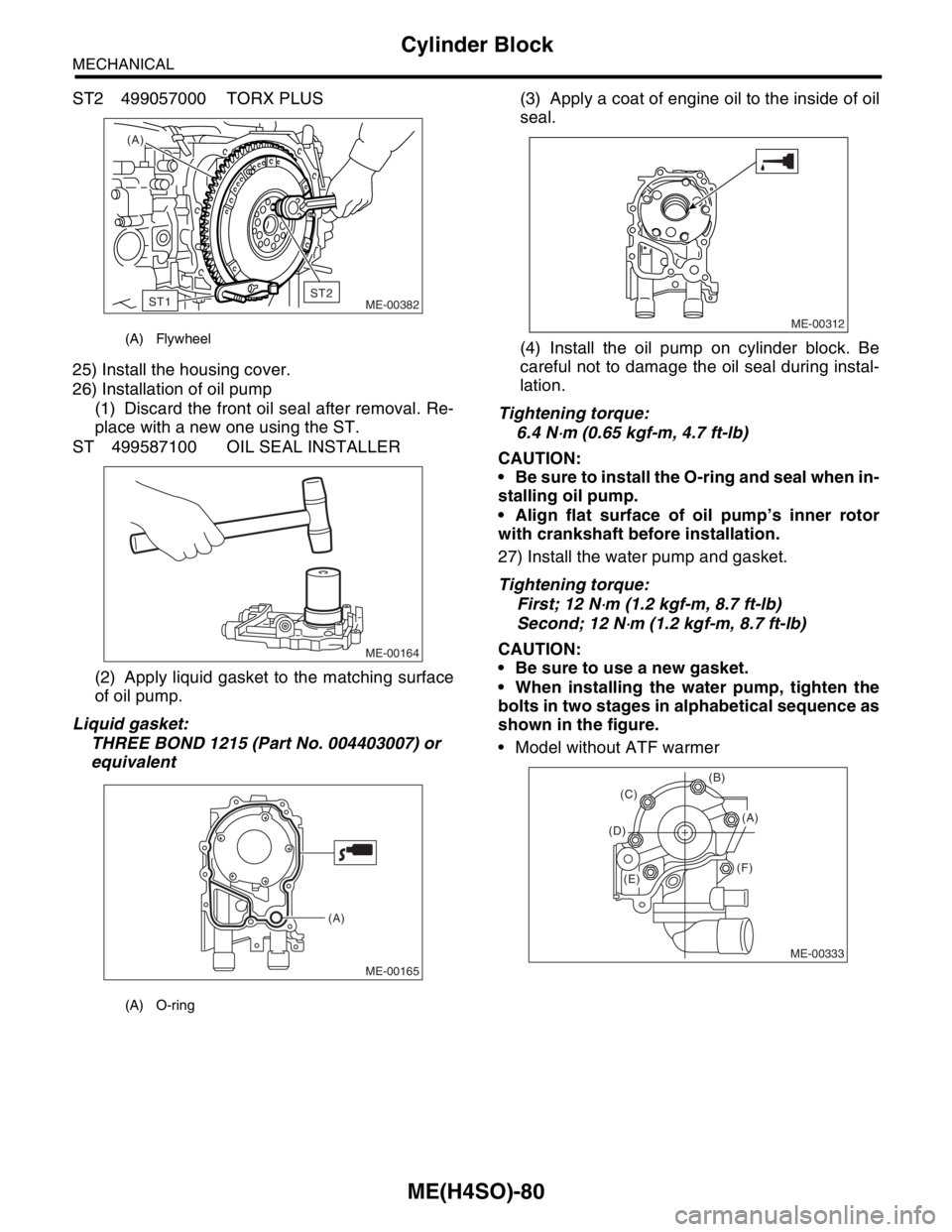

ST2 499057000 TORX PLUS

25) Install the housing cover.

26) Installation of oil pump

(1) Discard the front oil seal after removal. Re-

place with a new one using the ST.

ST 499587100 OIL SEAL INSTALLER

(2) Apply liquid gasket to the matching surface

of oil pump.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalent(3) Apply a coat of engine oil to the inside of oil

seal.

(4) Install the oil pump on cylinder block. Be

careful not to damage the oil seal during instal-

lation.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

CAUTION:

Be sure to install the O-ring and seal when in-

stalling oil pump.

Align flat surface of oil pump’s inner rotor

with crankshaft before installation.

27) Install the water pump and gasket.

Tightening torque:

First; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

CAUTION:

Be sure to use a new gasket.

When installing the water pump, tighten the

bolts in two stages in alphabetical sequence as

shown in the figure.

Model without ATF warmer

(A) Flywheel

(A) O-ring

(A)

ME-00382

ST1ST2

ME-00164

ME-00165

(A)

ME-00312

ME-00333

(B)

(F) (D)(C)

(A)

(E)

Page 967 of 2870

ME(H4SO)-96

MECHANICAL

Engine Noise

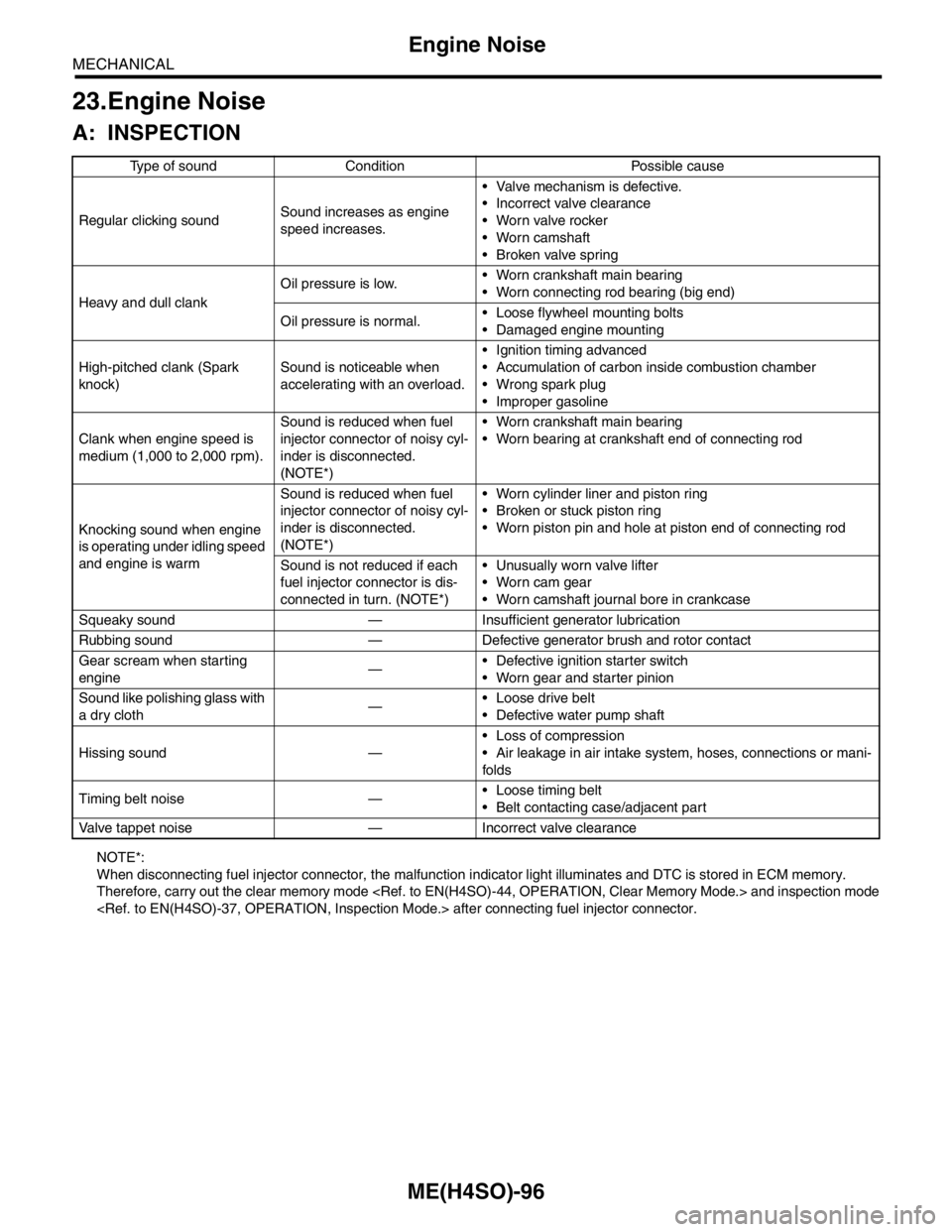

23.Engine Noise

A: INSPECTION

NOTE*:

When disconnecting fuel injector connector, the malfunction indicator light illuminates and DTC is stored in ECM memory.

Therefore, carry out the clear memory mode

Regular clicking soundSound increases as engine

speed increases. Valve mechanism is defective.

Incorrect valve clearance

Worn valve rocker

Worn camshaft

Broken valve spring

Heavy and dull clankOil pressure is low. Worn crankshaft main bearing

Worn connecting rod bearing (big end)

Oil pressure is normal. Loose flywheel mounting bolts

Damaged engine mounting

High-pitched clank (Spark

knock)Sound is noticeable when

accelerating with an overload. Ignition timing advanced

Accumulation of carbon inside combustion chamber

Wrong spark plug

Improper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm).Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*) Worn crankshaft main bearing

Worn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warmSound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*) Worn cylinder liner and piston ring

Broken or stuck piston ring

Worn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn. (NOTE*) Unusually worn valve lifter

Worn cam gear

Worn camshaft journal bore in crankcase

Squeaky sound — Insufficient generator lubrication

Rubbing sound — Defective generator brush and rotor contact

Gear scream when starting

engine— Defective ignition starter switch

Worn gear and starter pinion

Sound like polishing glass with

a dry cloth— Loose drive belt

Defective water pump shaft

Hissing sound — Loss of compression

Air leakage in air intake system, hoses, connections or mani-

folds

Timing belt noise — Loose timing belt

Belt contacting case/adjacent part

Valve tappet noise — Incorrect valve clearance