Led SUBARU FORESTER 2017 SJ / 4.G Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2017, Model line: FORESTER, Model: SUBARU FORESTER 2017 SJ / 4.GPages: 634, PDF Size: 11.77 MB

Page 595 of 634

Specifications/Bulb chart

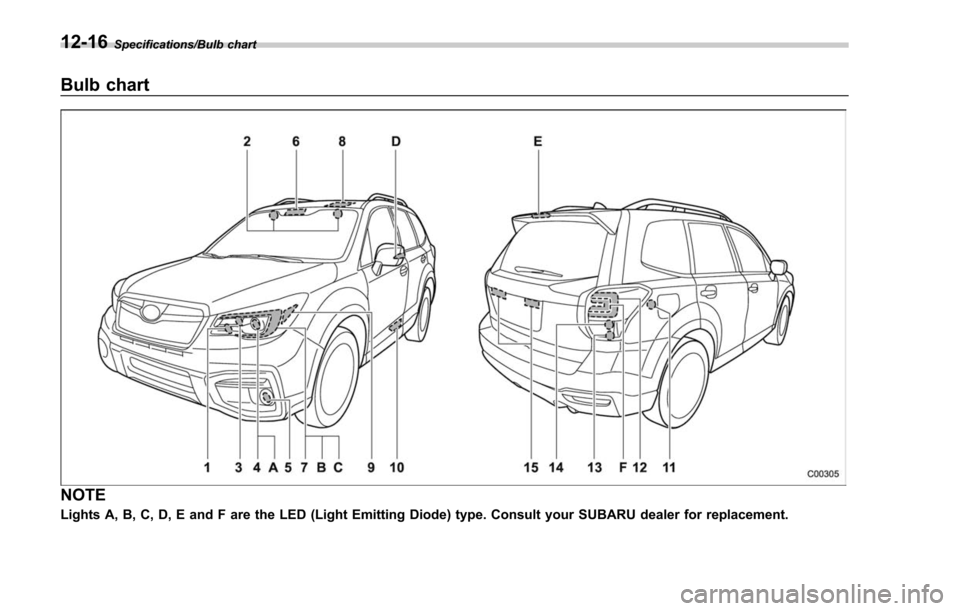

Bulb chart

NOTE

Lights A, B, C, D, E and F are the LED (Light Emitting Diode) type. Consult your SUBARU dealer for replacement.

12-16

Page 597 of 634

Specifications/Bulb chart

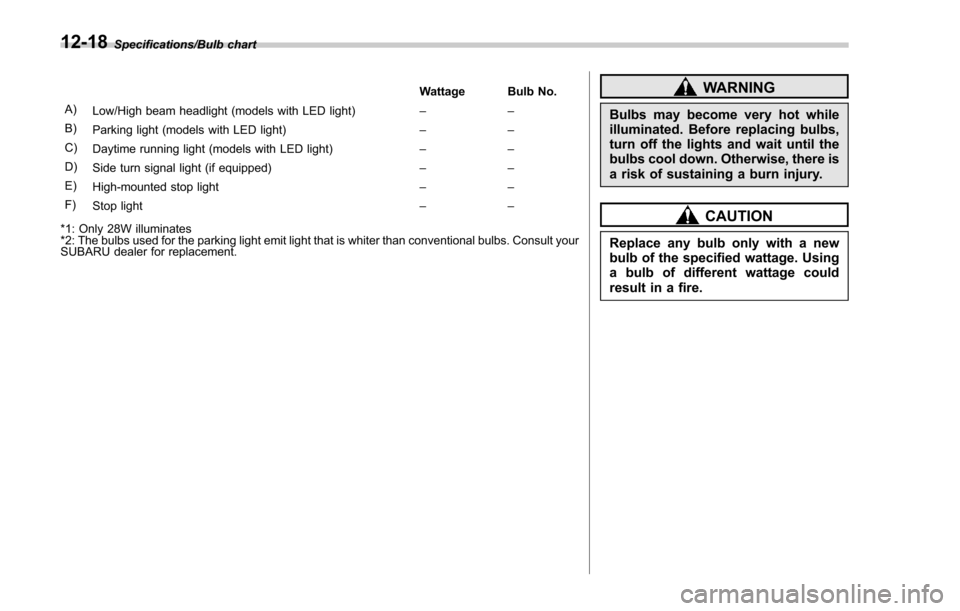

Wattage Bulb No.

A) Low/High beam headlight (models with LED light) ––

B) Parking light (models with LED light) ––

C) Daytime running light (models with LED light) ––

D) Side turn signal light (if equipped) ––

E) High-mounted stop light ––

F) Stop light ––

*1: Only 28W illuminates

*2: The bulbs used for the parking light emit light that is whiter than conventional bulbs. Consult your

SUBARU dealer for replacement.WARNING

Bulbs may become very hot while

illuminated. Before replacing bulbs,

turn off the lights and wait until the

bulbs cool down. Otherwise, there is

a risk of sustaining a burn injury.

CAUTION

Replace any bulb only with a new

bulb of the specified wattage. Using

a bulb of different wattage could

result in a fire.

12-18

Page 601 of 634

Consumer information and Reporting safety defects/For U.S.A.

For U.S.A.

The following information has been

compiled according to Code of

Federal Regulations“Title 49, Part

575 ”.

Tire information

& Tire labeling

Many markings (e.g. Tire size, Tire

Identification Number or TIN) are

placed on the sidewall of a tire by

tire manufacturers. These markings

can provide you with useful infor-

mation on the tire.

! Tire size

Your vehicle comes equipped with

P-Metric tire size. It is important to

understand the sizing system in

selecting the proper tire for your

vehicles. Here is a brief review of

the tire sizing system with a break-

down of its individual elements.

!P Metric

With the P-Metric system, Section

Width is measured in millimeters.

To convert millimeters into inches,

divide by 25.4. The Aspect Ratio

(Section Height divided by Section

Width) helps provide more dimen-

sional information about the tire

size.

Example:

(1) P = Certain tire type used on

light duty vehicles such as passen-

ger cars

(2) Section Width in millimeters

(3) Aspect Ratio (= section height

7 section width).

(4) R = Radial Construction

(5) Rim diameter in inches

! Load and Speed Rating De-

scriptions

The load and speed rating descrip-

tions will appear following the size

designation.

They provide two important facts

about the tire. First, the number

designation is its load index. Sec-

ond, the letter designation indicates

the tire’ s speed rating.

13-2

Page 604 of 634

crease in temperature could cause

tread separation, and failure of the

tire(s). Possible resulting loss of

vehicle control could lead to an

accident.

!Measuring and adjusting air

pressure to achieve proper in-

flation

Check and, if necessary, adjust the

pressure of each tire (including the

spare) at least once a month and

before any long journey. Check the

tire pressures when the tires are

cold. Use a pressure gauge to

adjust the tire pressures to the

specific values. Driving even a

short distance warms up the tires

and increases the tire pressures.

Also, the tire pressures are affected

by the outside temperature. It is

best to check tire pressure out-

doors before driving the vehicle.

When a tire becomes warm, the air

inside it expands, causing the tire

pressure to increase. Be careful not

to mistakenly release air from a

warm tire to reduce its pressure.

&Glossary of tire terminology

.Accessory weight

The combined weight (in excess of

those standard items which may be

replaced) of automatic transmis-

sion, power steering, power brakes,

power windows, power seats, radio,

and heater, to the extent that these

items are available as factory-in-

stalled equipment (whether in-

stalled or not).

.Bead

The part of the tire that is made of

steel wires, wrapped or reinforced

by ply cords and that is shaped to fit

the rim.

.Bead separation

A breakdown of the bond between

components in the bead.

.Bias ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at alternate angles substantially

less than 90 degrees to the center-

line of the tread.

.Carcass

The tire structure, except tread and sidewall rubber which, when in-

flated, bears the load.

.Chunking

The breaking away of pieces of the

tread or sidewall.

.Cold tire pressure

The pressure in a tire that has been

driven less than 1 mile or has been

standing for three hours or more.

.Cord

The strands forming the plies in the

tire.

.Cord separation

The parting of cords from adjacent

rubber compounds.

.Cracking

Any parting within the tread, side-

wall, or inner liner of the tire

extending to cord material.

.Curb weight

The weight of a motor vehicle with

standard equipment including the

maximum capacity of fuel, oil and

coolant, and if so equipped, air

conditioning and additional weight

optional engine.

Consumer information and Reporting safety defects/Tire information

–CONTINUED –13-5

Page 606 of 634

.Passenger car tire

A tire intended for use on passen-

ger cars, multipurpose passenger

vehicles, and trucks, that have a

gross vehicle weight rating (GVWR)

of 10,000 lbs (4,535 kg) or less.

.Ply

A layer of rubber-coated parallel

cords.

.Ply separation

A parting of rubber compound

between adjacent plies.

.Pneumatic tire

A mechanical device made of rub-

ber, chemicals, fabric and steel or

other materials, that, when

mounted on an automotive wheel,

provides the traction and contains

the gas or fluid that sustains the

load.

.Production options weight

The combined weight of those

installed regular production options

weighing over 5.1 lbs (2.3 kg) in

excess of those standard items

which they replace, not previously

considered in curb weight or acces-sory weight, including heavy duty

brakes, ride levelers, roof rack,

heavy duty battery, and special

trim.

.Radial ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at substantially 90 degrees to

the centerline of the tread.

.Recommended inflation pres-

sure

The cold inflation pressure recom-

mended by a vehicle manufacturer.

.Reinforced tire

A tire designed to operate at higher

loads and at higher inflation pres-

sures than the corresponding stan-

dard tire.

.Rim

A metal support for a tire or a tire

and tube assembly upon which the

tire beads are seated.

.Rim diameter

Nominal diameter of the bead seat.

.Rim size designation

Rim diameter and width.

.Rim type designation

The industry of manufacturer ’s des-

ignation for a rim by style or code.

.Rim width

Nominal distance between rim

flanges.

.Section width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, excluding elevations

due to labeling, decoration, or

protective bands.

.Sidewall

That portion of a tire between the

tread and bead.

.Sidewall separation

The parting of the rubber com-

pound from the cord material in

the sidewall.

.Test rim

The rim on which a tire is fitted for

testing, and it may be any rim listed

as appropriate for use with that tire.

.Tread

That portion of a tire that comes

into contact with the road.

Consumer information and Reporting safety defects/Tire information

–CONTINUED –13-7

Page 612 of 634

Example 2B

For example, if a person weighing

143 lbs (65 kg) and a child weighing

40 lbs (18 kg) now enter the same

vehicle (bringing the number of

occupants to three), and a child

restraint system weighing 11 lbs (5

kg) is installed in the vehicle for the

child to use, the calculations are as

follows.

1.Calculate the total weight.

2.Calculate the available load ca-

pacity.

3.The total weight now exceeds

the capacity weight by 32 lbs (15

kg), so the cargo weight must be

reduced by 32 lbs (15 kg) or more.

& Determining compatibility of

tire and vehicle load capaci-

ties

The sum of four tires ’maximum

load ratings must exceed the max-

imum loaded vehicle weight

( “GVWR ”). In addition, sum of the

maximum load ratings of two front

tires and of two rear tires must

exceed each axle ’smaximum

loaded capacity ( “GAWR ”). Original

equipment tires are designed to

fulfill those conditions.

The maximum loaded vehicle

weight is referred to Gross Vehicle

Weight Rating (GVWR). And each

axle ’s maximum loaded capacity is

referred to Gross Axle Weight Rat-

ing (GAWR). The GVWR and each

axle ’s GAWR are shown on the

vehicle certification label located at

the bottom of driver ’s side door

pillar.

The GVWR and front and rear

GAWRs are determined by not only

the maximum load rating of tires but

also loaded capacities of the vehi-

Consumer information and Reporting safety defects/Tire information

–CONTINUED –13-13

Page 614 of 634

Uniform tire quality grading

standards

This information indicates the rela-

tive performance of passenger car

tires in the area of treadwear,

traction, and temperature resis-

tance. This is to aid the consumer

in making an informed choice in the

purchase of tires.

Quality grades can be found where

applicable on the tire sidewall be-

tween tread shoulder and maxi-

mum section width. For example:

Treadwear 200 Traction AA Tem-

perature A

The quality grades apply to new

pneumatic tires for use on passen-

ger cars. However, they do not

apply to deep tread, winter type

snow tires, space-saver or tempor-

ary use spare tires, tires with

nominal rim diameters of 12 inches

or less, or to some limited produc-

tion tires.

All passenger car tires must con-form to Federal Safety Require-

ments in addition to these grades.

&

Treadwear

The treadwear grade is a compara-

tive rating based on the wear rate of

the tire when tested under con-

trolled conditions on a specified

government test course.

For example, a tire graded 150

would wear one and one-half (1-

1/2) times as well on the govern-

ment course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

due to variations in driving habits,

service practices and differences in

road characteristics and climate.

&Traction AA, A, B, C

The traction grades, from highest to

lowest, are AA, A, B and C. Those

grades represent the tire ’s ability to

stop on wet pavement as measured

under controlled conditions on spe- cified government test surfaces of

asphalt and concrete. A tire marked

C may have poor traction perfor-

mance.

WARNING

The traction grade assigned to

this tire is based on straight-

ahead braking traction tests,

and does not include accel-

eration, cornering, hydroplan-

ing, or peak traction charac-

teristics.

&

Temperature A, B, C

The temperature grades are A (the

highest), B, and C, representing the

tire ’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled con-

ditions on a specified indoor labora-

tory test wheel. Sustained high

temperature can cause the material

of the tire to degenerate and reduce

tire life, and excessive temperature

can lead to sudden tire failure. The

Consumer information and Reporting safety defects/Uniform tire quality grading standards

–CONTINUED –13-15