SUBARU IMPREZA WRX 2014 4.G Owners Manual

Manufacturer: SUBARU, Model Year: 2014, Model line: IMPREZA WRX, Model: SUBARU IMPREZA WRX 2014 4.GPages: 414, PDF Size: 14.22 MB

Page 381 of 414

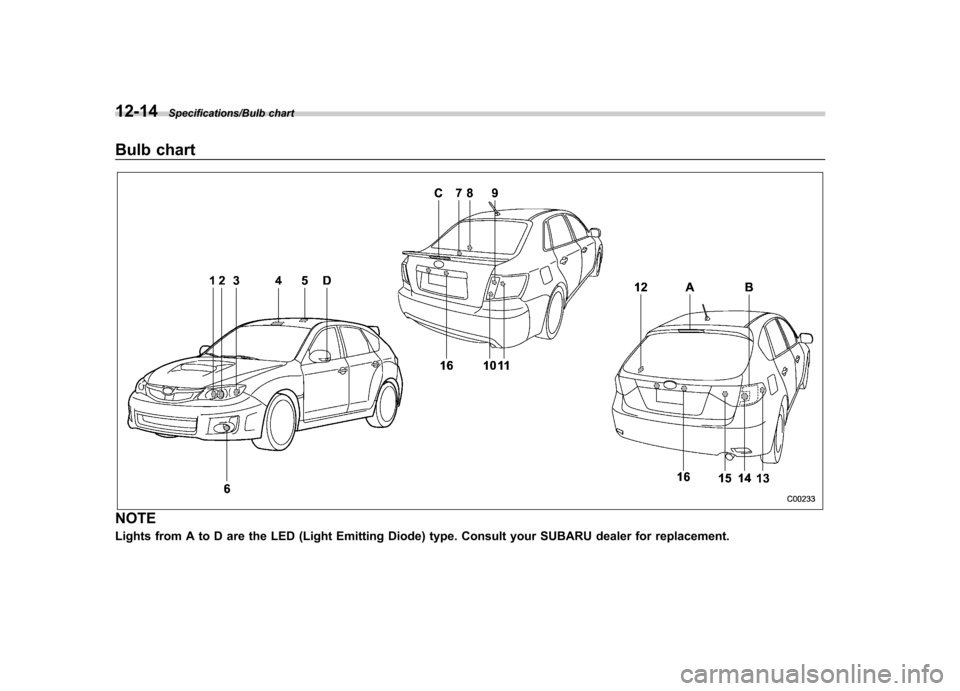

12-14Specifications/Bulb chart

Bulb chart

NOTE

Lights from A to D are the LED (Light Emitting Diode) type. Consult your SUBARU dealer for replacement.

Page 382 of 414

Wattage Bulb No.

1) High beam headlight 12V-60W 9005 (HB3)

2) Low beam headlight

Models with HID light 12V-35W D2S

Models with halogen light 12V-55W H11

3) Front turn signal light/Front side marker light 12V-27/8W 1157NA

4) Map light 12V-8W–

5) Dome light 12V-8W–

6) Front fog light 12V-51W 9006 (HB4)

7) Trunk light (4-door) 12V-5W 168 (W5W)

8) High-mounted stop light (4-door, if equipped) 12V-21W (P21W)

9) Rear turn signal light (4-door) 12V-21W (WY21W)

10) Backup light (4-door) 12V-16W 921

11) Stop light/Tail and rear side marker light (4-door) 12V-21/5W 7443 (W21/5W)

12) Cargo area light (5-door) 12V-5W–

13) Rear side marker light (5-door) 12V-5W 168 (W5W)

14) Rear turn signal light (5-door) 12V-21W (WY21W)

15) Backup light (5-door) 12V-21W 7440

16) Licence plate light 12V-5W 168 (W5W)

A) High-mounted stop light (5-door) ––

B) Stop light/Tail light (5-door) ––

C) High-mounted stop light (4-door, if equipped) ––

D) Side turn signal light (if equipped) ––WARNING

. Bulbs may become very hot while

illuminated. Before replacing

bulbs, turn off the lights and wait

until the bulbs cool down. Other-

wise, there is a risk of sustaining

a burn injury.

. For models with HID low beam

headlights, observe the following

precautions. Not doing so carries

the risk of an electric shock that

could result in serious injury

because the HID bulbs use an

extremely high voltage. – Do not replace any headlight

bulbs (both low beam and

high beam) by yourself.

– Do not remove/restore the

headlight assemblies by your-self.

– Do not remove any headlight-

assembly components byyourself.

For replacement, contact your SUBARU dealer.

Specifications/Bulb chart12-15

– CONTINUED –

Page 383 of 414

12-16Specifications/Bulb chart

CAUTION

Replace any bulb only with a new

bulb of the specified wattage. Using

a bulb of different wattage could

result in a fire.

Page 384 of 414

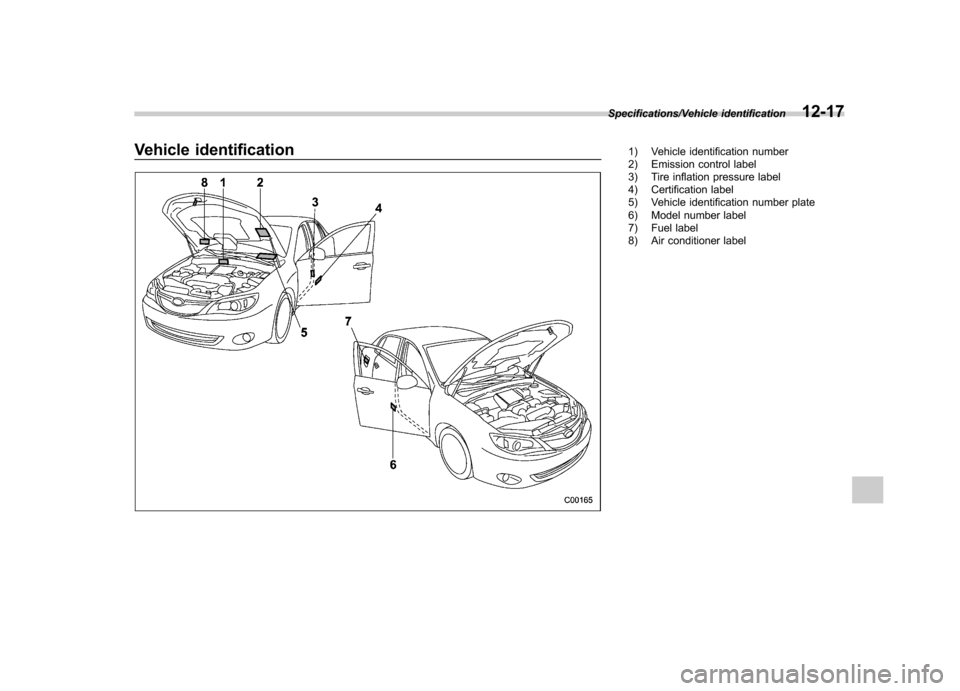

Vehicle identification1) Vehicle identification number

2) Emission control label

3) Tire inflation pressure label

4) Certification label

5) Vehicle identification number plate

6) Model number label

7) Fuel label

8) Air conditioner label

Specifications/Vehicle identification12-17

Page 385 of 414

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

Page 386 of 414

For U.S.A............................................................ 13-2

Tire information .................................................. 13-2

Tire labeling ....................................................... 13-2

Recommended tire inflation pressure .................. 13-4

Glossary of tire terminology ............................... 13-5

Tire care –maintenance and safety

practices ........................................................ 13-10

Vehicle load limit –how to determine ................ 13-10 Determining compatibility of tire and vehicle

load capacities .............................................. 13-13

Adverse safety consequences of overloading on handling and stopping and on tires ........... 13-14

Steps for Determining Correct Load Limit ......... 13-14

Uniform tire quality grading standards .......... 13-15

Treadwear ....................................................... 13-15

Traction AA, A, B, C ......................................... 13-15

Temperature A, B, C ......................................... 13-15

Reporting safety defects (U.S.A.) ................... 13-16

Consumer information and Reporting safety defects

13

Page 387 of 414

13-2Consumer information and Reporting safety defects/For U.S.A.

For U.S.A.

The following information has been

compiled according to Code of

Federal Regulations“Title 49, Part

575 ”. Tire information &

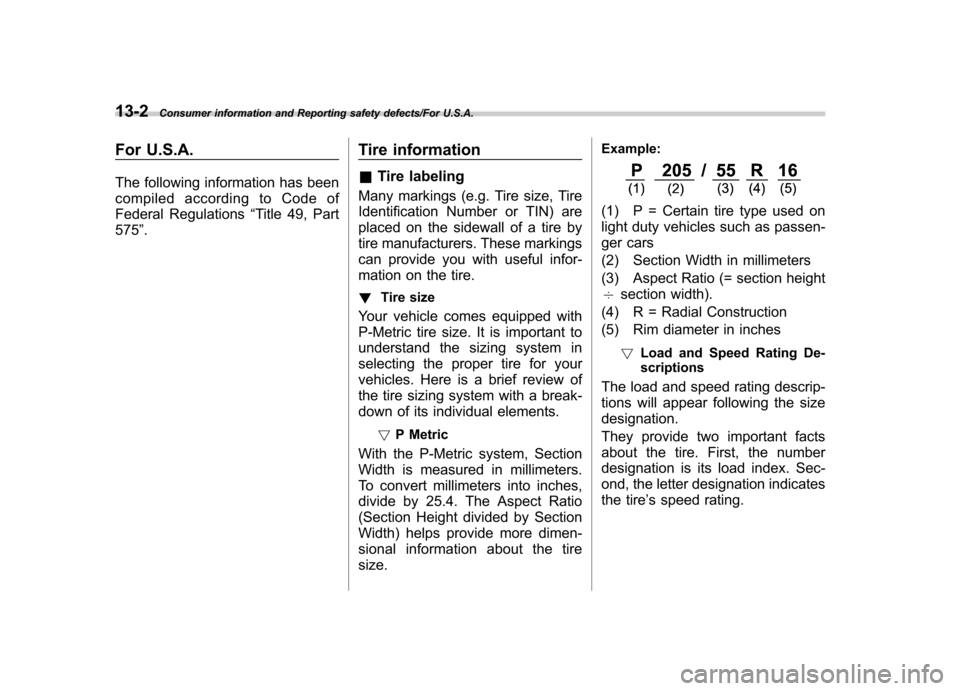

Tire labeling

Many markings (e.g. Tire size, Tire

Identification Number or TIN) are

placed on the sidewall of a tire by

tire manufacturers. These markings

can provide you with useful infor-

mation on the tire. ! Tire size

Your vehicle comes equipped with

P-Metric tire size. It is important to

understand the sizing system in

selecting the proper tire for your

vehicles. Here is a brief review of

the tire sizing system with a break-

down of its individual elements.

!P Metric

With the P-Metric system, Section

Width is measured in millimeters.

To convert millimeters into inches,

divide by 25.4. The Aspect Ratio

(Section Height divided by Section

Width) helps provide more dimen-

sional information about the tiresize. Example:

(1) P = Certain tire type used on

light duty vehicles such as passen-

ger cars

(2) Section Width in millimeters

(3) Aspect Ratio (= section height 7

section width).

(4) R = Radial Construction

(5) Rim diameter in inches

! Load and Speed Rating De-

scriptions

The load and speed rating descrip-

tions will appear following the size designation.

They provide two important facts

about the tire. First, the number

designation is its load index. Sec-

ond, the letter designation indicates

the tire ’s speed rating.

Page 388 of 414

Example:

(6) Load Index: A numerical code

which specifies the maximum load

a tire can carry at the speed

indicated by its speed symbol, at

maximum inflation pressure.

For example,“90 ”means 1,323 lbs

(600 kg), “89 ”means 1,278 lbs (580

kg).

WARNING

Load indices apply only to the

tire, not to the vehicle. Putting

a load rated tire on any vehicle

does not mean the vehicle can

be loaded up to the tire ’s rated

load.

(7) Speed Rating: An alphabetical

system describing a tire ’s capability

to travel at established and prede-

termined speeds.

For example, “V ” means 149 mph

(240 km/h)

WARNING

. Speed ratings apply only to

the tire, not to the vehicle.

Putting a speed rated tire on

any vehicle does not mean

the vehicle can be operated

at the tire ’s rated speed.

. The speed rating is void if

the tires are worn out, da-

maged, repaired, retreaded,

or otherwise altered from

their original condition. If

tires are repaired, re-

treaded, or otherwise al-

tered, they may not be sui-

table for original equipment

tire designed loads andspeeds.

! Tire Identification Number (TIN)

Tire Identification Number (TIN) is

marked on the intended outboard

sidewall. The TIN is composed of

four groups. Here is a brief review

of the TIN with a breakdown of its

individual elements.

(1) Manufacturer ’s Identification

Mark

(2) Tire Size

(3) Tire Type Code

(4) Date of Manufacture

The first two figures identify the

week, starting with “01 ”to represent

the first full week of the calendar

year; the second two figures repre-

sent the year. For example, 0101

means the 1st week of 2001.

! Other markings

The following makings are also

placed on the sidewall.

! Maximum permissible infla-

tion pressure

The maximum cold inflation pres-

sure to which this tire may be

inflated. For example, “300 kPa

(44 PSI) MAX. PRESS ”

Consumer information and Reporting safety defects/Tire information13-3

– CONTINUED –

Page 389 of 414

13-4Consumer information and Reporting safety defects/Tire information

!Maximum load rating

The load rating at the maximum

permissible weight load for this tire.

For example, “MAX. LOAD 580 kg

(1279 LBS) @ 300 kPa (44 PSI)

MAX. PRESS. ”

WARNING

Maximum load rating applies

only to the tire, not to the

vehicle. Putting a load rated

tire on any vehicle does not

mean the vehicle can be

loaded up to the tire ’s rated

load.

! Construction type

Applicable construction of this tire.

For example, “TUBELESS STEEL

BELTED RADIAL ”

! Construction

The generic name of each cord

material used in the plies (both

sidewall and tread area) of this tire.

For example, “PLIES: TREAD 2 STEEL + 2 POLYESTER SIDE-

WALL 2 POLYESTER

”

! Uniform Tire Quality Grading

(UTQG)

For details, refer to “Uniform tire

quality grading standards ”F 13-15 .

& Recommended tire inflation pressure

! Recommended cold tire infla-

tion pressure

For recommended cold tire inflation

pressure for your vehicle ’s tires,

refer to “Tires ”F 12-9 .

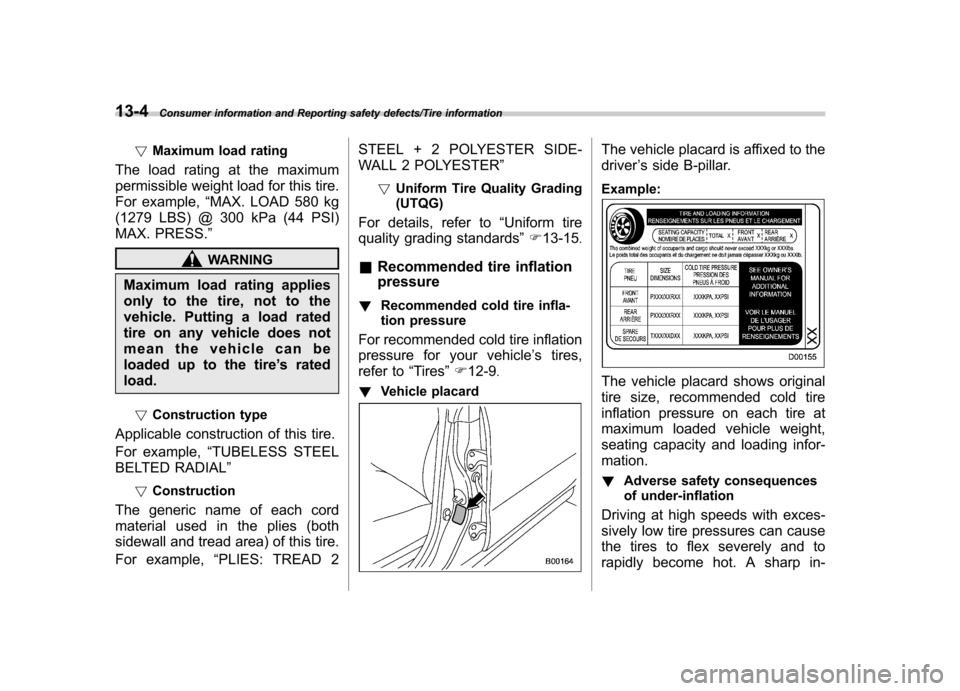

! Vehicle placard

The vehicle placard is affixed to the driver ’s side B-pillar.

Example:

The vehicle placard shows original

tire size, recommended cold tire

inflation pressure on each tire at

maximum loaded vehicle weight,

seating capacity and loading infor-mation. ! Adverse safety consequences

of under-inflation

Driving at high speeds with exces-

sively low tire pressures can cause

the tires to flex severely and to

rapidly become hot. A sharp in-

Page 390 of 414

crease in temperature could cause

tread separation, and failure of the

tire(s). Possible resulting loss of

vehicle control could lead to anaccident. !Measuring and adjusting air

pressure to achieve proper in-

flation

Check and, if necessary, adjust the

pressure of each tire (including the

spare) at least once a month and

before any long journey. Check the

tire pressures when the tires are

cold. Use a pressure gauge to

adjust the tire pressures to the

specific values. Driving even a

short distance warms up the tires

and increases the tire pressures.

Also, the tire pressures are affected

by the outside temperature. It is

best to check tire pressure out-

doors before driving the vehicle.

When a tire becomes warm, the air

inside it expands, causing the tire

pressure to increase. Be careful not

to mistakenly release air from a

warm tire to reduce its pressure. &

Glossary of tire terminology

. Accessory weight

The combined weight (in excess of

those standard items which may be

replaced) of automatic transmis-

sion, power steering, power brakes,

power windows, power seats, radio,

and heater, to the extent that these

items are available as factory-in-

stalled equipment (whether in-

stalled or not). . Bead

The part of the tire that is made of

steel wires, wrapped or reinforced

by ply cords and that is shaped to fit

the rim.. Bead separation

A breakdown of the bond between

components in the bead.. Bias ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at alternate angles substantially

less than 90 degrees to the center-

line of the tread. . Carcass

The tire structure, except tread and sidewall rubber which, when in-

flated, bears the load. .

Chunking

The breaking away of pieces of the

tread or sidewall.. Cold tire pressure

The pressure in a tire that has been

driven less than 1 mile or has been

standing for three hours or more.. Cord

The strands forming the plies in the tire. . Cord separation

The parting of cords from adjacent

rubber compounds.. Cracking

Any parting within the tread, side-

wall, or inner liner of the tire

extending to cord material. . Curb weight

The weight of a motor vehicle with

standard equipment including the

maximum capacity of fuel, oil and

coolant, and if so equipped, air

conditioning and additional weight

optional engine.

Consumer information and Reporting safety defects/Tire information13-5

– CONTINUED –