SUBARU LEGACY 1996 Service Repair Manual

LEGACY 1996

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57433/w960_57433-0.png

SUBARU LEGACY 1996 Service Repair Manual

Page 429 of 2890

G2M0765

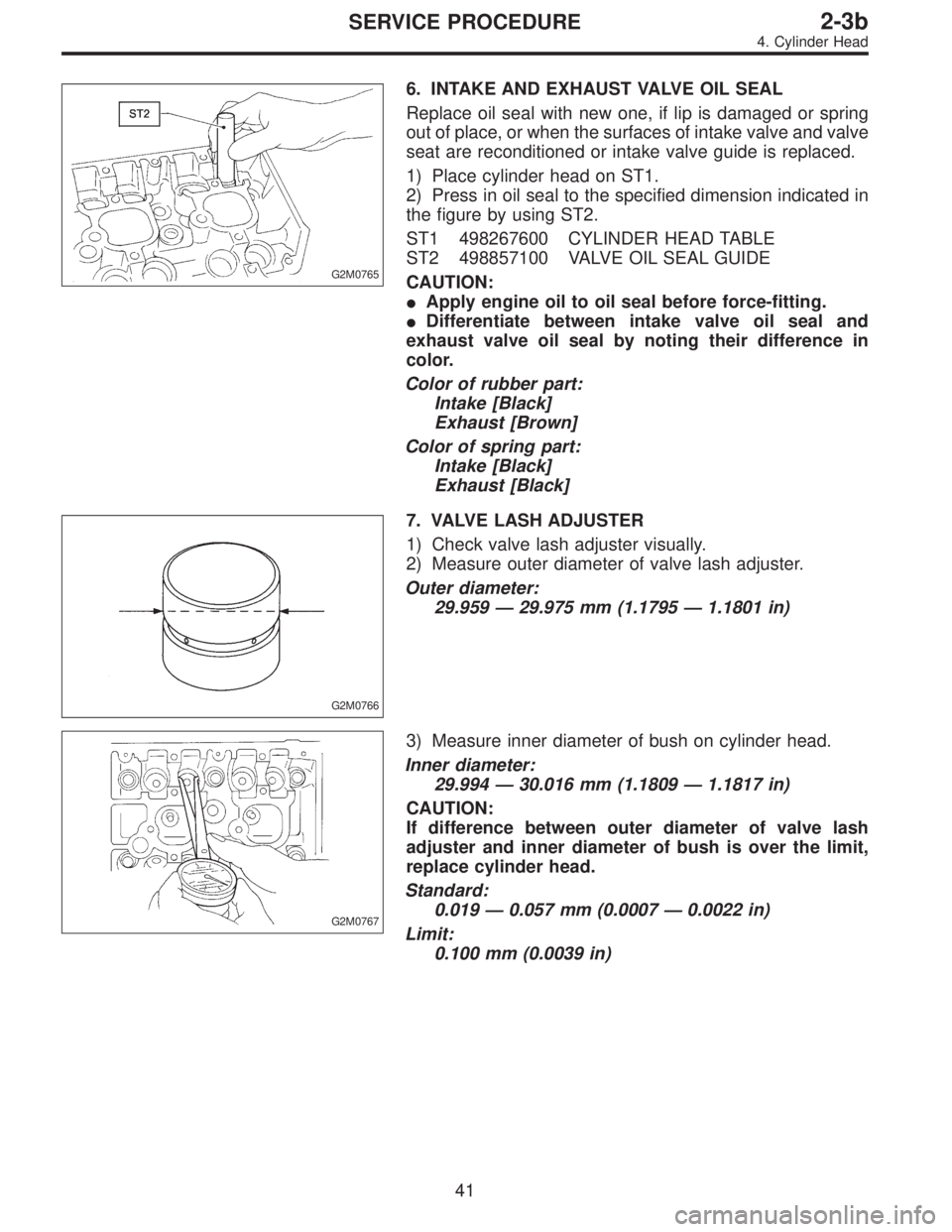

6. INTAKE AND EXHAUST VALVE OIL SEAL

Replace oil seal with new one, if lip is damaged or spring

out of place, or when the surfaces of intake valve and valve

seat are reconditioned or intake valve guide is replaced.

1) Place cylinder head on ST1.

2) Press in oil seal to the specified dimension indicated in

the figure by using ST2.

ST1 498267600 CYLINDER HEAD TABLE

ST2 498857100 VALVE OIL SEAL GUIDE

CAUTION:

�Apply engine oil to oil seal before force-fitting.

�Differentiate between intake valve oil seal and

exhaust valve oil seal by noting their difference in

color.

Color of rubber part:

Intake [Black]

Exhaust [Brown]

Color of spring part:

Intake [Black]

Exhaust [Black]

G2M0766

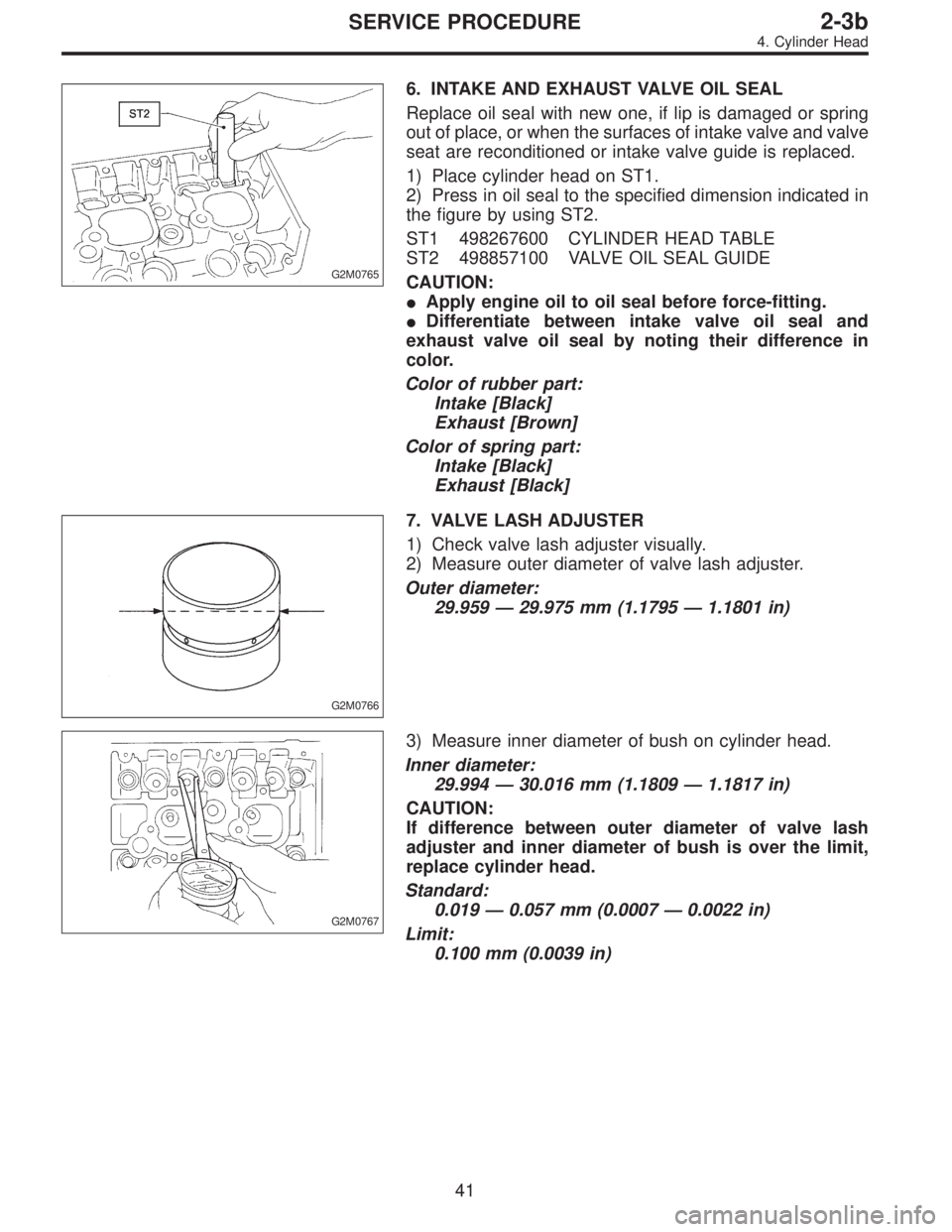

7. VALVE LASH ADJUSTER

1) Check valve lash adjuster visually.

2) Measure outer diameter of valve lash adjuster.

Outer diameter:

29.959—29.975 mm (1.1795—1.1801 in)

G2M0767

3) Measure inner diameter of bush on cylinder head.

Inner diameter:

29.994—30.016 mm (1.1809—1.1817 in)

CAUTION:

If difference between outer diameter of valve lash

adjuster and inner diameter of bush is over the limit,

replace cylinder head.

Standard:

0.019—0.057 mm (0.0007—0.0022 in)

Limit:

0.100 mm (0.0039 in)

41

2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 430 of 2890

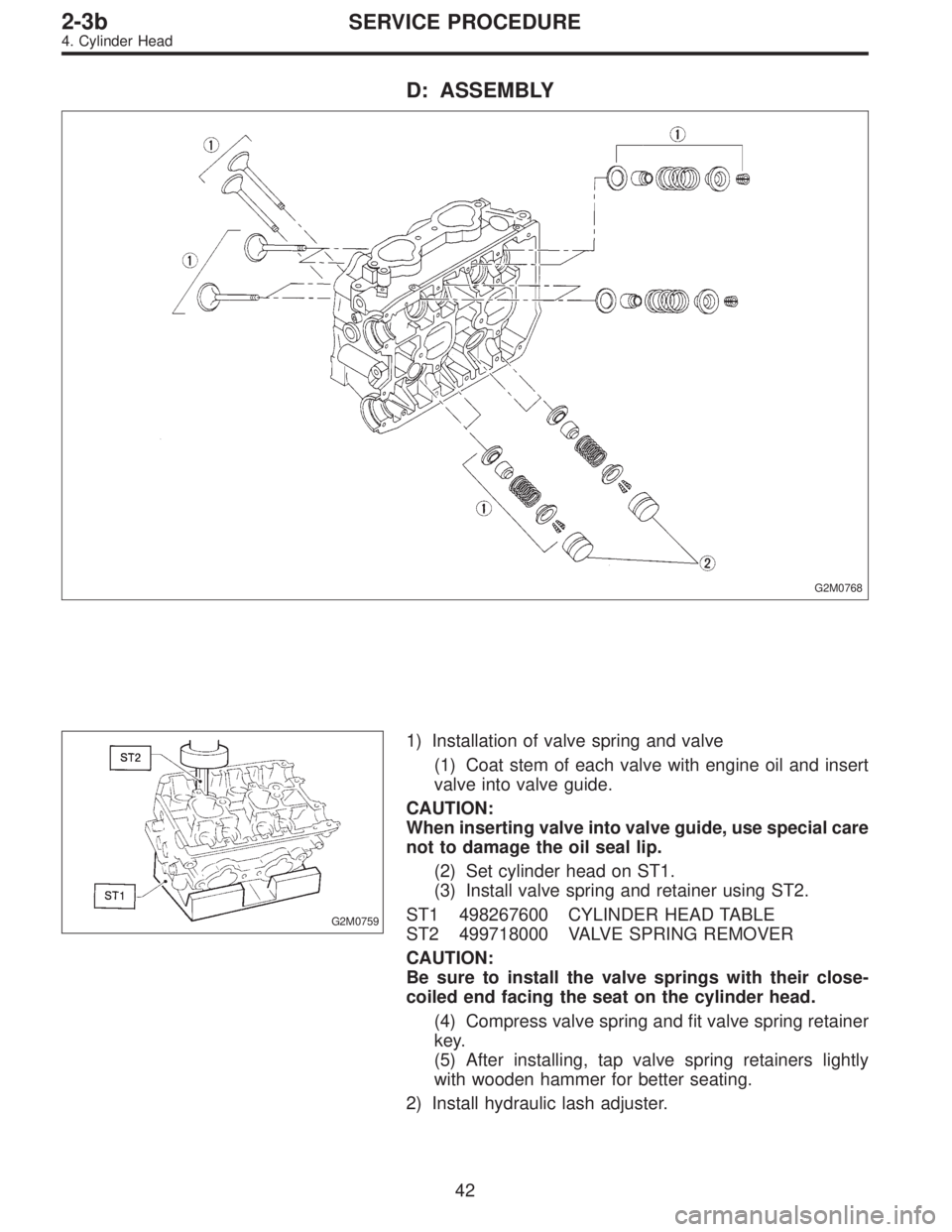

D: ASSEMBLY

G2M0768

G2M0759

1) Installation of valve spring and valve

(1) Coat stem of each valve with engine oil and insert

valve into valve guide.

CAUTION:

When inserting valve into valve guide, use special care

not to damage the oil seal lip.

(2) Set cylinder head on ST1.

(3) Install valve spring and retainer using ST2.

ST1 498267600 CYLINDER HEAD TABLE

ST2 499718000 VALVE SPRING REMOVER

CAUTION:

Be sure to install the valve springs with their close-

coiled end facing the seat on the cylinder head.

(4) Compress valve spring and fit valve spring retainer

key.

(5) After installing, tap valve spring retainers lightly

with wooden hammer for better seating.

2) Install hydraulic lash adjuster.

42

2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 431 of 2890

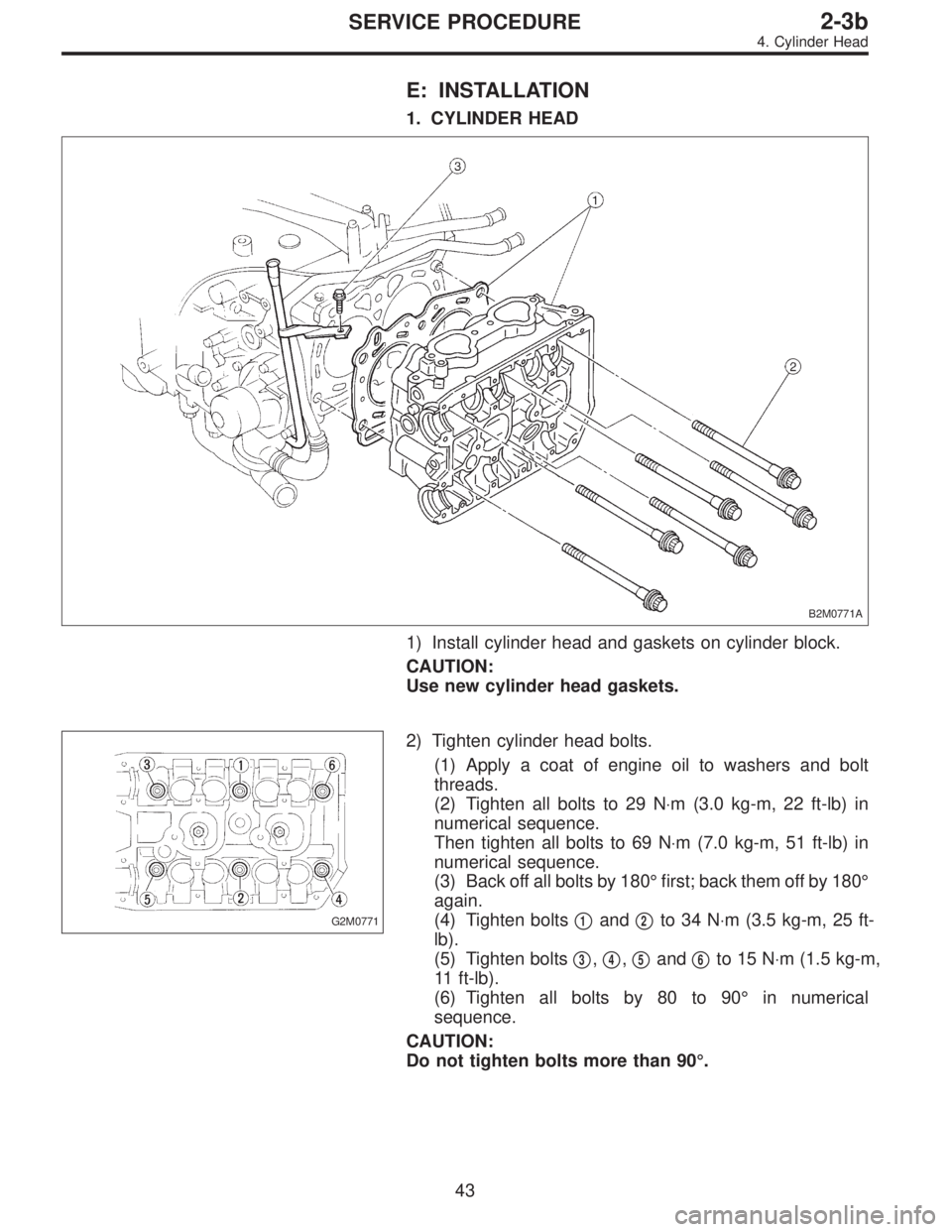

E: INSTALLATION

1. CYLINDER HEAD

B2M0771A

1) Install cylinder head and gaskets on cylinder block.

CAUTION:

Use new cylinder head gaskets.

G2M0771

2) Tighten cylinder head bolts.

(1) Apply a coat of engine oil to washers and bolt

threads.

(2) Tighten all bolts to 29 N⋅m (3.0 kg-m, 22 ft-lb) in

numerical sequence.

Then tighten all bolts to 69 N⋅m (7.0 kg-m, 51 ft-lb) in

numerical sequence.

(3) Back off all bolts by 180°first; back them off by 180°

again.

(4) Tighten bolts�

1and�2to 34 N⋅m (3.5 kg-m, 25 ft-

lb).

(5) Tighten bolts�

3,�4,�5and�6to 15 N⋅m (1.5 kg-m,

11 ft-lb).

(6) Tighten all bolts by 80 to 90°in numerical

sequence.

CAUTION:

Do not tighten bolts more than 90°.

43

2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 433 of 2890

2) Install camshaft sprockets, timing belt and related parts.

B2M0702

B2M0703

3) Install engine coolant pipe.

CAUTION:

Use new gaskets.

45

2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 438 of 2890

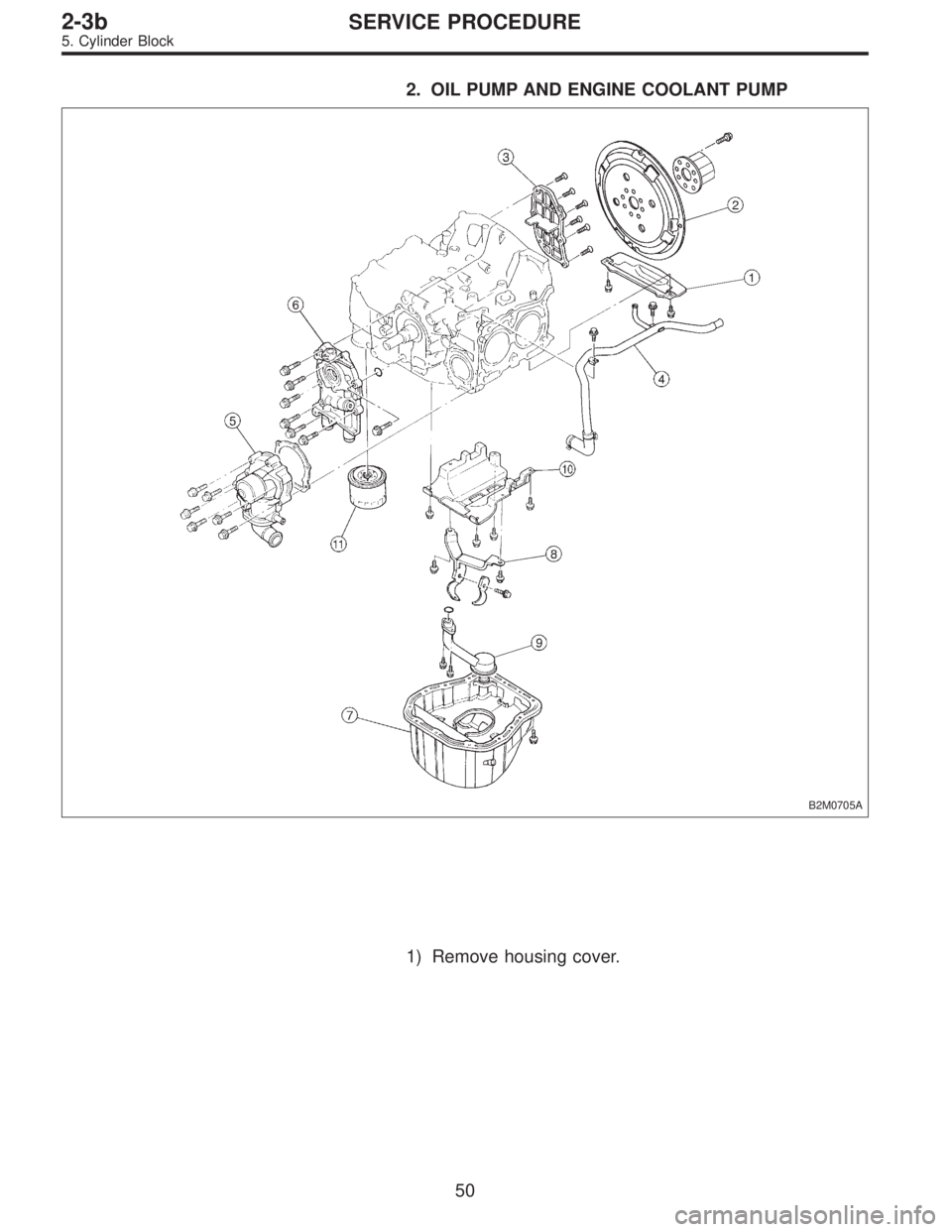

2. OIL PUMP AND ENGINE COOLANT PUMP

B2M0705A

1) Remove housing cover.

50

2-3bSERVICE PROCEDURE

5. Cylinder Block

Page 439 of 2890

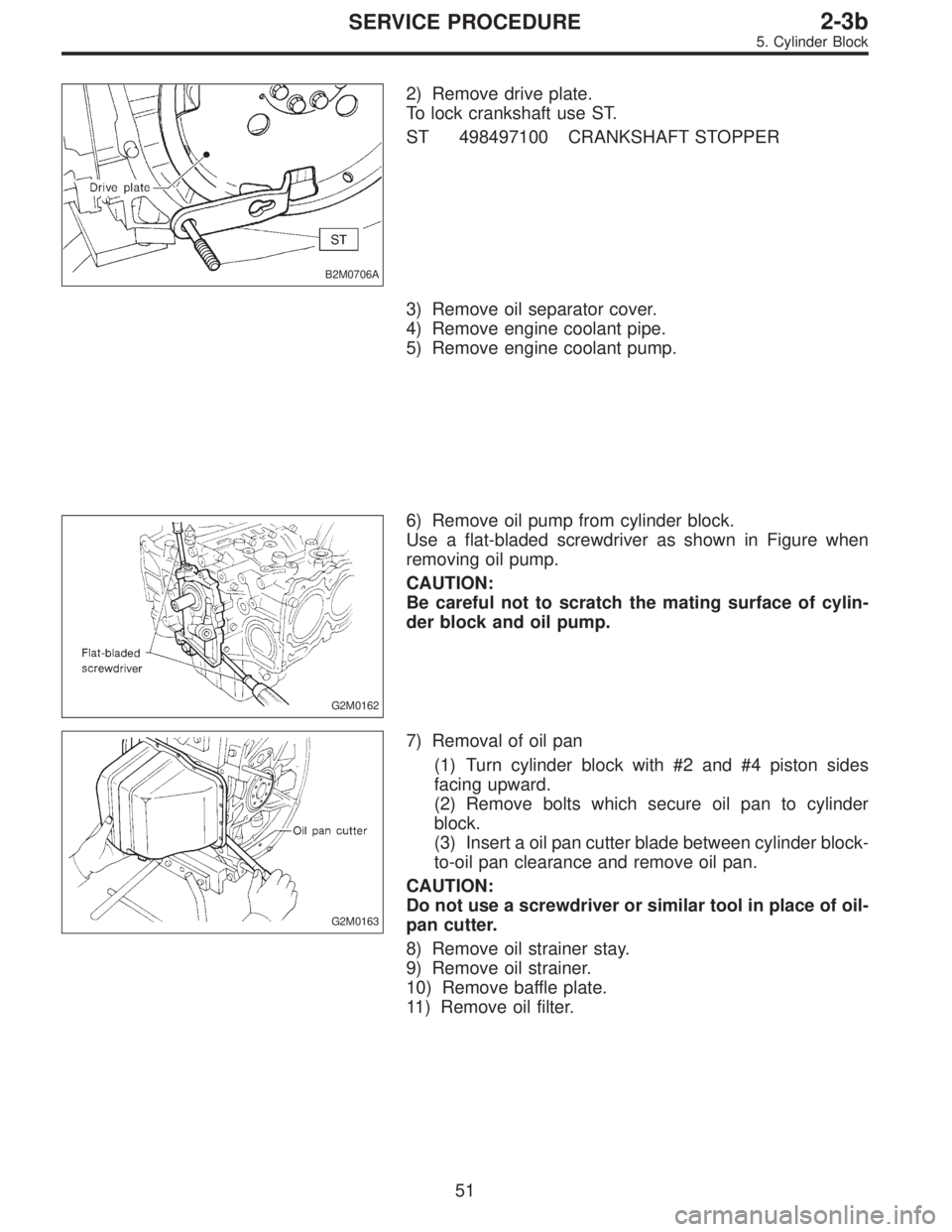

B2M0706A

2) Remove drive plate.

To lock crankshaft use ST.

ST 498497100 CRANKSHAFT STOPPER

3) Remove oil separator cover.

4) Remove engine coolant pipe.

5) Remove engine coolant pump.

G2M0162

6) Remove oil pump from cylinder block.

Use a flat-bladed screwdriver as shown in Figure when

removing oil pump.

CAUTION:

Be careful not to scratch the mating surface of cylin-

der block and oil pump.

G2M0163

7) Removal of oil pan

(1) Turn cylinder block with #2 and #4 piston sides

facing upward.

(2) Remove bolts which secure oil pan to cylinder

block.

(3) Insert a oil pan cutter blade between cylinder block-

to-oil pan clearance and remove oil pan.

CAUTION:

Do not use a screwdriver or similar tool in place of oil-

pan cutter.

8) Remove oil strainer stay.

9) Remove oil strainer.

10) Remove baffle plate.

11) Remove oil filter.

51

2-3bSERVICE PROCEDURE

5. Cylinder Block

Page 455 of 2890

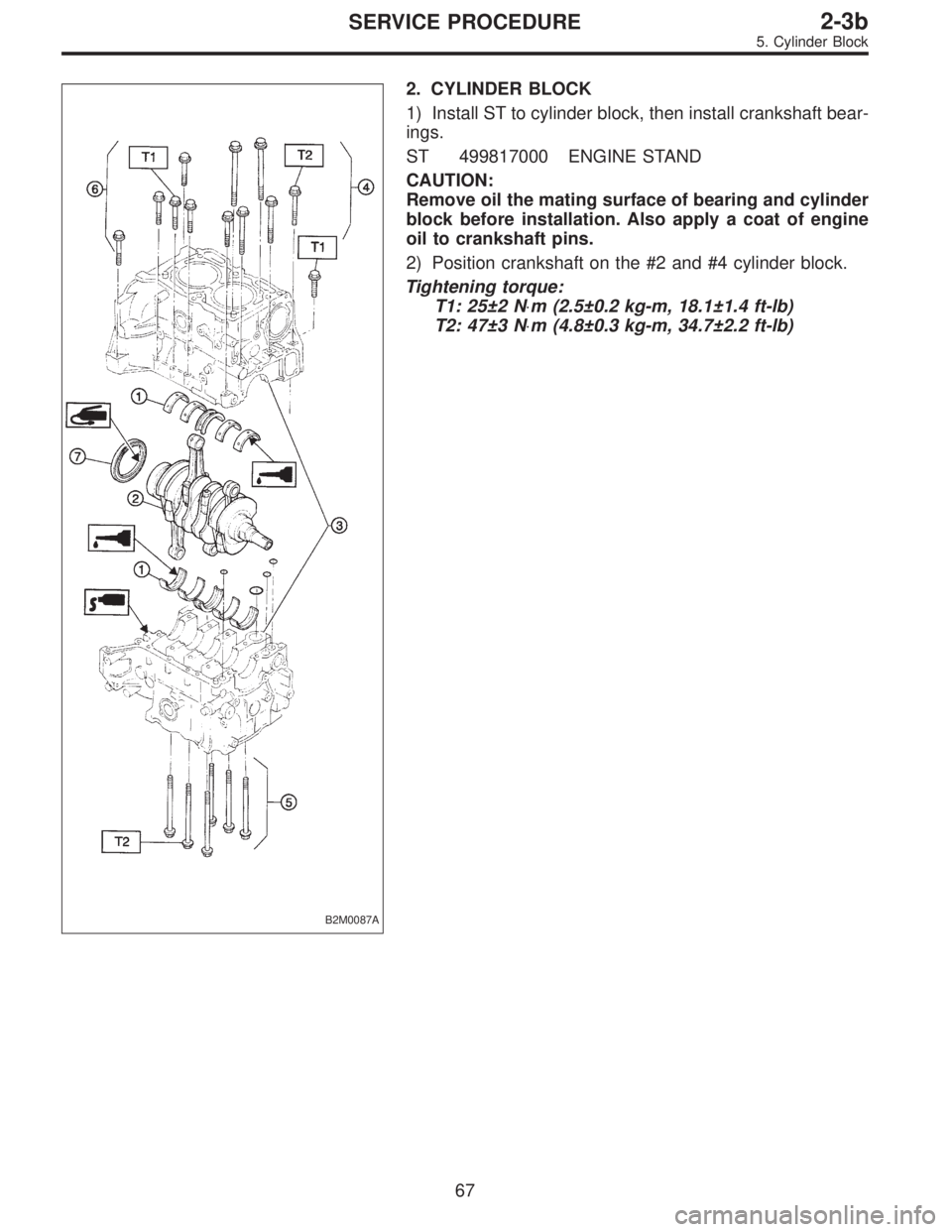

B2M0087A

2. CYLINDER BLOCK

1) Install ST to cylinder block, then install crankshaft bear-

ings.

ST 499817000 ENGINE STAND

CAUTION:

Remove oil the mating surface of bearing and cylinder

block before installation. Also apply a coat of engine

oil to crankshaft pins.

2) Position crankshaft on the #2 and #4 cylinder block.

Tightening torque:

T1: 25±2 N⋅m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

T2: 47±3 N⋅m (4.8±0.3 kg-m, 34.7±2.2 ft-lb)

67

2-3bSERVICE PROCEDURE

5. Cylinder Block

Page 457 of 2890

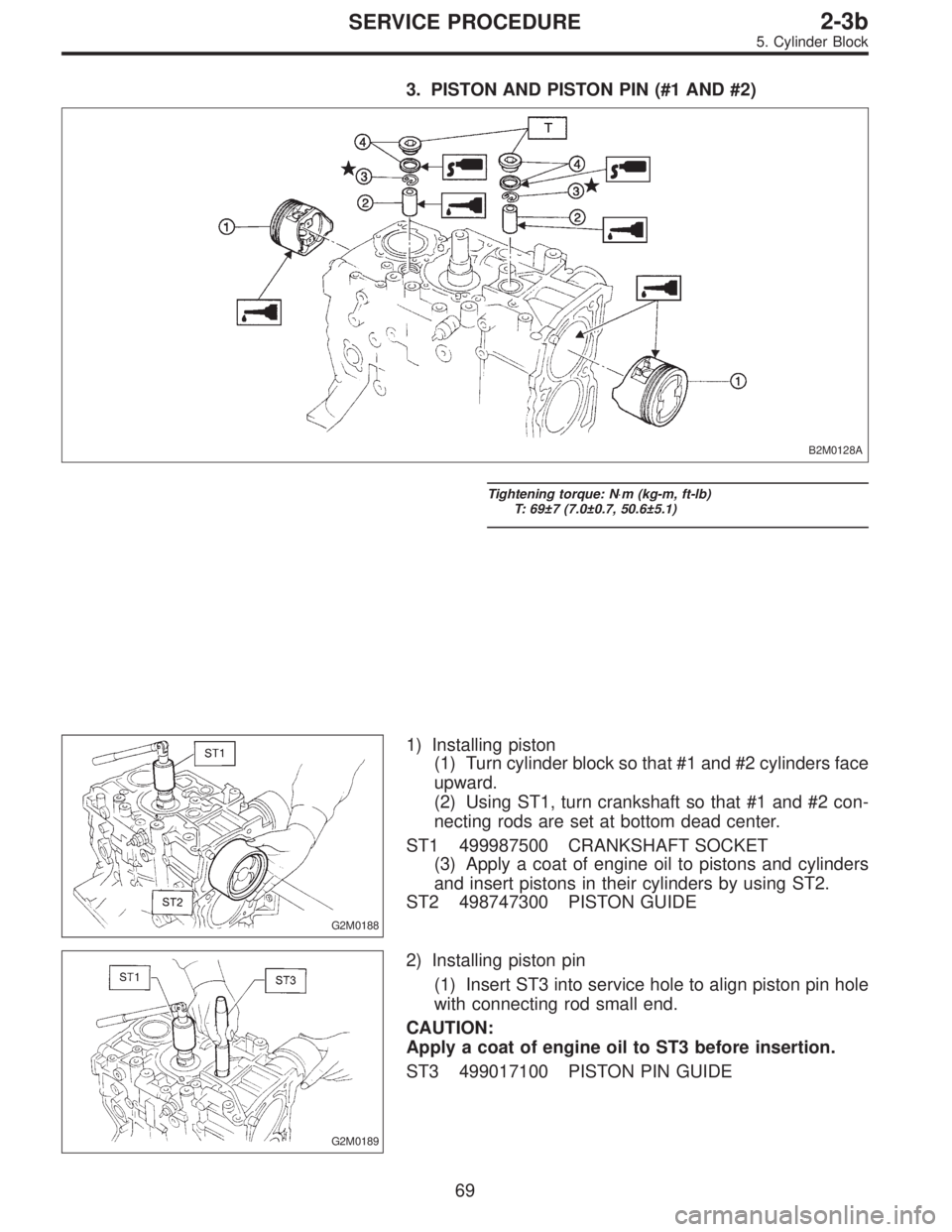

3. PISTON AND PISTON PIN (#1 AND #2)

B2M0128A

Tightening torque: N⋅m (kg-m, ft-lb)

T: 69±7 (7.0±0.7, 50.6±5.1)

G2M0188

1) Installing piston

(1) Turn cylinder block so that #1 and #2 cylinders face

upward.

(2) Using ST1, turn crankshaft so that #1 and #2 con-

necting rods are set at bottom dead center.

ST1 499987500 CRANKSHAFT SOCKET

(3) Apply a coat of engine oil to pistons and cylinders

and insert pistons in their cylinders by using ST2.

ST2 498747300 PISTON GUIDE

G2M0189

2) Installing piston pin

(1) Insert ST3 into service hole to align piston pin hole

with connecting rod small end.

CAUTION:

Apply a coat of engine oil to ST3 before insertion.

ST3 499017100 PISTON PIN GUIDE

69

2-3bSERVICE PROCEDURE

5. Cylinder Block

Page 458 of 2890

(2) Apply a coat of engine oil to piston pin and insert

piston pin into piston and connecting rod through ser-

vice hole.

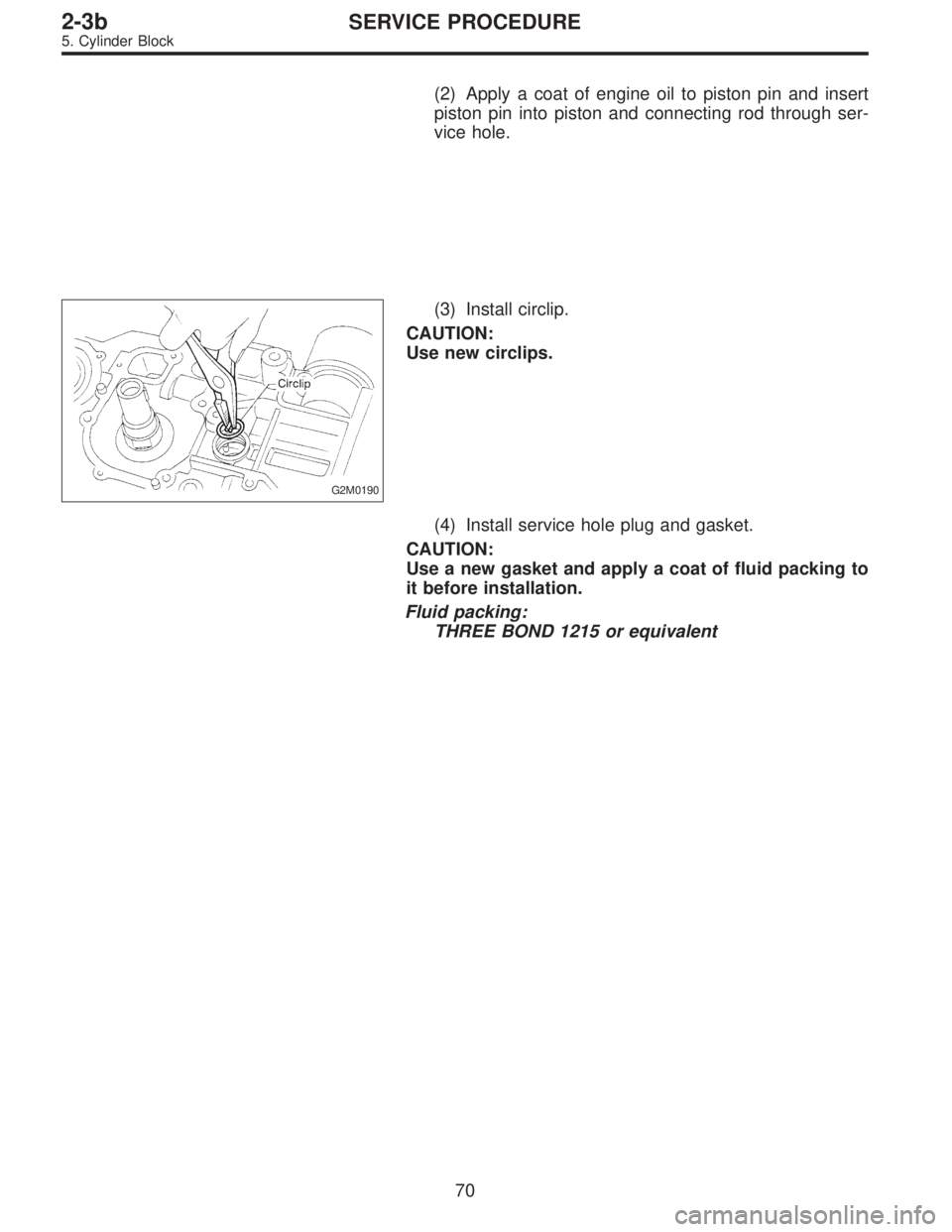

G2M0190

(3) Install circlip.

CAUTION:

Use new circlips.

(4) Install service hole plug and gasket.

CAUTION:

Use a new gasket and apply a coat of fluid packing to

it before installation.

Fluid packing:

THREE BOND 1215 or equivalent

70

2-3bSERVICE PROCEDURE

5. Cylinder Block

Page 460 of 2890

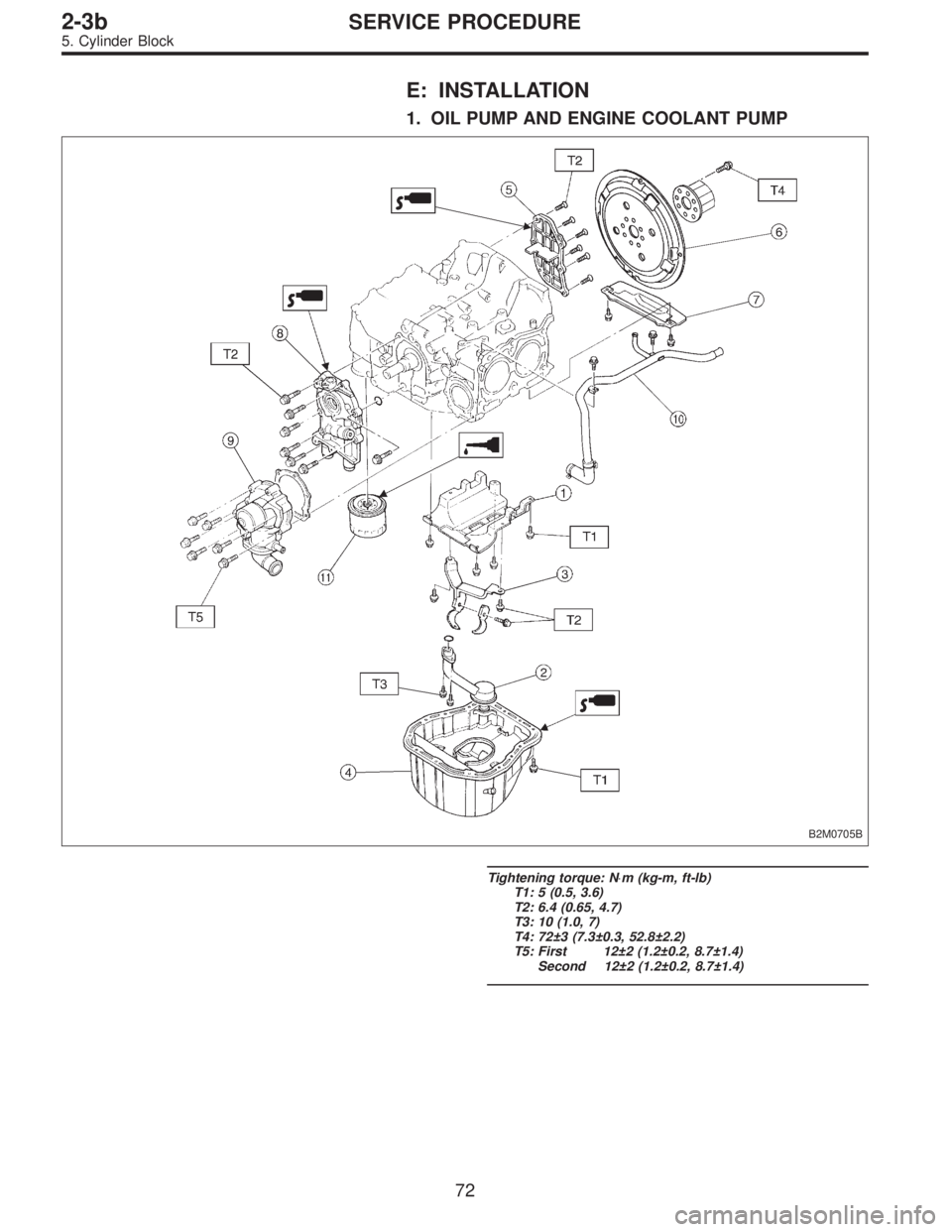

E: INSTALLATION

1. OIL PUMP AND ENGINE COOLANT PUMP

B2M0705B

Tightening torque: N⋅m (kg-m, ft-lb)

T1: 5 (0.5, 3.6)

T2: 6.4 (0.65, 4.7)

T3: 10 (1.0, 7)

T4: 72±3 (7.3±0.3, 52.8±2.2)

T5: First 12±2 (1.2±0.2, 8.7±1.4)

Second 12±2 (1.2±0.2, 8.7±1.4)

72

2-3bSERVICE PROCEDURE

5. Cylinder Block

![SUBARU LEGACY 1996 Service Repair Manual 2) Install camshaft sprockets, timing belt and related parts.

<Ref. to 2-3b [W2C0].>

B2M0702

B2M0703

3) Install engine coolant pipe.

CAUTION:

Use new gaskets.

45

2-3bSERVICE PROCEDURE

4. Cylinder Head SUBARU LEGACY 1996 Service Repair Manual 2) Install camshaft sprockets, timing belt and related parts.

<Ref. to 2-3b [W2C0].>

B2M0702

B2M0703

3) Install engine coolant pipe.

CAUTION:

Use new gaskets.

45

2-3bSERVICE PROCEDURE

4. Cylinder Head](/img/17/57433/w960_57433-432.png)