SUBARU LEGACY 1996 Service Repair Manual

LEGACY 1996

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57433/w960_57433-0.png

SUBARU LEGACY 1996 Service Repair Manual

Trending: engine oil, trailer, rear fog, spark plugs replace, Security, Fill coolant, battery replacement

Page 281 of 2890

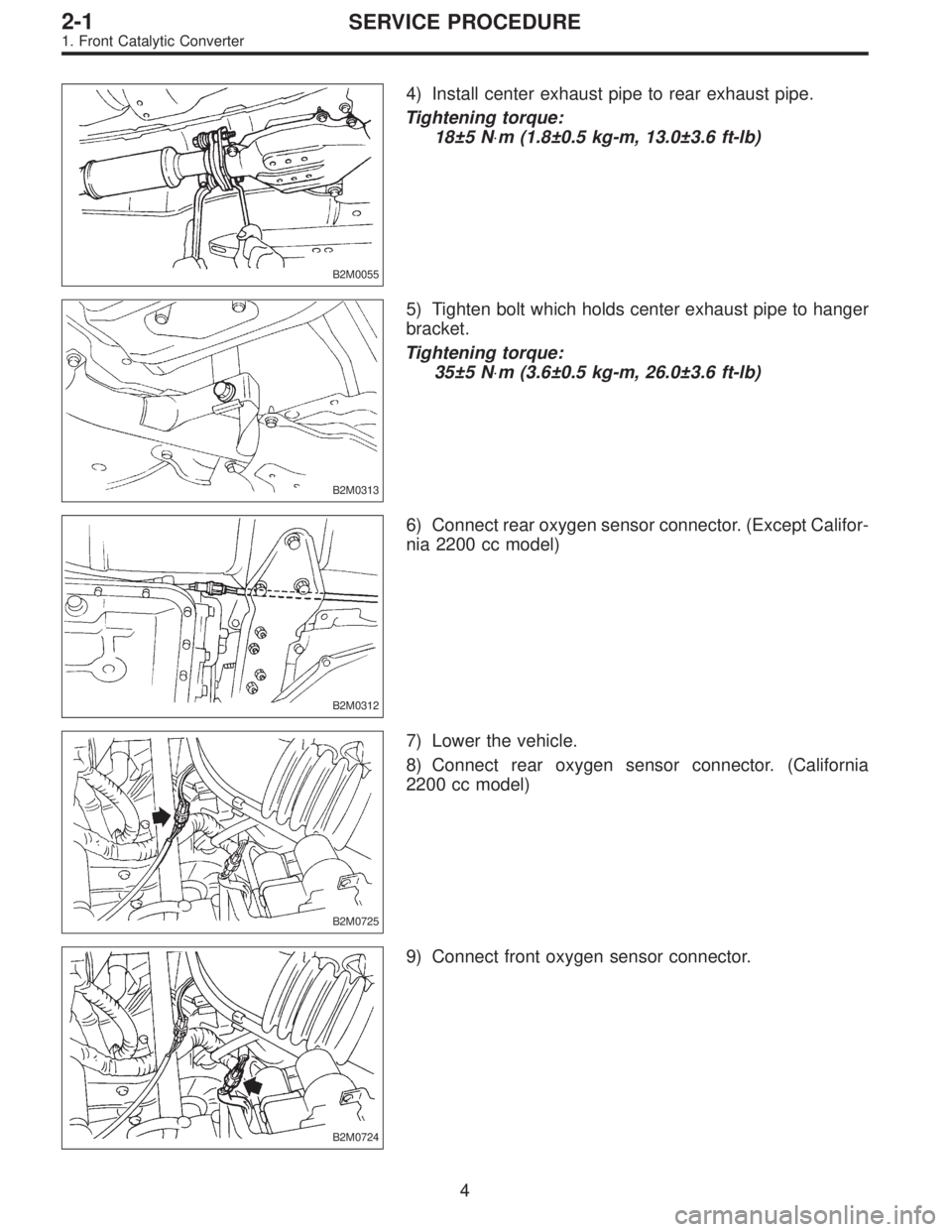

B2M0055

4) Install center exhaust pipe to rear exhaust pipe.

Tightening torque:

18±5 N⋅m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

B2M0313

5) Tighten bolt which holds center exhaust pipe to hanger

bracket.

Tightening torque:

35±5 N⋅m (3.6±0.5 kg-m, 26.0±3.6 ft-lb)

B2M0312

6) Connect rear oxygen sensor connector. (Except Califor-

nia 2200 cc model)

B2M0725

7) Lower the vehicle.

8) Connect rear oxygen sensor connector. (California

2200 cc model)

B2M0724

9) Connect front oxygen sensor connector.

4

2-1SERVICE PROCEDURE

1. Front Catalytic Converter

Page 282 of 2890

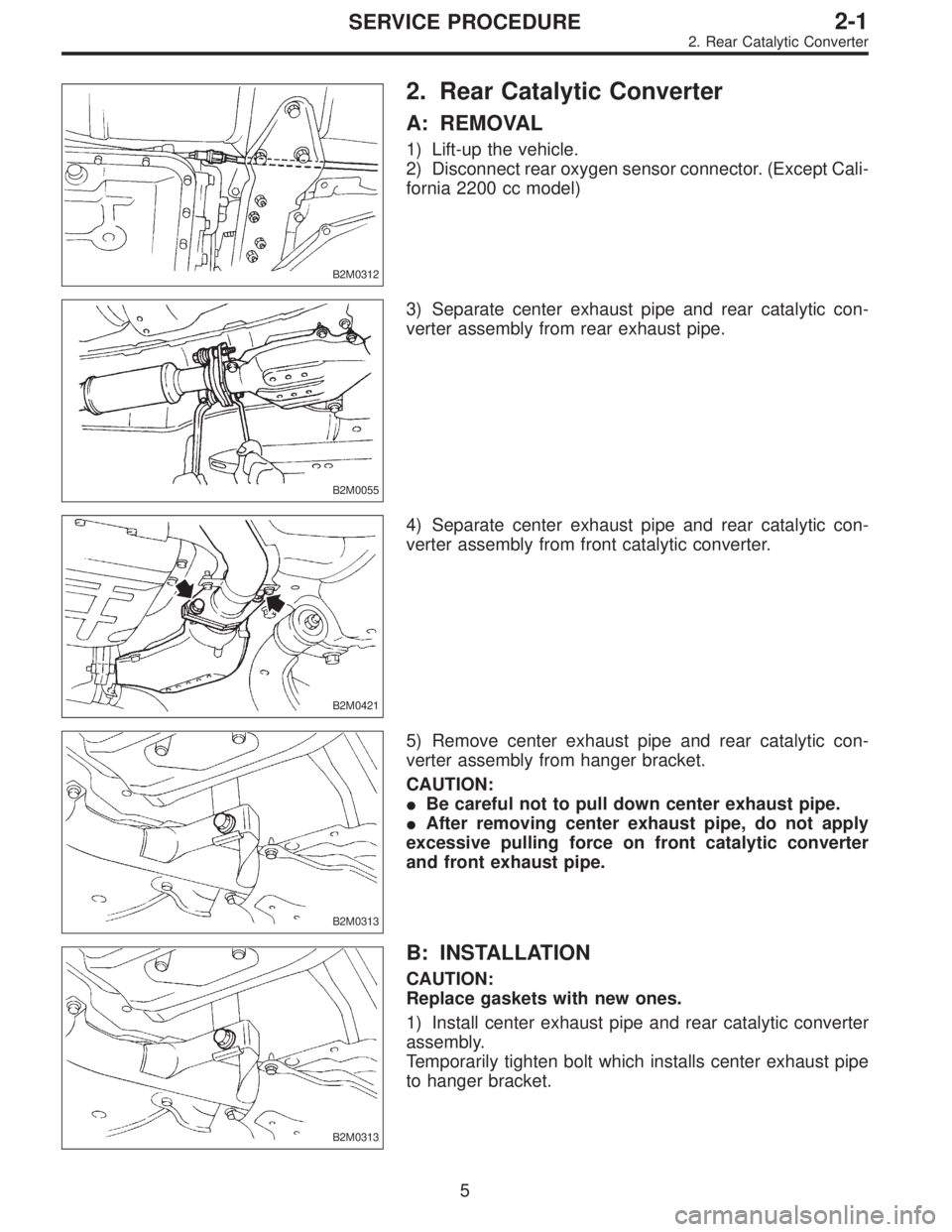

B2M0312

2. Rear Catalytic Converter

A: REMOVAL

1) Lift-up the vehicle.

2) Disconnect rear oxygen sensor connector. (Except Cali-

fornia 2200 cc model)

B2M0055

3) Separate center exhaust pipe and rear catalytic con-

verter assembly from rear exhaust pipe.

B2M0421

4) Separate center exhaust pipe and rear catalytic con-

verter assembly from front catalytic converter.

B2M0313

5) Remove center exhaust pipe and rear catalytic con-

verter assembly from hanger bracket.

CAUTION:

�Be careful not to pull down center exhaust pipe.

�After removing center exhaust pipe, do not apply

excessive pulling force on front catalytic converter

and front exhaust pipe.

B2M0313

B: INSTALLATION

CAUTION:

Replace gaskets with new ones.

1) Install center exhaust pipe and rear catalytic converter

assembly.

Temporarily tighten bolt which installs center exhaust pipe

to hanger bracket.

5

2-1SERVICE PROCEDURE

2. Rear Catalytic Converter

Page 283 of 2890

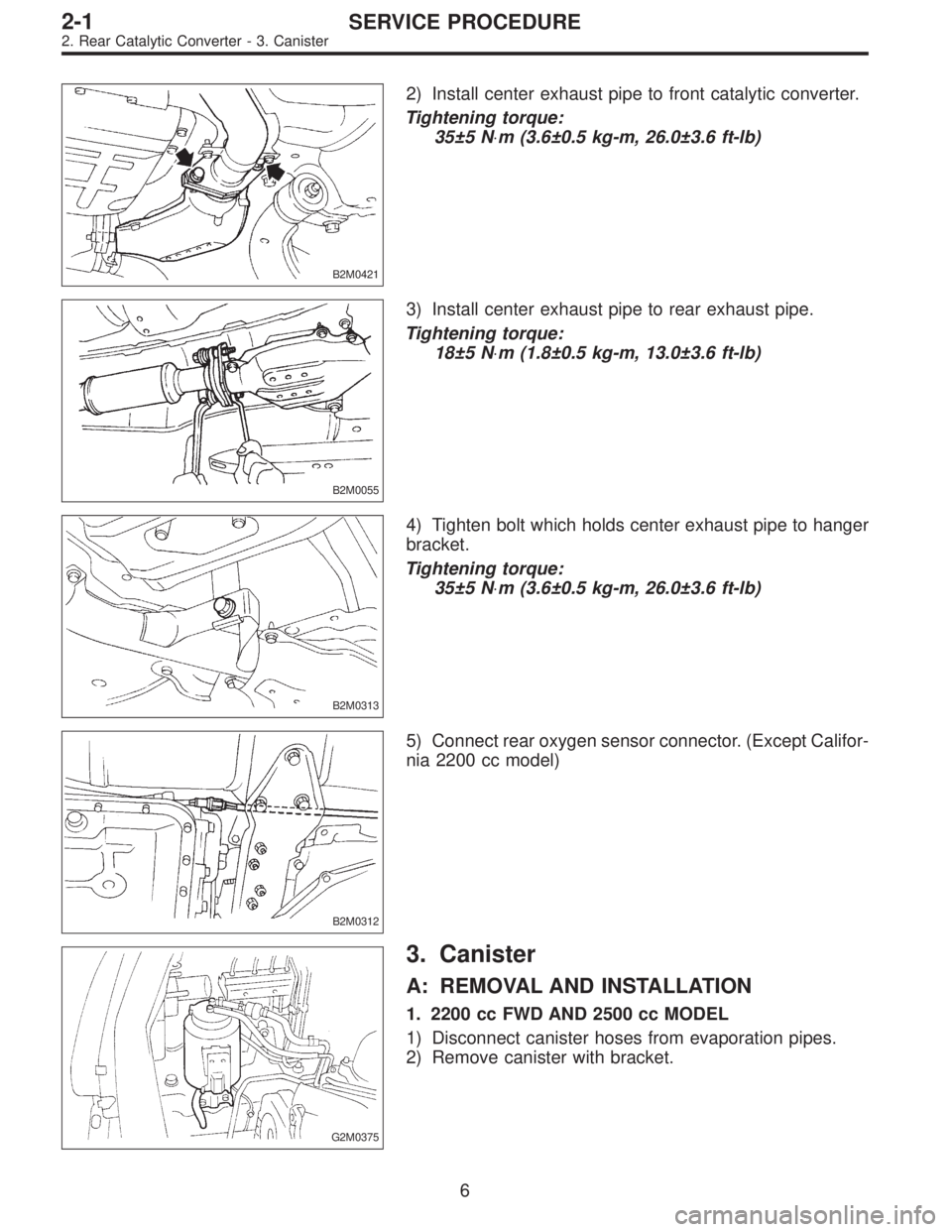

B2M0421

2) Install center exhaust pipe to front catalytic converter.

Tightening torque:

35±5 N⋅m (3.6±0.5 kg-m, 26.0±3.6 ft-lb)

B2M0055

3) Install center exhaust pipe to rear exhaust pipe.

Tightening torque:

18±5 N⋅m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

B2M0313

4) Tighten bolt which holds center exhaust pipe to hanger

bracket.

Tightening torque:

35±5 N⋅m (3.6±0.5 kg-m, 26.0±3.6 ft-lb)

B2M0312

5) Connect rear oxygen sensor connector. (Except Califor-

nia 2200 cc model)

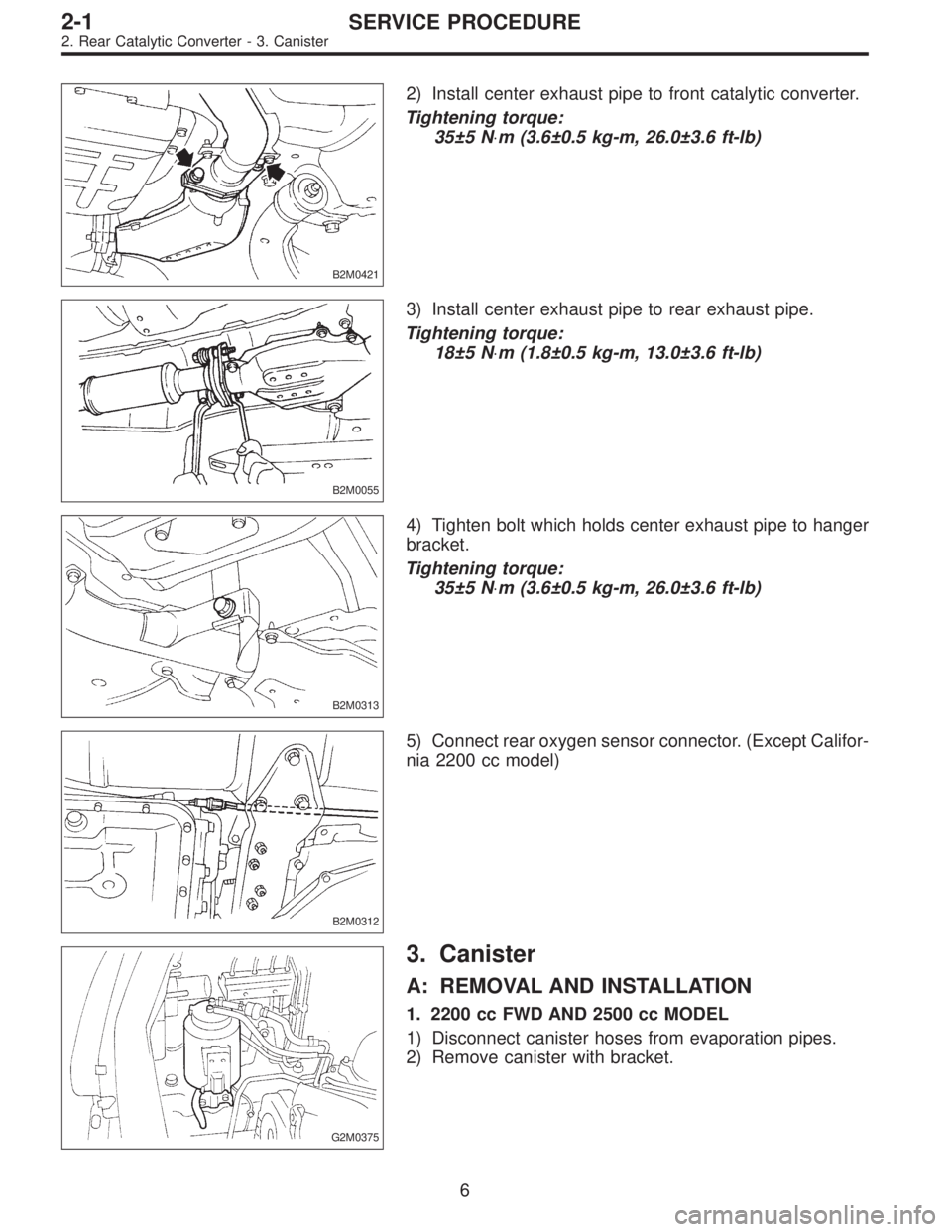

G2M0375

3. Canister

A: REMOVAL AND INSTALLATION

1. 2200 cc FWD AND 2500 cc MODEL

1) Disconnect canister hoses from evaporation pipes.

2) Remove canister with bracket.

6

2-1SERVICE PROCEDURE

2. Rear Catalytic Converter - 3. Canister

Page 284 of 2890

B2M0421

2) Install center exhaust pipe to front catalytic converter.

Tightening torque:

35±5 N⋅m (3.6±0.5 kg-m, 26.0±3.6 ft-lb)

B2M0055

3) Install center exhaust pipe to rear exhaust pipe.

Tightening torque:

18±5 N⋅m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

B2M0313

4) Tighten bolt which holds center exhaust pipe to hanger

bracket.

Tightening torque:

35±5 N⋅m (3.6±0.5 kg-m, 26.0±3.6 ft-lb)

B2M0312

5) Connect rear oxygen sensor connector. (Except Califor-

nia 2200 cc model)

G2M0375

3. Canister

A: REMOVAL AND INSTALLATION

1. 2200 cc FWD AND 2500 cc MODEL

1) Disconnect canister hoses from evaporation pipes.

2) Remove canister with bracket.

6

2-1SERVICE PROCEDURE

2. Rear Catalytic Converter - 3. Canister

Page 285 of 2890

3) Installation is in the reverse order of removal.

CAUTION:

Insert air vent hose of canister into the hole on body.

B2M0952

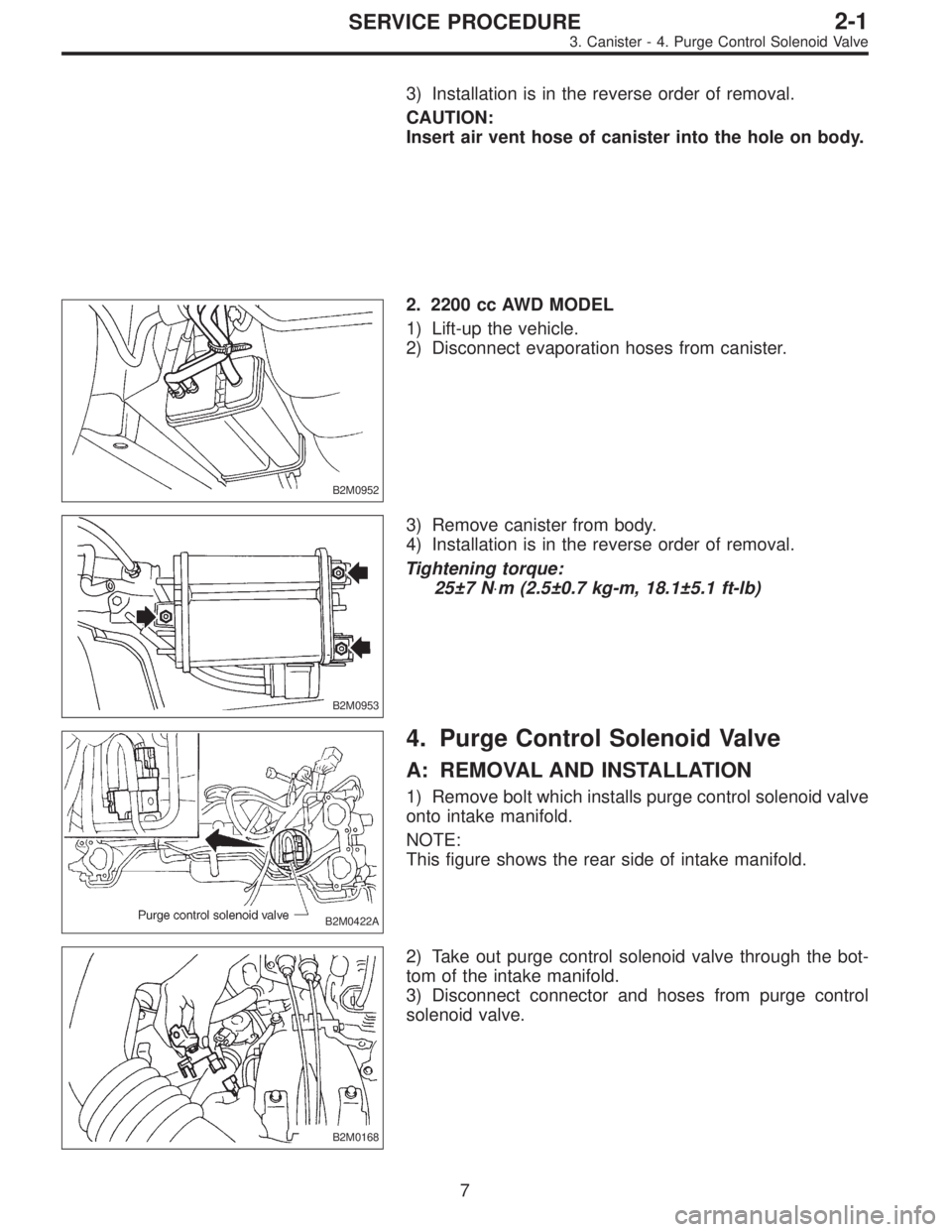

2. 2200 cc AWD MODEL

1) Lift-up the vehicle.

2) Disconnect evaporation hoses from canister.

B2M0953

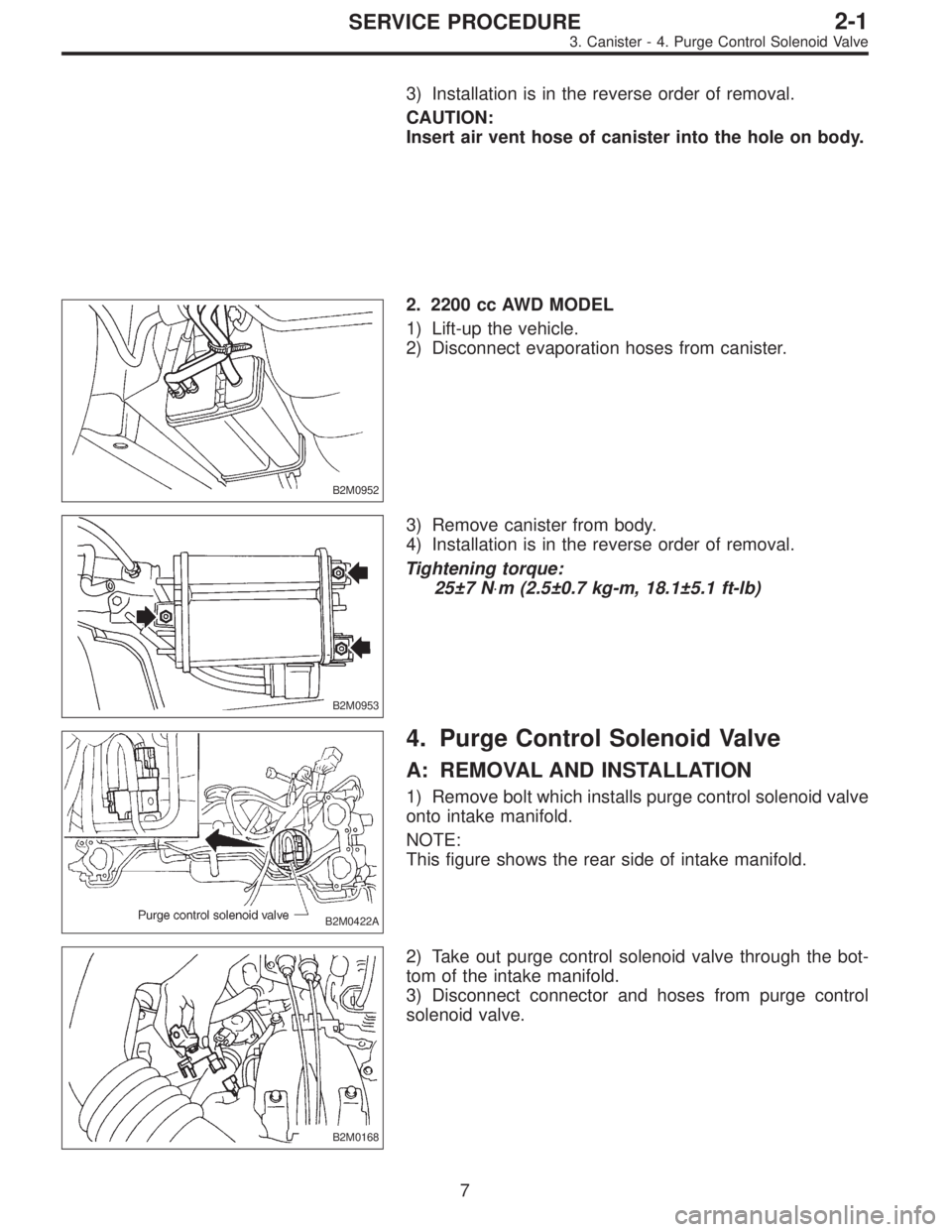

3) Remove canister from body.

4) Installation is in the reverse order of removal.

Tightening torque:

25±7 N⋅m (2.5±0.7 kg-m, 18.1±5.1 ft-lb)

B2M0422A

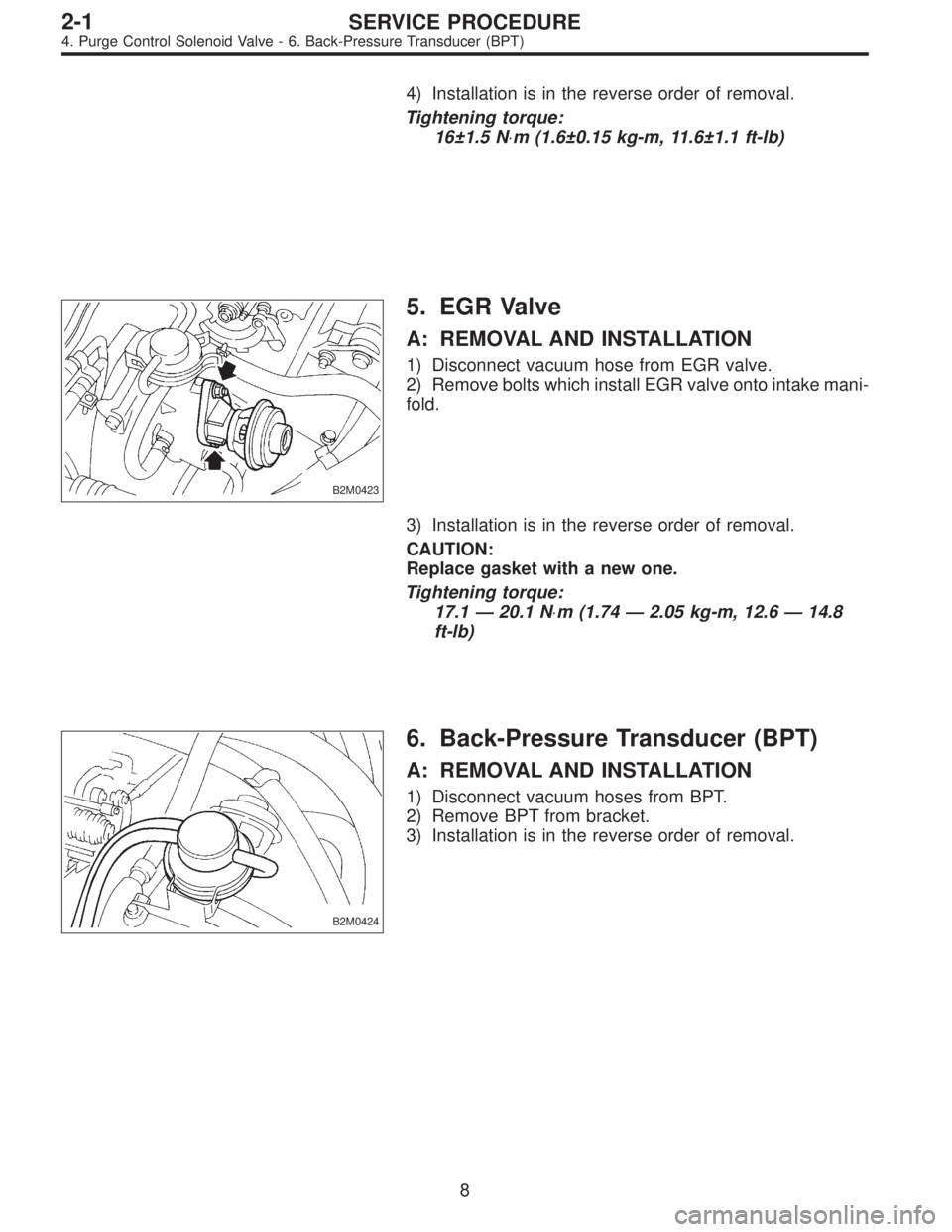

4. Purge Control Solenoid Valve

A: REMOVAL AND INSTALLATION

1) Remove bolt which installs purge control solenoid valve

onto intake manifold.

NOTE:

This figure shows the rear side of intake manifold.

B2M0168

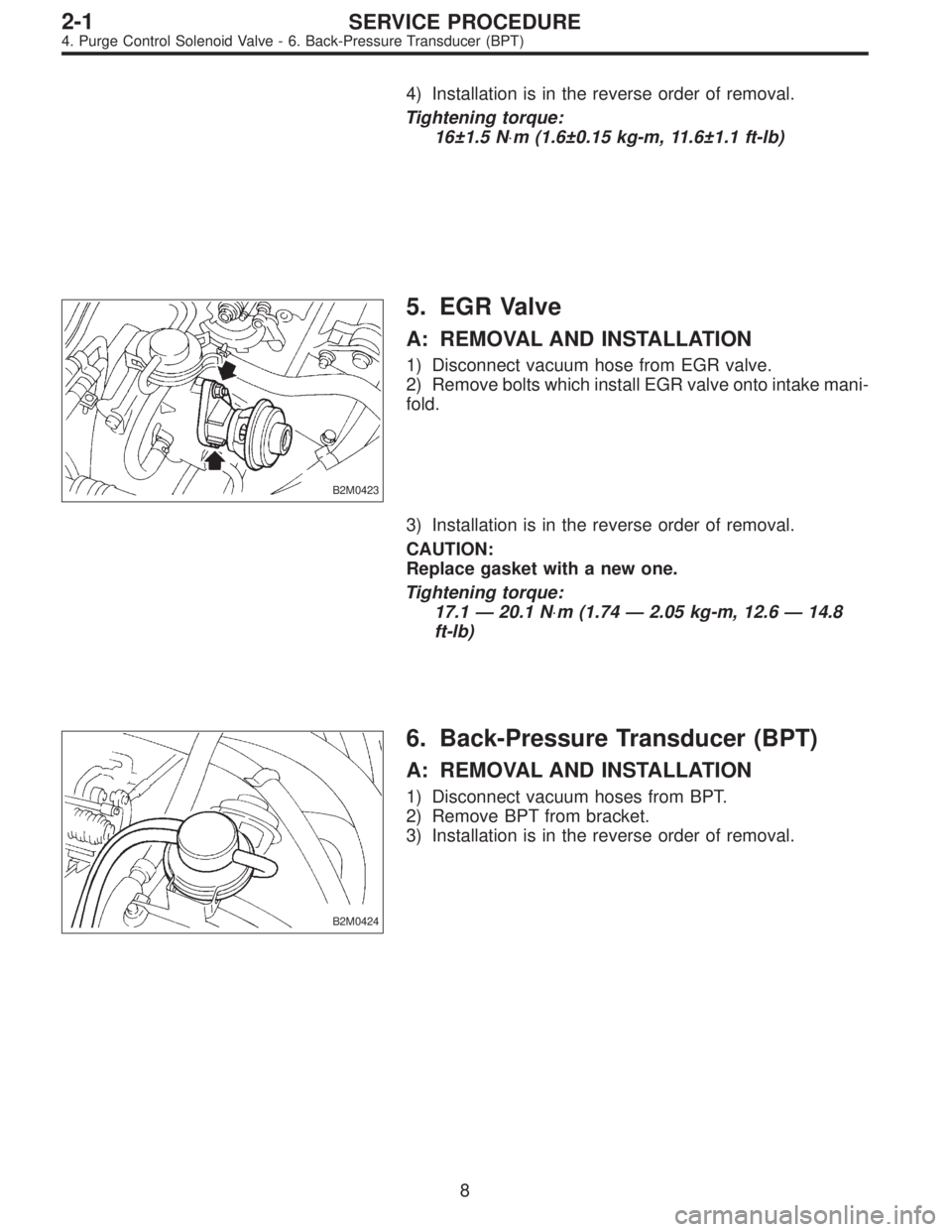

2) Take out purge control solenoid valve through the bot-

tom of the intake manifold.

3) Disconnect connector and hoses from purge control

solenoid valve.

7

2-1SERVICE PROCEDURE

3. Canister - 4. Purge Control Solenoid Valve

Page 286 of 2890

3) Installation is in the reverse order of removal.

CAUTION:

Insert air vent hose of canister into the hole on body.

B2M0952

2. 2200 cc AWD MODEL

1) Lift-up the vehicle.

2) Disconnect evaporation hoses from canister.

B2M0953

3) Remove canister from body.

4) Installation is in the reverse order of removal.

Tightening torque:

25±7 N⋅m (2.5±0.7 kg-m, 18.1±5.1 ft-lb)

B2M0422A

4. Purge Control Solenoid Valve

A: REMOVAL AND INSTALLATION

1) Remove bolt which installs purge control solenoid valve

onto intake manifold.

NOTE:

This figure shows the rear side of intake manifold.

B2M0168

2) Take out purge control solenoid valve through the bot-

tom of the intake manifold.

3) Disconnect connector and hoses from purge control

solenoid valve.

7

2-1SERVICE PROCEDURE

3. Canister - 4. Purge Control Solenoid Valve

Page 287 of 2890

4) Installation is in the reverse order of removal.

Tightening torque:

16±1.5 N⋅m (1.6±0.15 kg-m, 11.6±1.1 ft-lb)

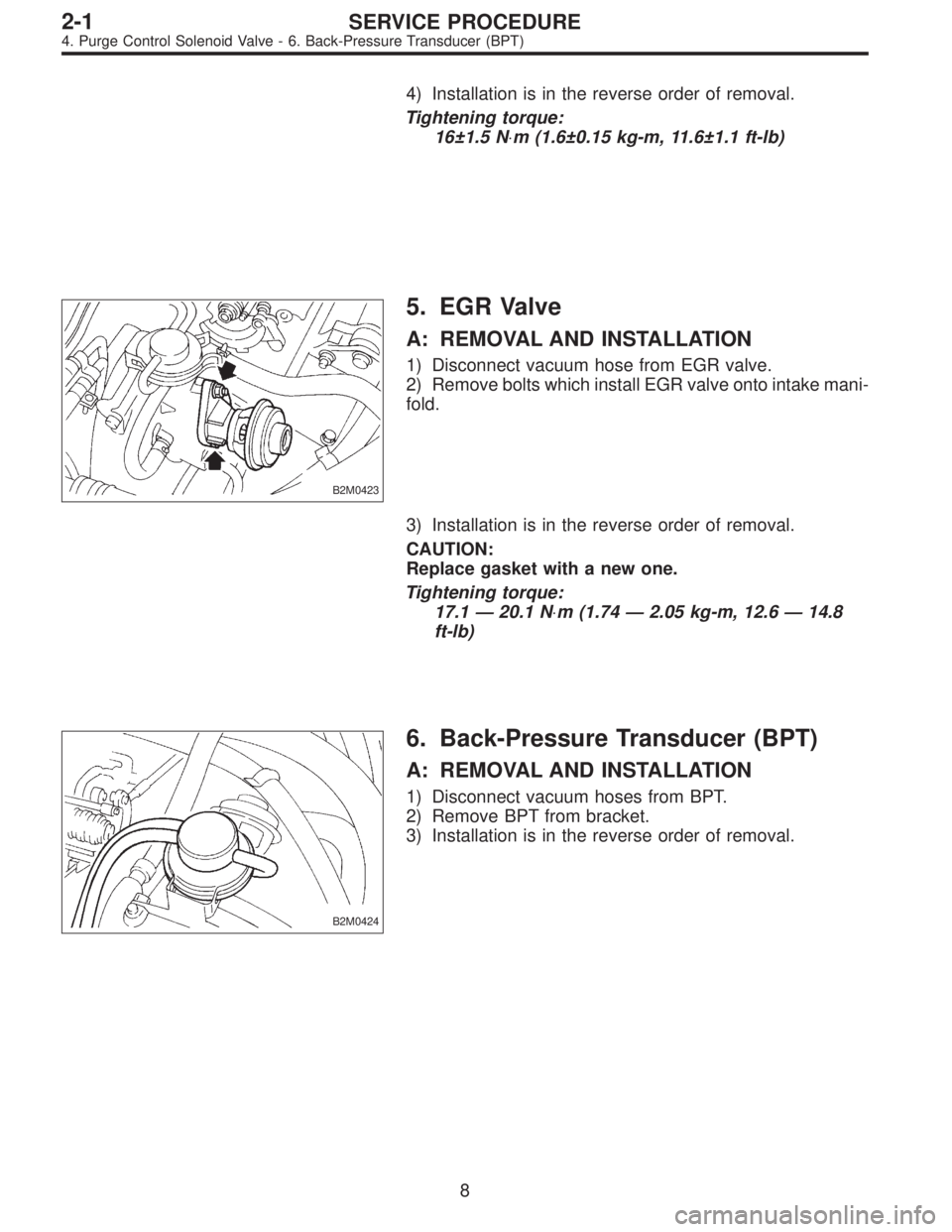

B2M0423

5. EGR Valve

A: REMOVAL AND INSTALLATION

1) Disconnect vacuum hose from EGR valve.

2) Remove bolts which install EGR valve onto intake mani-

fold.

3) Installation is in the reverse order of removal.

CAUTION:

Replace gasket with a new one.

Tightening torque:

17.1 — 20.1 N⋅m (1.74 — 2.05 kg-m, 12.6 — 14.8

ft-lb)

B2M0424

6. Back-Pressure Transducer (BPT)

A: REMOVAL AND INSTALLATION

1) Disconnect vacuum hoses from BPT.

2) Remove BPT from bracket.

3) Installation is in the reverse order of removal.

8

2-1SERVICE PROCEDURE

4. Purge Control Solenoid Valve - 6. Back-Pressure Transducer (BPT)

Page 288 of 2890

4) Installation is in the reverse order of removal.

Tightening torque:

16±1.5 N⋅m (1.6±0.15 kg-m, 11.6±1.1 ft-lb)

B2M0423

5. EGR Valve

A: REMOVAL AND INSTALLATION

1) Disconnect vacuum hose from EGR valve.

2) Remove bolts which install EGR valve onto intake mani-

fold.

3) Installation is in the reverse order of removal.

CAUTION:

Replace gasket with a new one.

Tightening torque:

17.1 — 20.1 N⋅m (1.74 — 2.05 kg-m, 12.6 — 14.8

ft-lb)

B2M0424

6. Back-Pressure Transducer (BPT)

A: REMOVAL AND INSTALLATION

1) Disconnect vacuum hoses from BPT.

2) Remove BPT from bracket.

3) Installation is in the reverse order of removal.

8

2-1SERVICE PROCEDURE

4. Purge Control Solenoid Valve - 6. Back-Pressure Transducer (BPT)

Page 289 of 2890

4) Installation is in the reverse order of removal.

Tightening torque:

16±1.5 N⋅m (1.6±0.15 kg-m, 11.6±1.1 ft-lb)

B2M0423

5. EGR Valve

A: REMOVAL AND INSTALLATION

1) Disconnect vacuum hose from EGR valve.

2) Remove bolts which install EGR valve onto intake mani-

fold.

3) Installation is in the reverse order of removal.

CAUTION:

Replace gasket with a new one.

Tightening torque:

17.1 — 20.1 N⋅m (1.74 — 2.05 kg-m, 12.6 — 14.8

ft-lb)

B2M0424

6. Back-Pressure Transducer (BPT)

A: REMOVAL AND INSTALLATION

1) Disconnect vacuum hoses from BPT.

2) Remove BPT from bracket.

3) Installation is in the reverse order of removal.

8

2-1SERVICE PROCEDURE

4. Purge Control Solenoid Valve - 6. Back-Pressure Transducer (BPT)

Page 290 of 2890

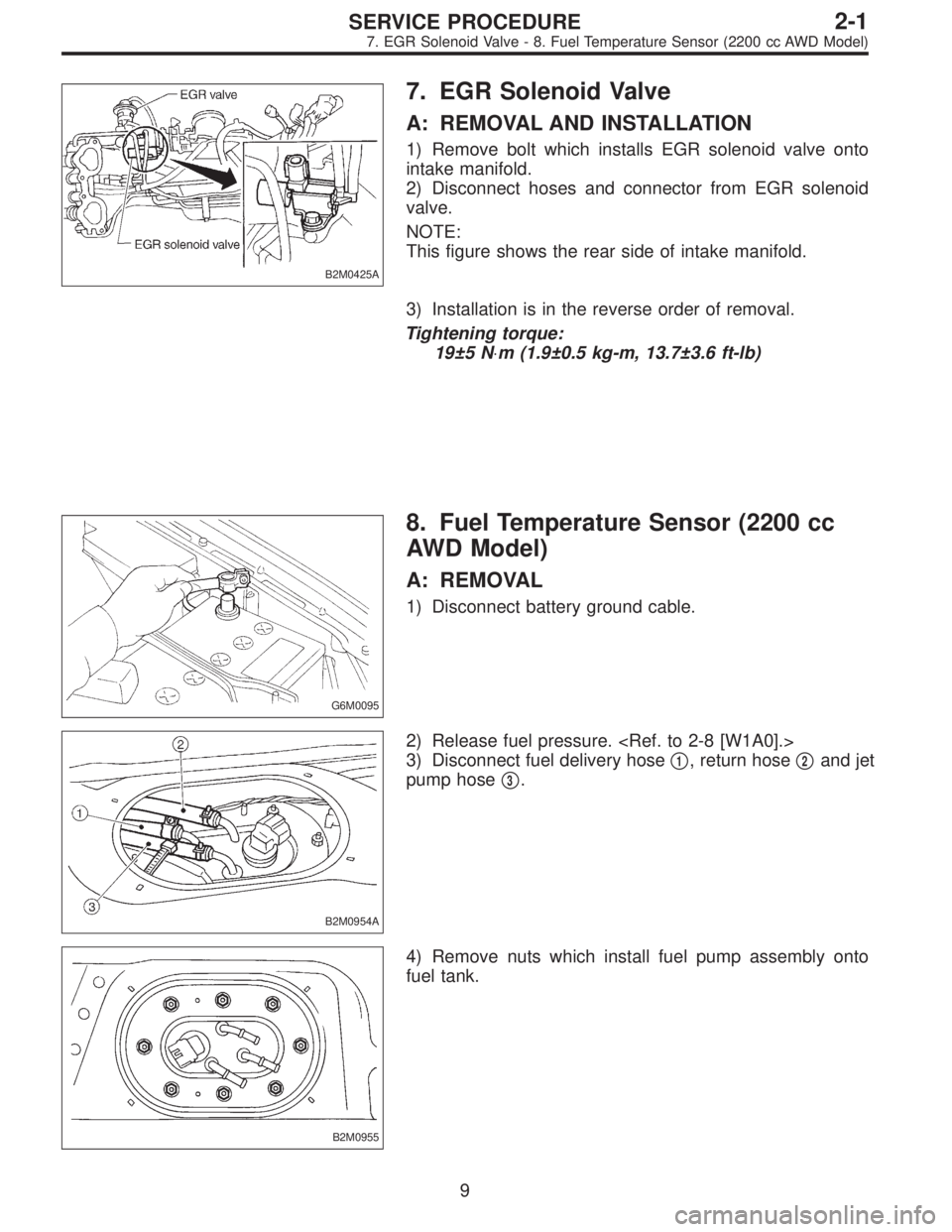

B2M0425A

7. EGR Solenoid Valve

A: REMOVAL AND INSTALLATION

1) Remove bolt which installs EGR solenoid valve onto

intake manifold.

2) Disconnect hoses and connector from EGR solenoid

valve.

NOTE:

This figure shows the rear side of intake manifold.

3) Installation is in the reverse order of removal.

Tightening torque:

19±5 N⋅m (1.9±0.5 kg-m, 13.7±3.6 ft-lb)

G6M0095

8. Fuel Temperature Sensor (2200 cc

AWD Model)

A: REMOVAL

1) Disconnect battery ground cable.

B2M0954A

2) Release fuel pressure.

3) Disconnect fuel delivery hose�

1, return hose�2and jet

pump hose�

3.

B2M0955

4) Remove nuts which install fuel pump assembly onto

fuel tank.

9

2-1SERVICE PROCEDURE

7. EGR Solenoid Valve - 8. Fuel Temperature Sensor (2200 cc AWD Model)

Trending: manual transmission, wiring diagram, rear fog, ignition, oil type, shift, fuses