turn SUBARU LEGACY 1996 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1996, Model line: LEGACY, Model: SUBARU LEGACY 1996Pages: 2890, PDF Size: 61.9 MB

Page 8 of 2890

![SUBARU LEGACY 1996 Service Repair Manual

SUPPLEMENTAL

RESTRAINT

SYSTEM

(ELECTRIC

SENSOR

TYPE)

[M2-4]

5-5b

2

.

Construction

4

.

SAFETY

SENSOR

AND

ELECTRIC

SENSOR

Safety

sensor

and

electric

sensor

are

built

into

the

airbag

control

module

.

SUBARU LEGACY 1996 Service Repair Manual

SUPPLEMENTAL

RESTRAINT

SYSTEM

(ELECTRIC

SENSOR

TYPE)

[M2-4]

5-5b

2

.

Construction

4

.

SAFETY

SENSOR

AND

ELECTRIC

SENSOR

Safety

sensor

and

electric

sensor

are

built

into

the

airbag

control

module

.](/img/17/57433/w960_57433-7.png)

SUPPLEMENTAL

RESTRAINT

SYSTEM

(ELECTRIC

SENSOR

TYPE)

[M2-4]

5-5b

2

.

Construction

4

.

SAFETY

SENSOR

AND

ELECTRIC

SENSOR

Safety

sensor

and

electric

sensor

are

built

into

the

airbag

control

module

.

Safety

sensor

is

the

magnet

piston

type

sensor

.

If

the

sensor

receives

a

frontal

impact

exceeding

a

certain

limit,

the

mass

in

the

sensor

moves

forward

to

turn

the

switch

ON

.

The

electric

sensor

consists

of

a

piezo-electric

device

and

generates

a

voltage

corresponding

to

the

deceleration

speed

that

occurs

in

the

body

.

SAFETY

SENSOR

Ma

s

(Magnet)

Spring

1

ELECTRIC

SENSOR

Piezo-electric

device

11

Bonding

wire

B5H0397A

5

Reed

Switch

Page 10 of 2890

![SUBARU LEGACY 1996 Service Repair Manual

SUPPLEMENTAL

RESTRAINT

SYSTEM

(ELECTRIC

SENSOR

TYPE)

[M2-10]

5-5b

2

.

Construction

U

Ullv

H5H0660

CAUTION

[BEFORE

INSTALLING]

1.

POINT

FRONT

WHEELS

STRAIGHT

AHEAD

.

2

.

ROTATE

2

.65

TURNS

FRO SUBARU LEGACY 1996 Service Repair Manual

SUPPLEMENTAL

RESTRAINT

SYSTEM

(ELECTRIC

SENSOR

TYPE)

[M2-10]

5-5b

2

.

Construction

U

Ullv

H5H0660

CAUTION

[BEFORE

INSTALLING]

1.

POINT

FRONT

WHEELS

STRAIGHT

AHEAD

.

2

.

ROTATE

2

.65

TURNS

FRO](/img/17/57433/w960_57433-9.png)

SUPPLEMENTAL

RESTRAINT

SYSTEM

(ELECTRIC

SENSOR

TYPE)

[M2-10]

5-5b

2

.

Construction

U

Ullv''

H5H0660

CAUTION

[BEFORE

INSTALLING]

1.

POINT

FRONT

WHEELS

STRAIGHT

AHEAD

.

2

.

ROTATE

2

.65

TURNS

FROM

RIGHT

END

STOP

.

3

.

ALIGN

MATCH-MARKS

(CENTER

MARKS

Y

)

.

4

.

READ

SERVICE

MANUAL

.

(~~J~1f~~~1~,)

2

.

~OO~~t~~J~~~J2

.65O0~OO~o

3

.

(CENTER

MARK

:

;

)

~o~tr~o

4

.

AIR

BAG

MODULE

98

00-4

.

FRU&t,~

-3F4

~

WARNING

To

prevent

personal

injury

.

Do

not

dismantle,

repair

or

install

in

another

vehicle

.

Service

or

dispose

as

directed

in

the

service

manual

.

r

8

ATTENTION

Pour

eviter

tout

risque

de

blessures

corporel-

les

:

Ne

pas

demonter,

reparer,

installer

dans

un

autre

vehi-

~~

cule

.

L'entretenir

ou

le

remplacer

comme

indique

dans

le

manual

d'entretien

.

ACHTUNG

Zur

Vermeidung

von

Verletzungen

.

Nicht

zer-

I

legen,reparieren

oder

in

einem

anderen

Fahrzeug

instal-

lieren

.

Wartung

and

Ausbau

wie

im

Reparaturhandbuch

beschrieben

.

G5H0287

AIRBAG

GAS

GENERATOR

HERG,

:94/94

UTM

TG-6

BAM

.

PTA

.0369

THIS

GAS

GENERATOR

SHOULD

ONLY

BE

INSTALLED

IN

VEHICLES

EQUIPPEDWITH

AIRBAG

SYSTEMS

AND

IS

TO

BE

INSTALLED

AND/OR

DISASSEMBLED

ONLY

BYTRAINED

PERSONNEL

.

CONTENTS

AREPOISONOUS

AND

EXTREMELY

FLAMMABLE

.

DO

NOT

DISMANTLE,

INCINERATE,

OR

BRING

INTO

CON-TACTWITH

ELECTRICITY,

OR

STORE

AT

TEMPERATURES

EXCEEDING

200°F

.

FIRST

AID

:

IF

CONTENTS

ARE

SWALLOWED,

INDUCE

VOM-

ITING

:

FOR

EYE

CONTACT,

FLUSH

EYES

WITH

WATER

FOR

15

MIN

.

IN

EVERY

CASE

GET

PROMPT

MEDICAL

ATTENTION

.

OO

s

UMGANG

NUR

DURCH

GESCHULTES

PERSONAL

ERLAUBT

~

VERWENDUNG

NUR

ALSINSASSEN-RUCKHALTE

SYSTEM

MIT

LUFTSACK

FUR

KRAFTFAHRZEUGE

ERLAUBT

BEI

AUS-

C

LOSUNG

KANN

DIE

NICHT

MONTIERTE

AIRBAG-EIN-HEIT

1

~

ZUM

GEFAHRLICHEN

WURFSTUCK

WERDEN

.

SUBARU

DEUTSCHLAND

GmbH

DUSSELDORF

MORTON

INTERNATIONAL,

INC

.

OGDEM,USA

DANGER

ACHTUNG

ATTENTION

G5H0288

Page 13 of 2890

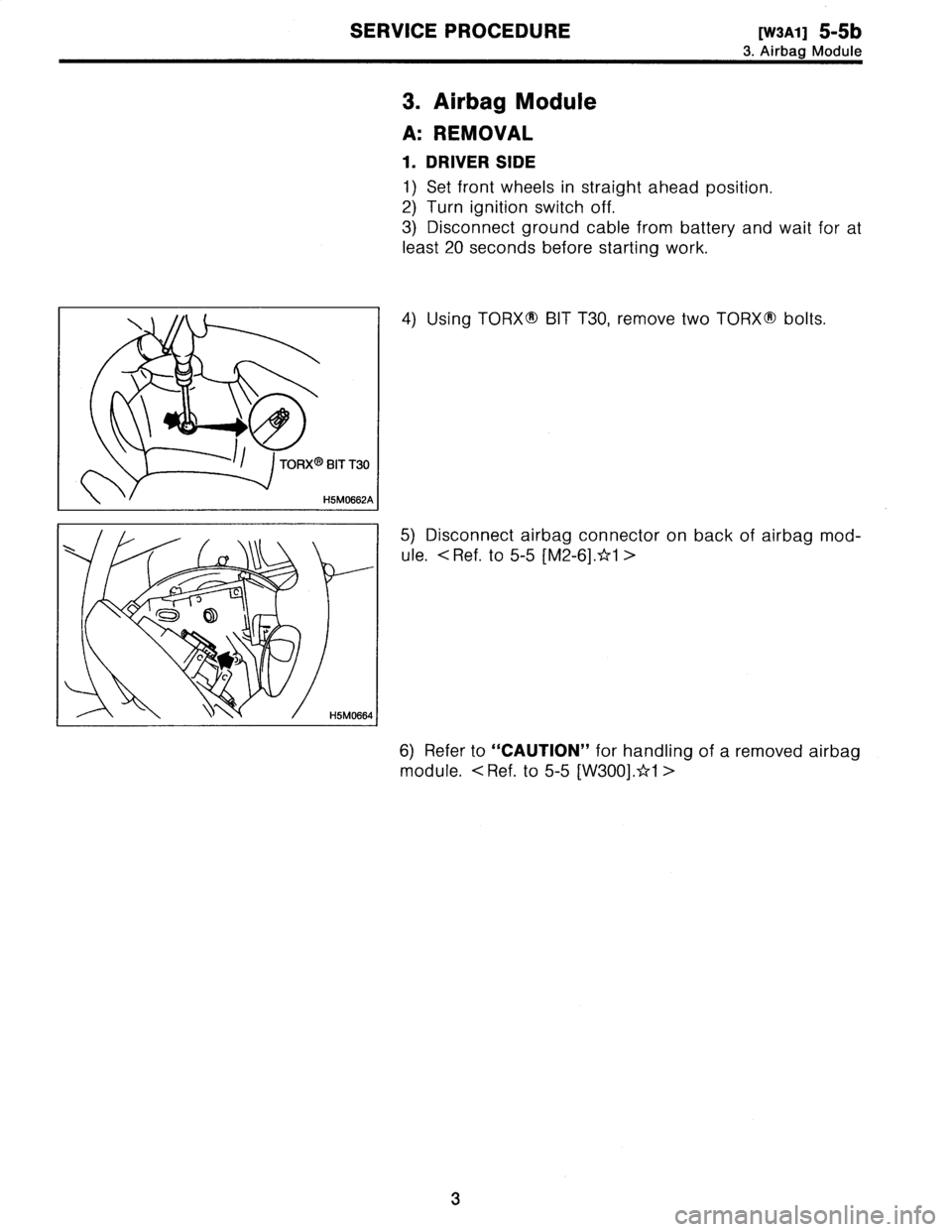

SERVICE

PROCEDURE

[w3A11

5-5b

3

.

Airbag

Module

3

.

Airbag

Module

A

:

REMOVAL

1

.

DRIVER

SIDE

1)

Set

front

wheels

in

straight

ahead

position

.

2)

Turn

ignition

switch

off

.

3)

Disconnect

ground

cable

from

battery

and

wait

forat

least

20

seconds

before

starting

work

.

4)

Using

TORX9

BIT

T30,

remove

two

TORXO

bolts

.

5)

Disconnect

airbag

connector

on

back

of

airbag

mod-

ule

.

<

Ref

.

to

5-5[M2-6].*1

>

6)

Refer

to

"CAUTION"

for

handling

of

a

removed

airbag

module

.

<

Ref

.

to

5-5

[W300]

.*1

>

3

Page 14 of 2890

![SUBARU LEGACY 1996 Service Repair Manual

5-5b

[W6A0]

SERVICE

PROCEDURE

6

.

Airbag

Control

Module

AB6

9~v~

BSM0400A

e

B5M0105

I

6

.

Airbag

Control

Module

A

:

REMOVAL

1)

Turn

ignition

switch

off

.

2)

Disconnect

ground

cablefrom

battery SUBARU LEGACY 1996 Service Repair Manual

5-5b

[W6A0]

SERVICE

PROCEDURE

6

.

Airbag

Control

Module

AB6

9~v~

BSM0400A

e

B5M0105

I

6

.

Airbag

Control

Module

A

:

REMOVAL

1)

Turn

ignition

switch

off

.

2)

Disconnect

ground

cablefrom

battery](/img/17/57433/w960_57433-13.png)

5-5b

[W6A0]

SERVICE

PROCEDURE

6

.

Airbag

Control

Module

AB6

9~v~

BSM0400A

e

B5M0105

I

6

.

Airbag

Control

Module

A

:

REMOVAL

1)

Turn

ignition

switch

off

.

2)

Disconnect

ground

cablefrom

battery

and

wait

forat

least

20

seconds

before

starting

work

.

3)

Remove

lower

cover

.

<

Ref

.

to

5-4

[W1A0]

.*1

>

Disconnect

airbag

connector

(AB3)

and

(AB8)below

steering

column

.

CAUTION

:

Do

notreconnect

airbag

connector

at

steering

column

until

airbag

control

module

is

securely

re-installed

.

4)

Remove

console

box

.

<

Ref

.

to

5-4

[W1A0]

.*1

>

5)

Disconnect

12-pinyellow

connector

fromairbagcon-

trol

module

.

<

Ref

.

to

5-5[M2-6].*1

>

6)

Using

TORXS

BIT

T40

(Tamper

resistant

type),

remove

two

TORXS

bolts

.

Discard

theold

TORXM

bolts

.

CAUTION

:

Use

new

TORXS

bolts

during

re-assembly

.

4

Page 15 of 2890

![SUBARU LEGACY 1996 Service Repair Manual

SERVICE

PROCEDURE

[W7AO]

5-5b

7

.

Combination

Switch

7

.

Combination

Switch

)

0)0

C

J

~

AB

,

.,

.

-^o/

G5M0312

A

:

REMOVAL

1)

Turn

ignition

switch

off

.

2)

Disconnect

ground

cable

from

batt SUBARU LEGACY 1996 Service Repair Manual

SERVICE

PROCEDURE

[W7AO]

5-5b

7

.

Combination

Switch

7

.

Combination

Switch

)

0)0

C

J

~

AB

,

.,

.

-^o/

G5M0312

A

:

REMOVAL

1)

Turn

ignition

switch

off

.

2)

Disconnect

ground

cable

from

batt](/img/17/57433/w960_57433-14.png)

SERVICE

PROCEDURE

[W7AO]

5-5b

7

.

Combination

Switch

7

.

Combination

Switch

)

0)0

C

J

~

AB

,

.,

.

-^o/

G5M0312

A

:

REMOVAL

1)

Turn

ignition

switch

off

.

2)

Disconnect

ground

cable

from

battery

and

wait

for

at

least

20

seconds

before

starting

work

.

3)

Remove

lower

cover

.

<

Ref,

to

5-4

[W1A0)

.*1

>

Dis-

connect

airbag

connector

(AB3)

and

(AB8)

below

steering

column

.

CAUTION

:

Do

not

reconnect

airbag

connector

at

steering

column

until

combination

switch

is

securely

re-installed

.

4)

Disconnect

combination

switch

connectors

from

body

harness

connector

.

5)

Set

front

wheels

in

straight

ahead

position

.

Using

TORX9

BIT

T30,

remove

two

TORX9

bolts

.

6)

Disconnect

airbag

connector

on

back

of

airbag

mod-

ule

.

<

Ref

.

to

5-5[M2-6]

.*1

>

Remove

airbag

module,

and

place

it

with

pad

side

facing

upward

.

<

Ref

.

to

5-5

[W300]

.*1

>

7)

Using

steering

puller,

remove

steering

wheel

.

CAUTION

:

Do

not

allow

connector

to

interfere

when

removing

steering

wheel

.

5

Page 16 of 2890

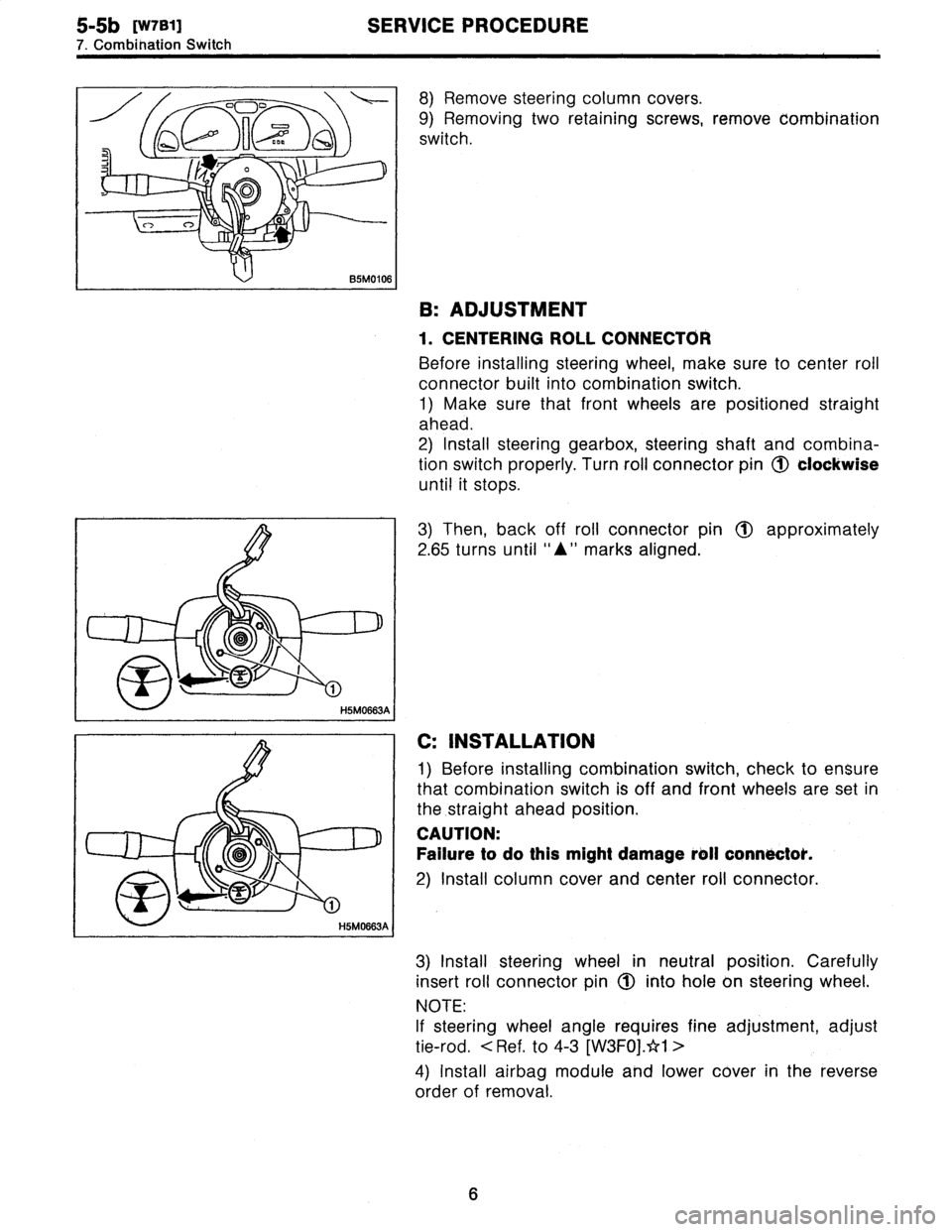

5-5b

[W7B1)

SERVICE

PROCEDURE

7

.

Combination

Switch

8)

Remove

steering

column

cowers

.

9)

Removing

two

retaining

screws,

remove

combination

switch

.

B

:

ADJUSTMENT

1

.

CENTERING

ROLL

CONNECTOR

Before

installing

steering

wheel,

make

sure

to

center

roil

connector

built

into

combination

switch

.

1)

Make

sure

that

front

wheels

are

positioned

straight

ahead

.

2)

Install

steering

gearbox,

steering

shaft

and

combina-

tion

switchproperly

.

Turn

roll

connector

pin

(J)

clockwise

until

it

stops

.

3)

Then,

back

off

roll

connector

pin

1~

approximately

2

.65

turns

until

"A"

marks

aligned

.

C

:

INSTALLATION

1)

Before

installing

combination

switch,

check

to

ensure

that

combination

switch

is

off

and

font

wheels

are

set

in

the

.straight

ahead

position

.

CAUTION

:

Failure

to

do

this

might

damage

roll

connoctok

.

2)

Install

column

cover

and

center

roll

connector

.

3)

Install

steering

wheel

in

neutral

position

.

Carefully

insert

roll

connector

pin

1(~

into

hole

on

steering

wheel

.

NOTE

:

If

steering

wheel

angle

requires

fine

adjustment,

adjust

tie-rod

.

<

Ref

.

to

4-3

[W3FOj

.*1

>

4)

Install

airbag

module

and

lower

cover

in

the

reverse

order

of

removal

.

6

Page 28 of 2890

ON-BOARD

DIAGNOSTICS

11

SYSTEM

[T3C1J

2-7

3

.

Diagnosis

System

0

-

ST2

0000000000

0000000000

STi

OBD0057A

4111

o000

0000

oaoo

F[

EJ0000

0000

G3M0150I

Subaru

select

monitor

:::

o

00000

aoaoonoaoooGoou

7

B2M0829A

3

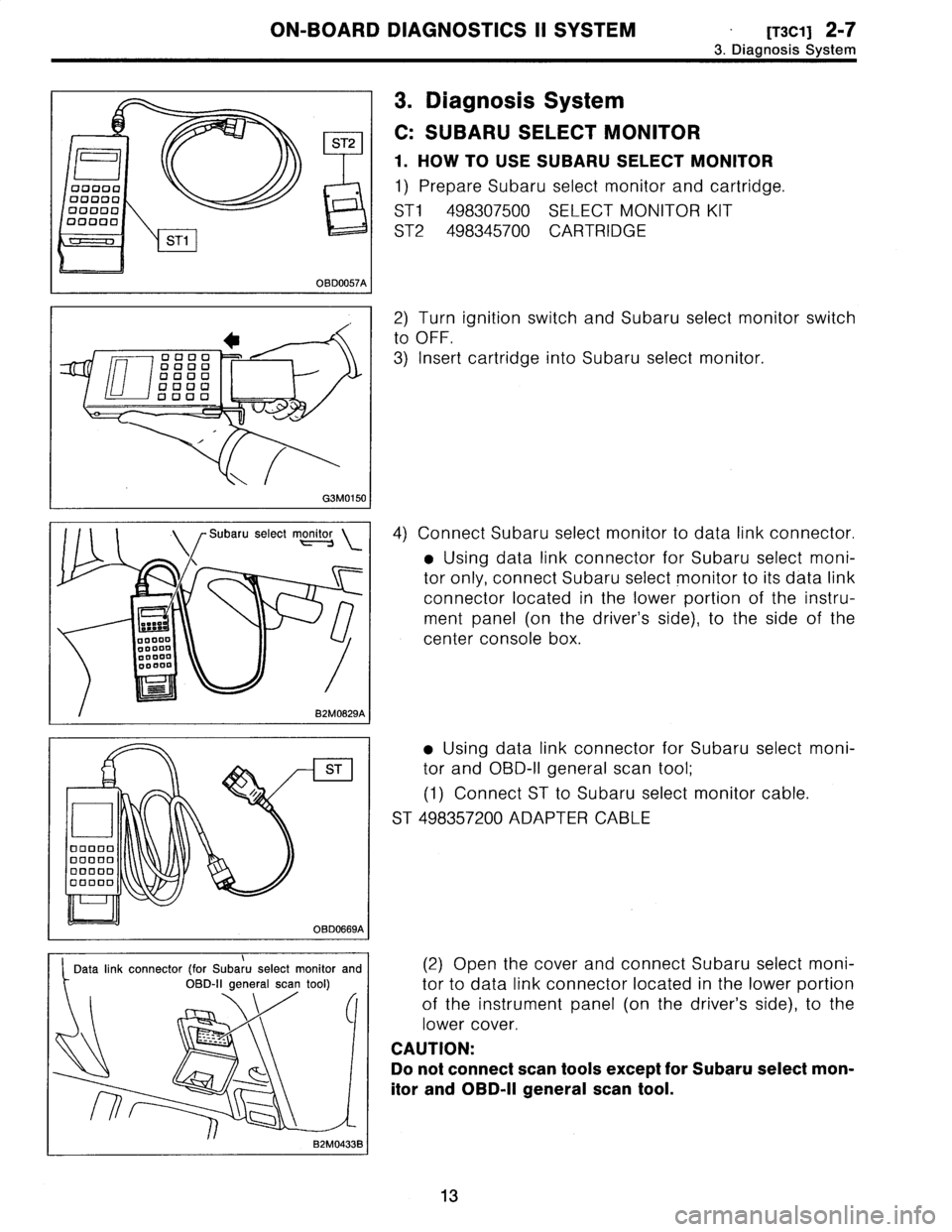

.

Diagnosis

System

C

:

SUBARU

SELECT

MONITOR

1

.

HOW

TO

USE

SUBARU

SELECT

MONITOR

1)

Prepare

Subaru

select

monitor

and

cartridge

.

ST1

498307500

SELECT

MONITOR

KIT

ST2

498345700

CARTRIDGE

2)

Turn

ignition

switch

and

Subaru

select

monitor

switch

to

OFF

.

3)

Insert

cartridge

into

Subaru

select

monitor

.

4)

Connect

Subaru

select

monitor

to

data

link

connector

.

*

Using

data

link

connector

for

Subaru

select

moni-

tor

only,

connect

Subaru

select

monitor

to

its

data

link

connector

located

in

the

lower

portion

of

the

instru-

ment

panel(on

the

driver's

side),

to

the

sideof

the

center

console

box

.

9

Using

data

link

connector

for

Subaru

select

moni-

tor

and

OBD-II

general

scan

tool

;

(1)

Connect

ST

to

Subaru

select

monitor

cable

.

ST

498357200

ADAPTER

CABLE

(2)

Open

the

cover

and

connect

Subaru

select

moni-

tor

to

data

link

connector

located

in

the

lower

portion

of

the

instrument

panel

(onthe

driver's

side),

to

the

lowercover

.

CAUTION

:

Do

not

connect

scan

tools

except

for

Subaru

select

mon-

itor

and

OBD-II

general

scan

tool

.

13

Page 29 of 2890

![SUBARU LEGACY 1996 Service Repair Manual 2-7

[T3C2]

ON-BOARD

DIAGNOSTICS

II

SYSTEM

3

.

Diagnosis

System

SELECT

SYSTEM

EGi

Y

:O,N

:/

1

101

H2M1149

I

=0=1

1H]

D

E

F

T

aor0l

oo

L

oo0

RD

FE-11

456

7

F111

0

0

F1_31

a

F03

0

FL-11

ED101

SUBARU LEGACY 1996 Service Repair Manual 2-7

[T3C2]

ON-BOARD

DIAGNOSTICS

II

SYSTEM

3

.

Diagnosis

System

SELECT

SYSTEM

EGi

Y

:O,N

:/

1

101

H2M1149

I

=0=1

1H]

D

E

F

T

aor0l

oo

L

oo0

RD

FE-11

456

7

F111

0

0

F1_31

a

F03

0

FL-11

ED101](/img/17/57433/w960_57433-28.png)

2-7

[T3C2]

ON-BOARD

DIAGNOSTICS

II

SYSTEM

3

.

Diagnosis

System

SELECT

SYSTEM

EGi

Y

:O,N

:/

1

101

H2M1149

I

=0=1

1H]

D

E

F

T

aor0l

oo

L

oo0

RD

FE-11

456

7

F111

0

0

F1_31

a

F03

0

FL-11

ED101

SUBARU

03M0152

I

OBD

(FB

1)

PO100

Diagnostic

trouble

code

Abbreviation

osooos2

OBD

(FB

1)

PO

115

OBD

(FBI)

P0120

<

THV

>

OBD0063

5)

Turn

ignition

switch

to

ON

(engine

OFF)

and

Subaru

select

monitor

switch

to

ON

.

6)

Using

Subaru

select

monitor,

call

up

diagnostic

trouble

code(s)

and

various

data,

then

record

them

.

2

.

READ

DIAGNOSTIC

TROUBLE

CODE

(DTC)

SHOWN

ON

DISPLAY

.

(MODE

FB1)

1)

Select

engine

mode

using

function

key

.

Press

thefunction

key

[0]

.

2)

Designate

mode

using

function

key

.

Press

[F]

[B]

[1]

[ENT]

in

that

order

.

3)

Ensure

diagnostic

trouble

code(s)

is

shown

.

(1)

When

there

is

only

one

diagnostic

trouble

code

.

(2)

When

there

are

multiple

diagnostic

trouble

codes

.

NOTE

:

For

details

concerning

diagnostic

trouble

codes,

referto

the

DIAGNOSTIC

TROUBLE

CODE

(DTC)

LIST,

2-7

[T11A0]*4

.

14

Page 42 of 2890

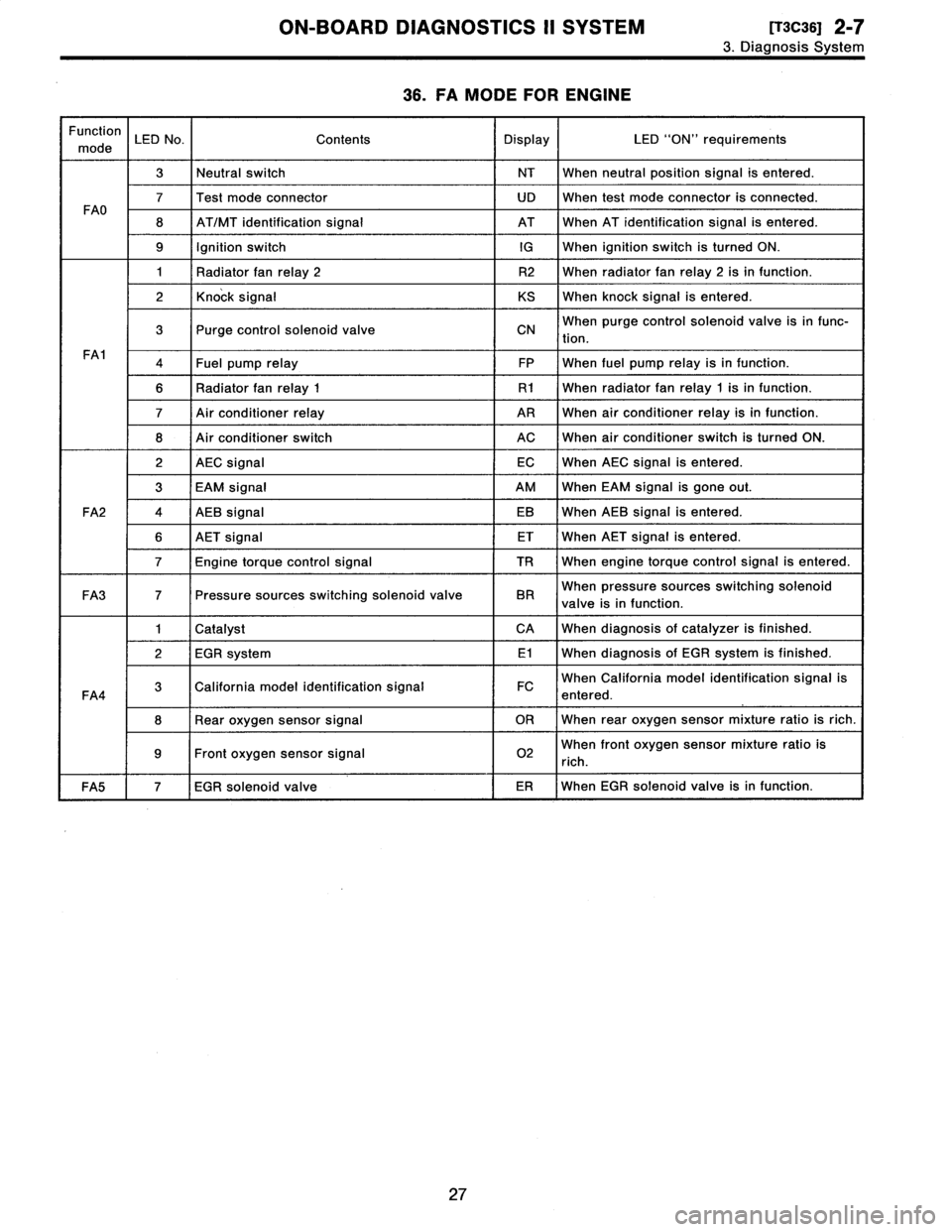

ON-BOARD

DIAGNOSTICS

II

SYSTEM

ITscas1

2-7

3

.

Diagnosis

System

36

.

FA

MODE

FOR

ENGINE

Function

mode

LED

No

.

Contents

Display

LED

"ON"

requirements

3Neutral

switch

NT

When

neutralposition

signal

is

entered

.

7Test

mode

connector

UD

When

test

mode

connector

is

connected

.

FAO

8

AT/MT

identification

signal

AT

When

AT

identification

signal

is

entered

.

9

Ignition

switchIG

When

ignition

switch

is

turned

ON

.

1

Radiator

fan

relay

2

R2

When

radiator

fanrelay2

isin

function

.

2

Knock

signal

KS

When

knock

signal

is

entered

.

3

Purge

control

solenoid

valve

CNWhen

purge

control

solenoid

valve

is

in

func-

tion

.

FA1

4Fuel

pump

relay

FP

When

fuel

pump

relay

isin

function

.

6

Radiator

fanrelay

1

R1

When

radiator

fanrelay

1

isin

function

.

7

Air

conditioner

relay

ARWhen

air

conditioner

relay

isin

function

.

8

Air

conditioner

switch

ACWhen

air

conditioner

switch

is

turned

ON

.

2

AEC

signal

ECWhen

AEC

signal

is

entered

.

3

EAM

signal

AM

When

EAM

signal

is

gone

out

.

FA2

4

AEB

signal

EB

When

AEB

signal

is

entered

.

6

AET

signal

ET

When

AET

signal

is

entered

.

7

Engine

torque

control

signal

TR

When

engine

torque

control

signal

is

entered

.

FA3

7

Pressure

sources

switching

solenoid

valve

BR

When

pressure

sources

switching

solenoid

valve

is

in

function

.

1

Catalyst

CA

When

diagnosis

of

catalyzer

is

finished

.

2

EGR

system

E1

When

diagnosis

of

EGR

system

is

finished

.

FA4

3

California

model

identification

signal

FC

When

California

model

identification

signal

is

entered

.

8

Rear

oxygen

sensor

signal

OR

When

rear

oxygen

sensor

mixture

ratio

is

rich

.

9Front

oxygen

sensor

signal

02

When

front

oxygen

sensor

mixture

ratio

is

rich

.

FA5

7

EGR

solenoid

valve

ER

When

EGR

solenoid

valve

is

in

function

.

27

Page 43 of 2890

![SUBARU LEGACY 1996 Service Repair Manual

Z-T

[T3C37]

ON-BOARD

DIAGNOSTICS

II

SYSTEM

3

.

Diagnosis

System

LED

No

.

Signal

name

Display

1

-

-

2

-

-

3Neutralswitch

NT

4

--

5

--

s

--

7

Test

mode

connector

LID

8

Identification

of

AT

mo SUBARU LEGACY 1996 Service Repair Manual

Z-T

[T3C37]

ON-BOARD

DIAGNOSTICS

II

SYSTEM

3

.

Diagnosis

System

LED

No

.

Signal

name

Display

1

-

-

2

-

-

3Neutralswitch

NT

4

--

5

--

s

--

7

Test

mode

connector

LID

8

Identification

of

AT

mo](/img/17/57433/w960_57433-42.png)

Z-T

[T3C37]

ON-BOARD

DIAGNOSTICS

II

SYSTEM

3

.

Diagnosis

System

LED

No

.

Signal

name

Display

1

-

-

2

-

-

3Neutralswitch

NT

4

--

5

--

s

--

7

Test

mode

connector

LID

8

Identification

of

AT

model

AT

9

Ignition

switchIG

r

0

-

-

NT

--

-

LID

AT

IG

-

ooooa

LEDNo

.

Signal

name

Display

1

Radiator

fan

relay

2

R2

2

Knock

signal

KS

Purge

control

solenoid

valve

CN

4

Fuel

pump

relay

FP

5

-

-

6

Radiator

fan

relay

1

R1

7

A/C

relay

AR

8

A/C

switch

AC

9

--

o

--

R2

KSCN

FP

-

R1

ARAC

--

37

.

FUNCTION

MODE

:

FAO

-

ON

H

OFF

SIGNAL

-

Requirement

for

LED

"ON"

.

LED

No

.

3

Shift

position

is

in

"P"or

"N"

.

LED

No

.

7

Test

mode

connector

is

connected

.

LED

No

.

8

Vehicle

is

AT

model

.

LED

No

.

9

Ignition

switch

is

turned

ON

.

38

.

FUNCTION

MODE

:

FA1

-

ON

H

OFF

SIGNAL

-

Requirement

for

LED

"ON"

.

LEDNo

.

1

Radiator

fan

relay

2

is

turned

ON

.

LEDNo

.

2

Engine

is

knocking

.

LED

No

.

3

Purge

control

solenoid

valve

is

in

function

.

LED

No

.

4

Fuel

pump

relay

is

turned

ON

.

LED

No

.

6

Radiator

fan

relay

1

is

turned

ON

.

LED

No

.

7

A/C

relay

is

turned

ON

.

LED

No

.

8

A/C

switch

is

turned

ON

.

NOTE

:

9

When

LED

No

.

1,3,

4,

6

and

7

blinks

with

the

test

mode

connector

connected

and

the

ignition

switch

turned

to

ON,

the

corresponding

part

is

functioning

properly

.

e

When

LED

No

.

4

illuminates

for

only

2

seconds

after

the

ignition

switch

is

turned

to

ON,

(and

then

goes

out),

the

corresponding

part

is

functioningproperly

.

28