diff SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 677 of 1456

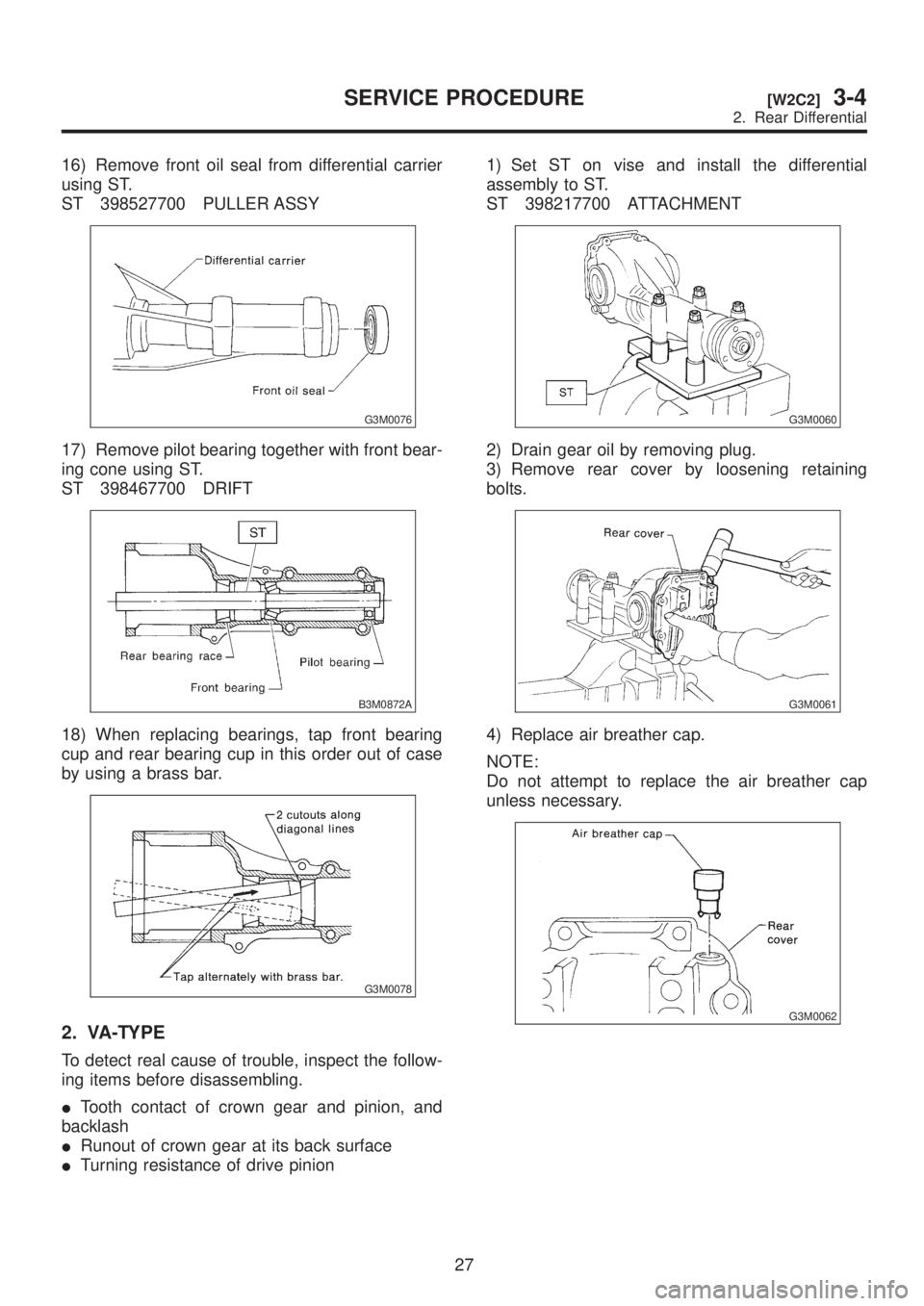

16) Remove front oil seal from differential carrier

using ST.

ST 398527700 PULLER ASSY

G3M0076

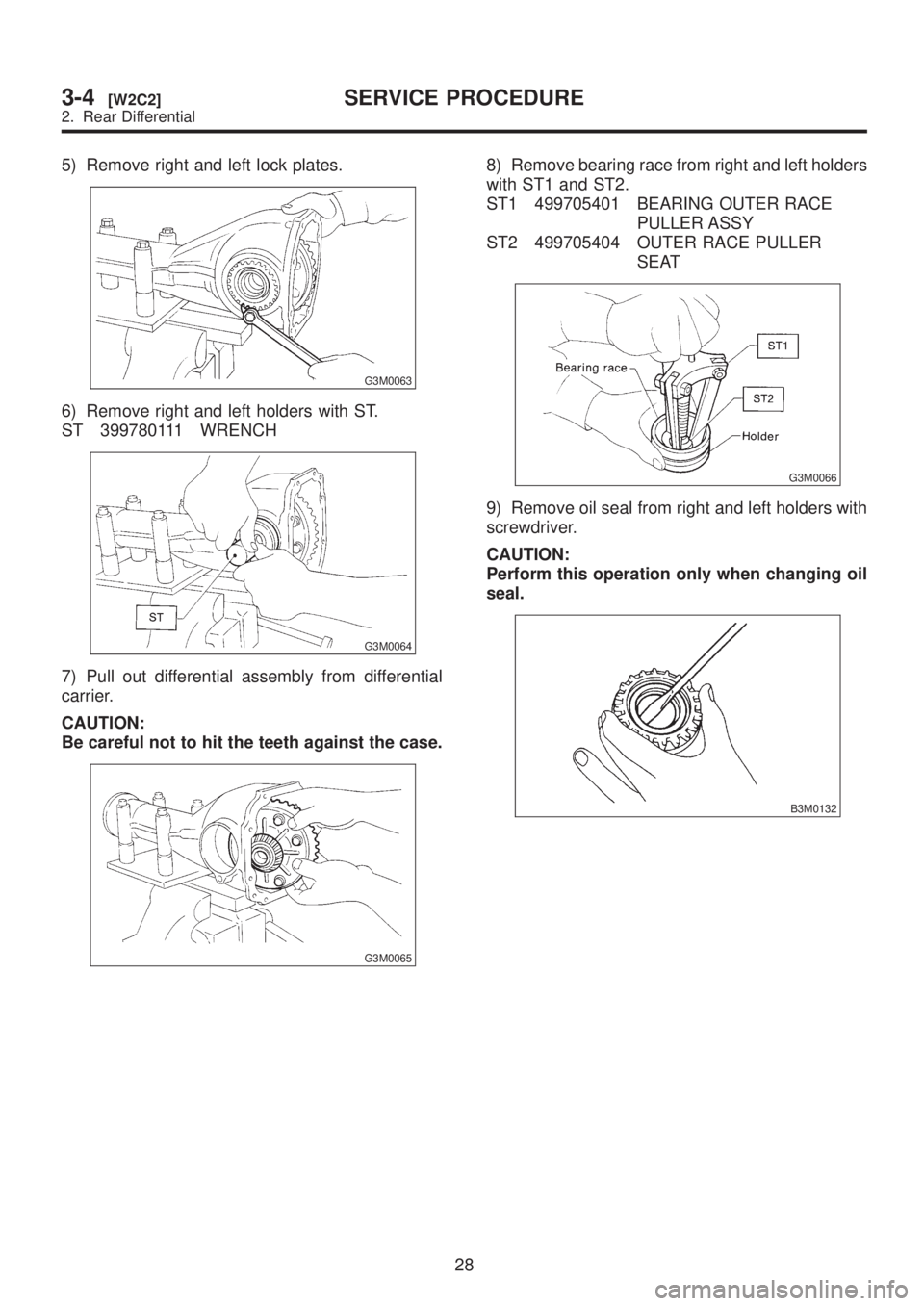

17) Remove pilot bearing together with front bear-

ing cone using ST.

ST 398467700 DRIFT

B3M0872A

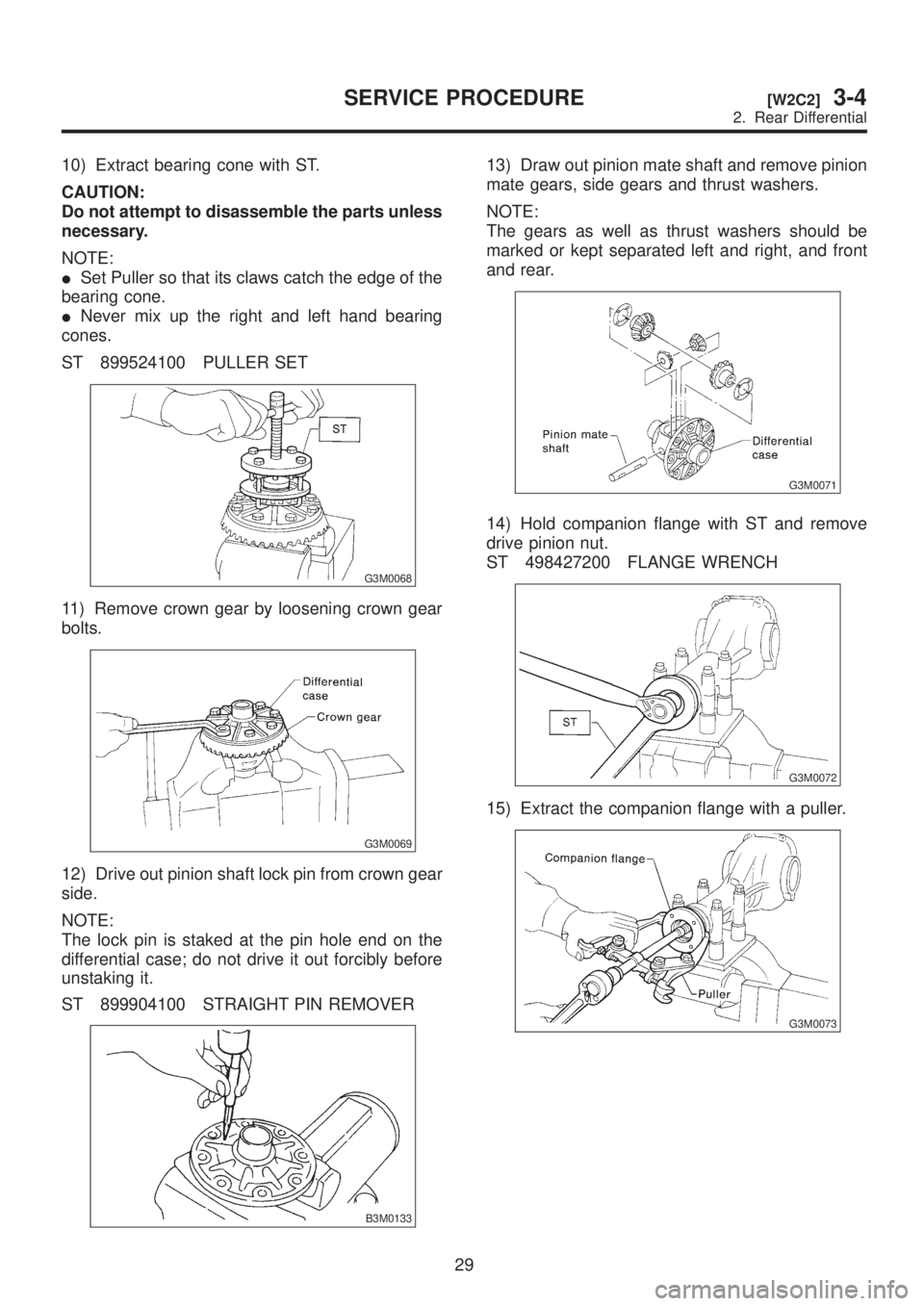

18) When replacing bearings, tap front bearing

cup and rear bearing cup in this order out of case

by using a brass bar.

G3M0078

2. VA-TYPE

To detect real cause of trouble, inspect the follow-

ing items before disassembling.

ITooth contact of crown gear and pinion, and

backlash

IRunout of crown gear at its back surface

ITurning resistance of drive pinion1) Set ST on vise and install the differential

assembly to ST.

ST 398217700 ATTACHMENT

G3M0060

2) Drain gear oil by removing plug.

3) Remove rear cover by loosening retaining

bolts.

G3M0061

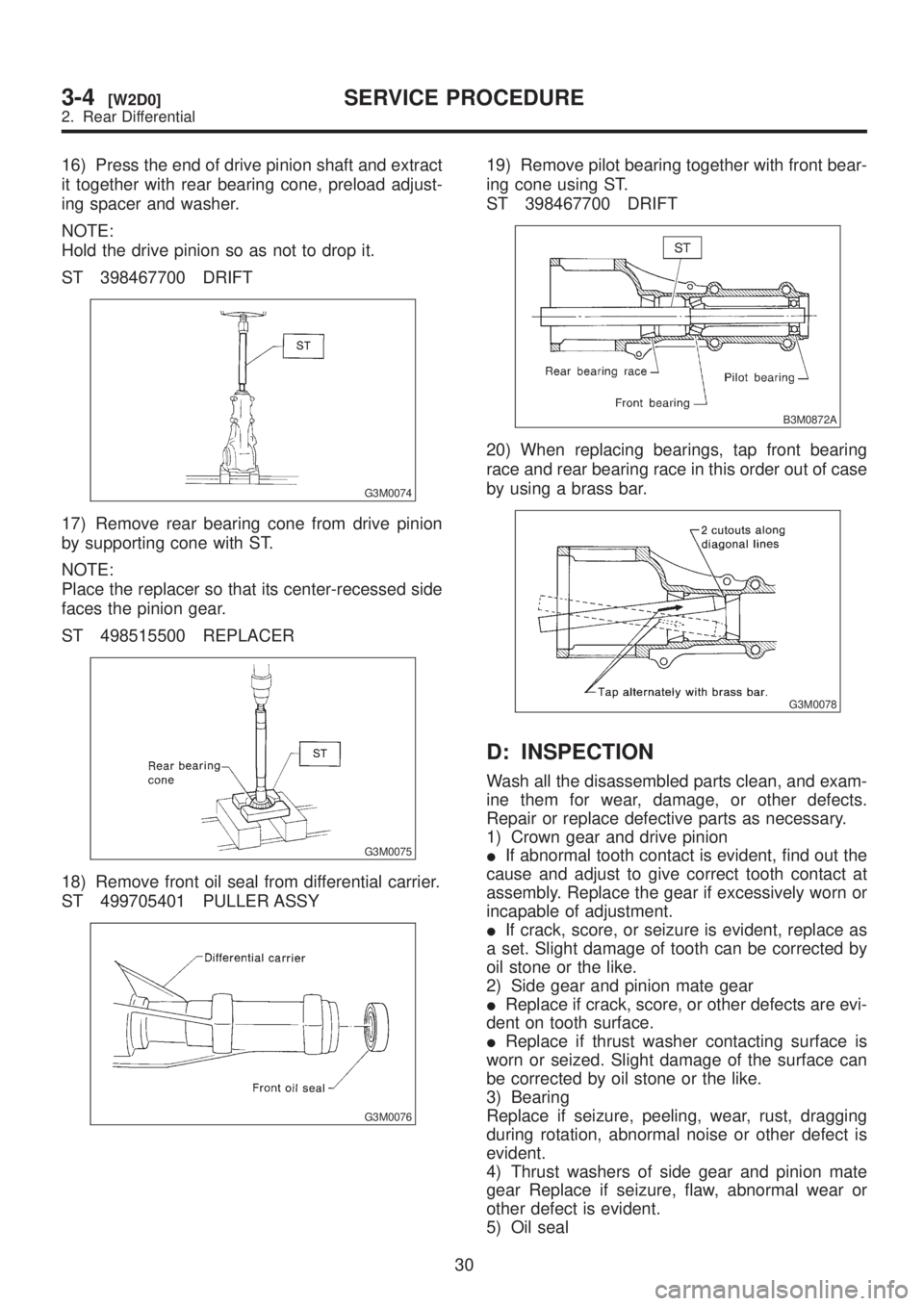

4) Replace air breather cap.

NOTE:

Do not attempt to replace the air breather cap

unless necessary.

G3M0062

27

[W2C2]3-4SERVICE PROCEDURE

2. Rear Differential

Page 678 of 1456

5) Remove right and left lock plates.

G3M0063

6) Remove right and left holders with ST.

ST 399780111 WRENCH

G3M0064

7) Pull out differential assembly from differential

carrier.

CAUTION:

Be careful not to hit the teeth against the case.

G3M0065

8) Remove bearing race from right and left holders

with ST1 and ST2.

ST1 499705401 BEARING OUTER RACE

PULLER ASSY

ST2 499705404 OUTER RACE PULLER

SEAT

G3M0066

9) Remove oil seal from right and left holders with

screwdriver.

CAUTION:

Perform this operation only when changing oil

seal.

B3M0132

28

3-4[W2C2]SERVICE PROCEDURE

2. Rear Differential

Page 679 of 1456

10) Extract bearing cone with ST.

CAUTION:

Do not attempt to disassemble the parts unless

necessary.

NOTE:

ISet Puller so that its claws catch the edge of the

bearing cone.

INever mix up the right and left hand bearing

cones.

ST 899524100 PULLER SET

G3M0068

11) Remove crown gear by loosening crown gear

bolts.

G3M0069

12) Drive out pinion shaft lock pin from crown gear

side.

NOTE:

The lock pin is staked at the pin hole end on the

differential case; do not drive it out forcibly before

unstaking it.

ST 899904100 STRAIGHT PIN REMOVER

B3M0133

13) Draw out pinion mate shaft and remove pinion

mate gears, side gears and thrust washers.

NOTE:

The gears as well as thrust washers should be

marked or kept separated left and right, and front

and rear.

G3M0071

14) Hold companion flange with ST and remove

drive pinion nut.

ST 498427200 FLANGE WRENCH

G3M0072

15) Extract the companion flange with a puller.

G3M0073

29

[W2C2]3-4SERVICE PROCEDURE

2. Rear Differential

Page 680 of 1456

16) Press the end of drive pinion shaft and extract

it together with rear bearing cone, preload adjust-

ing spacer and washer.

NOTE:

Hold the drive pinion so as not to drop it.

ST 398467700 DRIFT

G3M0074

17) Remove rear bearing cone from drive pinion

by supporting cone with ST.

NOTE:

Place the replacer so that its center-recessed side

faces the pinion gear.

ST 498515500 REPLACER

G3M0075

18) Remove front oil seal from differential carrier.

ST 499705401 PULLER ASSY

G3M0076

19) Remove pilot bearing together with front bear-

ing cone using ST.

ST 398467700 DRIFT

B3M0872A

20) When replacing bearings, tap front bearing

race and rear bearing race in this order out of case

by using a brass bar.

G3M0078

D: INSPECTION

Wash all the disassembled parts clean, and exam-

ine them for wear, damage, or other defects.

Repair or replace defective parts as necessary.

1) Crown gear and drive pinion

IIf abnormal tooth contact is evident, find out the

cause and adjust to give correct tooth contact at

assembly. Replace the gear if excessively worn or

incapable of adjustment.

IIf crack, score, or seizure is evident, replace as

a set. Slight damage of tooth can be corrected by

oil stone or the like.

2) Side gear and pinion mate gear

IReplace if crack, score, or other defects are evi-

dent on tooth surface.

IReplace if thrust washer contacting surface is

worn or seized. Slight damage of the surface can

be corrected by oil stone or the like.

3) Bearing

Replace if seizure, peeling, wear, rust, dragging

during rotation, abnormal noise or other defect is

evident.

4) Thrust washers of side gear and pinion mate

gear Replace if seizure, flaw, abnormal wear or

other defect is evident.

5) Oil seal

30

3-4[W2D0]SERVICE PROCEDURE

2. Rear Differential

Page 681 of 1456

Replace if deformed or damaged, and at every

disassembling.

6) Differential carrier

Replace if the bearing bores are worn or damaged.

7) Differential case

Replace if its sliding surfaces are worn or cracked.

8) Companion flange

Replace if the oil seal lip contacting surfaces have

flaws.

E: ASSEMBLY

1. T-TYPE

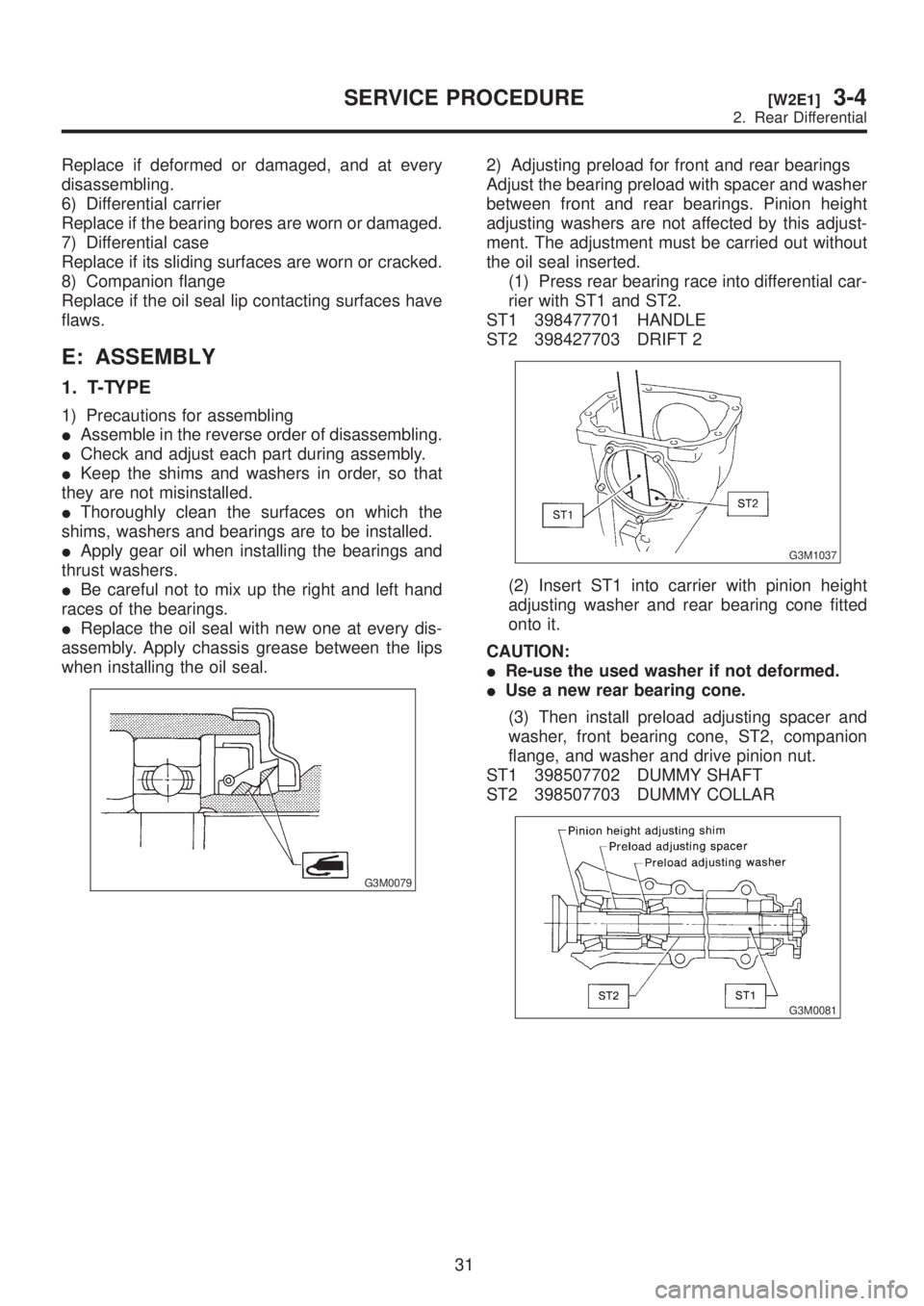

1) Precautions for assembling

IAssemble in the reverse order of disassembling.

ICheck and adjust each part during assembly.

IKeep the shims and washers in order, so that

they are not misinstalled.

IThoroughly clean the surfaces on which the

shims, washers and bearings are to be installed.

IApply gear oil when installing the bearings and

thrust washers.

IBe careful not to mix up the right and left hand

races of the bearings.

IReplace the oil seal with new one at every dis-

assembly. Apply chassis grease between the lips

when installing the oil seal.

G3M0079

2) Adjusting preload for front and rear bearings

Adjust the bearing preload with spacer and washer

between front and rear bearings. Pinion height

adjusting washers are not affected by this adjust-

ment. The adjustment must be carried out without

the oil seal inserted.

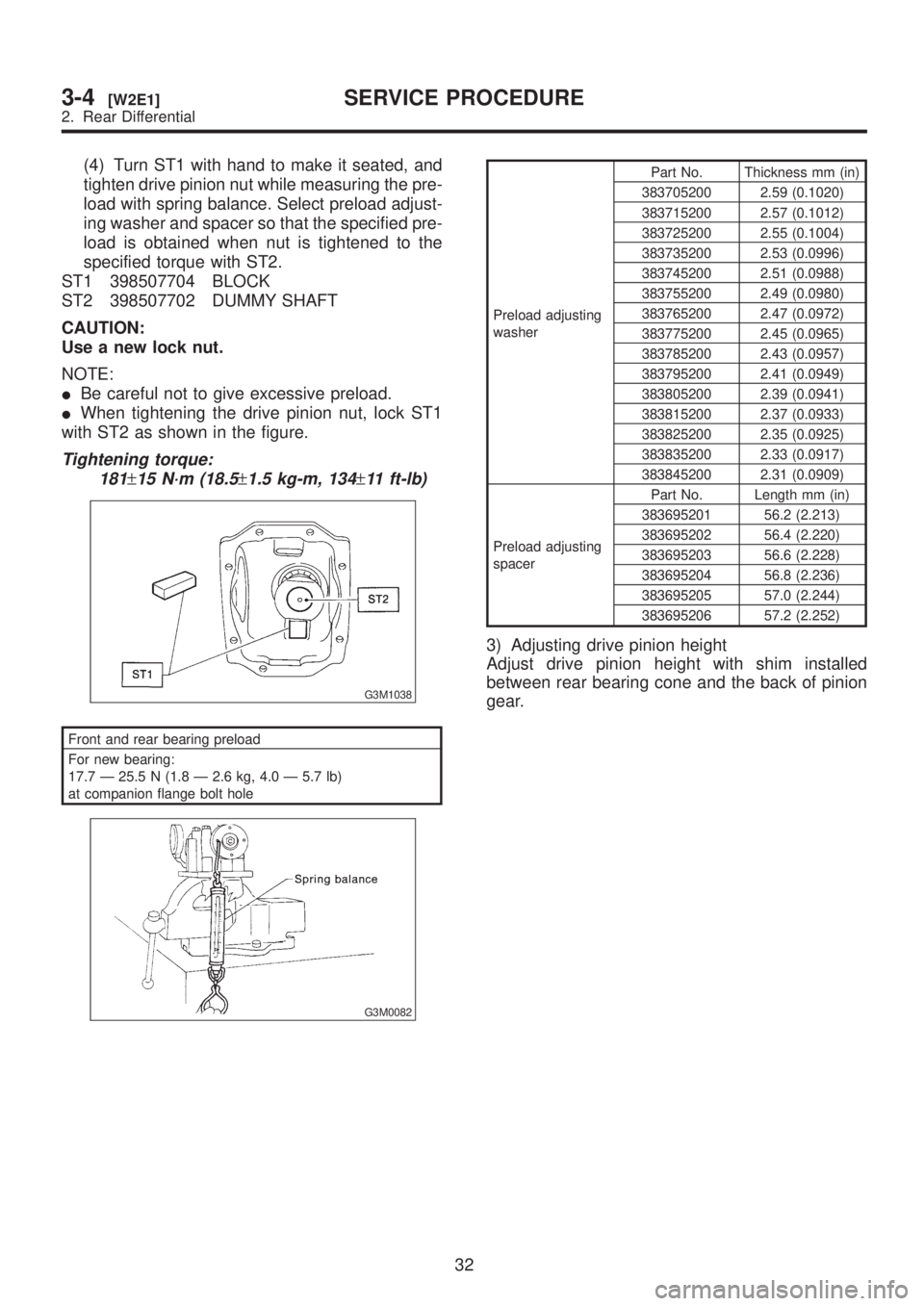

(1) Press rear bearing race into differential car-

rier with ST1 and ST2.

ST1 398477701 HANDLE

ST2 398427703 DRIFT 2

G3M1037

(2) Insert ST1 into carrier with pinion height

adjusting washer and rear bearing cone fitted

onto it.

CAUTION:

IRe-use the used washer if not deformed.

IUse a new rear bearing cone.

(3) Then install preload adjusting spacer and

washer, front bearing cone, ST2, companion

flange, and washer and drive pinion nut.

ST1 398507702 DUMMY SHAFT

ST2 398507703 DUMMY COLLAR

G3M0081

31

[W2E1]3-4SERVICE PROCEDURE

2. Rear Differential

Page 682 of 1456

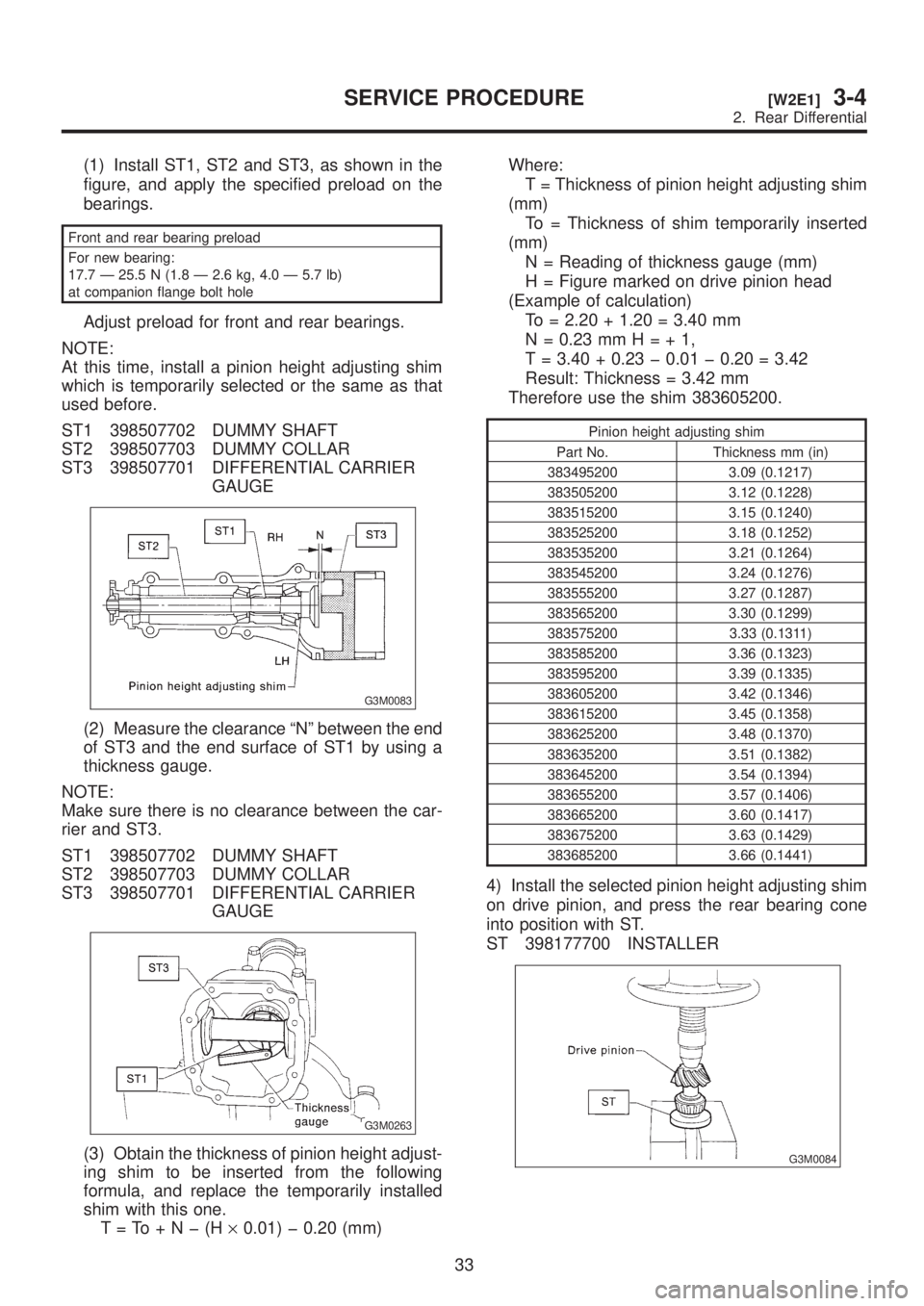

(4) Turn ST1 with hand to make it seated, and

tighten drive pinion nut while measuring the pre-

load with spring balance. Select preload adjust-

ing washer and spacer so that the specified pre-

load is obtained when nut is tightened to the

specified torque with ST2.

ST1 398507704 BLOCK

ST2 398507702 DUMMY SHAFT

CAUTION:

Use a new lock nut.

NOTE:

IBe careful not to give excessive preload.

IWhen tightening the drive pinion nut, lock ST1

with ST2 as shown in the figure.

Tightening torque:

181

±15 N´m (18.5±1.5 kg-m, 134±11 ft-lb)

G3M1038

Front and rear bearing preload

For new bearing:

17.7 Ð 25.5 N (1.8 Ð 2.6 kg, 4.0 Ð 5.7 lb)

at companion flange bolt hole

G3M0082

Preload adjusting

washerPart No. Thickness mm (in)

383705200 2.59 (0.1020)

383715200 2.57 (0.1012)

383725200 2.55 (0.1004)

383735200 2.53 (0.0996)

383745200 2.51 (0.0988)

383755200 2.49 (0.0980)

383765200 2.47 (0.0972)

383775200 2.45 (0.0965)

383785200 2.43 (0.0957)

383795200 2.41 (0.0949)

383805200 2.39 (0.0941)

383815200 2.37 (0.0933)

383825200 2.35 (0.0925)

383835200 2.33 (0.0917)

383845200 2.31 (0.0909)

Preload adjusting

spacerPart No. Length mm (in)

383695201 56.2 (2.213)

383695202 56.4 (2.220)

383695203 56.6 (2.228)

383695204 56.8 (2.236)

383695205 57.0 (2.244)

383695206 57.2 (2.252)

3) Adjusting drive pinion height

Adjust drive pinion height with shim installed

between rear bearing cone and the back of pinion

gear.

32

3-4[W2E1]SERVICE PROCEDURE

2. Rear Differential

Page 683 of 1456

(1) Install ST1, ST2 and ST3, as shown in the

figure, and apply the specified preload on the

bearings.

Front and rear bearing preload

For new bearing:

17.7 Ð 25.5 N (1.8 Ð 2.6 kg, 4.0 Ð 5.7 lb)

at companion flange bolt hole

Adjust preload for front and rear bearings.

NOTE:

At this time, install a pinion height adjusting shim

which is temporarily selected or the same as that

used before.

ST1 398507702 DUMMY SHAFT

ST2 398507703 DUMMY COLLAR

ST3 398507701 DIFFERENTIAL CARRIER

GAUGE

G3M0083

(2) Measure the clearance ªNº between the end

of ST3 and the end surface of ST1 by using a

thickness gauge.

NOTE:

Make sure there is no clearance between the car-

rier and ST3.

ST1 398507702 DUMMY SHAFT

ST2 398507703 DUMMY COLLAR

ST3 398507701 DIFFERENTIAL CARRIER

GAUGE

G3M0263

(3) Obtain the thickness of pinion height adjust-

ing shim to be inserted from the following

formula, and replace the temporarily installed

shim with this one.

T=To+Nþ(H´0.01) þ 0.20 (mm)Where:

T = Thickness of pinion height adjusting shim

(mm)

To = Thickness of shim temporarily inserted

(mm)

N = Reading of thickness gauge (mm)

H = Figure marked on drive pinion head

(Example of calculation)

To = 2.20 + 1.20 = 3.40 mm

N = 0.23 mmH=+1,

T = 3.40 + 0.23 þ 0.01 þ 0.20 = 3.42

Result: Thickness = 3.42 mm

Therefore use the shim 383605200.

Pinion height adjusting shim

Part No. Thickness mm (in)

383495200 3.09 (0.1217)

383505200 3.12 (0.1228)

383515200 3.15 (0.1240)

383525200 3.18 (0.1252)

383535200 3.21 (0.1264)

383545200 3.24 (0.1276)

383555200 3.27 (0.1287)

383565200 3.30 (0.1299)

383575200 3.33 (0.1311)

383585200 3.36 (0.1323)

383595200 3.39 (0.1335)

383605200 3.42 (0.1346)

383615200 3.45 (0.1358)

383625200 3.48 (0.1370)

383635200 3.51 (0.1382)

383645200 3.54 (0.1394)

383655200 3.57 (0.1406)

383665200 3.60 (0.1417)

383675200 3.63 (0.1429)

383685200 3.66 (0.1441)

4) Install the selected pinion height adjusting shim

on drive pinion, and press the rear bearing cone

into position with ST.

ST 398177700 INSTALLER

G3M0084

33

[W2E1]3-4SERVICE PROCEDURE

2. Rear Differential

Page 684 of 1456

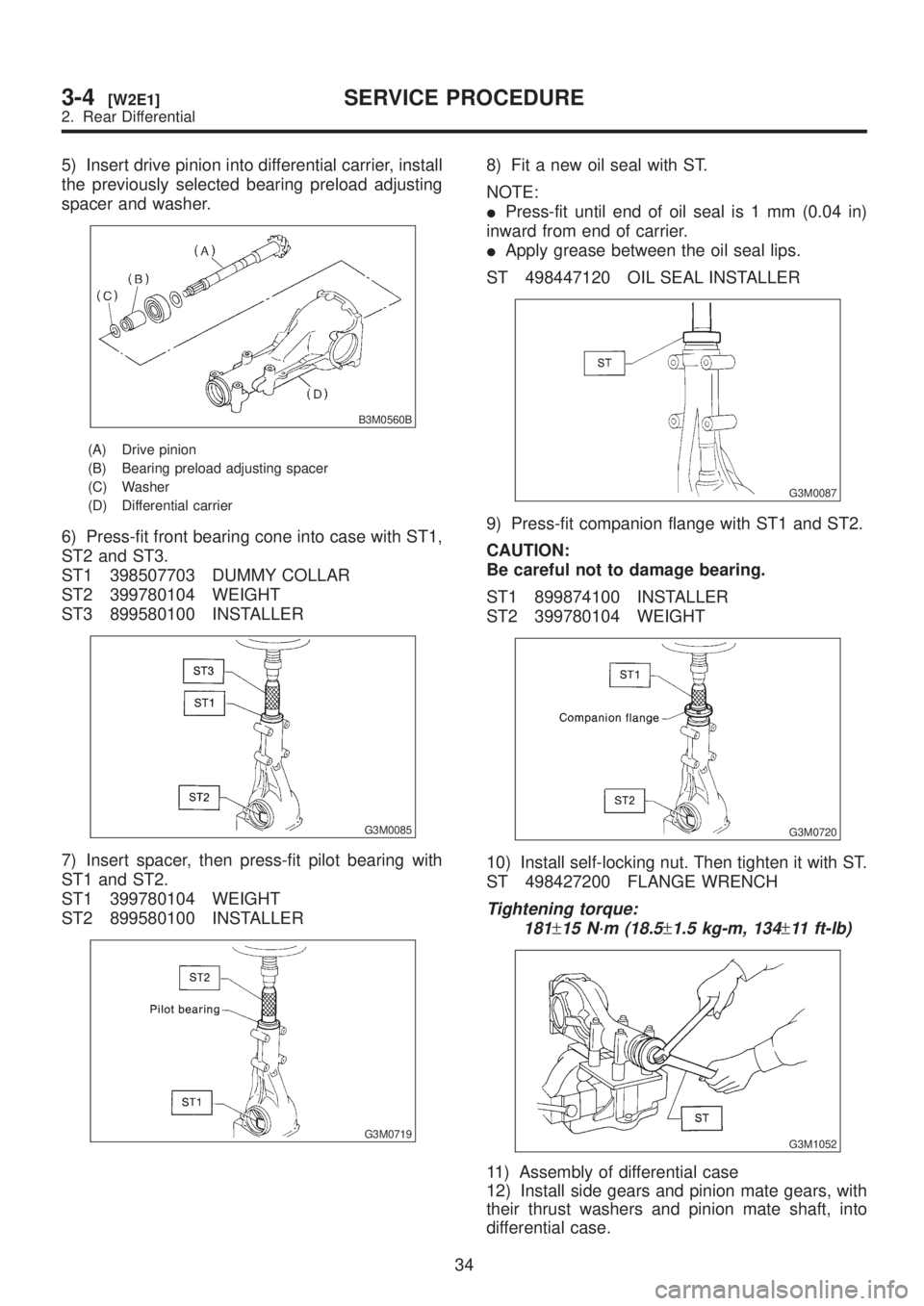

5) Insert drive pinion into differential carrier, install

the previously selected bearing preload adjusting

spacer and washer.

B3M0560B

(A) Drive pinion

(B) Bearing preload adjusting spacer

(C) Washer

(D) Differential carrier

6) Press-fit front bearing cone into case with ST1,

ST2 and ST3.

ST1 398507703 DUMMY COLLAR

ST2 399780104 WEIGHT

ST3 899580100 INSTALLER

G3M0085

7) Insert spacer, then press-fit pilot bearing with

ST1 and ST2.

ST1 399780104 WEIGHT

ST2 899580100 INSTALLER

G3M0719

8) Fit a new oil seal with ST.

NOTE:

IPress-fit until end of oil seal is 1 mm (0.04 in)

inward from end of carrier.

IApply grease between the oil seal lips.

ST 498447120 OIL SEAL INSTALLER

G3M0087

9) Press-fit companion flange with ST1 and ST2.

CAUTION:

Be careful not to damage bearing.

ST1 899874100 INSTALLER

ST2 399780104 WEIGHT

G3M0720

10) Install self-locking nut. Then tighten it with ST.

ST 498427200 FLANGE WRENCH

Tightening torque:

181

±15 N´m (18.5±1.5 kg-m, 134±11 ft-lb)

G3M1052

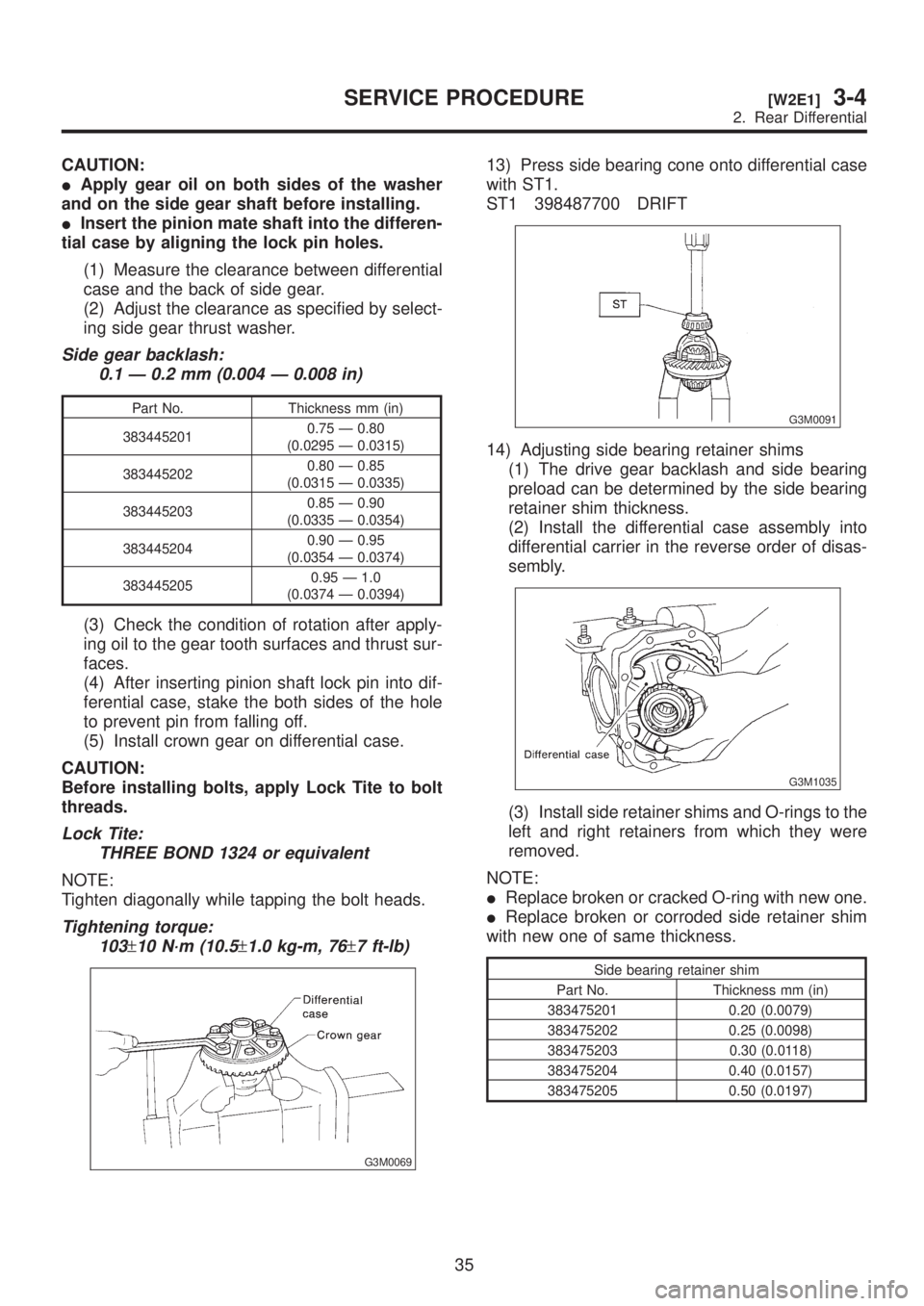

11) Assembly of differential case

12) Install side gears and pinion mate gears, with

their thrust washers and pinion mate shaft, into

differential case.

34

3-4[W2E1]SERVICE PROCEDURE

2. Rear Differential

Page 685 of 1456

CAUTION:

IApply gear oil on both sides of the washer

and on the side gear shaft before installing.

IInsert the pinion mate shaft into the differen-

tial case by aligning the lock pin holes.

(1) Measure the clearance between differential

case and the back of side gear.

(2) Adjust the clearance as specified by select-

ing side gear thrust washer.

Side gear backlash:

0.1 Ð 0.2 mm (0.004 Ð 0.008 in)

Part No. Thickness mm (in)

3834452010.75 Ð 0.80

(0.0295 Ð 0.0315)

3834452020.80 Ð 0.85

(0.0315 Ð 0.0335)

3834452030.85 Ð 0.90

(0.0335 Ð 0.0354)

3834452040.90 Ð 0.95

(0.0354 Ð 0.0374)

3834452050.95 Ð 1.0

(0.0374 Ð 0.0394)

(3) Check the condition of rotation after apply-

ing oil to the gear tooth surfaces and thrust sur-

faces.

(4) After inserting pinion shaft lock pin into dif-

ferential case, stake the both sides of the hole

to prevent pin from falling off.

(5) Install crown gear on differential case.

CAUTION:

Before installing bolts, apply Lock Tite to bolt

threads.

Lock Tite:

THREE BOND 1324 or equivalent

NOTE:

Tighten diagonally while tapping the bolt heads.

Tightening torque:

103

±10 N´m (10.5±1.0 kg-m, 76±7 ft-lb)

G3M0069

13) Press side bearing cone onto differential case

with ST1.

ST1 398487700 DRIFT

G3M0091

14) Adjusting side bearing retainer shims

(1) The drive gear backlash and side bearing

preload can be determined by the side bearing

retainer shim thickness.

(2) Install the differential case assembly into

differential carrier in the reverse order of disas-

sembly.

G3M1035

(3) Install side retainer shims and O-rings to the

left and right retainers from which they were

removed.

NOTE:

IReplace broken or cracked O-ring with new one.

IReplace broken or corroded side retainer shim

with new one of same thickness.

Side bearing retainer shim

Part No. Thickness mm (in)

383475201 0.20 (0.0079)

383475202 0.25 (0.0098)

383475203 0.30 (0.0118)

383475204 0.40 (0.0157)

383475205 0.50 (0.0197)

35

[W2E1]3-4SERVICE PROCEDURE

2. Rear Differential

Page 686 of 1456

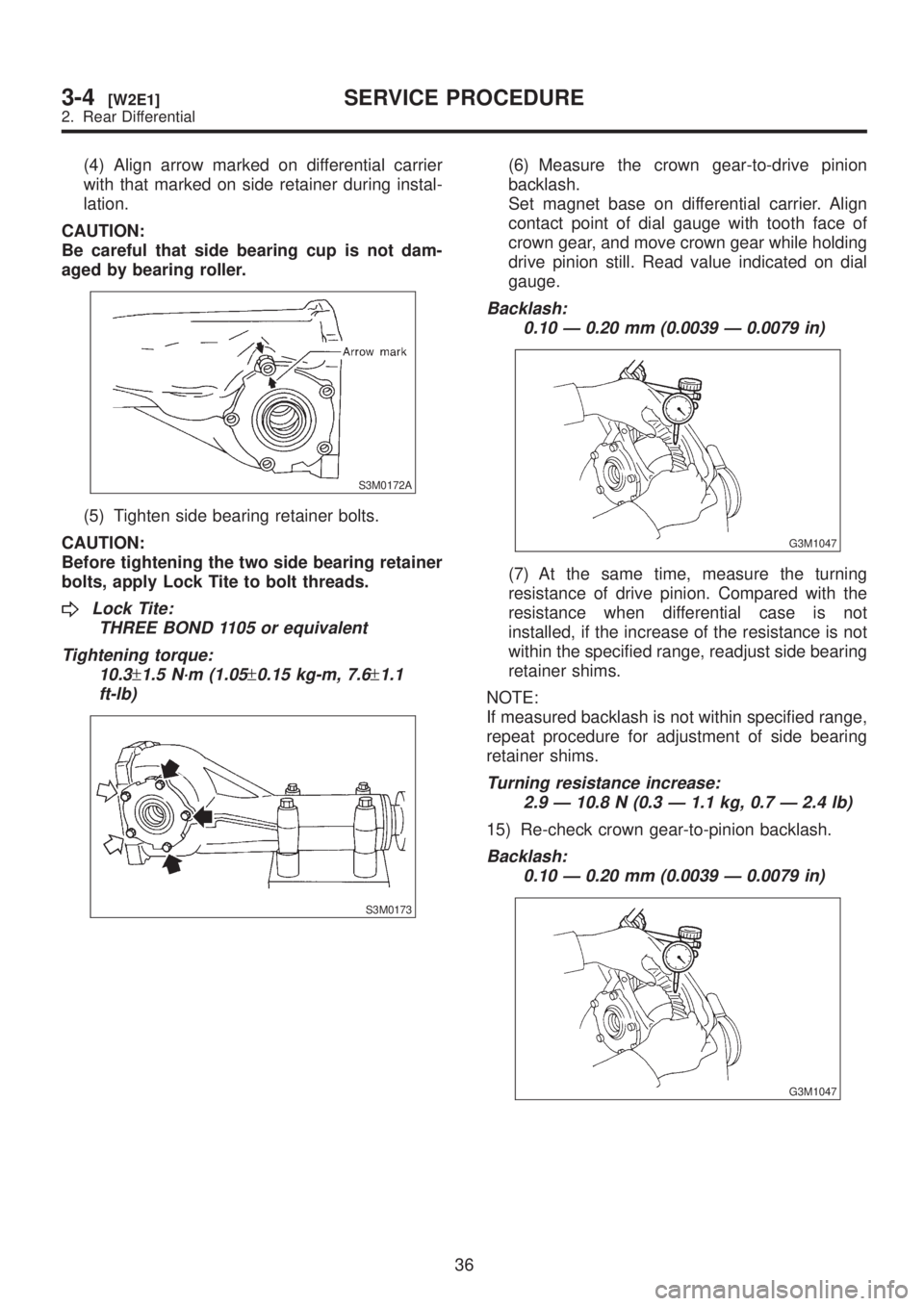

(4) Align arrow marked on differential carrier

with that marked on side retainer during instal-

lation.

CAUTION:

Be careful that side bearing cup is not dam-

aged by bearing roller.

S3M0172A

(5) Tighten side bearing retainer bolts.

CAUTION:

Before tightening the two side bearing retainer

bolts, apply Lock Tite to bolt threads.

Lock Tite:

THREE BOND 1105 or equivalent

Tightening torque:

10.3

±1.5 N´m (1.05±0.15 kg-m, 7.6±1.1

ft-lb)

S3M0173

(6) Measure the crown gear-to-drive pinion

backlash.

Set magnet base on differential carrier. Align

contact point of dial gauge with tooth face of

crown gear, and move crown gear while holding

drive pinion still. Read value indicated on dial

gauge.

Backlash:

0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

G3M1047

(7) At the same time, measure the turning

resistance of drive pinion. Compared with the

resistance when differential case is not

installed, if the increase of the resistance is not

within the specified range, readjust side bearing

retainer shims.

NOTE:

If measured backlash is not within specified range,

repeat procedure for adjustment of side bearing

retainer shims.

Turning resistance increase:

2.9 Ð 10.8 N (0.3 Ð 1.1 kg, 0.7 Ð 2.4 lb)

15) Re-check crown gear-to-pinion backlash.

Backlash:

0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

G3M1047

36

3-4[W2E1]SERVICE PROCEDURE

2. Rear Differential