torque specifications SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 711 of 1456

2. CAMBER (FRONT AND REAR)

IInspection

1) Place front wheel on turning radius gauge.

Make sure ground contacting surfaces of front and

rear wheels are set at the same height.

2) Set ST into the center of the wheel, and then

install the wheel alignment gauge.

ST 927380000 ADAPTER

B4M0567A

NOTE:

Refer to the ªSPECIFICATIONS AND SERVICE

DATAº for the camber values.

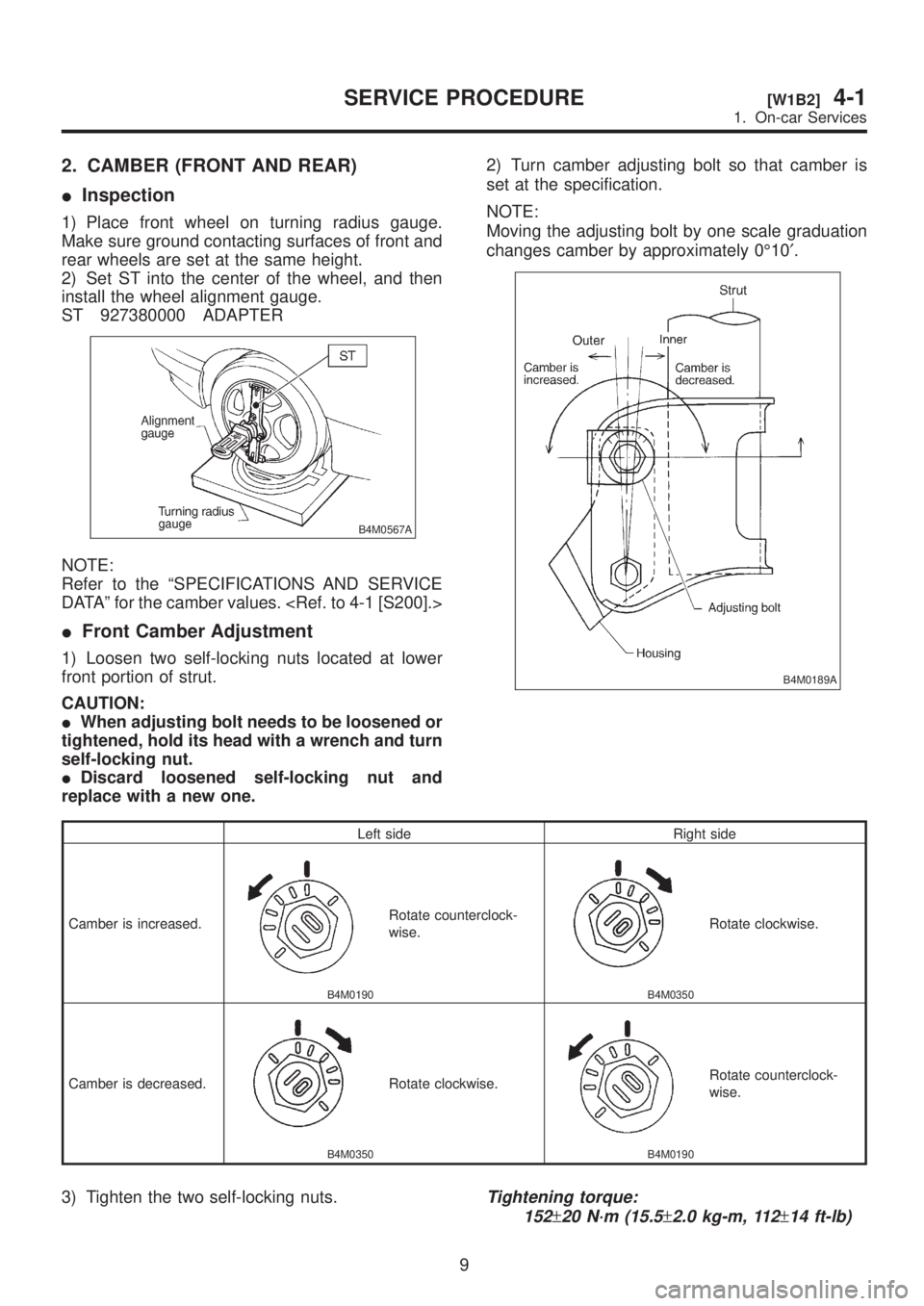

IFront Camber Adjustment

1) Loosen two self-locking nuts located at lower

front portion of strut.

CAUTION:

IWhen adjusting bolt needs to be loosened or

tightened, hold its head with a wrench and turn

self-locking nut.

IDiscard loosened self-locking nut and

replace with a new one.2) Turn camber adjusting bolt so that camber is

set at the specification.

NOTE:

Moving the adjusting bolt by one scale graduation

changes camber by approximately 0É10¢.

B4M0189A

Left side Right side

Camber is increased.

B4M0190

Rotate counterclock-

wise.

B4M0350

Rotate clockwise.

Camber is decreased.

B4M0350

Rotate clockwise.

B4M0190

Rotate counterclock-

wise.

3) Tighten the two self-locking nuts.Tightening torque:

152

±20 N´m (15.5±2.0 kg-m, 112±14 ft-lb)

9

[W1B2]4-1SERVICE PROCEDURE

1. On-car Services

Page 712 of 1456

3. CASTER (FRONT)

IInspection

1) Place front wheel on turning radius gauge.

Make sure ground contacting surfaces of front and

rear wheels are set at the same height.

2) Set ST into the center of the wheel, and then

install the wheel alignment gauge.

ST 927380000 ADAPTER

B4M0567A

NOTE:

Refer to the ªSPECIFICATIONS AND SERVICE

DATAº for the caster value.

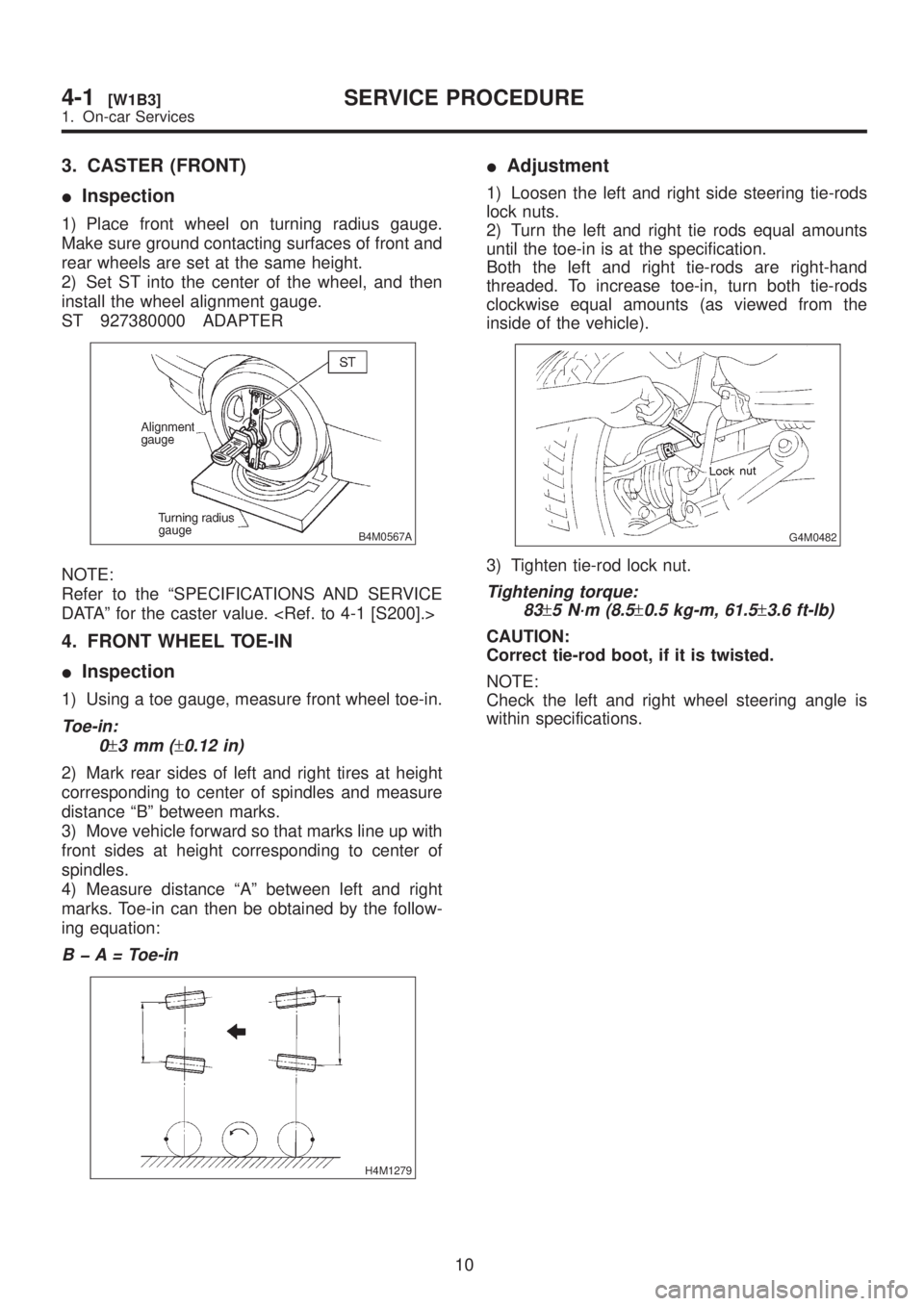

4. FRONT WHEEL TOE-IN

IInspection

1) Using a toe gauge, measure front wheel toe-in.

Toe-in:

0

±3mm(±0.12 in)

2) Mark rear sides of left and right tires at height

corresponding to center of spindles and measure

distance ªBº between marks.

3) Move vehicle forward so that marks line up with

front sides at height corresponding to center of

spindles.

4) Measure distance ªAº between left and right

marks. Toe-in can then be obtained by the follow-

ing equation:

B þ A = Toe-in

H4M1279

IAdjustment

1) Loosen the left and right side steering tie-rods

lock nuts.

2) Turn the left and right tie rods equal amounts

until the toe-in is at the specification.

Both the left and right tie-rods are right-hand

threaded. To increase toe-in, turn both tie-rods

clockwise equal amounts (as viewed from the

inside of the vehicle).

G4M0482

3) Tighten tie-rod lock nut.

Tightening torque:

83

±5 N´m (8.5±0.5 kg-m, 61.5±3.6 ft-lb)

CAUTION:

Correct tie-rod boot, if it is twisted.

NOTE:

Check the left and right wheel steering angle is

within specifications.

10

4-1[W1B3]SERVICE PROCEDURE

1. On-car Services

Page 931 of 1456

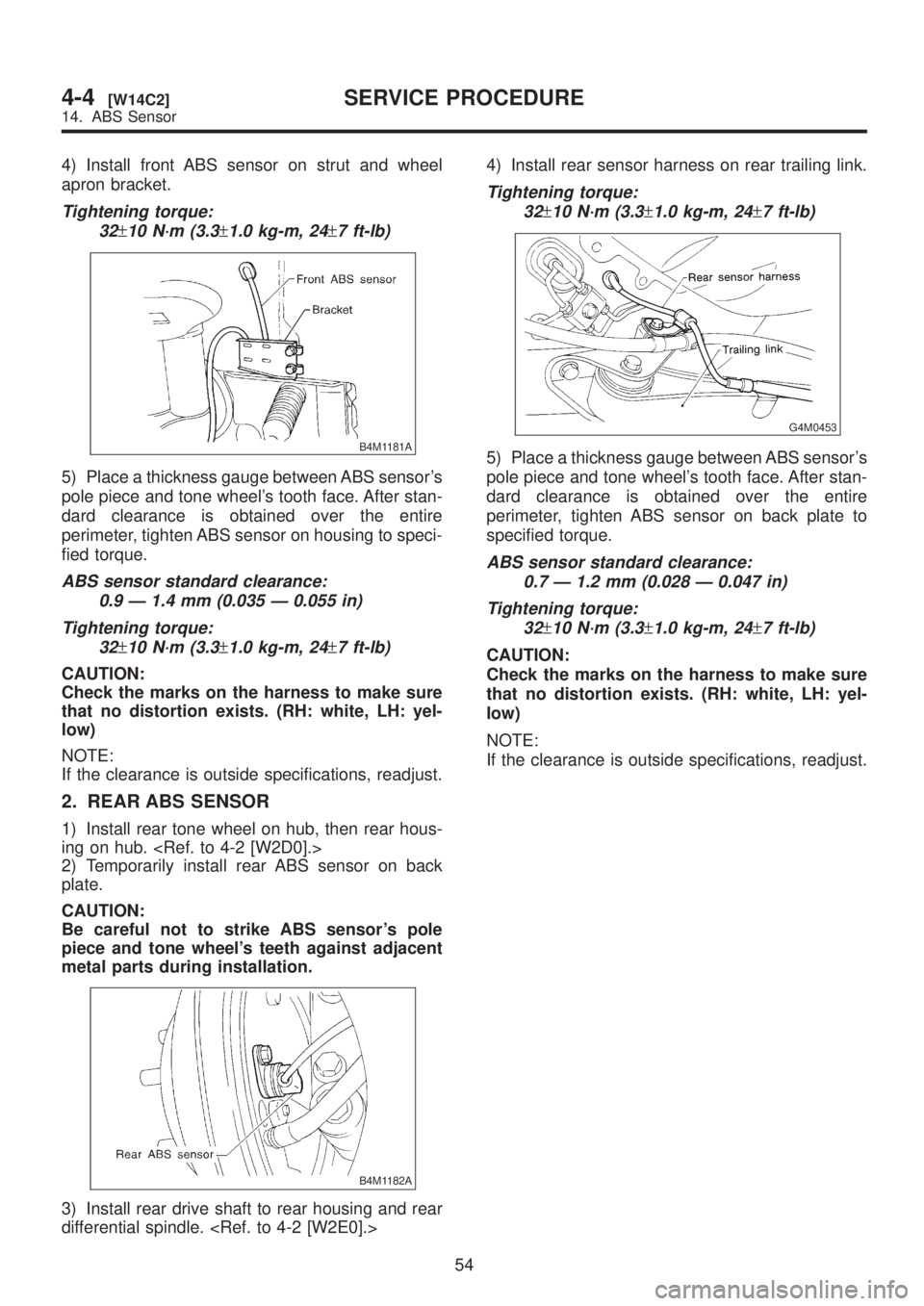

4) Install front ABS sensor on strut and wheel

apron bracket.

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

B4M1181A

5) Place a thickness gauge between ABS sensor's

pole piece and tone wheel's tooth face. After stan-

dard clearance is obtained over the entire

perimeter, tighten ABS sensor on housing to speci-

fied torque.

ABS sensor standard clearance:

0.9 Ð 1.4 mm (0.035 Ð 0.055 in)

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

CAUTION:

Check the marks on the harness to make sure

that no distortion exists. (RH: white, LH: yel-

low)

NOTE:

If the clearance is outside specifications, readjust.

2. REAR ABS SENSOR

1) Install rear tone wheel on hub, then rear hous-

ing on hub.

2) Temporarily install rear ABS sensor on back

plate.

CAUTION:

Be careful not to strike ABS sensor's pole

piece and tone wheel's teeth against adjacent

metal parts during installation.

B4M1182A

3) Install rear drive shaft to rear housing and rear

differential spindle.

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

G4M0453

5) Place a thickness gauge between ABS sensor's

pole piece and tone wheel's tooth face. After stan-

dard clearance is obtained over the entire

perimeter, tighten ABS sensor on back plate to

specified torque.

ABS sensor standard clearance:

0.7 Ð 1.2 mm (0.028 Ð 0.047 in)

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

CAUTION:

Check the marks on the harness to make sure

that no distortion exists. (RH: white, LH: yel-

low)

NOTE:

If the clearance is outside specifications, readjust.

54

4-4[W14C2]SERVICE PROCEDURE

14. ABS Sensor

Page 937 of 1456

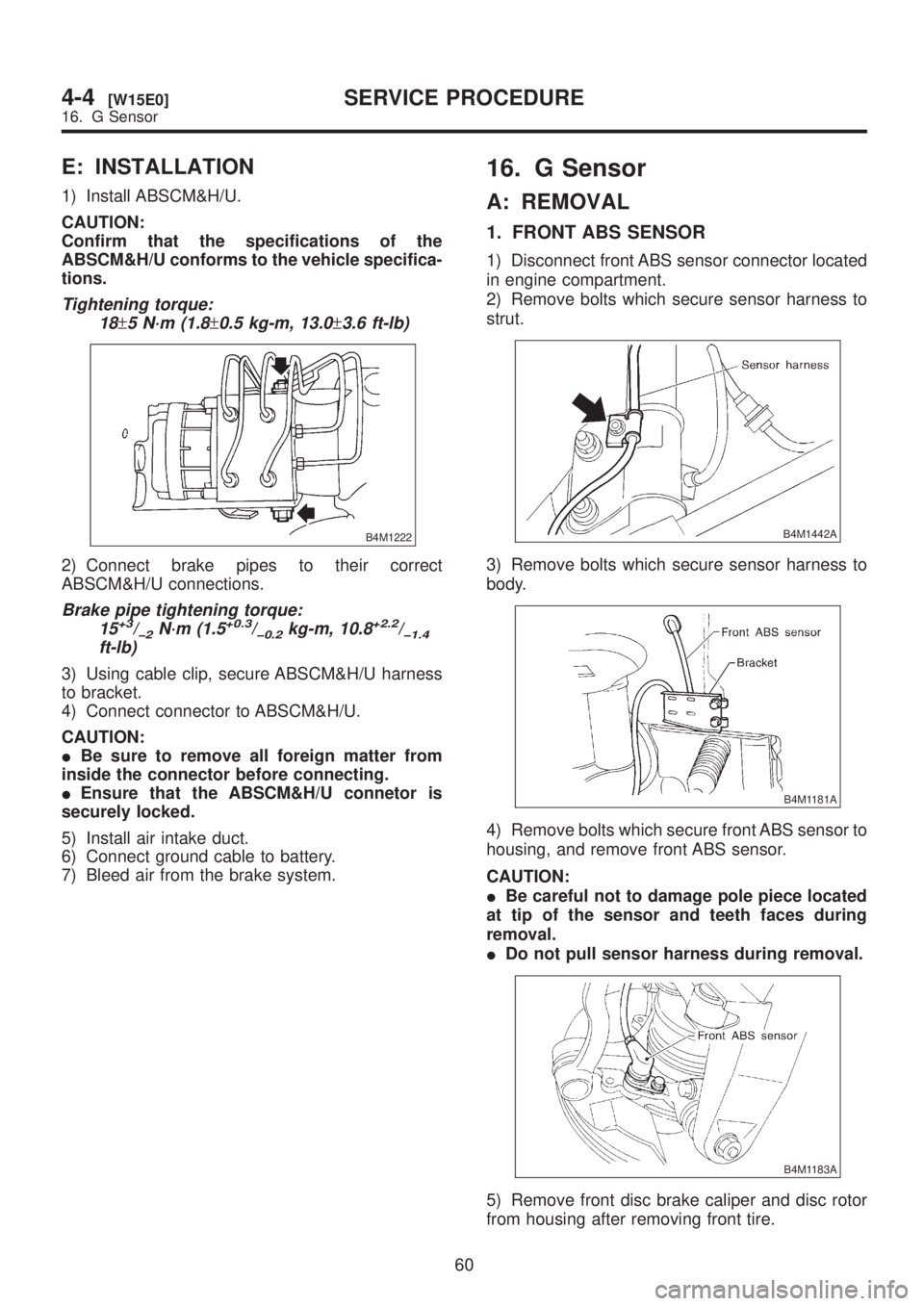

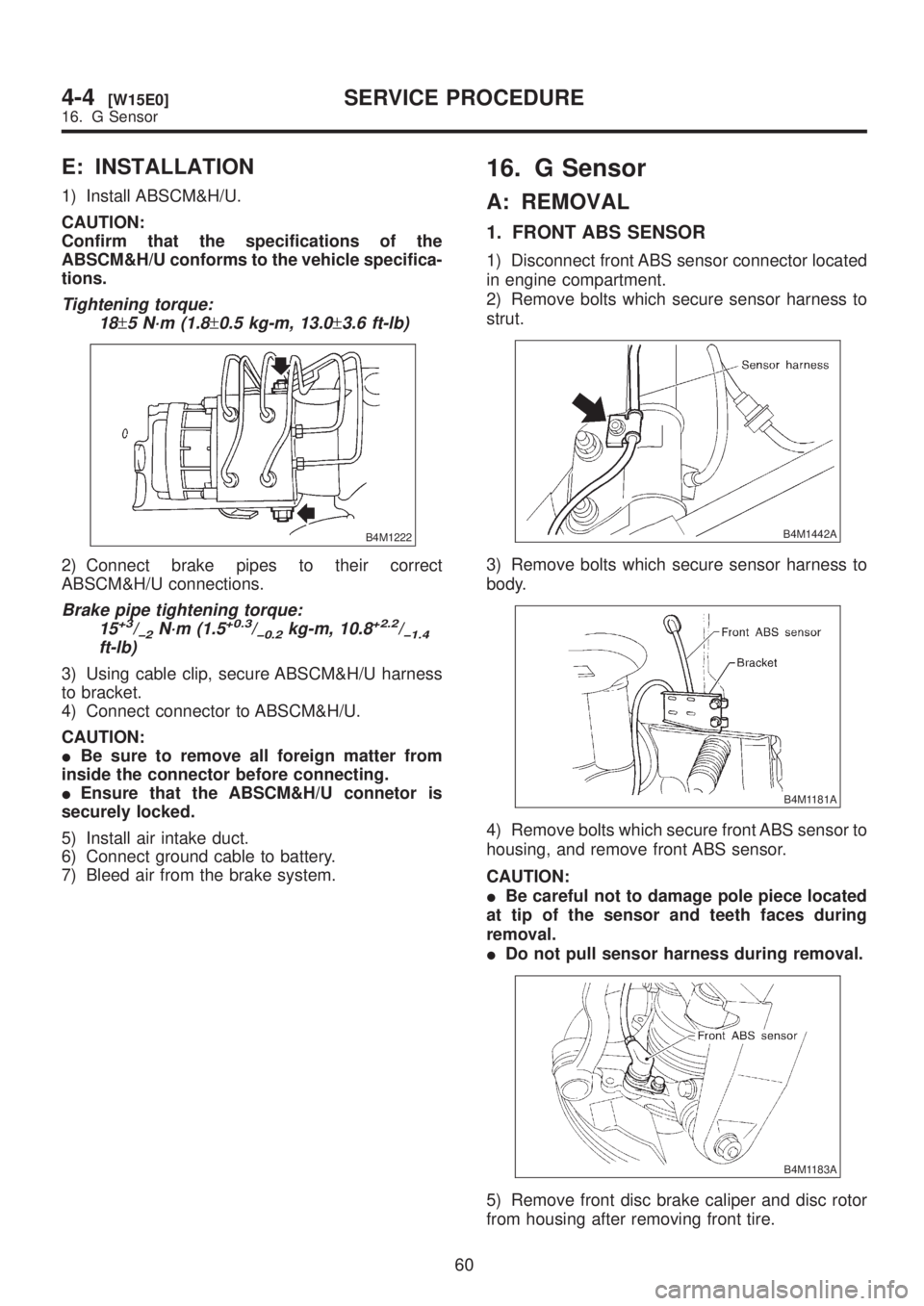

E: INSTALLATION

1) Install ABSCM&H/U.

CAUTION:

Confirm that the specifications of the

ABSCM&H/U conforms to the vehicle specifica-

tions.

Tightening torque:

18

±5 N´m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

B4M1222

2) Connect brake pipes to their correct

ABSCM&H/U connections.

Brake pipe tightening torque:

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

3) Using cable clip, secure ABSCM&H/U harness

to bracket.

4) Connect connector to ABSCM&H/U.

CAUTION:

IBe sure to remove all foreign matter from

inside the connector before connecting.

IEnsure that the ABSCM&H/U connetor is

securely locked.

5) Install air intake duct.

6) Connect ground cable to battery.

7) Bleed air from the brake system.

16. G Sensor

A: REMOVAL

1. FRONT ABS SENSOR

1) Disconnect front ABS sensor connector located

in engine compartment.

2) Remove bolts which secure sensor harness to

strut.

B4M1442A

3) Remove bolts which secure sensor harness to

body.

B4M1181A

4) Remove bolts which secure front ABS sensor to

housing, and remove front ABS sensor.

CAUTION:

IBe careful not to damage pole piece located

at tip of the sensor and teeth faces during

removal.

IDo not pull sensor harness during removal.

B4M1183A

5) Remove front disc brake caliper and disc rotor

from housing after removing front tire.

60

4-4[W15E0]SERVICE PROCEDURE

16. G Sensor

Page 938 of 1456

E: INSTALLATION

1) Install ABSCM&H/U.

CAUTION:

Confirm that the specifications of the

ABSCM&H/U conforms to the vehicle specifica-

tions.

Tightening torque:

18

±5 N´m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

B4M1222

2) Connect brake pipes to their correct

ABSCM&H/U connections.

Brake pipe tightening torque:

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

3) Using cable clip, secure ABSCM&H/U harness

to bracket.

4) Connect connector to ABSCM&H/U.

CAUTION:

IBe sure to remove all foreign matter from

inside the connector before connecting.

IEnsure that the ABSCM&H/U connetor is

securely locked.

5) Install air intake duct.

6) Connect ground cable to battery.

7) Bleed air from the brake system.

16. G Sensor

A: REMOVAL

1. FRONT ABS SENSOR

1) Disconnect front ABS sensor connector located

in engine compartment.

2) Remove bolts which secure sensor harness to

strut.

B4M1442A

3) Remove bolts which secure sensor harness to

body.

B4M1181A

4) Remove bolts which secure front ABS sensor to

housing, and remove front ABS sensor.

CAUTION:

IBe careful not to damage pole piece located

at tip of the sensor and teeth faces during

removal.

IDo not pull sensor harness during removal.

B4M1183A

5) Remove front disc brake caliper and disc rotor

from housing after removing front tire.

60

4-4[W15E0]SERVICE PROCEDURE

16. G Sensor

Page 941 of 1456

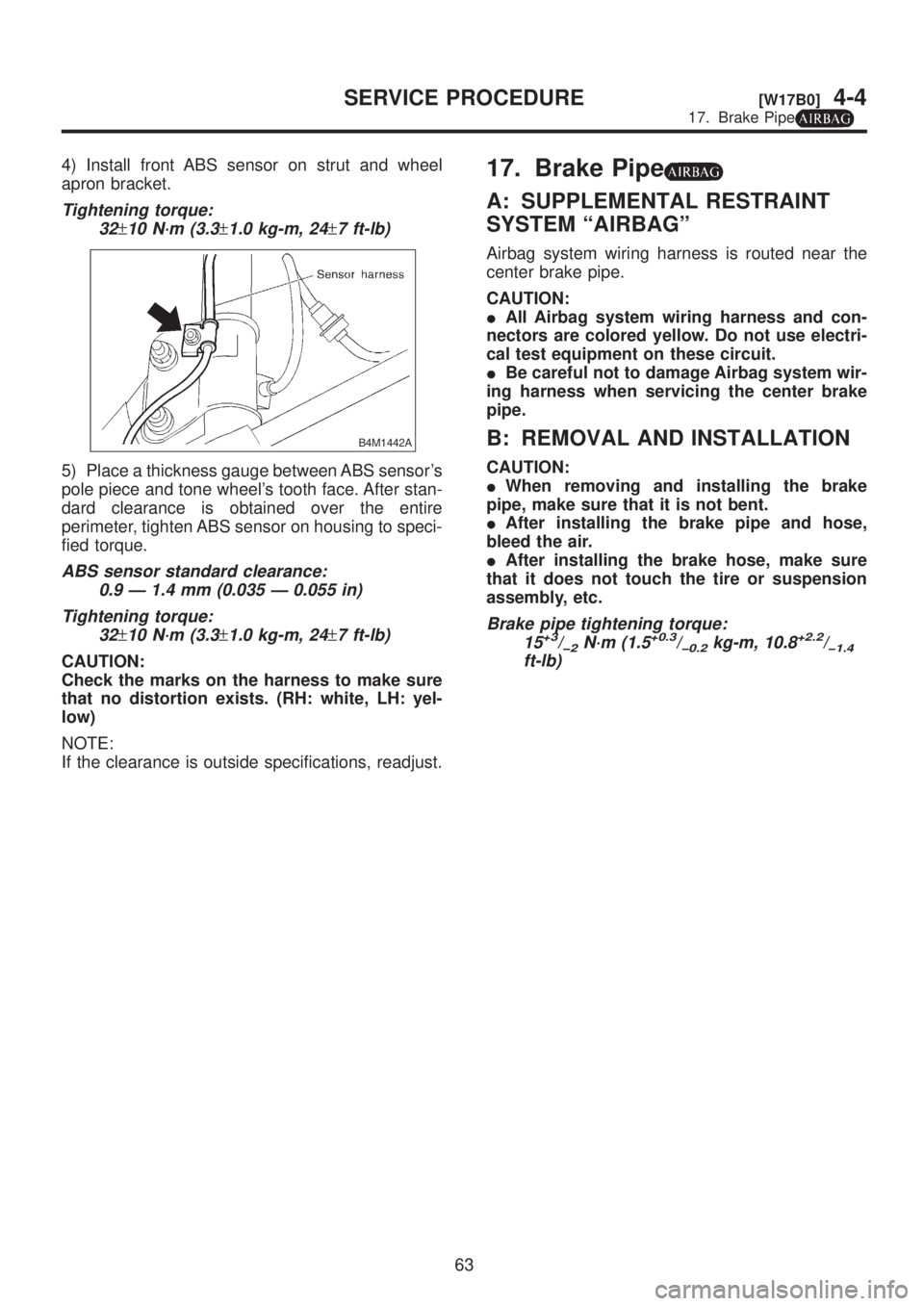

4) Install front ABS sensor on strut and wheel

apron bracket.

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

B4M1442A

5) Place a thickness gauge between ABS sensor's

pole piece and tone wheel's tooth face. After stan-

dard clearance is obtained over the entire

perimeter, tighten ABS sensor on housing to speci-

fied torque.

ABS sensor standard clearance:

0.9 Ð 1.4 mm (0.035 Ð 0.055 in)

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

CAUTION:

Check the marks on the harness to make sure

that no distortion exists. (RH: white, LH: yel-

low)

NOTE:

If the clearance is outside specifications, readjust.

17. Brake Pipe

A: SUPPLEMENTAL RESTRAINT

SYSTEM ªAIRBAGº

Airbag system wiring harness is routed near the

center brake pipe.

CAUTION:

IAll Airbag system wiring harness and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuit.

IBe careful not to damage Airbag system wir-

ing harness when servicing the center brake

pipe.

B: REMOVAL AND INSTALLATION

CAUTION:

IWhen removing and installing the brake

pipe, make sure that it is not bent.

IAfter installing the brake pipe and hose,

bleed the air.

IAfter installing the brake hose, make sure

that it does not touch the tire or suspension

assembly, etc.

Brake pipe tightening torque:

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

63

[W17B0]4-4SERVICE PROCEDURE

17. Brake Pipe

Page 942 of 1456

4) Install front ABS sensor on strut and wheel

apron bracket.

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

B4M1442A

5) Place a thickness gauge between ABS sensor's

pole piece and tone wheel's tooth face. After stan-

dard clearance is obtained over the entire

perimeter, tighten ABS sensor on housing to speci-

fied torque.

ABS sensor standard clearance:

0.9 Ð 1.4 mm (0.035 Ð 0.055 in)

Tightening torque:

32

±10 N´m (3.3±1.0 kg-m, 24±7 ft-lb)

CAUTION:

Check the marks on the harness to make sure

that no distortion exists. (RH: white, LH: yel-

low)

NOTE:

If the clearance is outside specifications, readjust.

17. Brake Pipe

A: SUPPLEMENTAL RESTRAINT

SYSTEM ªAIRBAGº

Airbag system wiring harness is routed near the

center brake pipe.

CAUTION:

IAll Airbag system wiring harness and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuit.

IBe careful not to damage Airbag system wir-

ing harness when servicing the center brake

pipe.

B: REMOVAL AND INSTALLATION

CAUTION:

IWhen removing and installing the brake

pipe, make sure that it is not bent.

IAfter installing the brake pipe and hose,

bleed the air.

IAfter installing the brake hose, make sure

that it does not touch the tire or suspension

assembly, etc.

Brake pipe tightening torque:

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

63

[W17B0]4-4SERVICE PROCEDURE

17. Brake Pipe

Page 956 of 1456

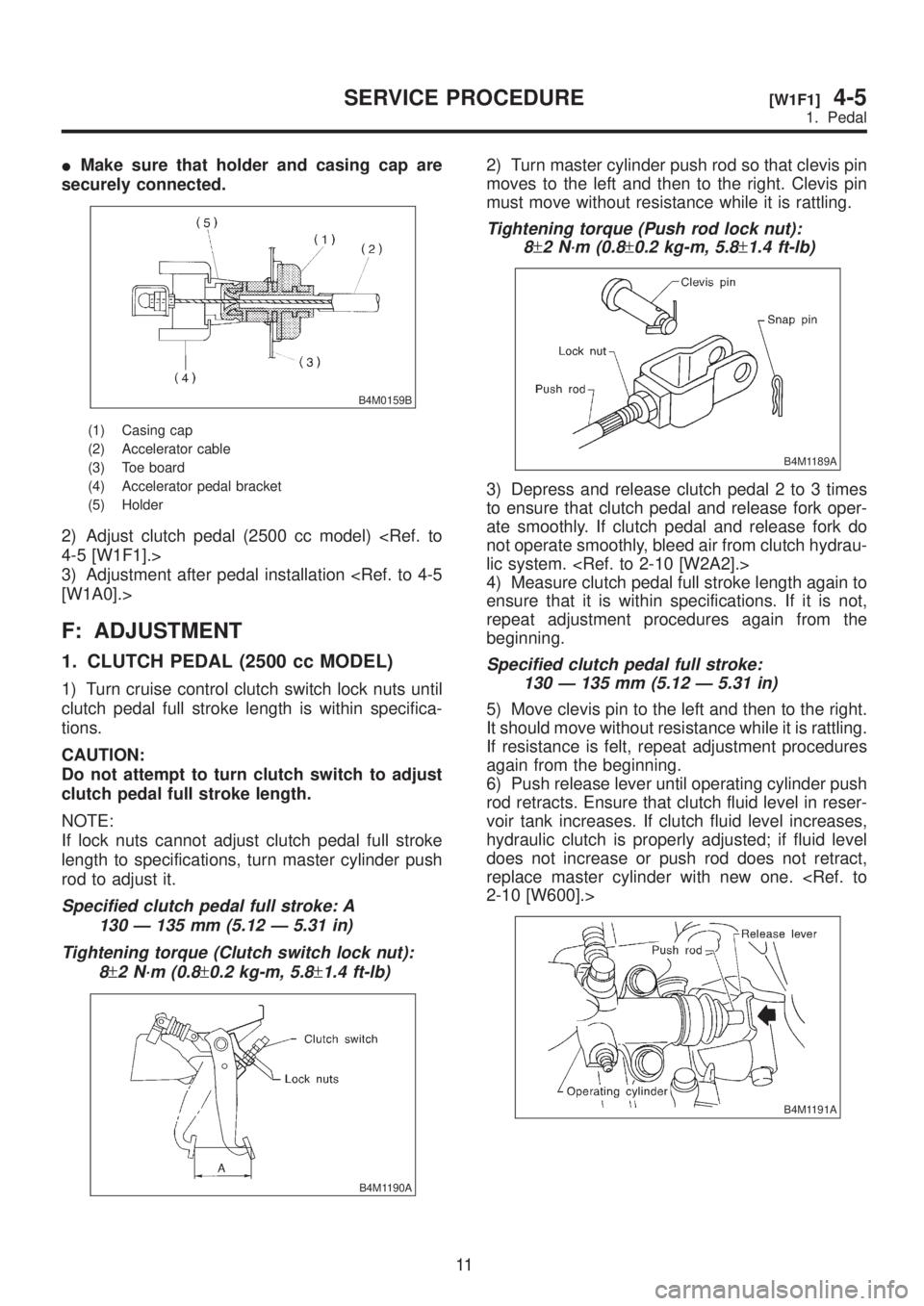

IMake sure that holder and casing cap are

securely connected.

B4M0159B

(1) Casing cap

(2) Accelerator cable

(3) Toe board

(4) Accelerator pedal bracket

(5) Holder

2) Adjust clutch pedal (2500 cc model)

3) Adjustment after pedal installation

F: ADJUSTMENT

1. CLUTCH PEDAL (2500 cc MODEL)

1) Turn cruise control clutch switch lock nuts until

clutch pedal full stroke length is within specifica-

tions.

CAUTION:

Do not attempt to turn clutch switch to adjust

clutch pedal full stroke length.

NOTE:

If lock nuts cannot adjust clutch pedal full stroke

length to specifications, turn master cylinder push

rod to adjust it.

Specified clutch pedal full stroke: A

130 Ð 135 mm (5.12 Ð 5.31 in)

Tightening torque (Clutch switch lock nut):

8

±2 N´m (0.8±0.2 kg-m, 5.8±1.4 ft-lb)

B4M1190A

2) Turn master cylinder push rod so that clevis pin

moves to the left and then to the right. Clevis pin

must move without resistance while it is rattling.

Tightening torque (Push rod lock nut):

8

±2 N´m (0.8±0.2 kg-m, 5.8±1.4 ft-lb)

B4M1189A

3) Depress and release clutch pedal 2 to 3 times

to ensure that clutch pedal and release fork oper-

ate smoothly. If clutch pedal and release fork do

not operate smoothly, bleed air from clutch hydrau-

lic system.

4) Measure clutch pedal full stroke length again to

ensure that it is within specifications. If it is not,

repeat adjustment procedures again from the

beginning.

Specified clutch pedal full stroke:

130 Ð 135 mm (5.12 Ð 5.31 in)

5) Move clevis pin to the left and then to the right.

It should move without resistance while it is rattling.

If resistance is felt, repeat adjustment procedures

again from the beginning.

6) Push release lever until operating cylinder push

rod retracts. Ensure that clutch fluid level in reser-

voir tank increases. If clutch fluid level increases,

hydraulic clutch is properly adjusted; if fluid level

does not increase or push rod does not retract,

replace master cylinder with new one.

B4M1191A

11

[W1F1]4-5SERVICE PROCEDURE

1. Pedal

Page 1183 of 1456

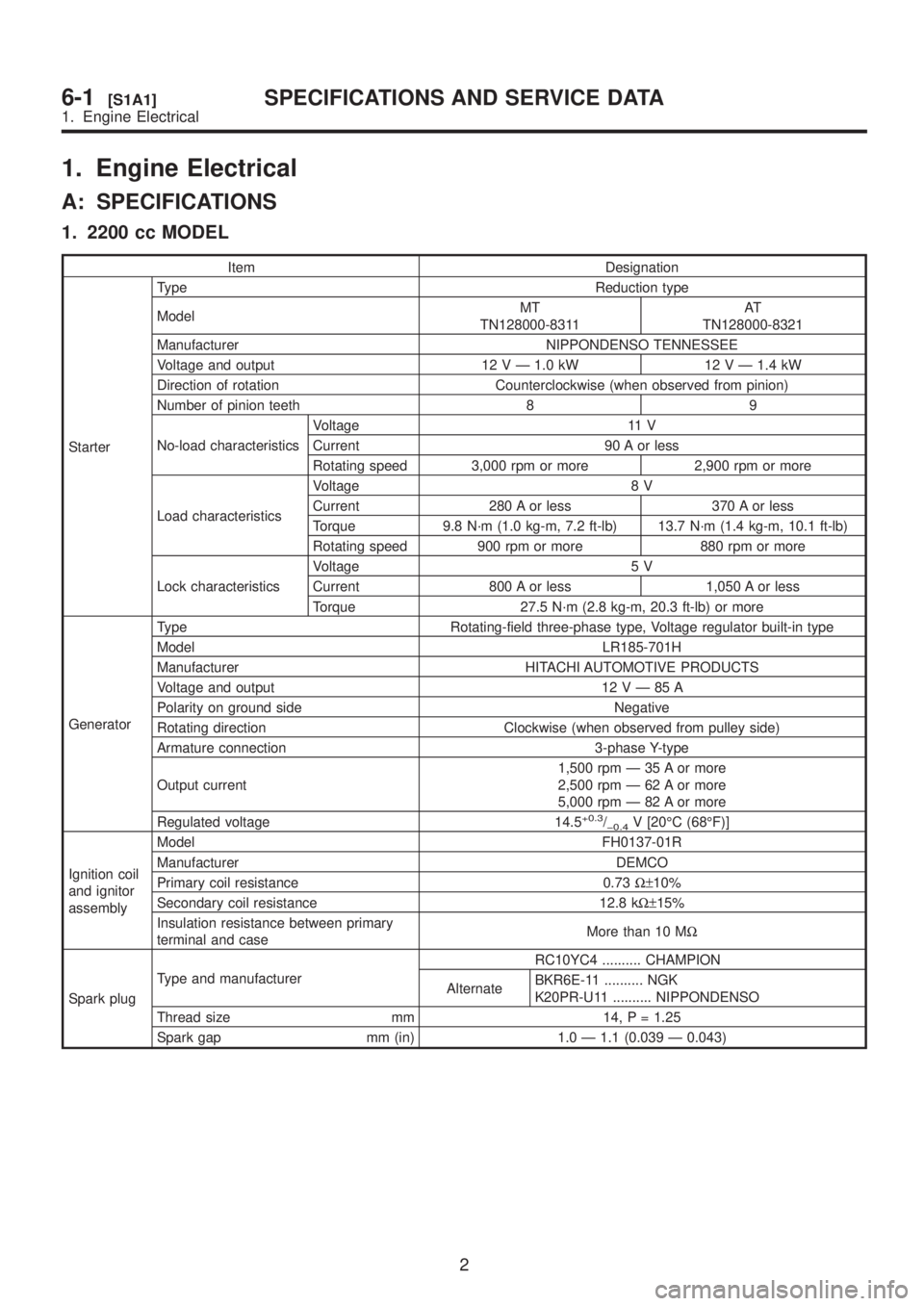

1. Engine Electrical

A: SPECIFICATIONS

1. 2200 cc MODEL

Item Designation

StarterType Reduction type

ModelMT

TN128000-8311AT

TN128000-8321

Manufacturer NIPPONDENSO TENNESSEE

Voltage and output 12 V Ð 1.0 kW 12 V Ð 1.4 kW

Direction of rotation Counterclockwise (when observed from pinion)

Number of pinion teeth 8 9

No-load characteristicsVoltage 11 V

Current 90 A or less

Rotating speed 3,000 rpm or more 2,900 rpm or more

Load characteristicsVoltage 8 V

Current 280 A or less 370 A or less

Torque 9.8 N´m (1.0 kg-m, 7.2 ft-lb) 13.7 N´m (1.4 kg-m, 10.1 ft-lb)

Rotating speed 900 rpm or more 880 rpm or more

Lock characteristicsVoltage 5 V

Current 800 A or less 1,050 A or less

Torque 27.5 N´m (2.8 kg-m, 20.3 ft-lb) or more

GeneratorType Rotating-field three-phase type, Voltage regulator built-in type

Model LR185-701H

Manufacturer HITACHI AUTOMOTIVE PRODUCTS

Voltage and output 12VÐ85A

Polarity on ground side Negative

Rotating direction Clockwise (when observed from pulley side)

Armature connection 3-phase Y-type

Output current1,500 rpm Ð 35 A or more

2,500 rpm Ð 62 A or more

5,000 rpm Ð 82 A or more

Regulated voltage 14.5

+0.3/þ0.4V [20ÉC (68ÉF)]

Ignition coil

and ignitor

assemblyModel FH0137-01R

Manufacturer DEMCO

Primary coil resistance 0.73W±10%

Secondary coil resistance 12.8 kW±15%

Insulation resistance between primary

terminal and caseMore than 10 MW

Spark plugType and manufacturerRC10YC4 .......... CHAMPION

AlternateBKR6E-11 .......... NGK

K20PR-U11 .......... NIPPONDENSO

Thread size mm 14, P = 1.25

Spark gap mm (in) 1.0 Ð 1.1 (0.039 Ð 0.043)

2

6-1[S1A1]SPECIFICATIONS AND SERVICE DATA

1. Engine Electrical

Page 1184 of 1456

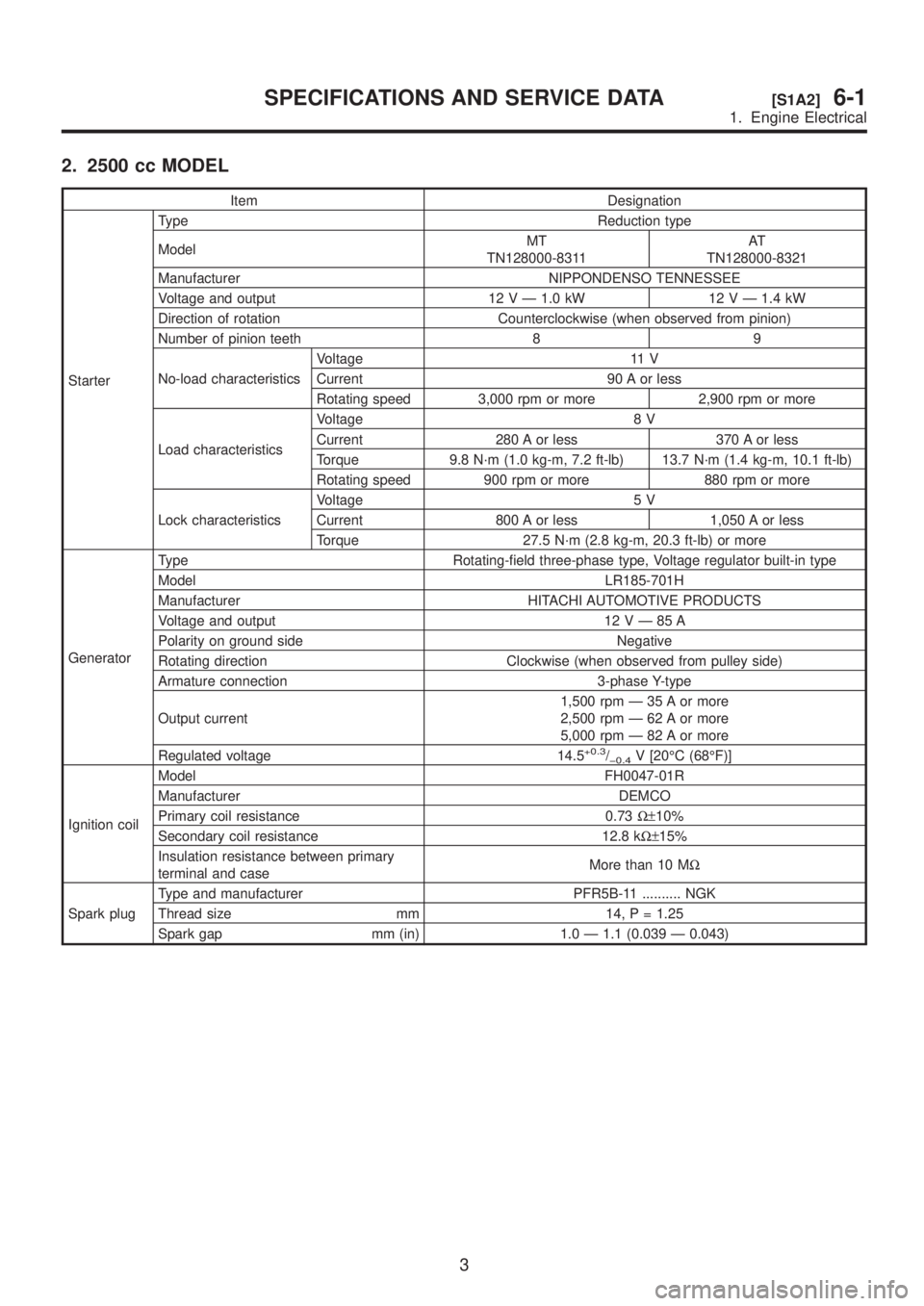

2. 2500 cc MODEL

Item Designation

StarterType Reduction type

ModelMT

TN128000-8311AT

TN128000-8321

Manufacturer NIPPONDENSO TENNESSEE

Voltage and output 12 V Ð 1.0 kW 12 V Ð 1.4 kW

Direction of rotation Counterclockwise (when observed from pinion)

Number of pinion teeth 8 9

No-load characteristicsVoltage 11 V

Current 90 A or less

Rotating speed 3,000 rpm or more 2,900 rpm or more

Load characteristicsVoltage 8 V

Current 280 A or less 370 A or less

Torque 9.8 N´m (1.0 kg-m, 7.2 ft-lb) 13.7 N´m (1.4 kg-m, 10.1 ft-lb)

Rotating speed 900 rpm or more 880 rpm or more

Lock characteristicsVoltage 5 V

Current 800 A or less 1,050 A or less

Torque 27.5 N´m (2.8 kg-m, 20.3 ft-lb) or more

GeneratorType Rotating-field three-phase type, Voltage regulator built-in type

Model LR185-701H

Manufacturer HITACHI AUTOMOTIVE PRODUCTS

Voltage and output 12VÐ85A

Polarity on ground side Negative

Rotating direction Clockwise (when observed from pulley side)

Armature connection 3-phase Y-type

Output current1,500 rpm Ð 35 A or more

2,500 rpm Ð 62 A or more

5,000 rpm Ð 82 A or more

Regulated voltage 14.5

+0.3/þ0.4V [20ÉC (68ÉF)]

Ignition coilModel FH0047-01R

Manufacturer DEMCO

Primary coil resistance 0.73W±10%

Secondary coil resistance 12.8 kW±15%

Insulation resistance between primary

terminal and caseMore than 10 MW

Spark plugType and manufacturer PFR5B-11 .......... NGK

Thread size mm 14, P = 1.25

Spark gap mm (in) 1.0 Ð 1.1 (0.039 Ð 0.043)

3

[S1A2]6-1SPECIFICATIONS AND SERVICE DATA

1. Engine Electrical