read SUBARU LEGACY 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 553 of 1456

range (above the center between upper and lower

marks). When the transmission is hot, the level

should be above the center of upper and lower

marks, and when it is cold, the level should be

found below the center of these two marks.

CAUTION:

IUse care not to exceed the upper limit level.

IATF level varies with temperature. Remem-

ber that the addition of fluid to the upper limit

mark when the transmission is cold will result

in the overfilling of fluid.

4) Fluid temperature rising speed

IBy idling the engine

Time for temperature rise to 60ÉC (140ÉF) with

atmospheric temperature of 0ÉC (32ÉF): More than

25 minutes

Time for temperature rise to 30ÉC (86ÉF) with

atmospheric temperature of 0ÉC (32ÉF): Approx. 8

minutes

IBy running the vehicle

Time for temperature rise to 60ÉC (140ÉF) with

atmospheric temperature of 0ÉC (32ÉF): More than

10 minutes

5) Method for checking fluid level upon delivery or

at periodic inspection

Check fluid level after a warm-up run of approx. 10

minutes. During the warm-up period, the automatic

transmission functions can also be checked.

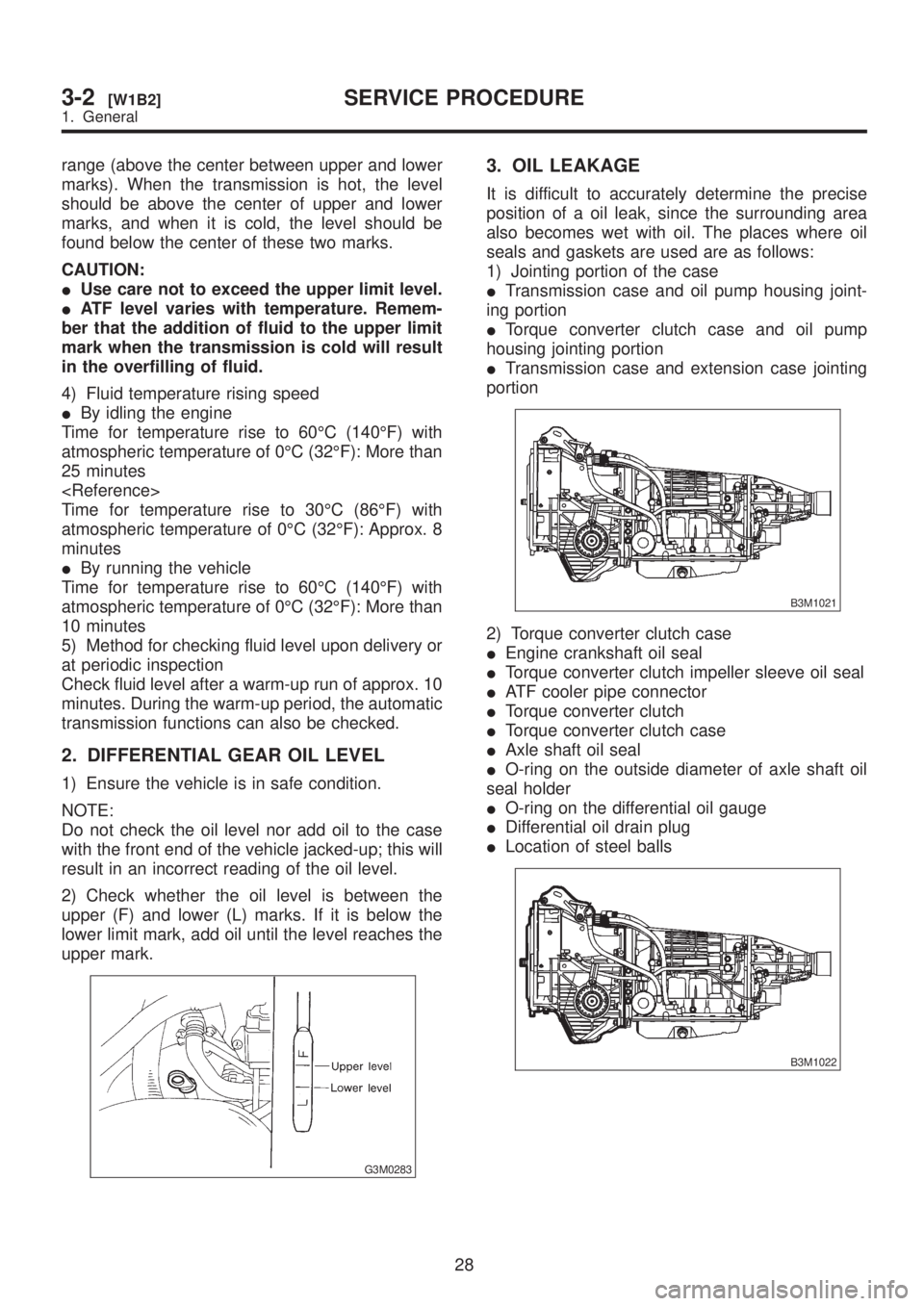

2. DIFFERENTIAL GEAR OIL LEVEL

1) Ensure the vehicle is in safe condition.

NOTE:

Do not check the oil level nor add oil to the case

with the front end of the vehicle jacked-up; this will

result in an incorrect reading of the oil level.

2) Check whether the oil level is between the

upper (F) and lower (L) marks. If it is below the

lower limit mark, add oil until the level reaches the

upper mark.

G3M0283

3. OIL LEAKAGE

It is difficult to accurately determine the precise

position of a oil leak, since the surrounding area

also becomes wet with oil. The places where oil

seals and gaskets are used are as follows:

1) Jointing portion of the case

ITransmission case and oil pump housing joint-

ing portion

ITorque converter clutch case and oil pump

housing jointing portion

ITransmission case and extension case jointing

portion

B3M1021

2) Torque converter clutch case

IEngine crankshaft oil seal

ITorque converter clutch impeller sleeve oil seal

IATF cooler pipe connector

ITorque converter clutch

ITorque converter clutch case

IAxle shaft oil seal

IO-ring on the outside diameter of axle shaft oil

seal holder

IO-ring on the differential oil gauge

IDifferential oil drain plug

ILocation of steel balls

B3M1022

28

3-2[W1B2]SERVICE PROCEDURE

1. General

Page 570 of 1456

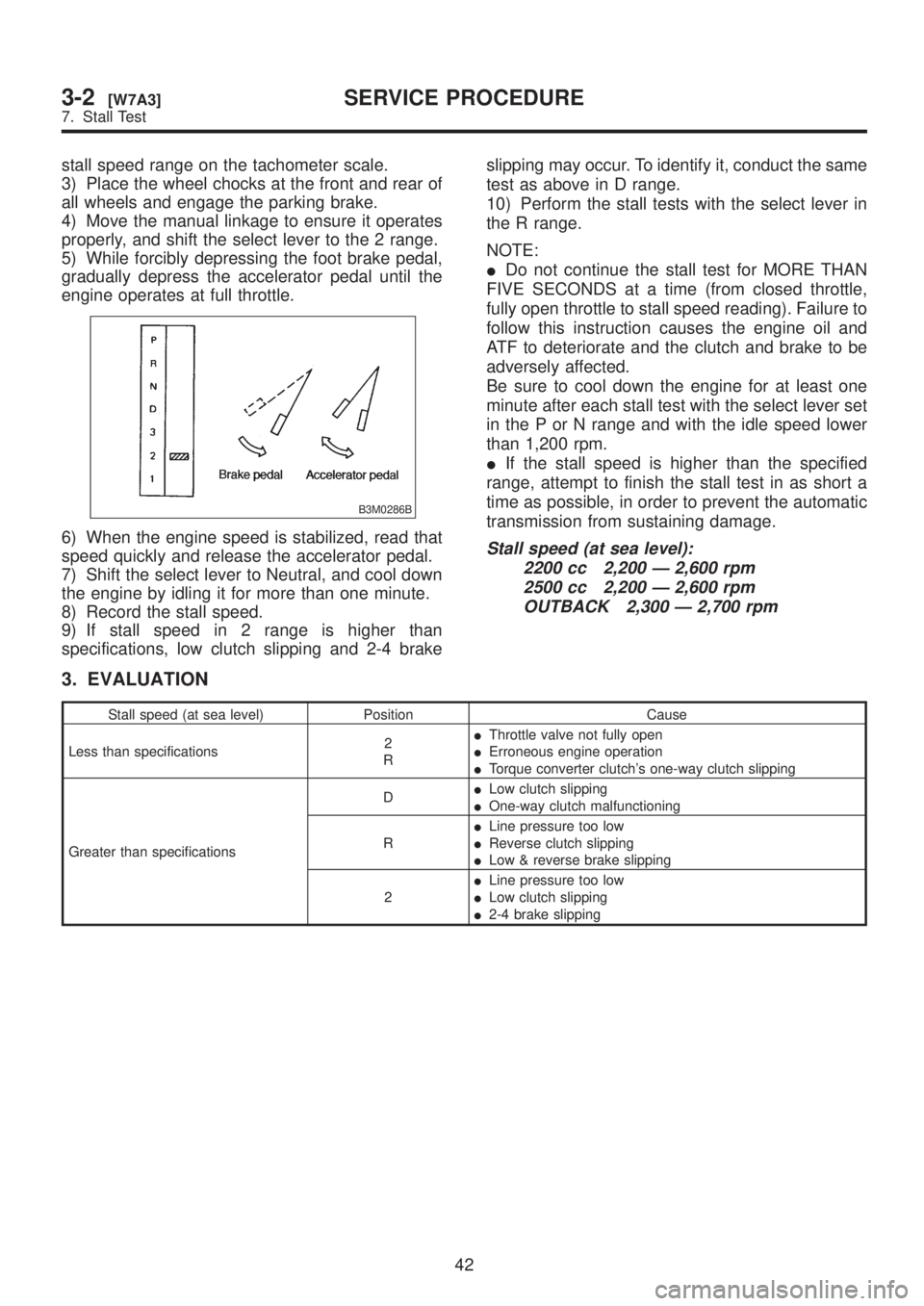

stall speed range on the tachometer scale.

3) Place the wheel chocks at the front and rear of

all wheels and engage the parking brake.

4) Move the manual linkage to ensure it operates

properly, and shift the select lever to the 2 range.

5) While forcibly depressing the foot brake pedal,

gradually depress the accelerator pedal until the

engine operates at full throttle.

B3M0286B

6) When the engine speed is stabilized, read that

speed quickly and release the accelerator pedal.

7) Shift the select lever to Neutral, and cool down

the engine by idling it for more than one minute.

8) Record the stall speed.

9) If stall speed in 2 range is higher than

specifications, low clutch slipping and 2-4 brakeslipping may occur. To identify it, conduct the same

test as above in D range.

10) Perform the stall tests with the select lever in

the R range.

NOTE:

IDo not continue the stall test for MORE THAN

FIVE SECONDS at a time (from closed throttle,

fully open throttle to stall speed reading). Failure to

follow this instruction causes the engine oil and

ATF to deteriorate and the clutch and brake to be

adversely affected.

Be sure to cool down the engine for at least one

minute after each stall test with the select lever set

in the P or N range and with the idle speed lower

than 1,200 rpm.

IIf the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.Stall speed (at sea level):

2200 cc 2,200 Ð 2,600 rpm

2500 cc 2,200 Ð 2,600 rpm

OUTBACK 2,300 Ð 2,700 rpm

3. EVALUATION

Stall speed (at sea level) Position Cause

Less than specifications2

RIThrottle valve not fully open

IErroneous engine operation

ITorque converter clutch's one-way clutch slipping

Greater than specificationsDILow clutch slipping

IOne-way clutch malfunctioning

RILine pressure too low

IReverse clutch slipping

ILow & reverse brake slipping

2ILine pressure too low

ILow clutch slipping

I2-4 brake slipping

42

3-2[W7A3]SERVICE PROCEDURE

7. Stall Test

Page 584 of 1456

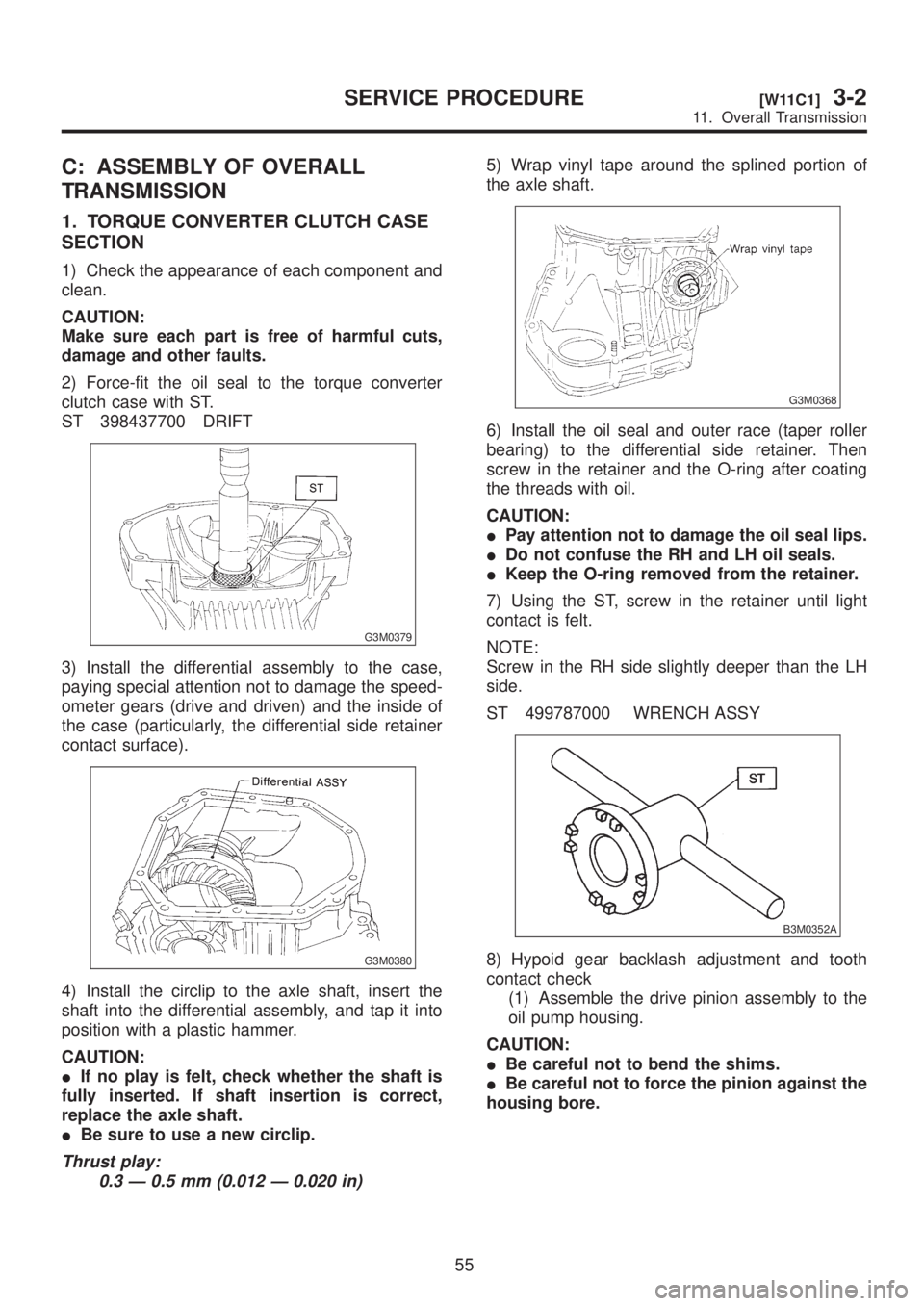

C: ASSEMBLY OF OVERALL

TRANSMISSION

1. TORQUE CONVERTER CLUTCH CASE

SECTION

1) Check the appearance of each component and

clean.

CAUTION:

Make sure each part is free of harmful cuts,

damage and other faults.

2) Force-fit the oil seal to the torque converter

clutch case with ST.

ST 398437700 DRIFT

G3M0379

3) Install the differential assembly to the case,

paying special attention not to damage the speed-

ometer gears (drive and driven) and the inside of

the case (particularly, the differential side retainer

contact surface).

G3M0380

4) Install the circlip to the axle shaft, insert the

shaft into the differential assembly, and tap it into

position with a plastic hammer.

CAUTION:

IIf no play is felt, check whether the shaft is

fully inserted. If shaft insertion is correct,

replace the axle shaft.

IBe sure to use a new circlip.

Thrust play:

0.3 Ð 0.5 mm (0.012 Ð 0.020 in)

5) Wrap vinyl tape around the splined portion of

the axle shaft.

G3M0368

6) Install the oil seal and outer race (taper roller

bearing) to the differential side retainer. Then

screw in the retainer and the O-ring after coating

the threads with oil.

CAUTION:

IPay attention not to damage the oil seal lips.

IDo not confuse the RH and LH oil seals.

IKeep the O-ring removed from the retainer.

7) Using the ST, screw in the retainer until light

contact is felt.

NOTE:

Screw in the RH side slightly deeper than the LH

side.

ST 499787000 WRENCH ASSY

B3M0352A

8) Hypoid gear backlash adjustment and tooth

contact check

(1) Assemble the drive pinion assembly to the

oil pump housing.

CAUTION:

IBe careful not to bend the shims.

IBe careful not to force the pinion against the

housing bore.

55

[W11C1]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 586 of 1456

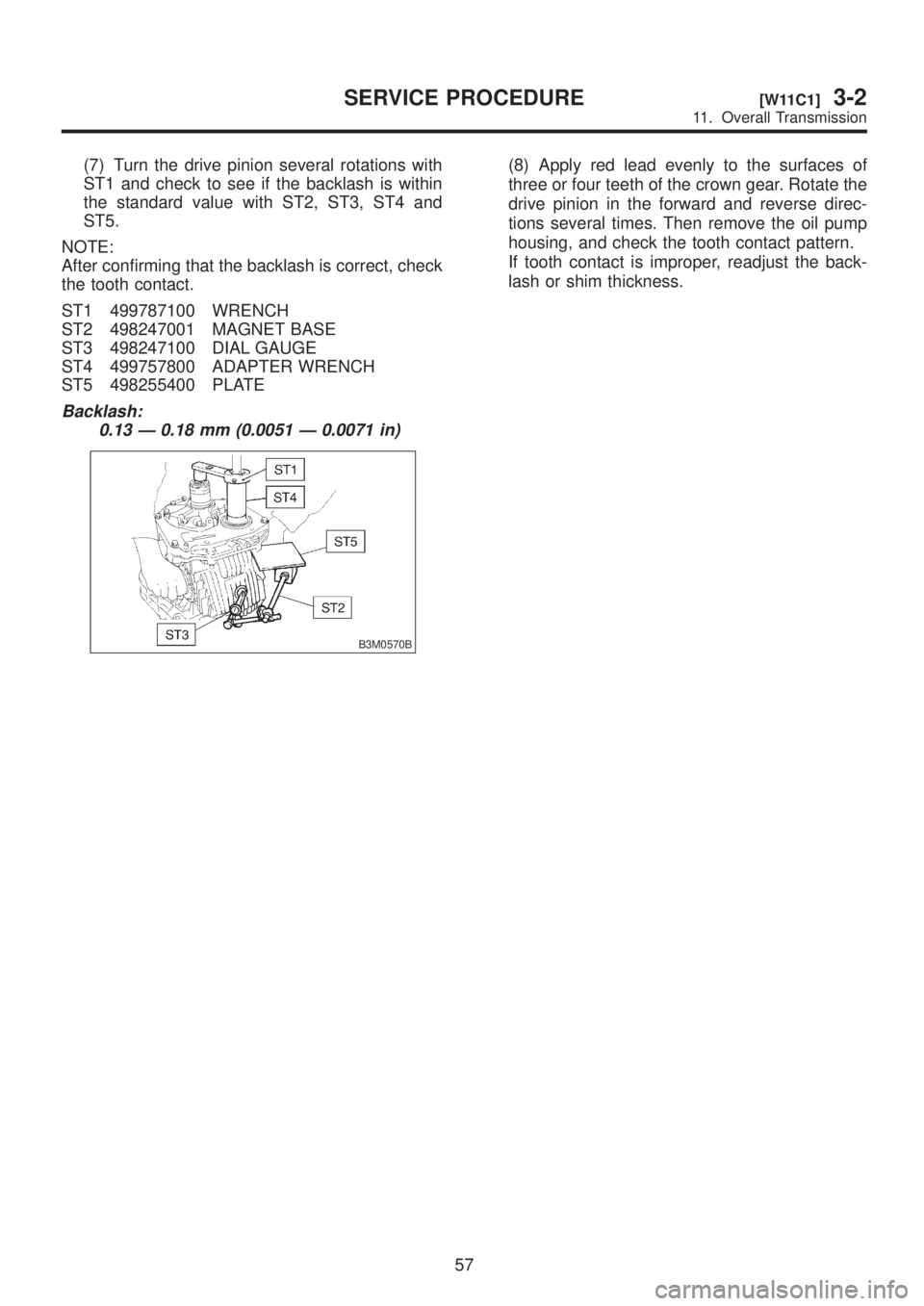

(7) Turn the drive pinion several rotations with

ST1 and check to see if the backlash is within

the standard value with ST2, ST3, ST4 and

ST5.

NOTE:

After confirming that the backlash is correct, check

the tooth contact.

ST1 499787100 WRENCH

ST2 498247001 MAGNET BASE

ST3 498247100 DIAL GAUGE

ST4 499757800 ADAPTER WRENCH

ST5 498255400 PLATE

Backlash:

0.13 Ð 0.18 mm (0.0051 Ð 0.0071 in)

B3M0570B

(8) Apply red lead evenly to the surfaces of

three or four teeth of the crown gear. Rotate the

drive pinion in the forward and reverse direc-

tions several times. Then remove the oil pump

housing, and check the tooth contact pattern.

If tooth contact is improper, readjust the back-

lash or shim thickness.

57

[W11C1]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 648 of 1456

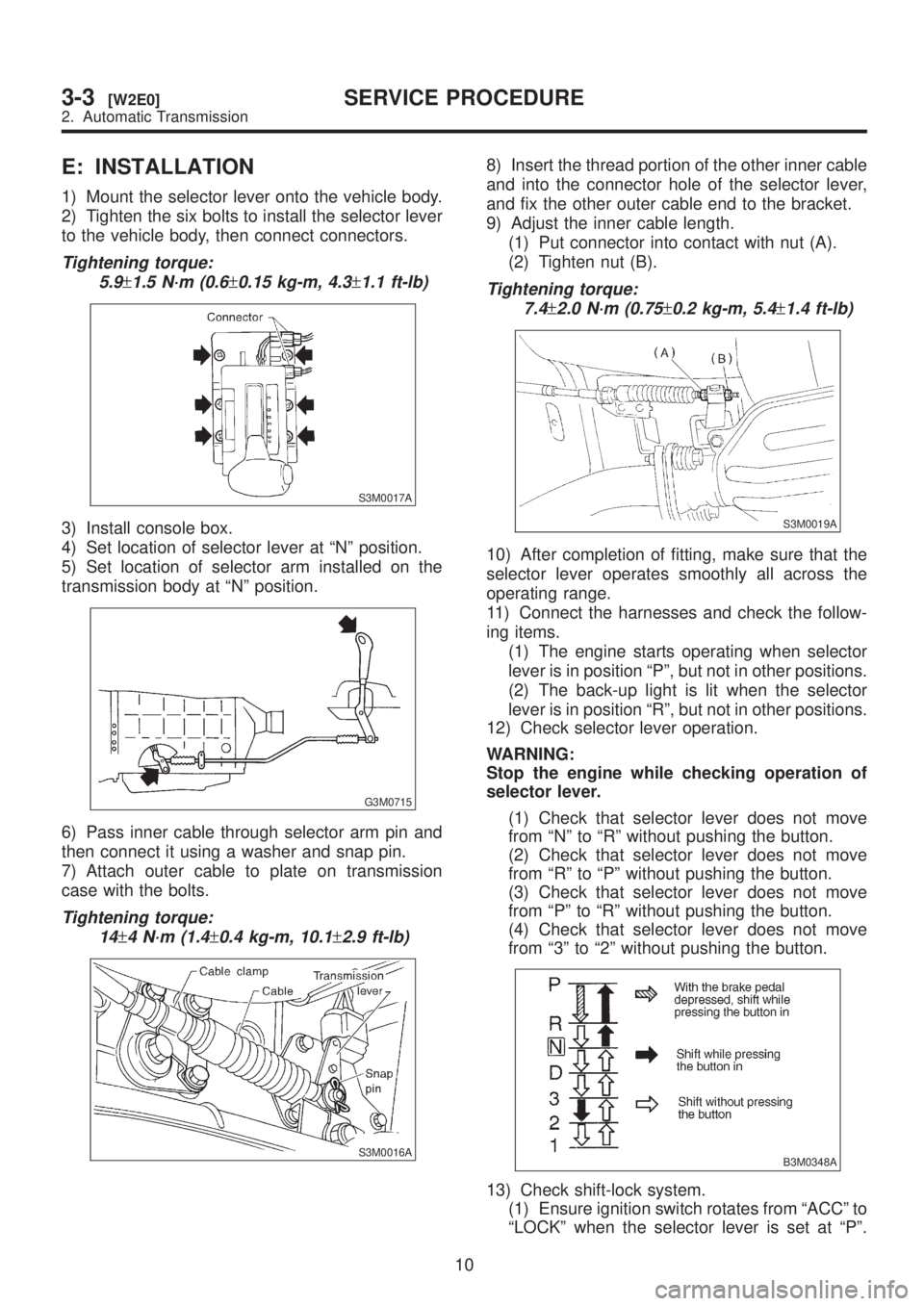

E: INSTALLATION

1) Mount the selector lever onto the vehicle body.

2) Tighten the six bolts to install the selector lever

to the vehicle body, then connect connectors.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

S3M0017A

3) Install console box.

4) Set location of selector lever at ªNº position.

5) Set location of selector arm installed on the

transmission body at ªNº position.

G3M0715

6) Pass inner cable through selector arm pin and

then connect it using a washer and snap pin.

7) Attach outer cable to plate on transmission

case with the bolts.

Tightening torque:

14

±4 N´m (1.4±0.4 kg-m, 10.1±2.9 ft-lb)

S3M0016A

8) Insert the thread portion of the other inner cable

and into the connector hole of the selector lever,

and fix the other outer cable end to the bracket.

9) Adjust the inner cable length.

(1) Put connector into contact with nut (A).

(2) Tighten nut (B).

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S3M0019A

10) After completion of fitting, make sure that the

selector lever operates smoothly all across the

operating range.

11) Connect the harnesses and check the follow-

ing items.

(1) The engine starts operating when selector

lever is in position ªPº, but not in other positions.

(2) The back-up light is lit when the selector

lever is in position ªRº, but not in other positions.

12) Check selector lever operation.

WARNING:

Stop the engine while checking operation of

selector lever.

(1) Check that selector lever does not move

from ªNº to ªRº without pushing the button.

(2) Check that selector lever does not move

from ªRº to ªPº without pushing the button.

(3) Check that selector lever does not move

from ªPº to ªRº without pushing the button.

(4) Check that selector lever does not move

from ª3º to ª2º without pushing the button.

B3M0348A

13) Check shift-lock system.

(1) Ensure ignition switch rotates from ªACCº to

ªLOCKº when the selector lever is set at ªPº.

10

3-3[W2E0]SERVICE PROCEDURE

2. Automatic Transmission

Page 683 of 1456

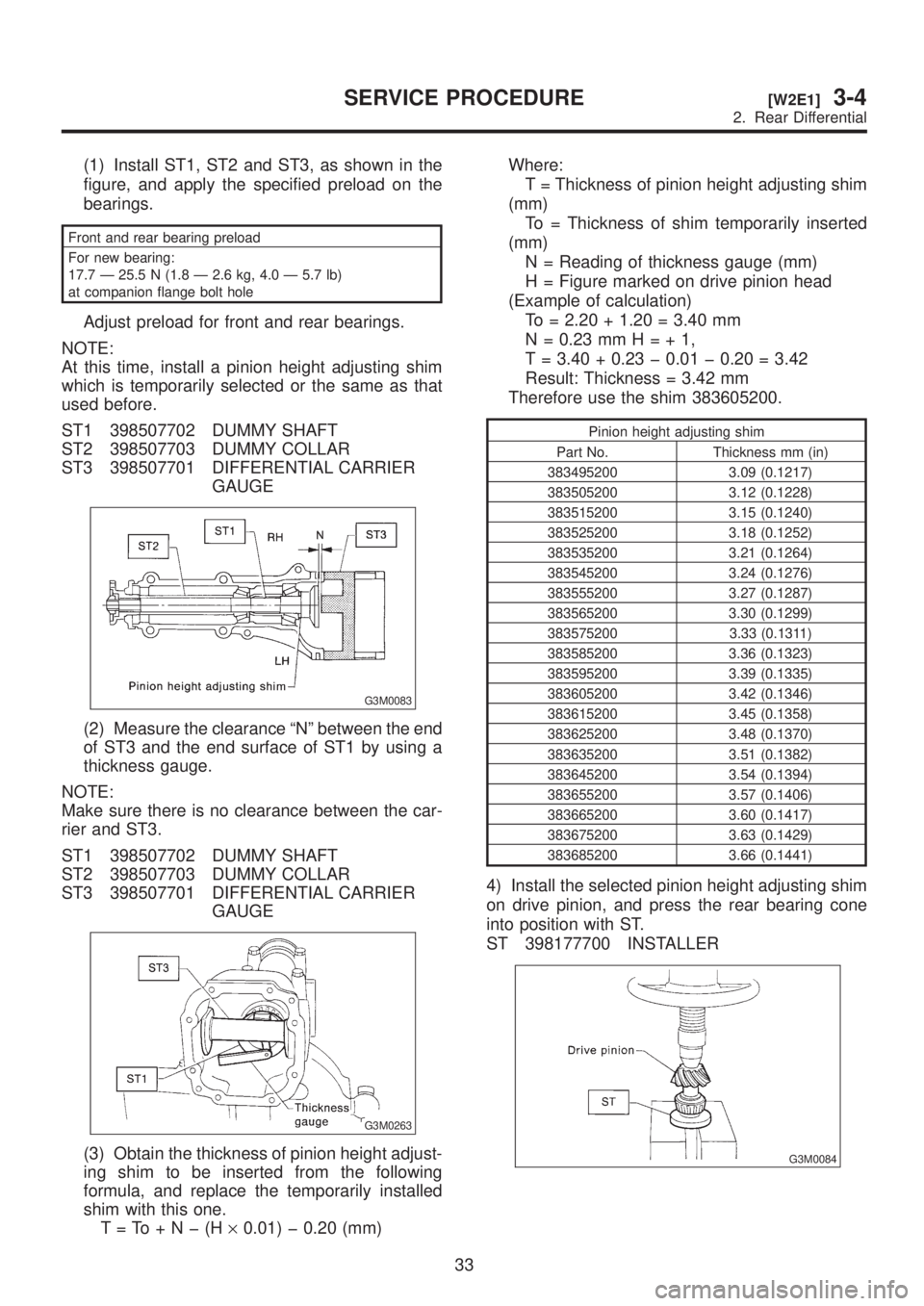

(1) Install ST1, ST2 and ST3, as shown in the

figure, and apply the specified preload on the

bearings.

Front and rear bearing preload

For new bearing:

17.7 Ð 25.5 N (1.8 Ð 2.6 kg, 4.0 Ð 5.7 lb)

at companion flange bolt hole

Adjust preload for front and rear bearings.

NOTE:

At this time, install a pinion height adjusting shim

which is temporarily selected or the same as that

used before.

ST1 398507702 DUMMY SHAFT

ST2 398507703 DUMMY COLLAR

ST3 398507701 DIFFERENTIAL CARRIER

GAUGE

G3M0083

(2) Measure the clearance ªNº between the end

of ST3 and the end surface of ST1 by using a

thickness gauge.

NOTE:

Make sure there is no clearance between the car-

rier and ST3.

ST1 398507702 DUMMY SHAFT

ST2 398507703 DUMMY COLLAR

ST3 398507701 DIFFERENTIAL CARRIER

GAUGE

G3M0263

(3) Obtain the thickness of pinion height adjust-

ing shim to be inserted from the following

formula, and replace the temporarily installed

shim with this one.

T=To+Nþ(H´0.01) þ 0.20 (mm)Where:

T = Thickness of pinion height adjusting shim

(mm)

To = Thickness of shim temporarily inserted

(mm)

N = Reading of thickness gauge (mm)

H = Figure marked on drive pinion head

(Example of calculation)

To = 2.20 + 1.20 = 3.40 mm

N = 0.23 mmH=+1,

T = 3.40 + 0.23 þ 0.01 þ 0.20 = 3.42

Result: Thickness = 3.42 mm

Therefore use the shim 383605200.

Pinion height adjusting shim

Part No. Thickness mm (in)

383495200 3.09 (0.1217)

383505200 3.12 (0.1228)

383515200 3.15 (0.1240)

383525200 3.18 (0.1252)

383535200 3.21 (0.1264)

383545200 3.24 (0.1276)

383555200 3.27 (0.1287)

383565200 3.30 (0.1299)

383575200 3.33 (0.1311)

383585200 3.36 (0.1323)

383595200 3.39 (0.1335)

383605200 3.42 (0.1346)

383615200 3.45 (0.1358)

383625200 3.48 (0.1370)

383635200 3.51 (0.1382)

383645200 3.54 (0.1394)

383655200 3.57 (0.1406)

383665200 3.60 (0.1417)

383675200 3.63 (0.1429)

383685200 3.66 (0.1441)

4) Install the selected pinion height adjusting shim

on drive pinion, and press the rear bearing cone

into position with ST.

ST 398177700 INSTALLER

G3M0084

33

[W2E1]3-4SERVICE PROCEDURE

2. Rear Differential

Page 685 of 1456

CAUTION:

IApply gear oil on both sides of the washer

and on the side gear shaft before installing.

IInsert the pinion mate shaft into the differen-

tial case by aligning the lock pin holes.

(1) Measure the clearance between differential

case and the back of side gear.

(2) Adjust the clearance as specified by select-

ing side gear thrust washer.

Side gear backlash:

0.1 Ð 0.2 mm (0.004 Ð 0.008 in)

Part No. Thickness mm (in)

3834452010.75 Ð 0.80

(0.0295 Ð 0.0315)

3834452020.80 Ð 0.85

(0.0315 Ð 0.0335)

3834452030.85 Ð 0.90

(0.0335 Ð 0.0354)

3834452040.90 Ð 0.95

(0.0354 Ð 0.0374)

3834452050.95 Ð 1.0

(0.0374 Ð 0.0394)

(3) Check the condition of rotation after apply-

ing oil to the gear tooth surfaces and thrust sur-

faces.

(4) After inserting pinion shaft lock pin into dif-

ferential case, stake the both sides of the hole

to prevent pin from falling off.

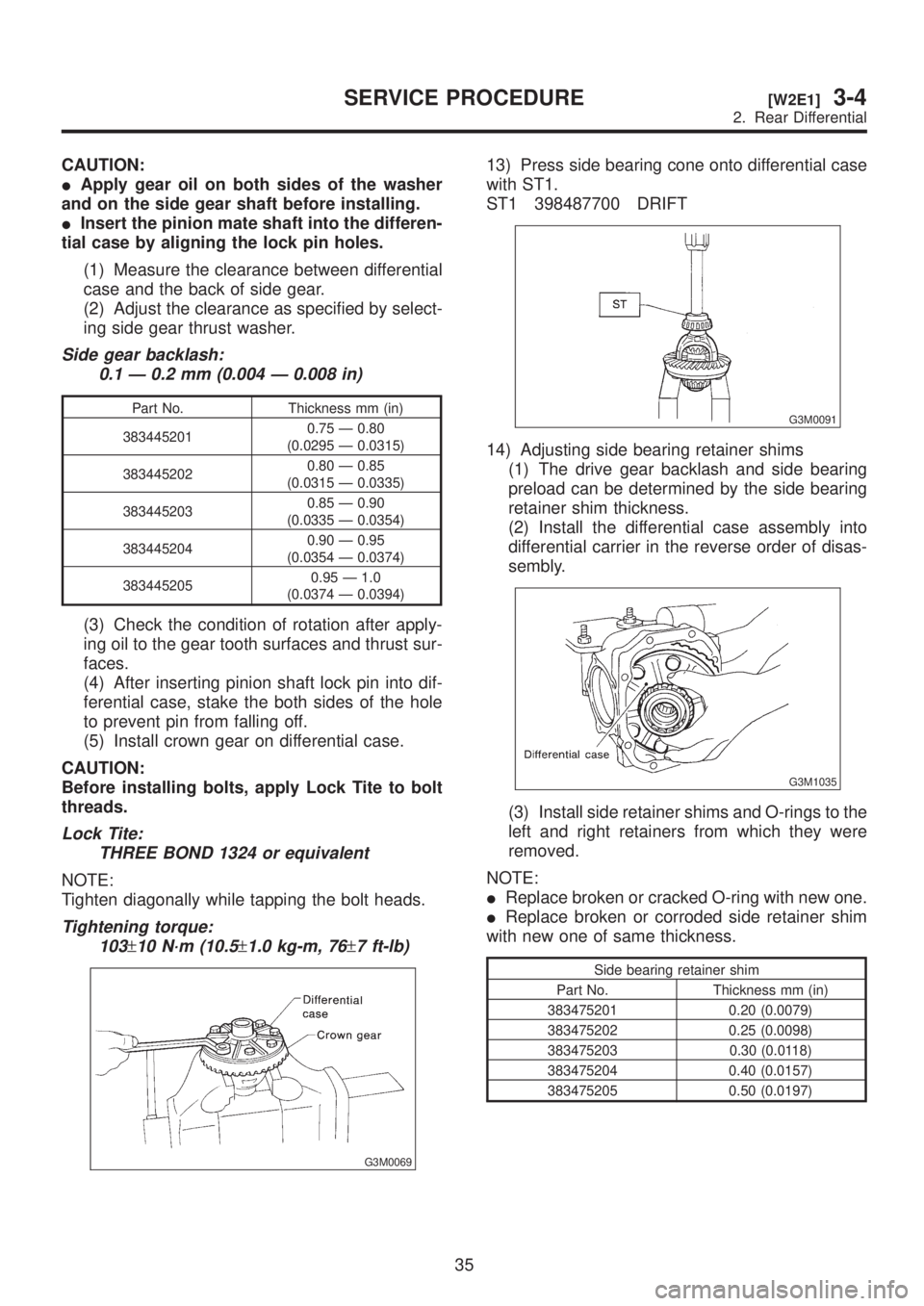

(5) Install crown gear on differential case.

CAUTION:

Before installing bolts, apply Lock Tite to bolt

threads.

Lock Tite:

THREE BOND 1324 or equivalent

NOTE:

Tighten diagonally while tapping the bolt heads.

Tightening torque:

103

±10 N´m (10.5±1.0 kg-m, 76±7 ft-lb)

G3M0069

13) Press side bearing cone onto differential case

with ST1.

ST1 398487700 DRIFT

G3M0091

14) Adjusting side bearing retainer shims

(1) The drive gear backlash and side bearing

preload can be determined by the side bearing

retainer shim thickness.

(2) Install the differential case assembly into

differential carrier in the reverse order of disas-

sembly.

G3M1035

(3) Install side retainer shims and O-rings to the

left and right retainers from which they were

removed.

NOTE:

IReplace broken or cracked O-ring with new one.

IReplace broken or corroded side retainer shim

with new one of same thickness.

Side bearing retainer shim

Part No. Thickness mm (in)

383475201 0.20 (0.0079)

383475202 0.25 (0.0098)

383475203 0.30 (0.0118)

383475204 0.40 (0.0157)

383475205 0.50 (0.0197)

35

[W2E1]3-4SERVICE PROCEDURE

2. Rear Differential

Page 686 of 1456

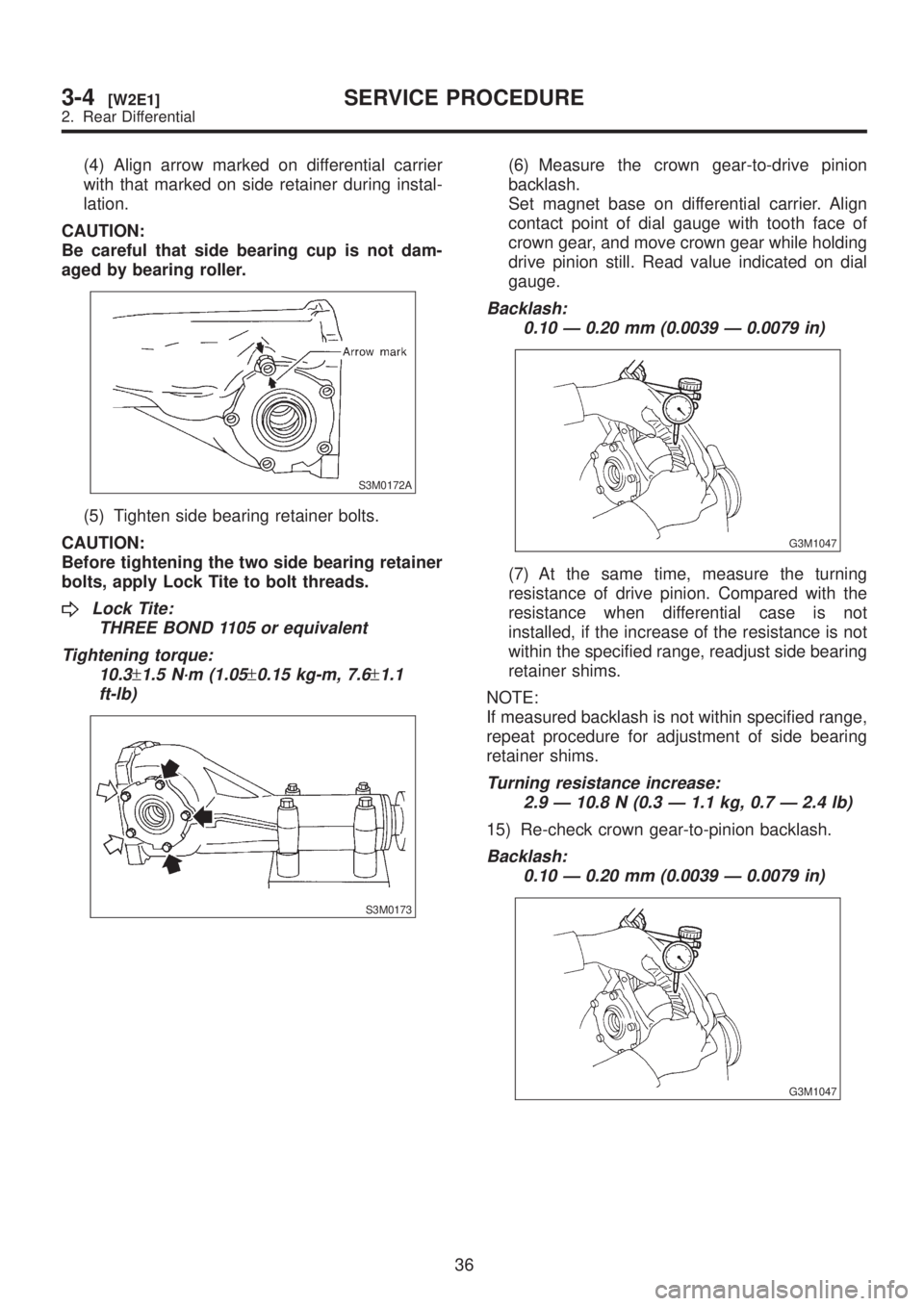

(4) Align arrow marked on differential carrier

with that marked on side retainer during instal-

lation.

CAUTION:

Be careful that side bearing cup is not dam-

aged by bearing roller.

S3M0172A

(5) Tighten side bearing retainer bolts.

CAUTION:

Before tightening the two side bearing retainer

bolts, apply Lock Tite to bolt threads.

Lock Tite:

THREE BOND 1105 or equivalent

Tightening torque:

10.3

±1.5 N´m (1.05±0.15 kg-m, 7.6±1.1

ft-lb)

S3M0173

(6) Measure the crown gear-to-drive pinion

backlash.

Set magnet base on differential carrier. Align

contact point of dial gauge with tooth face of

crown gear, and move crown gear while holding

drive pinion still. Read value indicated on dial

gauge.

Backlash:

0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

G3M1047

(7) At the same time, measure the turning

resistance of drive pinion. Compared with the

resistance when differential case is not

installed, if the increase of the resistance is not

within the specified range, readjust side bearing

retainer shims.

NOTE:

If measured backlash is not within specified range,

repeat procedure for adjustment of side bearing

retainer shims.

Turning resistance increase:

2.9 Ð 10.8 N (0.3 Ð 1.1 kg, 0.7 Ð 2.4 lb)

15) Re-check crown gear-to-pinion backlash.

Backlash:

0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

G3M1047

36

3-4[W2E1]SERVICE PROCEDURE

2. Rear Differential

Page 687 of 1456

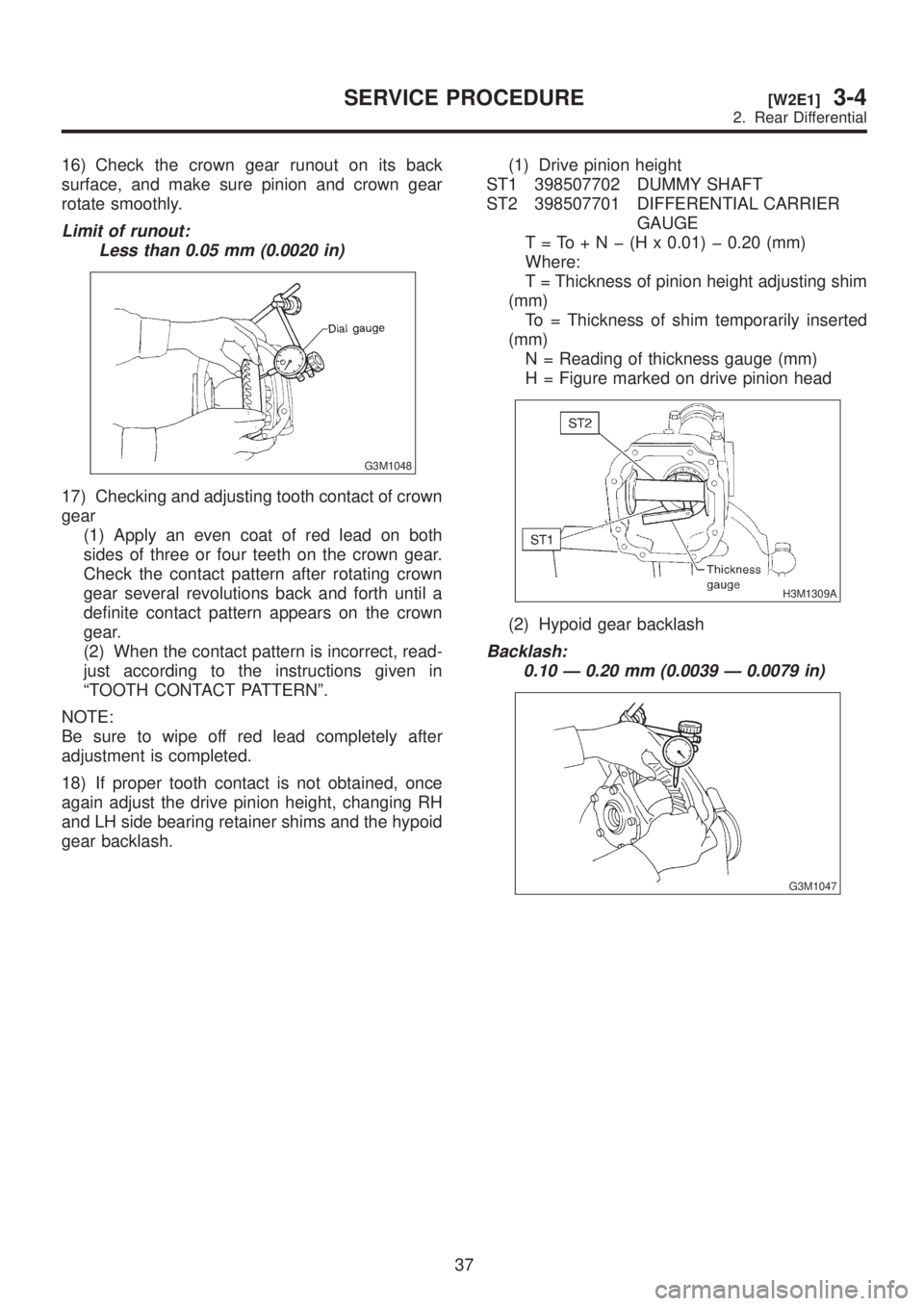

16) Check the crown gear runout on its back

surface, and make sure pinion and crown gear

rotate smoothly.

Limit of runout:

Less than 0.05 mm (0.0020 in)

G3M1048

17) Checking and adjusting tooth contact of crown

gear

(1) Apply an even coat of red lead on both

sides of three or four teeth on the crown gear.

Check the contact pattern after rotating crown

gear several revolutions back and forth until a

definite contact pattern appears on the crown

gear.

(2) When the contact pattern is incorrect, read-

just according to the instructions given in

ªTOOTH CONTACT PATTERNº.

NOTE:

Be sure to wipe off red lead completely after

adjustment is completed.

18) If proper tooth contact is not obtained, once

again adjust the drive pinion height, changing RH

and LH side bearing retainer shims and the hypoid

gear backlash.(1) Drive pinion height

ST1 398507702 DUMMY SHAFT

ST2 398507701 DIFFERENTIAL CARRIER

GAUGE

T=To+Nþ(Hx0.01) þ 0.20 (mm)

Where:

T = Thickness of pinion height adjusting shim

(mm)

To = Thickness of shim temporarily inserted

(mm)

N = Reading of thickness gauge (mm)

H = Figure marked on drive pinion head

H3M1309A

(2) Hypoid gear backlash

Backlash:

0.10 Ð 0.20 mm (0.0039 Ð 0.0079 in)

G3M1047

37

[W2E1]3-4SERVICE PROCEDURE

2. Rear Differential

Page 691 of 1456

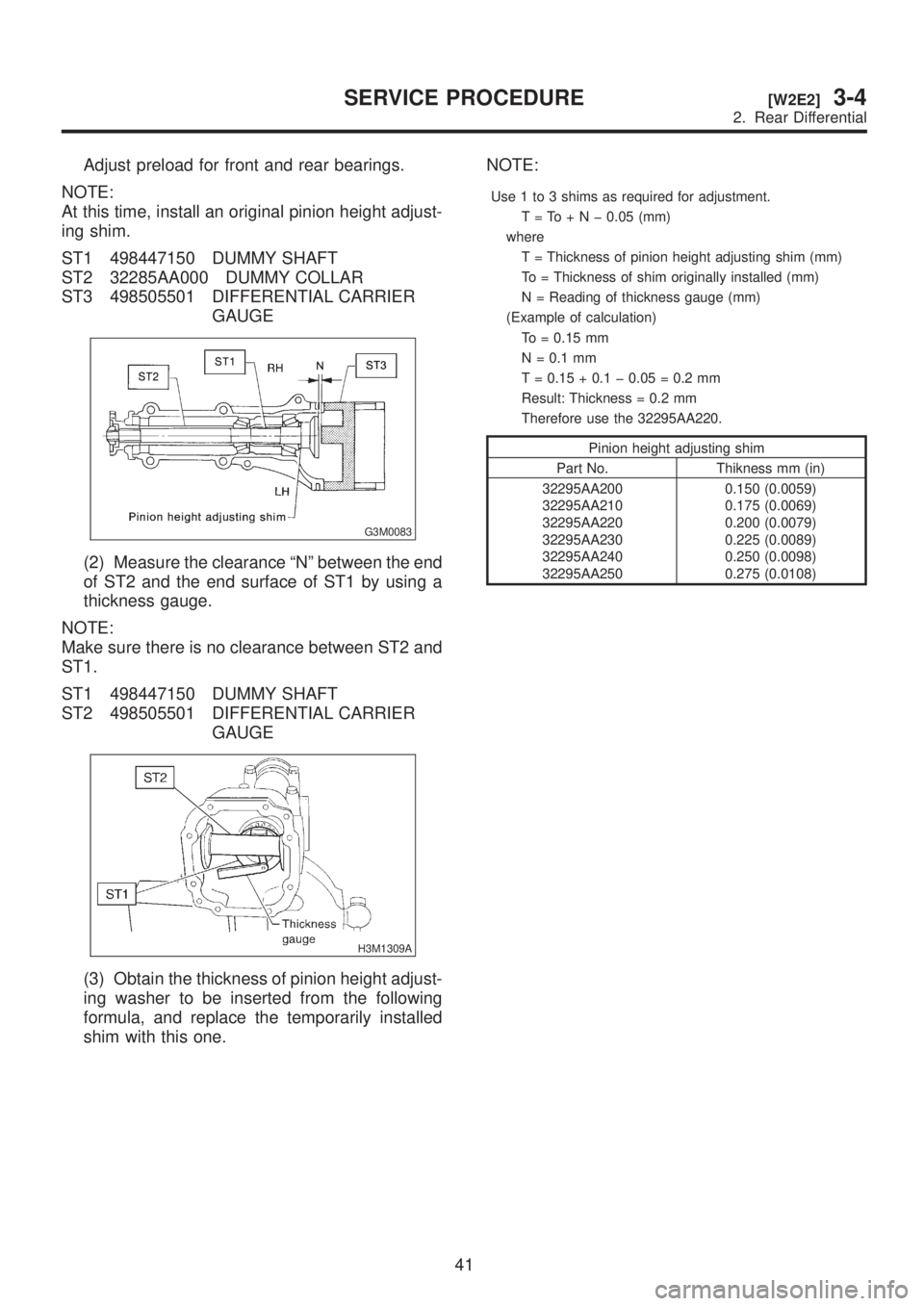

Adjust preload for front and rear bearings.

NOTE:

At this time, install an original pinion height adjust-

ing shim.

ST1 498447150 DUMMY SHAFT

ST2 32285AA000 DUMMY COLLAR

ST3 498505501 DIFFERENTIAL CARRIER

GAUGE

G3M0083

(2) Measure the clearance ªNº between the end

of ST2 and the end surface of ST1 by using a

thickness gauge.

NOTE:

Make sure there is no clearance between ST2 and

ST1.

ST1 498447150 DUMMY SHAFT

ST2 498505501 DIFFERENTIAL CARRIER

GAUGE

H3M1309A

(3) Obtain the thickness of pinion height adjust-

ing washer to be inserted from the following

formula, and replace the temporarily installed

shim with this one.NOTE:

Use 1 to 3 shims as required for adjustment.

T=To+Nþ0.05 (mm)

where

T = Thickness of pinion height adjusting shim (mm)

To = Thickness of shim originally installed (mm)

N = Reading of thickness gauge (mm)

(Example of calculation)

To = 0.15 mm

N = 0.1 mm

T = 0.15 + 0.1 þ 0.05 = 0.2 mm

Result: Thickness = 0.2 mm

Therefore use the 32295AA220.

Pinion height adjusting shim

Part No. Thikness mm (in)

32295AA200

32295AA210

32295AA220

32295AA230

32295AA240

32295AA2500.150 (0.0059)

0.175 (0.0069)

0.200 (0.0079)

0.225 (0.0089)

0.250 (0.0098)

0.275 (0.0108)

41

[W2E2]3-4SERVICE PROCEDURE

2. Rear Differential